Quartz Mineral Purification and Application Technology in Strategic Emerging Industries

-

摘要:

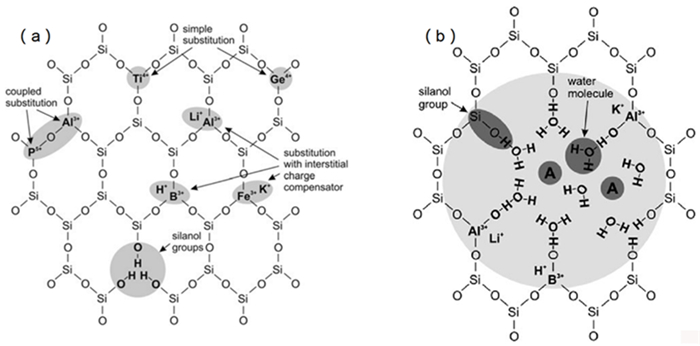

随着全球科学技术的发展以及高新技术领域应用需求的提升,新兴产业的发展和开发得到了特别地关注,其中石英矿物资源的开发和应用也受到了各国极大的重视。针对石英矿物资源的开发和应用现状和遇到的技术问题,概述了我国石英的类型、储量和消费结构,阐述了石英的杂质类型和石英的提纯与合成技术,详细分析高纯石英在半导体行业、光纤行业、光伏产业、光学领域、航空航天等战略性新兴产业中的应用现状和技术难点,阐明杂质对于这些领域的产品性能的关键影响作用与控制方法。

Abstract:Great attention has been paid to the development and application of emerging industries, due to the rapid development of science and technology and the improved demand in the field of new and high-tech areas, among which the application of quartz minerals has attracted very high level concerns. Based on the situation and problems during the development and application of quartz minerals, this review summarizes the types, reservation data, and the consumption ways of quartz in our country; Then the types of impurities, the purification methods, and synthesis technology of quartz are included; The application status of quartz as well as the technical difficulty in such strategic emerging industries as the semiconductor industry, optical industry, photovoltaic industry, aerospace field are analyzed in detail. Finally, the effects of impurities on performances of different products in these areas and their control methods are clarified.

-

-

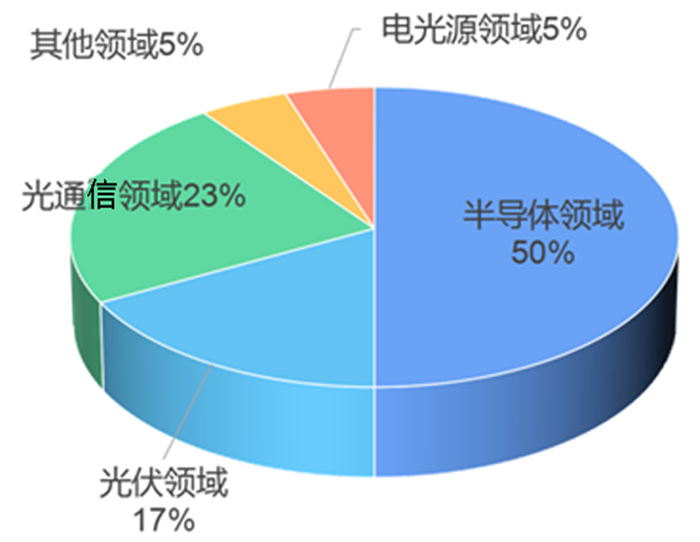

图 1 2019年高纯石英消费结构[10]

Figure 1.

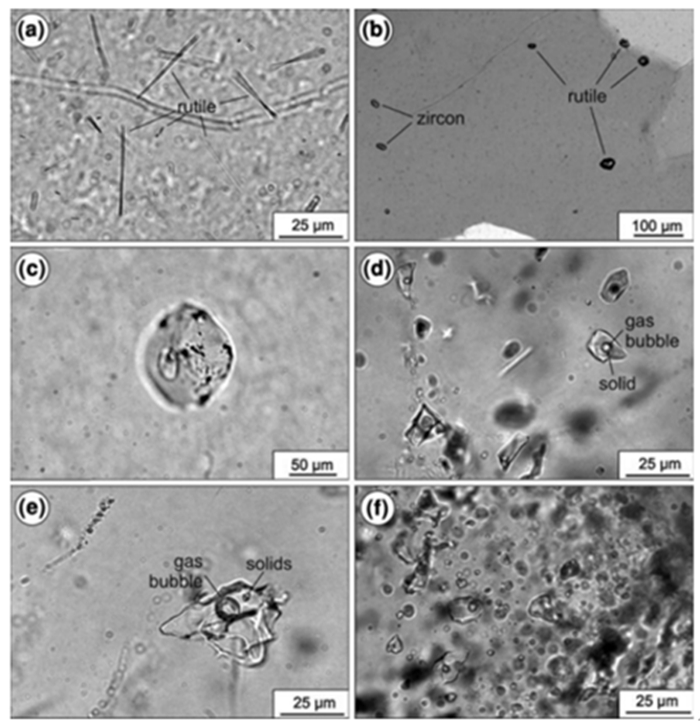

图 3 石英中微夹杂物的光学显微镜图像[24]

Figure 3.

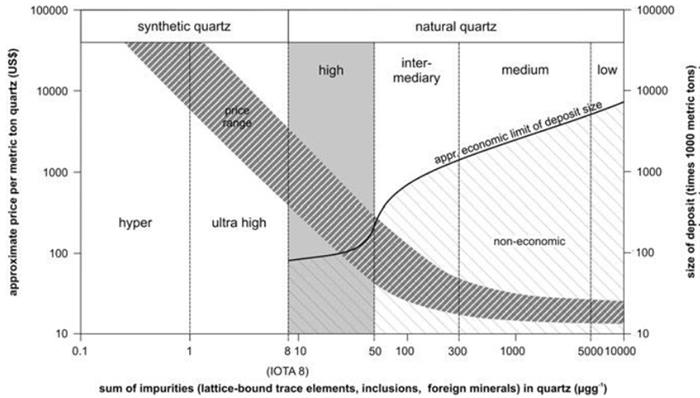

图 4 石英品质分类(根据杂质总量)、价格范围和作为矿床开采所需的最小规模[25]

Figure 4.

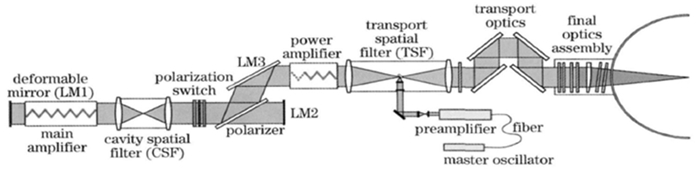

图 6 高功率激光驱动器的基本组成[83]

Figure 6.

表 1 美国尤尼明IOTA系列高纯石英相关指标[27]

/10-6 Table 1. United States Unimin IOTA series high purity quartz related indicators[27]

元素 Al B Ca Cr Cu Fe K Li Mg Mn Na Ni IOTA-Std 16.2 0.08 0.5 < 0.05 < 0.05 0.23 0.60 0.90 < 0.05 < 0.05 0.9 < 0.05 IOTA-4 8.0 0.04 0.6 < 0.05 < 0.05 0.3 0.35 0.15 < 0.05 < 0.05 0.9 < 0.05 IOTA-6 8.0 0.04 0.6 < 0.05 < 0.05 0.15 0.15 0.15 < 0.05 < 0.05 0.08 < 0.05 IOTA-8 7.0 < 0.04 0.5 < 0.02 < 0.02 < 0.03 < 0.04 < 0.02 < 0.02 < 0.02 - < 0.02 表 2 常规粉碎和电动力学破碎的0.1~0.3 mm石英样品化学分析结果[24]

/10-6 Table 2. Chemical analysis 0.1~0.3 mm quartz samples were crushed by conventional crushing and electrokinetic crushing[24]

元素 Al Fe Na K Li Ti Zr 石英原料 41 4.9 12 15 0.5 1.3 < 0.1 传统粉碎 23 464 10 3.5 0.6 1.9 < 0.1 电动破碎 28 1.3 13 4.7 0.6 0.5 < 0.1 分选方法 原理 选出的杂质 特点 磨擦 通过机械力和沙粒之间的磨剥力除去表面的杂质 薄膜铁、泥性杂质矿物 擦碎未成单体的矿物集合体,再经过分级作业 色选 矿物光学特性 深色或浅色的杂质矿物 经济效率高 磁选 矿物磁性 褐铁矿、赤铁矿、黑云母、钛铁矿、磁铁矿 多次磁选、除铁效果好 浮选 矿物表面性质 云母、长石、铁矿石等 反浮选、多次精选 表 4 0.1~0.3 mm的石英样品经化学处理后化学成分分析[24]

/10-6 Table 4. Chemical analysis Quartz samples after chemical treatment of 0.1-0.3 mm[24]

成分 Al Fe Na K Li Ti Zr 磁选石英 21 0.2 3.1 1.0 2.2 1.2 < 0.1 酸洗 21 < 0.1 2.8 0.9 2.2 1.2 < 0.1 浸出 20 < 0.1 0.7 0.3 2.2 1.2 < 0.1 热氯化 21 < 0.1 0.2 < 0.1 1.6 1.1 < 0.1 表 5 半导体用透明石英玻璃管、棒杂质含量要求

/10-6 Table 5. Content of impurities in transparent quartz glass tube and rod for semiconductor

13种总杂质含量 Fe Ti Cu B Li、Na、K总含量 半导体用透明石英玻璃管 T级 ≤30.00 ≤1.50 ≤3.00 ≤0.80 ≤0.20 ≤5.00 半导体用透明石英玻璃棒

半导体用透明石英玻璃器件D级 ≤25.00 ≤0.80 ≤2.00 ≤0.50 ≤0.10 ≤2.50 太阳能电池硅片用石英舟

太阳能电池硅片用石英玻璃扩散管T级 ≤30.00 ≤1.50 ≤3.00 ≤0.80 ≤0.20 ≤5.00 单晶硅生长用石英坩埚(太阳能级) T级 ≤20.00 ≤0.50 ≤0.20 ≤2.00 单晶硅生长用石英坩埚(半导体级) B级 ≤17.00 ≤0.30 ≤0.10 ≤2.00 注:13种杂质含量元素为Al、Fe、Ca、Mg、Ti、Cu、Co、Mn、Ni、Li、Na、K、B。 -

[1] 贾德龙, 张万益, 陈丛林, 等. 高纯石英全球资源现状与我国发展建议[J]. 矿产保护与利用, 2019, 39(5): 111-117. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=e759486c-8f66-4a5b-b137-23322ead3cfb

[2] 焦伟伟, 金瞰昆, 刘彦华. 江苏省水晶矿床成因分析[J]. 河北工程大学学报(自然科学版), 2007(3): 34-37. doi: 10.3969/j.issn.1673-9469.2007.03.011

[3] 申士富. 高纯石英砂研究与生产现状[J]. 中国非金属矿工业导刊, 2006(5): 13-16. doi: 10.3969/j.issn.1007-9386.2006.05.004

[4] 金达表, 张兄明, 邹蔚蔚. 高纯石英的加工工艺研究[J]. 中国非金属矿工业导刊, 2004(4): 44-46+48. doi: 10.3969/j.issn.1007-9386.2004.04.013

[5] 邵厥年, 陶维屏. 矿产资源工业要求手册[M]. 北京: 地质出版社, 2014: 600-650.

[6] 颜玲亚, 高树学, 陈正国, 等. 我国脉石英矿床类型及成矿规律[J]. 中国非金属矿工业导刊, 2020(5): 10-14. doi: 10.3969/j.issn.1007-9386.2020.05.004

[7] 詹建华, 王依, 陈正国, 等. 我国脉石英资源现状分析[J]. 中国非金属矿工业导刊, 2020(5): 1-4. doi: 10.3969/j.issn.1007-9386.2020.05.002

[8] 张佩聪, 刘岫峰, 李峻峰, 等. 高纯石英矿物资源工程研究[J]. 矿物岩石, 2012, 32(2): 38-44. doi: 10.3969/j.issn.1001-6872.2012.02.006

[9] 李光惠, 王超峰, 詹建华, 等. 高纯石英原料作为战略性矿产的分析及建议[J]. 中国非金属矿工业导刊, 2020(5): 20-24. doi: 10.3969/j.issn.1007-9386.2020.05.006

[10] 陈正国, 颜玲亚, 高树学. 战略性非金属矿产资源形势分析[J]. 中国非金属矿工业导刊, 2021(2): 1-8+23. doi: 10.3969/j.issn.1007-9386.2021.02.001

[11] 郝文俊, 冯书文, 詹建华, 等. 全球高纯石英资源现状、生产、消费及贸易格局[J]. 中国非金属矿工业导刊, 2020(5): 15-19. doi: 10.3969/j.issn.1007-9386.2020.05.005

[12] 陈军元, 刘艳飞, 颜玲亚, 等. 石墨、萤石等战略非金属矿产发展趋势研究[J]. 地球学报, 2021, 42(2): 287-296. https://www.cnki.com.cn/Article/CJFDTOTAL-DQXB202102022.htm

[13] BEURLEN H, MüLLER A, SILVA D, et al. Petrogenetic significance of LA-ICP-MS trace-element data on quartz from the Borborema Pegmatite Province, northeast Brazil[J]. Mineralogical Magazine, 2011, 75(5): 2703-2719. doi: 10.1180/minmag.2011.075.5.2703

[14] BRUHN F, BRUCKSCHEN P, MEIJER J, et al. Cathodoluminescence investigations and trace-element analysis of quartz by micro-PIXE; implications for diagenetic and provenance studies in sandstone[J]. The Canadian Mineralogist, 1996, 34(6): 1223-1232.

[15] 岳丽琴. 高纯石英制备技术评述[J]. 矿产综合利用, 2014(1): 16-19. doi: 10.3969/j.issn.1000-6532.2014.01.004

[16] SEIFERT W, RHEDE D, THOMAS R, et al. Distinctive properties of rock-forming blue quartz: inferences from a multi-analytical study of submicron mineral inclusions[J]. Mineralogical Magazine, 2011, 75(4): 2519-2534. doi: 10.1180/minmag.2011.075.4.2519

[17] MVLLER A, Wiedenbeck M, KERKHOF A M V D, et al. Trace elements in quartz-a combined electron microprobe, secondary ion mass spectrometry, laser-ablation ICP-MS, and cathodoluminescence study[J]. European Journal of Mineralogy, 2003, 15(4): 747-763. doi: 10.1127/0935-1221/2003/0015-0747

[18] MVLLER A, KOCH-MVLLER M. Hydrogen speciation and trace element contents of igneous, hydrothermal and metamorphic quartz from Norway[J]. Mineralogical Magazine, 2009, 73(4): 569-583. doi: 10.1180/minmag.2009.073.4.569

[19] GTZE J. Chemistry, textures and physical properties of quartz - geological interpretation and technical application[J]. Mineralogical Magazine, 2009, 73(4): 645-671. doi: 10.1180/minmag.2009.073.4.645

[20] HAUS R. High demands on high purity[J]. Ind Miner, 2005, 10: 62-67.

[21] 杨晓勇, 孙超, 曹荆亚, 施建斌. 高纯石英的研究进展及发展趋势[J/OL]. 地学前缘: 1-14[2022-01-21].

[22] PLATIAS S, VATALIS K I, CHARALABIDIS G. Innovative Processing Techniques for the Production of a Critical Raw Material the High Purity Quartz[J]. Procedia Economics & Finance, 2013, 5: 597-604.

[23] 吴逍. 高纯石英原料选择评价及提纯工艺研究[D]. 绵阳: 西南科技大学, 2016.

[24] GÖTZE J, MÖCKEL R. Quartz: Deposits, Mineralogy and Analytics[M]. Berlin: Springer. 2012: 89.

[25] KONSTANTINOS, I., VATALIS, et al. Market Developments and Industrial Innovative Applications of High Purity Quartz Refines - ScienceDirect[J]. Procedia Economics and Finance, 2014, 14(14): 624-633.

[26] VATALIS K I, Charalambides G, Benetis N P. Market of high purity quartz innovative applications[J]. Procedia Economics and Finance, 2015, 24: 734-742. doi: 10.1016/S2212-5671(15)00688-7

[27] 杨军. 美国尤尼明高纯度石英砂[C]//全国高新技术用石英制品及相关材料技术研讨会. 江苏: 中国电子材料行业协会, 2003.

[28] SATO TATSUHIRO, WATANABEHIROYUKI, PONTO WERNER. Process for continuous refining of quartz powder, US5637284[P]. 1997-06-10.

[29] 刘国库, 张文军, 马正先, 等. 硅石选矿提纯工艺研究现状[J]. 有色矿冶, 2007(6): 26-30. doi: 10.3969/j.issn.1007-967X.2007.06.008

[30] 彭寿, 陈志强. 我国硅质原料产业现状及发展趋势[J]. 国外建材科技, 2008(2): 40-46. doi: 10.3963/j.issn.1674-6066.2008.02.012

[31] NEPOMNYASHCHIKH A I, VOLKOVA M G, ZHABOEDOV A P, et al. Optical glass based on the east sayan mountain quartzites[J]. Glass Physics & Chemistry, 2018, 44(2): 130-136.

[32] ZHONG T, YU W, SHEN C, et al. Research on preparation and characterisation of high-purity silica sands by purification of quartz vein ore from dabie mountain[J]. Silicon, 2021: 1-7.

[33] 马进海, 张洁, 马文智. 青海省柴北缘高纯石英用脉石英矿提纯研究[J]. 中国非金属矿工业导刊, 2017(3): 26-27+40. doi: 10.3969/j.issn.1007-9386.2017.03.009

[34] 丁亚卓. 低品位石英矿提纯制备高纯度石英的研究[D]. 沈阳: 东北大学, 2010.

[35] VERESHCHAGIN V I, SAFRONOV V N, KOTENKO L K. The effect of a high-voltage pulse discharge on the crystal lattice and the surface of quartz grains[J]. Glass & Ceramics, 2002, 59(1): 47-49.

[36] MARTELLO E D, BERNARDIS S, LARSEN R B, et al. Electrical fragmentation as a novel route for the refinement of quartz raw materials for trace mineral impurities[J]. Powder Technology, 2012, 224: 209-216. doi: 10.1016/j.powtec.2012.02.055

[37] 吴晗, 刘嵘, 钟志华. 一种新型的地质样品分离技术: 电力学崩解法的工作原理及应用前景[J]. 地质科技情报, 2016, 35(6): 257-261. https://www.cnki.com.cn/Article/CJFDTOTAL-DZKQ201606037.htm

[38] MARTYNOV N, AVRAMOV D, KOZLOV G, et al. Pulsed electric discharge for environmentally friendly cleaning and crushing of quartz sand[J]. E3S Web of Conferences, 2020, 203: 1-10.

[39] 崔振红, 解志锋, 陈亮亮. 河北某高品质石英砂矿石提纯试验[J]. 现代矿业, 2019, 35(10): 119-120+123. doi: 10.3969/j.issn.1674-6082.2019.10.035

[40] 廖青, 朱建军, 石玉光. 超声波提纯石英砂的试验研究[J]. 江苏冶金, 2002(4): 15-18. doi: 10.3969/j.issn.1005-6068.2002.04.005

[41] 马超, 冯安生, 刘长淼, 等. 高纯石英原料矿物学特征与加工技术进展[J]. 矿产保护与利用, 2019, 39(6): 48-57. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=f8d0ad56-4a9b-498c-9bfc-4bfca34bcc24

[42] 郑翠红, 孙颜刚, 杨文雁, 等. 石英砂提纯方法研究[J]. 中国非金属矿工业导刊, 2008(5): 16-18. doi: 10.3969/j.issn.1007-9386.2008.05.005

[43] 庞庆乐, 沈建兴, 程传兵, 等. 高纯石英的加工技术及应用[J]. 江苏陶瓷, 2020, 53(4): 43-47. doi: 10.3969/j.issn.1006-7337.2020.04.014

[44] YIN W, WANG D, DRELICH J W, et al. Reverse flotation separation of hematite from quartz assisted with magnetic seeding aggregation[J]. Minerals Engineering, 2019, 139: 1-8.

[45] ABUKHADRA M R, SHABAN M, MOHAMED A S, et al. Characterization and beneficiation of gold mining by-products as source of high-quality silica for high technical applications; response surface studies and optimization[J]. Silicon, 2019, 11(2): 615-625. doi: 10.1007/s12633-018-9865-5

[46] 刘宝贵. 高纯石英的提取工艺及其浮选药剂的研究[D]. 武汉: 武汉工程大学, 2017.

[47] JIANG X, SHI J, CHEN C, et al. Flotation mechanism and application of PEA with different chain lengths in quartz flotation[J]. Chemical Engineering Science, 2021: 116813: 1-10.

[48] 雷绍民, 龚文琪, 张高科. 阴/阳离子捕收剂反浮选制备高纯石英砂研究[J]. 金属矿山, 2002(09): 25-26+29. doi: 10.3321/j.issn:1001-1250.2002.09.008

[49] LI F, JIANG X, ZUO Q, et al. Purification mechanism of quartz sand by combination of microwave heating and ultrasound assisted acid leaching treatment[J]. Silicon, 2021, 13(2): 531-541. doi: 10.1007/s12633-020-00457-7

[50] YANG C. Advanced purification of industrial quartz using calcination pretreatment combined with ultrasound-assisted leaching[J]. Acta Geodynamica et Geomaterialia, 2018, 15(2): 187-195.

[51] 熊康, 雷绍民, 钟乐乐, 等. 脉石英热压浸出纯化及热力学机理研究[J]. 中国矿业, 2016, 25(2): 129-133. doi: 10.3969/j.issn.1004-4051.2016.02.025

[52] VEGLIó F, PASSARIELLO B, BARBARO M, et al. Drum leaching tests in iron removal from quartz using oxalic and sulphuric acids[J]. International Journal of Mineral Processing, 1998, 54(3-4): 183-200. doi: 10.1016/S0301-7516(98)00014-3

[53] LEI S M, LIN M, PEI Z Y, et al. Occurrence and removal of mineral impurities in quartz[J]. China Min. Mag., 2016: 79-83.

[54] ELGHNIJI K, AMOR C O, VIRLAN C, et al. Separation and identification of minerals composing the silica sands (southwestern tunisia)[J]. Mining, Metallurgy & Exploration, 2020, 37(5): 1753-1763.

[55] ZHANG H, GUO S, WU J, et al. Effect of quartz crystal structure transformations on the removal of iron impurities[J]. Hydrometallurgy, 2021, 204: 105715: 1-7.

[56] 邵竹锋. 打破国外垄断研发世界一流石英玻璃[J]. 中国建材, 2015(7): 80-83. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJC201507027.htm

[57] 张国君, 张寒, 黄若杰, 等. 超纯石英玻璃用二氧化硅的环保型制备工艺研究[J]. 广东化工, 2019, 46(4): 73-74. doi: 10.3969/j.issn.1007-1865.2019.04.033

[58] 王玉芬, 宋学富, 孙元成, 等. 超纯石英玻璃制备工艺研究[J]. 武汉理工大学学报, 2010, 32(22): 98-101. doi: 10.3963/j.issn.1671-4431.2010.22.026

[59] 聂兰舰, 王玉芬, 向在奎, 等. 高性能光学合成石英玻璃的制备和应用[J]. 光学精密工程, 2016, 24(12): 2916-2924. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201612006.htm

[60] CHOI J H, YOON J S, JUNG Y S, et al. Analysis of plasma etching resistance for commercial quartz glasses used in semiconductor apparatus in fluorocarbon plasma[J]. Materials Chemistry and Physics, 2021(36): 1-7.

[61] SEIDL A, MARTEN R, MüLLER G. Oxygen distribution in Czochralski silicon melts measured by an electrochemical oxygen sensor[J]. C, H, N and O in Si and Characterization and Simulation of Materials and Processes, 1996, 36(1-3): 46-49.

[62] 李昆, 史冰川, 董俊, 等. 直拉硅单晶制备中来自于石英坩埚的受主杂质污染定量分析[J]. 云南冶金, 2016, 45(2): 114-118. doi: 10.3969/j.issn.1006-0308.2016.02.013

[63] HUANG X, KOH S, WU K, et al. Reaction at the interface between Si melt and a Ba-doped silica crucible[J]. Journal of Crystal Growth, 2005, 277(1-4): 154-161. doi: 10.1016/j.jcrysgro.2005.01.101

[64] 罗晓斌, 张波, 辛玉龙. 直拉法硅单晶中石英坩埚析晶问题的探讨[J]. 河南科技, 2014(4): 64. https://www.cnki.com.cn/Article/CJFDTOTAL-HNKJ201404046.htm

[65] 黄振飞, 王文. 大规模集成电路级硅单晶硅使用石英坩埚发展介绍[C]. 2005.

[66] 朱纯. 石英坩埚企业在光伏产业链中发展的策略研究[J]. 科教导刊(上旬刊), 2013(5): 191-192. https://www.cnki.com.cn/Article/CJFDTOTAL-KJDS201305108.htm

[67] 谭毅, 秦世强, 石爽, 等. 太阳能级硅中轻质元素(C, N, O)研究进展[J]. 材料工程, 2017, 45(2): 112-118. https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC201702018.htm

[68] LI J, LIU M, TAN Y, et al. Effect of the silicon nitride coating of quartz crucible on impurity distribution in ingot‐cast multicrystalline silicon[J]. International Journal of Applied Ceramic Technology, 2013, 10(1): 40-44. doi: 10.1111/j.1744-7402.2012.02832.x

[69] 陶明顿, 濮阳坤, 张尧. 适用于单晶生产的低变形率坩埚用石英原料的制备方法: 江苏, CN104743779A[P]. 2015-07-01.

[70] 农剑. 光纤有线通讯技术在现代通信工程中的应用[J]. 电子技术与软件工程, 2017(14): 24. https://www.cnki.com.cn/Article/CJFDTOTAL-DZRU201714022.htm

[71] 罗文芸. 石英光纤材料辐射诱导缺陷的形成机理研究[D]. 上海: 上海大学, 2013.

[72] 苏君红, 张玉龙. 光纤材料技术[M]. 杭州: 浙江科学技术出版社, 2009.

[73] 张全, 贠发红, 贺卿. 石英光纤空间辐射损伤机理及性能改善研究[J]. 光纤与电缆及其应用技术, 2020(6): 7-9+14. https://www.cnki.com.cn/Article/CJFDTOTAL-GYYD202006002.htm

[74] VAN UFFELEN M, GIRARD S, GOUTALAND F, et al. Gamma radiation effects in Er-doped silica fibers[J]. IEEE Transactions on Nuclear Science, 2004, 51(5): 2763-2769. doi: 10.1109/TNS.2004.835059

[75] WILLIAMS G M, FRIEBELE E J. Space radiation effects on erbium-doped fiber devices: sources, amplifiers, and passive measurements[C]//RADECS 97. Fourth European Conference on Radiation and its Effects on Components and Systems (Cat. No. 97TH8294). IEEE, 1997: 399-404.

[76] SHIKAMA T, KAKUTA T, NARUI M, et al. Optical properties in fibers during irradiation in a fission reactor[J]. Journal of Nuclear Materials, 1995, 225(none): 324-327.

[77] 刘茵紫, 邢颍滨, 徐中巍, 等. 高功率掺铥石英光纤激光器研究进展[J]. 激光与光电子学进展, 2018, 55(5): 27-41. https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ201805003.htm

[78] 彭智星. 石英光纤缺陷相互作用的机制研究[D]. 北京: 北京邮电大学, 2019.

[79] 邓涛. 石英玻璃及石英光纤的抗辐射性能研究[D]. 武汉: 武汉理工大学, 2010.

[80] XIN G L, XU X M, YU R, et al. Bn/sibcn light-leakage-proof coatings of silica optical fiber for long term sensors at high temperatures[J]. Chinese Journal of Aeronautics, 2021, 34(5): 93-102. doi: 10.1016/j.cja.2020.07.031

[81] 宋启良, 胡振峰, 涂龙, 等. 石英光纤表面Cu-石墨烯复合镀层的性能研究[J]. 稀有金属材料与工程, 2021, 50(1): 85-94. https://www.cnki.com.cn/Article/CJFDTOTAL-COSE202101013.htm

[82] 陈冲. 光学石英玻璃在超精密加工过程中的纳观物化行为研究[D]. 大连: 大连理工大学, 2019.

[83] 李富全, 韩伟, 王芳, 等. 高功率激光驱动器终端光学组件研究现状[J]. 激光与光电子学进展, 2013, 50(6): 13-19. https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ201306003.htm

[84] 燕来荣. 浅谈电光源玻璃[J]. 玻璃, 2011, 38(11): 13-18. doi: 10.3969/j.issn.1003-1987.2011.11.004

[85] 梁贞, 叶欣. 中国电光源用石英玻璃发展情况调研报告[J]. 中国照明电器, 2011(5): 1-3. doi: 10.3969/j.issn.1002-6150.2011.05.001

[86] 潘国璋. 电光源用石英玻璃的现状—低羟基石英管的研究与生产[J]. 灯与照明, 2003(1): 52-54. doi: 10.3969/j.issn.1008-5521.2003.01.015

[87] KHAN N, ABAS N. Comparative study of energy saving light sources[J]. Renewable & Sustainable Energy Reviews, 2011, 15(1): 296-309.

[88] 刘德顺. 无钠无铅电光源玻璃的制备与研究[D]. 上海: 东华大学, 2012.

[89] 宋海锋, 张翼, 韩乃红, 等. 石英陶瓷的应用[J]. 现代技术陶瓷, 2003, 24(3): 37-39. doi: 10.3969/j.issn.1005-1198.2003.03.010

[90] 雷景轩, 邬浩, 赵中坚. 石英陶瓷天线罩材料研究进展[J]. 中国陶瓷, 2020, 56(4): 7-12. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTC202004002.htm

[91] 荆富, 王磊. 石英陶瓷的研究及应用进展[J]. 中国非金属矿工业导刊, 2013(3): 16-20. doi: 10.3969/j.issn.1007-9386.2013.03.006

[92] SUZDAL'TSEV E I. Fabrication of high-density quartz ceramics: Research and practical aspects. Part 5. A study of the sintering of modified quartz ceramics[J]. Refractories and Industrial Ceramics, 2006, 47(1): 36-45. doi: 10.1007/s11148-006-0051-8

[93] 刘恒波, 蒋述兴. 石英陶瓷材料的研究进展[J]. 玻璃, 2008(4): 16-20. https://www.cnki.com.cn/Article/CJFDTOTAL-BLZZ200804006.htm

[94] 李爱农, 潘宇飞, 何博, 等. 熔模铸造用型壳材料的优选[J]. 热加工工艺, 2018, 47(5): 106-110+114. https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201805026.htm

[95] 赵红亮, 翁康荣, 关绍康, 等. 空心叶片用陶瓷型芯[J]. 特种铸造及有色合金, 2004(5): 38-40+3. doi: 10.3321/j.issn:1001-2249.2004.05.015

[96] 陈冰. 制壳耐火材料新秀—熔融石英—国外精铸技术进展述评(5)[J]. 特种铸造及有色合金, 2005(5): 294-297+255. doi: 10.3321/j.issn:1001-2249.2005.05.015

[97] SNOW J D, SCOTT D H. Comparing fused silica and alumino-silicate investment refractories[J]. Modern casting, 2001, 91(1): 45-47.

[98] 曹腊梅. 国外定向和单晶空心叶片用型芯的工艺特点[J]. 材料工程, 1995(5): 3. https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC505.006.htm

[99] 贺靠团, 马德文, 蒋殷鸿, 等. 空心叶片复杂硅基陶瓷型芯的粉料粒度[J]. 材料工程, 1992(1): 34-35. https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC199201012.htm

[100] 徐子烨, 玄伟东, 张金垚, 等. 烧结温度和粒度分布对多孔氧化硅陶瓷型芯材料性能的影响[J]. 上海大学学报(自然科学版), 2015, 21(1): 28-37. https://www.cnki.com.cn/Article/CJFDTOTAL-SDXZ201501004.htm

[101] 曾岩. Y2O3与方石英对氧化硅陶瓷型芯性能的影响[D]. 哈尔滨: 哈尔滨工业大学, 2014.

[102] 张玲, 黄静, 杜洪强, 等. 莫来石为矿化剂的硅基陶瓷型芯性能研究[J]. 铸造, 2015, 64(12): 1251-1253. doi: 10.3969/j.issn.1001-4977.2015.12.013

[103] 姚仲成. 空心叶片用氧化硅基陶瓷型芯性能改进研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.

[104] 刘晓光, 齐长见, 贺莉丽, 等. 烧结温度对SiO2-ZrO2体系陶瓷型芯材料性能影响研究[J]. 航空材料学报, 2011, 31(5): 62-65. https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201105013.htm

[105] 杨嘉楠. 硅基陶瓷型芯的制备及性能研究[D]. 南京: 东南大学, 2017.

[106] 郭新力, 娄延春, 黄国华, 等. 强化处理对硅基陶瓷型芯高温性能的影响[J]. 铸造, 2012, 61(11): 1299-1302. doi: 10.3969/j.issn.1001-4977.2012.11.006

[107] 赵宪涛, 成来飞, 张立同, 等. 强化对硅基陶瓷型芯高温强度的影响[J]. 热加工工艺, 2012, 41(1): 1-4. doi: 10.3969/j.issn.1001-3814.2012.01.001

-

下载:

下载: