The Application of X-ray Sorting-Reverse Flotation in Phosphate Rock Beneficiation of Yichang Phosphor Layer Ore

-

摘要:

宜昌中磷层磷矿平均P2O5品位仅为22%左右,难以直接工业利用。中磷层磷矿有价磷矿物为磷灰石和胶磷矿,其嵌布粒度较细、在0.03~0.5 mm之间,磷灰石和胶磷矿多呈富磷矿物集合体形式存在,富磷矿物集合体嵌布粒度较粗,能够作为选别对象。中磷层磷矿经过筛分处理,-10 mm粒级磷精矿P2O5品位约为26%,可直接给入浮选作业处理。而-30+10 mm粒级产品采用X射线拣选技术,可获得P2O5品位26%以上、作业回收率80%~86%的磷精矿。筛分作业-10 mm粒级磷精矿与X射线拣选得到的磷精矿合并送往反浮选作业,最终可获得P2O5品位32%以上的优质磷精矿。试验结果表明,X射线拣选—浮选联合工艺表现出优良的分选效果,在处理其它类似低品位、嵌布粒度细的磷矿资源时,该联合工艺有巨大的推广潜力。

Abstract:The P2O5 grade of Yichang middle phosphate rock is only about 22% on average, it is difficult to direct industrial use. Apatite and collophane are the main valuable P-containing minerals in Yichang ore. They have fine dissemination size of 0.03-0.5 mm. But they exists in the form of coarse-grained aggregate of P-containing minerals which can be used as separation objects. After ore of Yichang middle phosphate rock layer was screen, P2O5 grade in -10 mm class is about 26% which can be directly as feed of flotation. While the -30+10 mm class was treated using X-ray sorting technology, after that, phosphorus concentrate was obtained with P2O5 grade of more than 26% and recovery of 80%-86%. The -10 mm class products and X-ray sorting concentrate together feed into reverse flotation. Flotation concentrate with P2O5 grade of more than 32% was obtained eventually. The test results show that the X-ray sorting-reverse flotation process will show a good separation effect, in dealing with other similar low grade phosphate rock1 resources, and the combined process has great potential of popularization.

-

Key words:

- Yichang middle phosphate layer /

- screening /

- X-ray sorting /

- preconcentration /

- reverse flotation

-

-

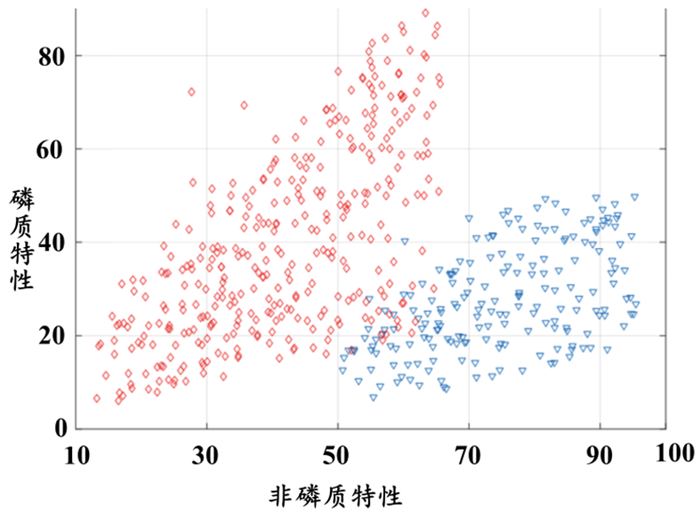

图 5 湖北宜昌杉树桠磷矿石聚类训练效果图[6]

Figure 5.

表 1 中低品位(P2O5 22%左右)原矿筛分结果

Table 1. Size distribution of medium- and low-grade (P2O5 22%) raw ore

/% -10 mm粒级 +10 mm粒级 产率 回收率 品位(P2O5) 产率 回收率 品位(P2O5) 24.65 29.76 26.89 75.35 70.24 20.43 表 2 X射线分选试验结果

Table 2. Results of X-ray sorting of +10-30 class ore

/% 原矿 精矿指标 尾矿指标 品位 产率 品位 回收率 产率 品位 回收率 19.17 54.88 28.27 80.94 45.12 8.10 19.06 19.95 58.18 27.85 81.22 41.82 8.96 18.78 20.32 63.48 27.66 86.41 36.52 7.56 13.59 表 3 反浮选技术指标

Table 3. Technical index of reverse flotation

/% 原矿 精矿 尾矿 P2O5品位 P2O5品位 产率 回收率 P2O5品位 产率 回收率 27.25 32.15 80.27 94.7 7.32 19.73 5.3 -

[1] 黄启生, 李宇新. 宜昌矿区条带状磷块岩选矿技术研究与实践[J]. 武汉工程大学学报, 2011(2): 58-60. https://www.cnki.com.cn/Article/CJFDTOTAL-WHHG201102017.htm

[2] 韩豫川, 夏学惠, 肖荣阁, 等. 中国磷矿床[M]. 北京: 地质出版社, 2012: 1-723.

[3] 杨刚忠, 廖宗明. 宜昌磷矿中磷层(Ph2)选矿试验探讨[J]. 矿产保护与利用, 2009(4): 24-28. doi: 10.3969/j.issn.1001-0076.2009.04.006 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=1d08c60a-3e99-4bc5-bc1a-5731894351db

[4] 罗惠华, 刘连坤, 朱道鹏, 等. 浮选回收宜昌磷矿重介质分选产生的微细级低品位胶磷矿[J]. 矿产综合利用, 2016(3): 67-70. doi: 10.3969/j.issn.1000-6532.2016.03.016

[5] 王修缘. X射线分选机拣选钼矿石试验研究[J]. 才智, 2011(35): 49-51. https://www.cnki.com.cn/Article/CJFDTOTAL-CAIZ201135046.htm

[6] 李宇新, 童晓蕾, 李艳, 等. 重介质选矿、X射线分选在宜昌磷矿各矿层选矿的工业应用对比[J]. 化工矿产地质, 2020(1): 77-82. https://www.cnki.com.cn/Article/CJFDTOTAL-HGKC202001013.htm

[7] 韩跃新, 王泽红, 陈晓龙. X射线辐射分选技术及设备的发展与应用[J]. 矿产综合利用, 2013(6): 11-15. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201306006.htm

[8] 印万忠, 吴尧, 韩跃新, 等. X射线辐射分选原理及应用[J]. 中国矿业, 2011(12): 88-92. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA201112029.htm

[9] HUANG Z, CHENG C, LIU Z, et al. Utilization of a new Gemini surfactant as the collector for the reverse froth flotation of phosphate ore in sustainable production of phosphate fertilizer[J]. Journal of Cleaner Production, 2019, 221: 108-112. http://www.sciencedirect.com/science/article/pii/S0959652619306560

[10] LIU X, LI C, LUO H, et al. Selective reverse flotation of apatite from dolomite in collophanite ore using saponified gutter oil fatty acid as a collector[J]. International Journal of Mineral Processing, 2017, 165: 20-27. http://www.sciencedirect.com/science/article/pii/S0301751617301308

-

下载:

下载: