Experimental Study on Stage Grinding and Stepwise Flotation of a Gold Ore in Inner Mongolia

-

摘要:

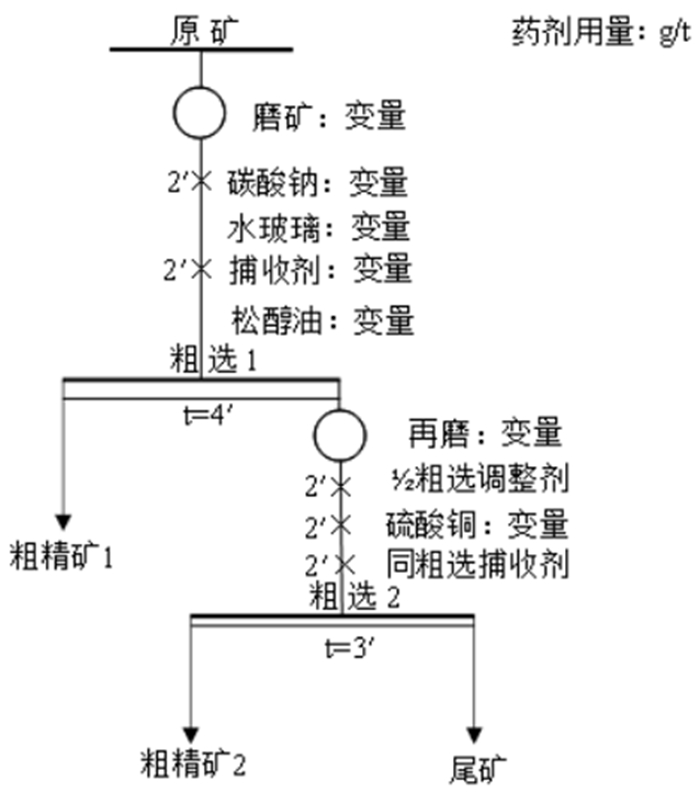

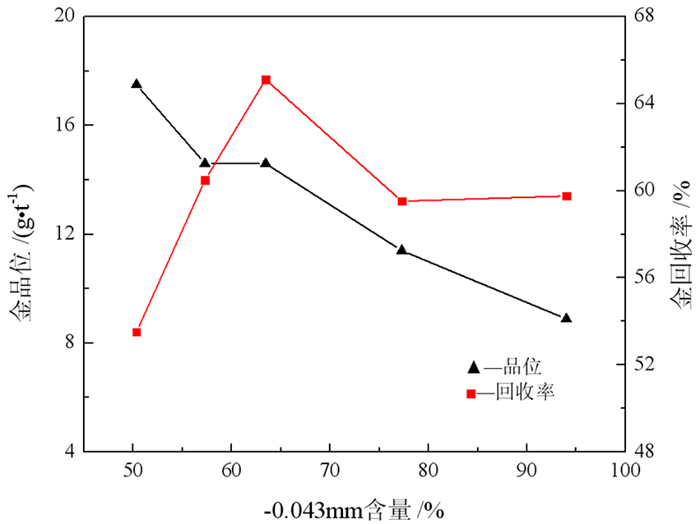

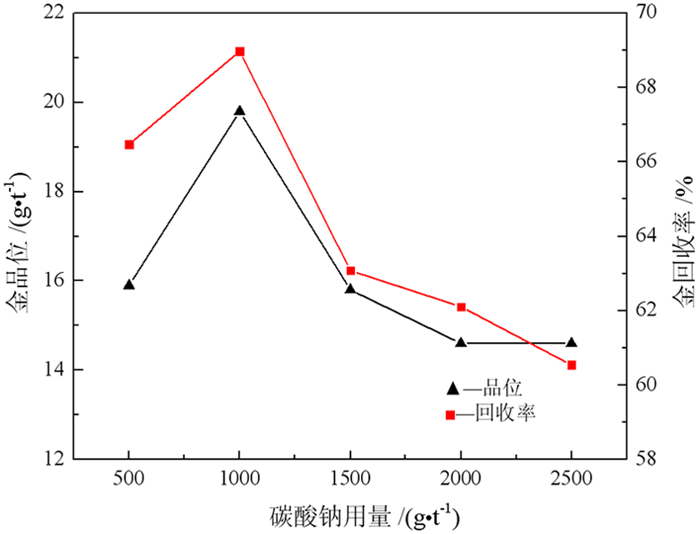

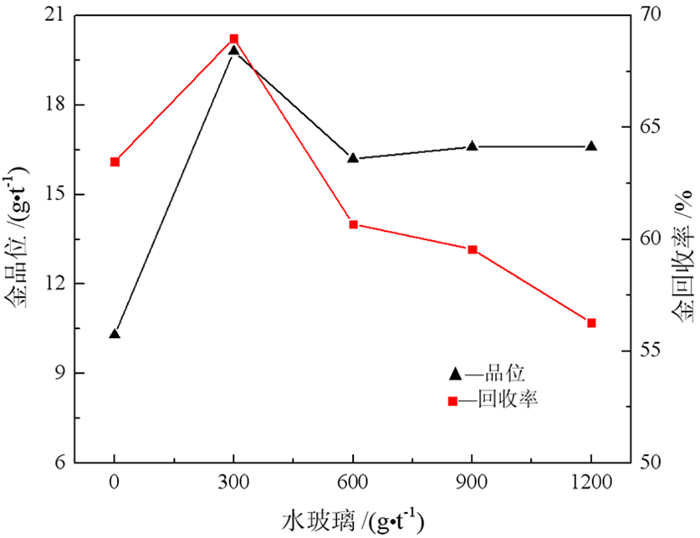

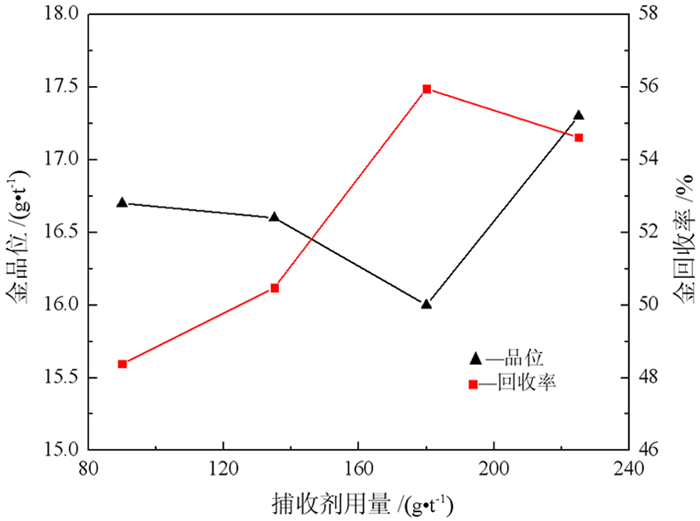

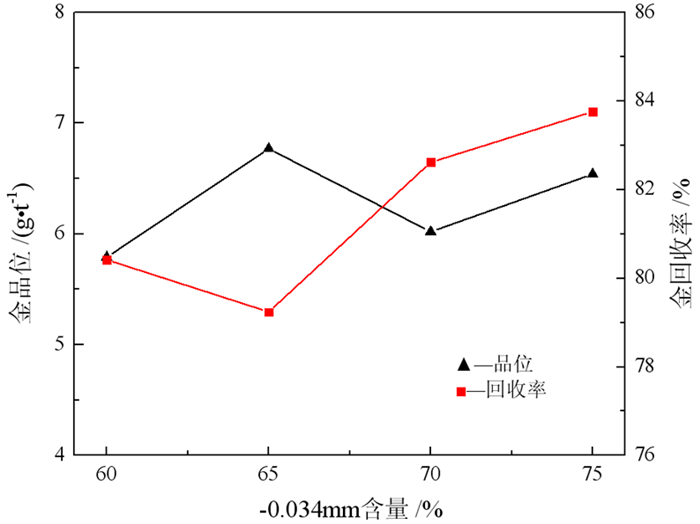

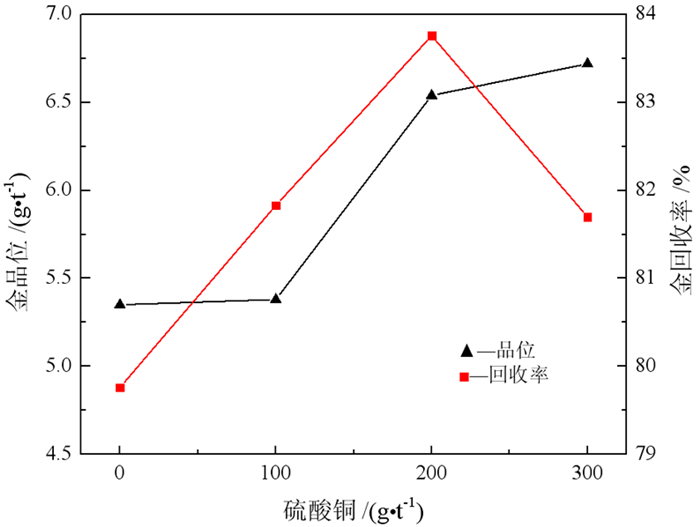

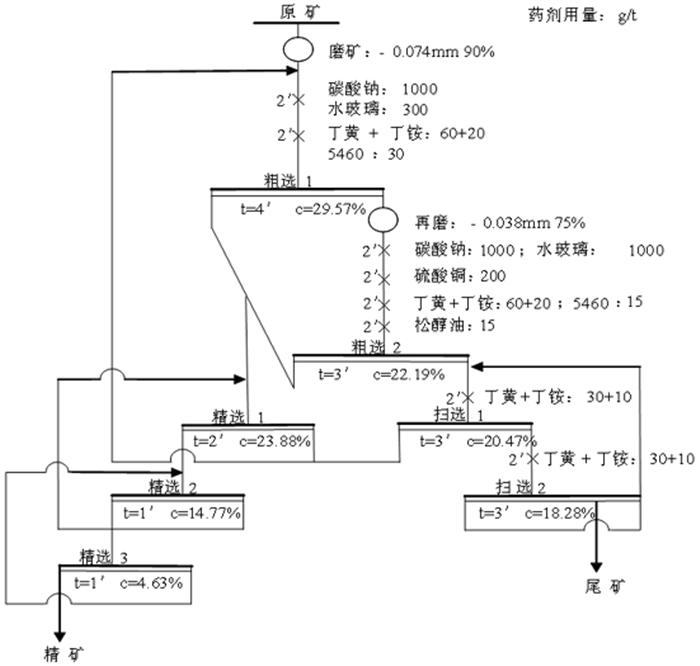

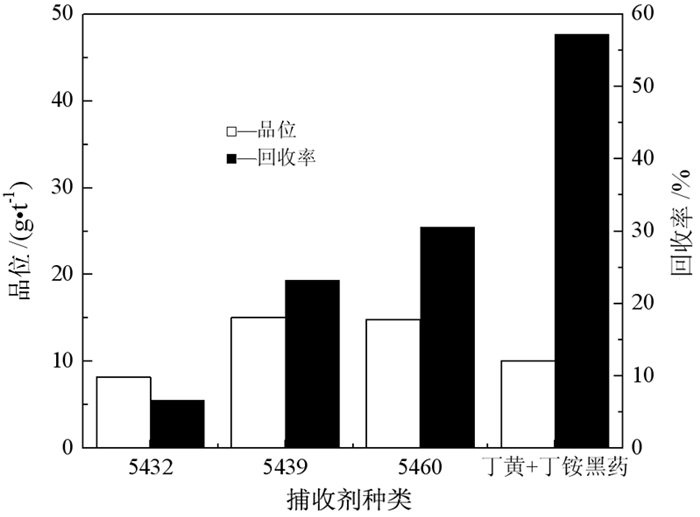

内蒙古某金矿山原矿金品位为2.83 g/t,其中金银矿物嵌布粒度细且与脉石矿物连生紧密,不利于单体解离。为了进一步实现金矿的高效富集,在工艺矿物学研究基础上确定了阶段磨矿—阶段浮选工艺流程,并进行了详细的浮选试验。结果表明:(1)矿石中含有少量银金矿和碲银矿,主要载金矿物为黄铁矿和磁黄铁矿,其中黄铁矿中金含量为62.20 g/t,占矿石中金总量的41.61%,磁黄铁矿中金含量为32.30 g/t,占矿石中金总量的23.77%,脉石矿物以石英、绿帘石、绿泥石、长石和云母等矿物为主。(2)以"丁基黄药+丁铵黑药"为主要捕收剂,5460为辅助捕收剂,在一段磨矿细度为-0.074 mm占90%、二段磨矿细度为-0.038 mm占75%的条件下,采用两次粗选三次精选两次扫选、中矿顺序返回的闭路工艺流程,获得了金品位38.00 g/t、回收率80.06%的精矿产品,较原浮选流程中金矿品位提高13.8%个百分点,回收率提高6.75个百分点,有效实现了金矿的富集。

Abstract:In a gold mine in Inner Mongolia, the gold grade in the raw ore is 2.83 g/t. The gold occurred as fine disseminated particles in gold ore, and the embedding relationship between gold and gangue minerals was close, indicating the recovery of gold minerals was difficult. In order to realize the effective concentration of the gold ore, the process flow of stage grinding and separation was determined on the basis of process mineralogy tests, and the flotation condition tests were carried out. Results demonstrated that the gold ore contains a slight amount of precious minerals such as electrum and hessite. The main gold-bearing minerals are pyrite and pyrrhotite. The gold content in pyrite was 62.20 g/t and distribution 41.61%, and that in pyrrhotite was 32.30 g/t and 23.77%. The gangue minerals mainly were quartz, epidote, chlorite, feldspar and mica. The flotation test results showed that the concentrate with gold grade of 38.00 g/t and recovery of 80.06 % was obtained under using butyl xanthate + butylamine dithiophosphate as main collector and 5460 as auxiliary collector, and the first stage grinding fineness of -0.074 mm 90% and the second stage grinding fineness of -0.038 mm 75% with closed-circuit flowsheet containing two roughing, two cleaning and three scavenging, and the middling returned in sequence. In addition, compared with the original flotation process, the gold grade and recovery of concentrate were increased by 13.8% and 6.75%, respectively.

-

Key words:

- gold ore /

- stage grinding /

- flotation /

- concentration

-

-

表 1 原矿化学多元素分析结果

Table 1. The results of chemical multi-element analysis of raw ore

/% 元素 Au* Ag* Pb Cu Zn As C TFe S K 含量 2.83 2.80 < 0.05 0.014 < 0.05 0.007 0.796 7.15 1.51 1.95 元素 Na TiO2 Ni Cr Co SiO2 Al2O3 MgO CaO 烧失 含量 1.04 2.02 0.004 0.008 0.005 56.81 12.34 4.18 5.35 5.08 注: “*”单位为g/t。 表 2 原矿金的分布率

Table 2. The gold distribution of raw ore

/% 矿物种类 矿物含量 金含量 分布率 磁黄铁矿 3.08 32.30 23.77 黄铁矿 2.80 62.20 41.61 其他矿物 94.12 1.54 34.62 合计 100.00 4.19 100.00 表 3 闭路浮选试验结果

Table 3. Results of closed-circuit flotation

产品 产率/% 金品位/(g·t-1) 银品位/(g·t-1) 金回收率/% 银回收率/% 精矿 5.96 38.00 18.30 80.06 38.95 尾矿 94.04 0.60 1.82 19.94 64.05 合计 100.00 2.47 2.80 100.00 100.00 -

[1] 王燕东. 2009-2019年我国金矿资源勘查形势分析与对策[J]. 中国矿业, 2020, 29(11): 7-13. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA202011002.htm

[2] 王海博, 吕超, 赵轩, 等. 某多金属硫化物石英脉型金矿浮选试验[J]. 金属矿山, 2020(2): 77-81. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202002015.htm

[3] 姚兰星, 王毓华, 何建璋, 等. 某高砷含碳低品位难选金矿浮选试验研究[J]. 矿冶工程, 2018, 38(2): 38-42. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC201802010.htm

[4] 包文童, 袁要伟. 金矿地质勘查现状及找矿方向分析[J]. 世界有色金属, 2020(14): 81-82. https://www.cnki.com.cn/Article/CJFDTOTAL-COLO202014037.htm

[5] 贾先兵, 谢磊. 陕西某难选金矿浮选试验研究[J]. 矿产综合利用, 2016(1): 37-40. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201601009.htm

[6] 黄宇林. 应用尼尔森重选优化河南某氧化型金矿选别指标[J]. 金属矿山, 2020(3): 120-125. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202003019.htm

[7] 倪青青, 高志, 宋祖光. 提高河南某低品位金矿金回收率试验研究[J]. 金属矿山, 2020(9): 125-130. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202009018.htm

[8] 陈桥, 杨洪英, 佟琳琳. 海南某金矿尼尔森重选-浮选试验[J]. 东北大学学报(自然科学版), 2020, 41(3): 413-417+451. https://www.cnki.com.cn/Article/CJFDTOTAL-DBDX202003020.htm

[9] 周思含, 李鹏程, 沈海涛. 辽宁某金矿浮选试验研究[J]. 有色矿冶, 2015, 31(2): 23-25+14. https://www.cnki.com.cn/Article/CJFDTOTAL-YSKY201502007.htm

[10] 周东琴, 代淑娟. 陕西某卡林型金矿选矿试验研究[J]. 有色矿冶, 2009, 25(2): 20-22. https://www.cnki.com.cn/Article/CJFDTOTAL-YSKY200902006.htm

[11] 贺国帅, 范予晨. 陕西某金矿选矿试验研究[J]. 铜业工程, 2020(4): 38-43. https://www.cnki.com.cn/Article/CJFDTOTAL-TYGC202004022.htm

[12] 杨超, 王怀, 郝福来, 等. 贵州某卡林型金矿浮选试验研究[J]. 黄金, 2018, 39(6): 56-59. https://www.cnki.com.cn/Article/CJFDTOTAL-HJZZ201806013.htm

[13] 刘莉君, 付艳红, 王纪镇, 等. 陕西某金矿选矿试验研究[J]. 西安科技大学学报, 2017, 37(1): 121-126. https://www.cnki.com.cn/Article/CJFDTOTAL-XKXB201701018.htm

-

下载:

下载: