Process Mineralogy of the Zhaojinggou Tantalum-niobium Ore Deposit in Inner Mongolia Province

-

摘要:

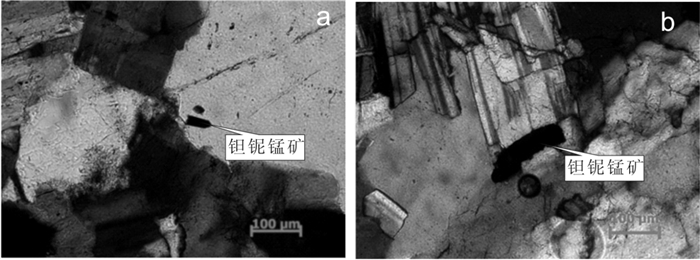

针对内蒙古赵井沟钽铌矿,通过光学显微镜、人工重砂、X射线衍射分析以及电子探针分析,确定了该矿主要矿物组成及含量,详细研究了钽铌类矿物的化学成分、粒度和嵌布特征,以及钽、铌等元素的赋存状态。钽铌锰矿类矿物的粒度微细,一般在0.02~0.074 mm之间,以包裹体形式分布为主,占66.83%,粒间分布占33.17%。有用矿物为钽铌锰矿、铌钽锰矿2个矿物亚种,钽铌锰矿类矿物以富铁和富锰类为主,有一定量的钛等元素混入。根据金属量平衡结果,该矿钽、铌主要集中在钽铌锰矿类矿物中,主要分散分布在云母、长石、石英等脉石矿物中,Nb2O5的集中系数为61.23%,Ta2O5的集中系数为57.17%。在该研究的基础上,选矿工艺制定了合理的流程,取得了良好的选矿指标。

Abstract:Taking the Zhaojinggou tantalum-niobium ore in Inner Mongolia as the research object, the main mineral compositions and the relevant content of raw ore are determined by optical microscope, artificial heavy sand, X-ray diffraction and electron probe analysis. The chemical composition, particle size and embedded features, as well as the occurrence state of tantalum, niobium and other elements are also studied in detail. Tantalum and niobium manganese minerals have fine grain sizes, usually in the range of 0.02—0.074 mm. Inclusion form is the main distribution state, and accounting for 66.83%. Valuable minerals include two mineral subspecies, namely tantalum-niobium manganese ore and niobium-tantalum manganese ore. The tantalum-niobium manganese ore is rich in iron or manganese with a certain content of titanium. According to the results of metal balance, the tantalum and niobium are mainly concentrated in tantalum-niobium manganese ore, and dispersed in gangue minerals such as mica, feldspar and quartz. The concentration coefficient of Nb2O5 is 61.23%, and that of Ta2O5 is 57.17%. Based on this study, a reasonable process of ore dressing process has been made, and good dressing indexes have been obtained.

-

Key words:

- tantalum-niobium ore /

- process mineralogy /

- Inner Mongolia /

- occurrence state

-

-

表 1 原矿化学多项分析结果 /%

Table 1. Chemical analysis results of raw ore

成分 Ta2O5 Nb2O5 Li2O Rb2O Fe2O3 TiO2 SiO2 Al2O3 CaO MgO K2O Na2O MnO WO3 Cs2O Ag RExOy ThO2 含量 0.0111 0.0134 0.029 0.084 0.67 0.007 73.46 14.51 0.12 0.05 3.11 6.02 0.038 0.016 0.000 5 1.68 0.006 4 0.001 7 注:Ag单位为g/t。 表 2 矿石中主要矿物的相对含量 /%

Table 2. Relative content of the main minerals in raw ore

矿物 钽铌锰矿 黄铁矿 石英 天河石 白云母 钠长石 萤石 钽锡石 褐铁矿 黄玉 锆石 独居石 含量 0.018 0.04 25.5 15.2 2.4 55.7 0.22 少量 0.03 0.022 微量 微量 表 3 铌钽锰矿-钽铌锰矿电子探针测定结果 /%

Table 3. Results of electron probe measurements of niobium-tantalum manganese ore and tantalum-niobium manganese ore

MnO Nb2O5 K2O FeO CaO Al2O3 TiO2 Ta2O5 Total 12.568 68.106 0 6.662 0.015 0 0.081 11.114 98.547 13.673 64.400 0 4.873 0.026 0 0.092 16.274 99.339 13.077 64.239 0 5.965 0.01 0.006 0 13.479 96.777 13.681 64.127 0.015 5.594 0.017 0.008 0.142 15.591 99.175 13.497 63.975 0.003 5.765 0 0 0.109 13.865 97.214 14.000 62.003 0.02 5.015 0.063 0.028 0.815 17.259 99.247 14.067 37.394 0.008 2.892 0.036 0.015 0.343 41.941 96.695 13.842 31.722 0.01 2.177 0.066 0.034 0.136 47.643 95.677 14.042 30.103 0 2.283 0.012 0 0.183 53.682 100.305 13.954 21.208 0.002 1.329 0.023 0 0.284 60.889 97.689 13.413 20.380 0 6.676 0.011 0.038 0.194 57.534 98.246 表 4 钽铌锰矿晶体形态统计结果

Table 4. Statistical results of crystal morphology of tantalum-niobium manganese ore

晶形 板状 长条状 不规则粒状 粒状 合计 颗粒数/粒 168 85 64 23 340 含量/% 49.41 25.00 18.82 6.77 100.00 表 5 钽铌锰矿的原生粒度分布

Table 5. Primary particle size distribution of tantalum-niobium manganese ore

粒级/mm +0.15 -0.15+0.074 -0.074+0.02 -0.02 含量/% 4.11 18.77 66.86 10.26 累计含量/% 4.11 22.88 89.74 100 表 6 钽、铌的金属量平衡表

Table 6. Metal balance sheet of tantalum and niobium

矿物名称 含量/% Nb2O5 Ta2O5 Nb2O5品位/% Nb2O5金属量/g 分布率/% Ta2O5品位/% Ta2O5金属量/g 分布率/% 钽铌锰矿 0.018 47.96 0.008 632 8 61.225 53 31.76 0.005 716 8 57.168 白云母 2.4 0.026 6 0.000 638 4 4.527 66 0.033 0.000 792 7.92 黄铁矿 0.04 0.006 0.000 002 4 0.017 021 0.003 9 0.000 001 56 0.015 6 褐铁矿 0.03 0.072 6 0.000 021 78 0.154 468 0.034 6 0.000 0103 8 0.103 8 萤石 0.22 0.002 9 0.000 006 38 0.045 248 0.001 3 0.000 002 86 0.028 6 黄玉 0.022 0.003 1 0.000 000 682 0.004 837 0.002 4 0.000 000 528 0.005 28 天河石 15.2 0.002 7 0.000 410 4 2.910 638 0.002 1 0.000 319 2 3.192 石英 25.5 0.006 0.001 53 10.851 06 0.001 5 0.000 382 5 3.825 钠长石 55.7 0.005 0.002 835 20.106 38 0.005 0.002 785 27.85 合计 0.014 077 842 99.842 85 0.010 010 828 100.108 3 -

[1] 孙延锦.钽铁矿-铌铁矿组矿物鉴定方法[J].地质与勘探, 1964(3):28-31. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=dzkt196403009&dbname=CJFD&dbcode=CJFQ

[2] 梁冬云, 何国伟.蚀变花岗岩型钽铌矿石的工艺矿物学研究[J].有色金属(选矿部分), 2004(1):1-3. http://www.cqvip.com/QK/90879A/201305/45943843.html

[3] 罗明标, 郭国龙, 郭国林, 等.包头稀土精矿中钍的赋存状态研究[J].稀有金属, 2010, 34(3):471-473. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_xyjs201003028

[4] 程寄皋, 龚文浩, 何先池, 等.体视学在工艺矿物学定量中的应用[J].武汉冶金科技大学学报, 1996, 19(2):135-137. http://www.cqvip.com/QK/91120A/199602/2204644.html

[5] 夏建明, 陈邦建.苏州富铌钽花岗岩的物质组成及钽的赋存状态研究[J].江苏地质, 1999, 23 (4):236-240. http://www.cnki.com.cn/Article/CJFDTOTAL-YKCS201302018.htm

[6] 梁冬云, 喻连香, 张永进, 等.花岗伟晶岩型铌钽矿石的工艺矿物学研究[J].有色金属(选矿部分), 2004(5):1-3. http://www.doc88.com/p-747873125714.html

[7] 伍超群.电子探针在工艺矿物学中的应用[J].岩矿测试, 1994, 13(1):45-48. http://doi.wanfangdata.com.cn/10.3969/j.issn.1006-0308.2011.01.014

-

下载:

下载: