Test for a Low-grade Scheelite Ore with Improving the Grade of Concentrate by Optimization of Agents

-

摘要:

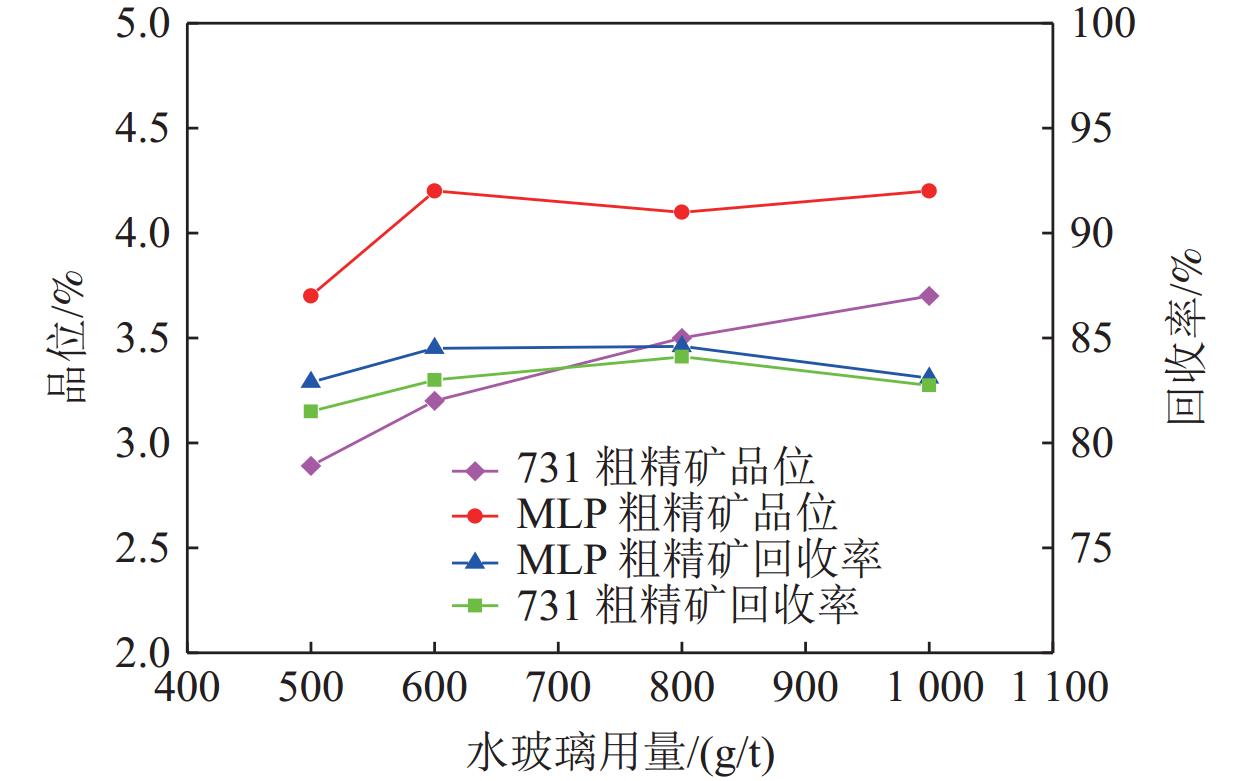

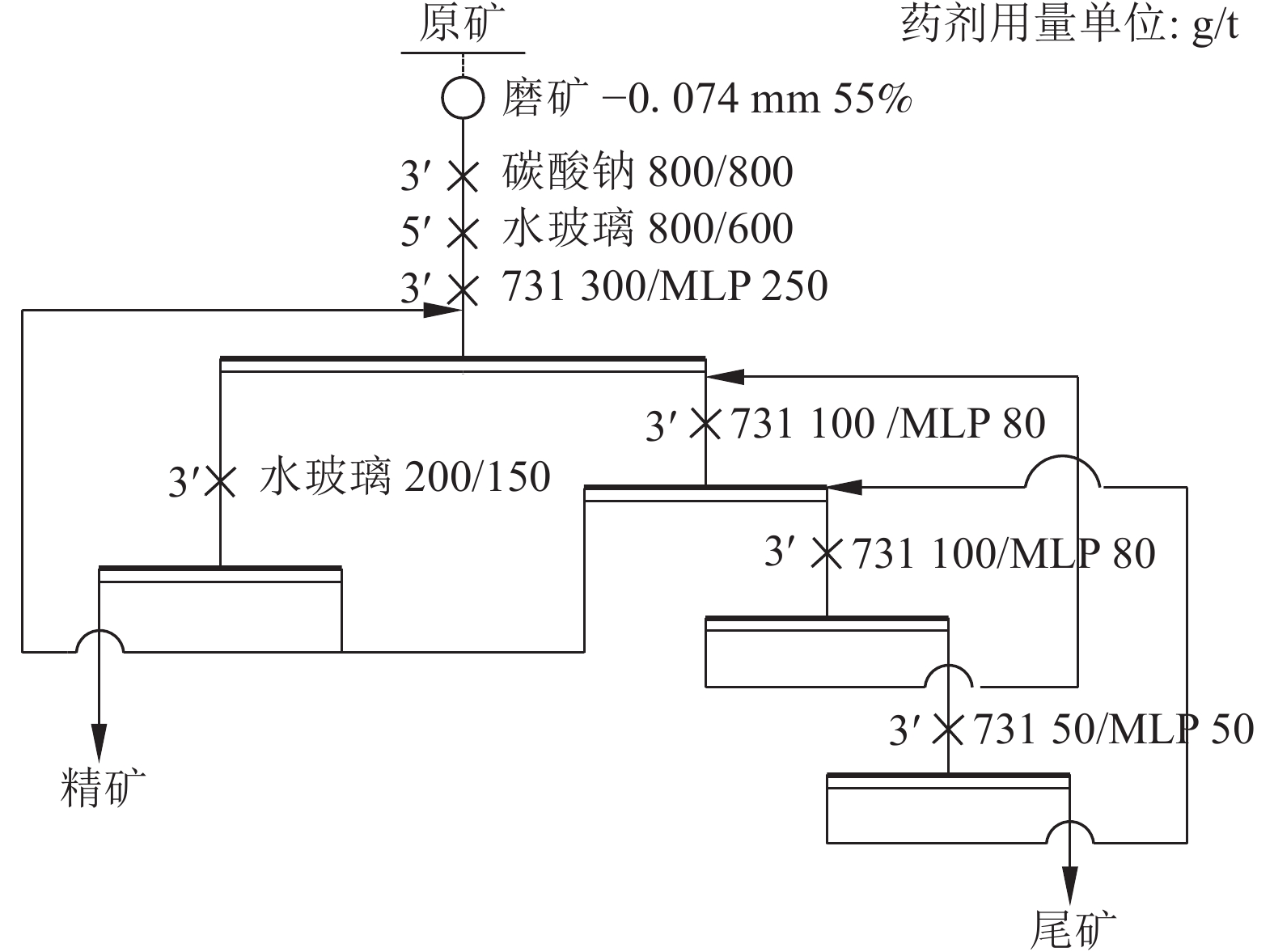

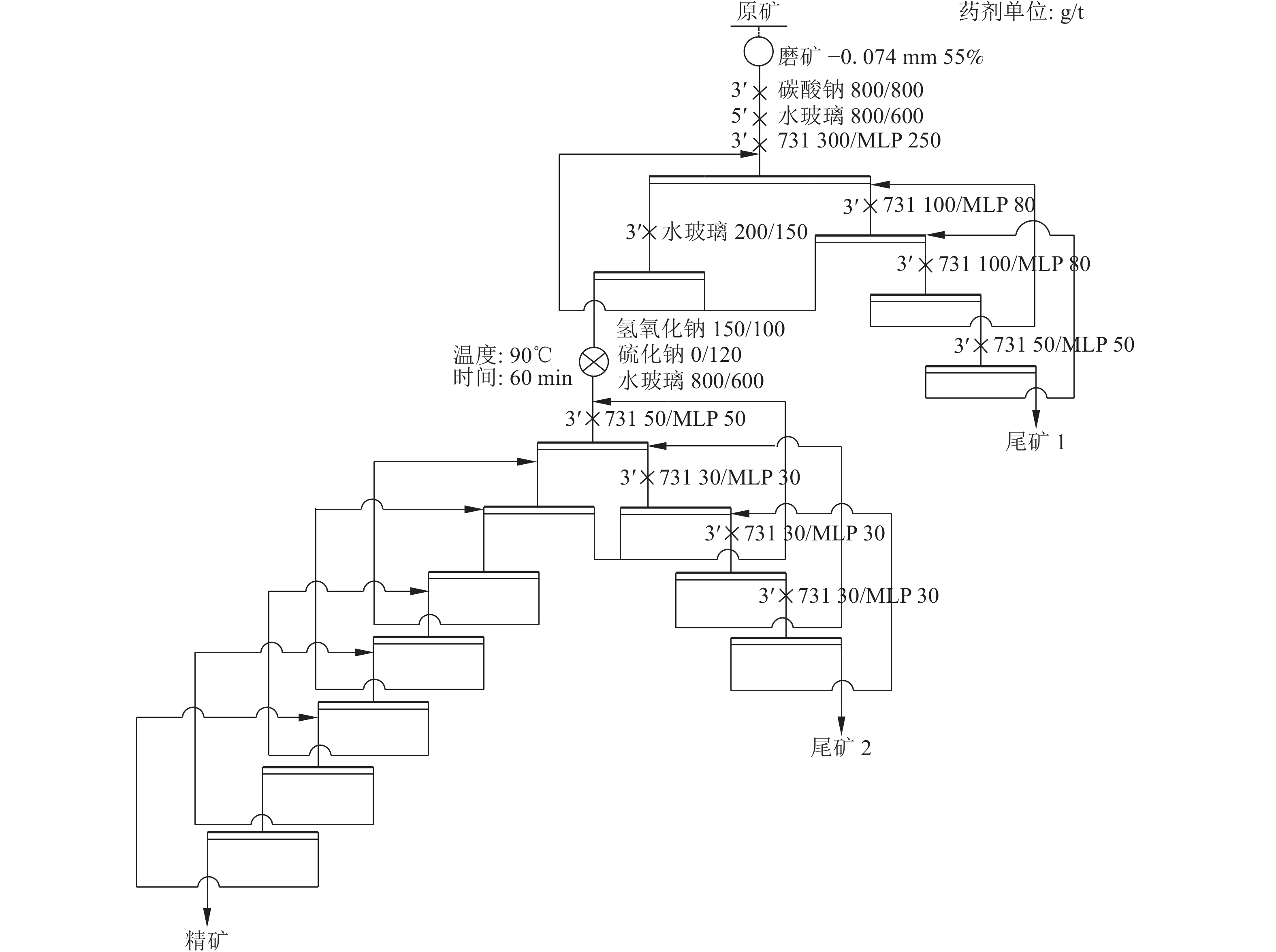

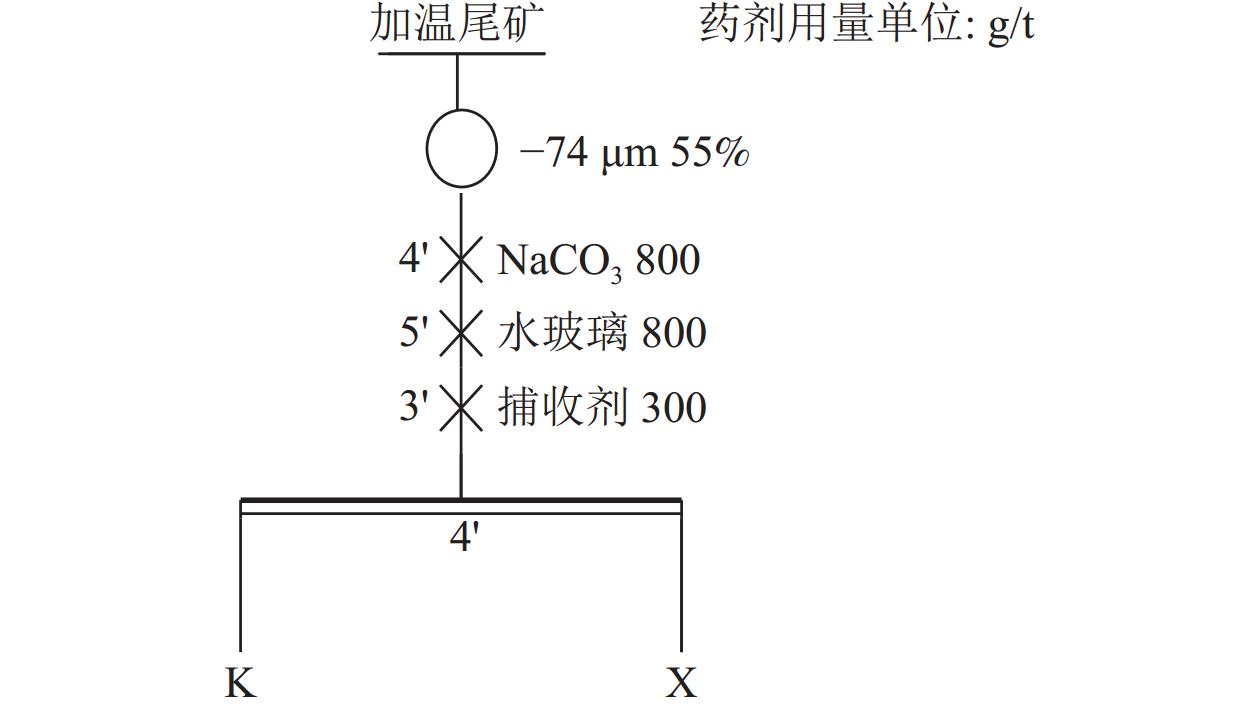

某白钨矿WO3含量为0.27%,现场生产钨精矿品位较低,为53.11%,出售计价系数低。为提高钨精矿品位,实验针对矿石的性质特点,优化药剂制度,常温浮选采用组合捕收剂MLP,加温浮选采用辅助抑制剂硫化钠后,可显著提高钨精矿品位至66.18%,回收率基本不变,且抑制剂水玻璃用量显著降低。优化后技术经济效果显著。

Abstract:There are 0.27% WO3 in a scheelite Ore. The grade of scheelite concentrate produced on site is 53.11%. Because the grade of the concentrate is low, the pricing coefficient of the concentrate is low. In order to improve the grade of scheelite concentrate, according to the properties of the ore, combined collector was used for flotation at room temperature, sodium sulfide was used as an auxiliary inhibitor at heating flotation. After the flotation reagent is optimized, the grade of scheelite concentrate can be significantly increased to 66.18%, the recovery rate of the concentrate remains basically unchanged, and the dosage of inhibitor sodium silicate is significantly reduced. The technical and economic effects of the optimized process are significantly improved.

-

-

表 1 原矿多元素分析结果/%

Table 1. Analysis results of multi-elements of the raw ore

WO3 CaF2 CaO P Fe CaO Sn Mn Na2O 0.27 0.38 0.98 0.060 5.08 12.17 0.032 0.040 1.08 K2O MgO Al2O3 S As SiO2 Cu Mo Zn 0.63 1.41 6.65 0.22 0.005 51.99 0.006 4 0.001 8 0.04 表 2 钨物相分析结果

Table 2. Analysis results of gold phase

名称 白钨矿之WO3 黑钨矿之WO3 钨华之WO3 总WO3 含量/% 0.25 0.001 9 0.002 9 0.263 占有率/% 98.10 0.80 1.10 100.00 表 3 常温浮选工艺指标对比/%

Table 3. Test result of flotation at room temperature

捕收剂

体系工艺名称 产品名称 产率/% WO3

品位/%WO3

回收率/%MLP 常温浮选 粗精矿 3.33 7.870 92.81 尾矿 96.67 0.021 7.19 原矿 100.00 0.282 100.00 731 常温浮选 粗精矿 4.36 6.148 92.72 尾矿 95.64 0.022 7.28 原矿 100.00 0.289 100.00 表 4 不同加温药剂条件开路实验结果

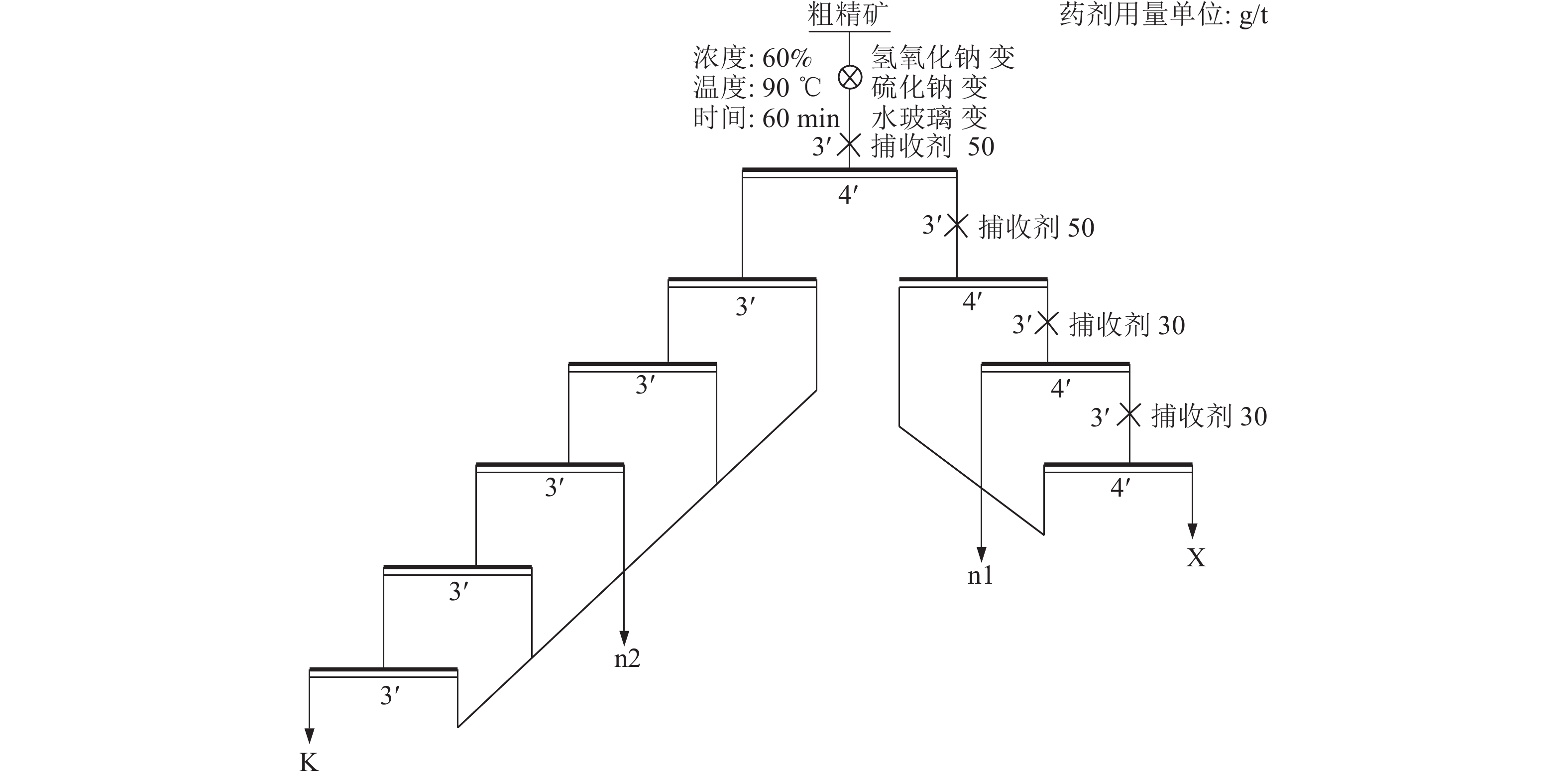

Table 4. Test result of open-circuit flotation at different heating conditions

药剂制度/(g/t) 产品

名称产率/% WO3

品位/%WO3回

收率/%原有药

剂制度氢氧化钠:150 K 11.12 61.71 85.38 硫化钠:0 n1 4.95 14.18 8.73 水玻璃:800 n2 3.80 6.13 2.90 731:50+50+30+30 X 80.13 0.30 2.99 合计 100.00 8.04 100.00 优化药

剂制度氢氧化钠:100 K 9.68 70.71 85.74 硫化钠:120 n1 4.95 13.80 8.56 水玻璃:600 n2 3.80 5.53 2.63 MLP:50+50+30+30 X 81.57 0.30 3.07 合计 100.00 7.98 100.00 表 5 闭路实验对比结果/%

Table 5. Comparative results of closed-circuit tests

捕收剂体系 产品名称 产率/% WO3品位/% WO3回收率/% MLP 精矿 0.374 66.180 89.65 尾矿1 96.670 0.021 7.35 尾矿2 2.956 0.280 3.00 原矿 100.000 0.276 100.00 731 精矿 0.480 53.110 89.12 尾矿1 95.644 0.022 7.36 尾矿2 3.876 0.260 3.52 原矿 100.000 0.286 100.00 -

[1] 王星, 陈慧杰, 张莉, 等. 低品位白钨矿选矿技术的研究发展[J]. 中国金属通报, 2020(3):7-8.WANG X, CHEN H J, ZHANG L, et al. Research and development of low-grade scheelite beneficiation technology[J]. China Metal Bulletin, 2020(3):7-8. doi: 10.3969/j.issn.1672-1667.2020.03.005

WANG X, CHEN H J, ZHANG L, et al. Research and development of low-grade scheelite beneficiation technology[J]. China Metal Bulletin, 2020(3):7-8. doi: 10.3969/j.issn.1672-1667.2020.03.005

[2] 叶雪均, 刘军, 刘智林. 某低品位白钨矿浮选实验研究[J]. 中国钨业, 2006(5):20-23.YE X J, LIU J, LIU Z L. Experimental study on flotation of a low-grade scheelite ore[J]. China Tungsten Industry, 2006(5):20-23. doi: 10.3969/j.issn.1009-0622.2006.05.007

YE X J, LIU J, LIU Z L. Experimental study on flotation of a low-grade scheelite ore[J]. China Tungsten Industry, 2006(5):20-23. doi: 10.3969/j.issn.1009-0622.2006.05.007

[3] 黄艳芳, 王甜甜, 张红新, 等. 某低品位白钨矿浮选实验研究[J]. 中国矿业, 2019, 28(10):147-151.HUANG Y F, WANG T T, ZHANG H X, et al. Experimental study on flotation of a low-grade scheelite ore[J]. China Mining Industry, 2019, 28(10):147-151. doi: 10.12075/j.issn.1004-4051.2019.10.014

HUANG Y F, WANG T T, ZHANG H X, et al. Experimental study on flotation of a low-grade scheelite ore[J]. China Mining Industry, 2019, 28(10):147-151. doi: 10.12075/j.issn.1004-4051.2019.10.014

[4] 卫召, 孙伟, 韩海生, 等. 钨矿浮选工艺进展与实践[J]. 金属矿山, 2021, 540(6):60-72.WEI Z, SUN W, HAN H S, et al. Progress and practice of tungsten ore flotation process[J]. Metal Mining, 2021, 540(6):60-72.

WEI Z, SUN W, HAN H S, et al. Progress and practice of tungsten ore flotation process[J]. Metal Mining, 2021, 540(6):60-72.

[5] 黎继永, 谢贤, 童雄, 等. 低品位白钨矿选矿技术的研究发展[J]. 矿产综合利用, 2015(4):1-6+11.LI J Y, XIE X, TONG X, et al. Research and development of low-grade scheelite ore dressing technology[J]. Multipurpose Utilization of Mineral Resources, 2015(4):1-6+11. doi: 10.3969/j.issn.1000-6532.2015.04.001

LI J Y, XIE X, TONG X, et al. Research and development of low-grade scheelite ore dressing technology[J]. Multipurpose Utilization of Mineral Resources, 2015(4):1-6+11. doi: 10.3969/j.issn.1000-6532.2015.04.001

[6] 王辉洲, 杨剑波, 任建国, 等. 白钨粗选工艺流程优化研究及应用[J]. 中国钨业, 2021, 282(2):43-47.WANG H Z, YANG J B, REN J G, et al. Optimisation study and application of scheelite roughing process[J]. China Tungsten Industry, 2021, 282(2):43-47. doi: 10.3969/j.issn.1009-0622.2021.02.007

WANG H Z, YANG J B, REN J G, et al. Optimisation study and application of scheelite roughing process[J]. China Tungsten Industry, 2021, 282(2):43-47. doi: 10.3969/j.issn.1009-0622.2021.02.007

-

下载:

下载: