Influence of Different Flocculants on Settling Effect of Lead-Zinc Tailings

-

摘要:

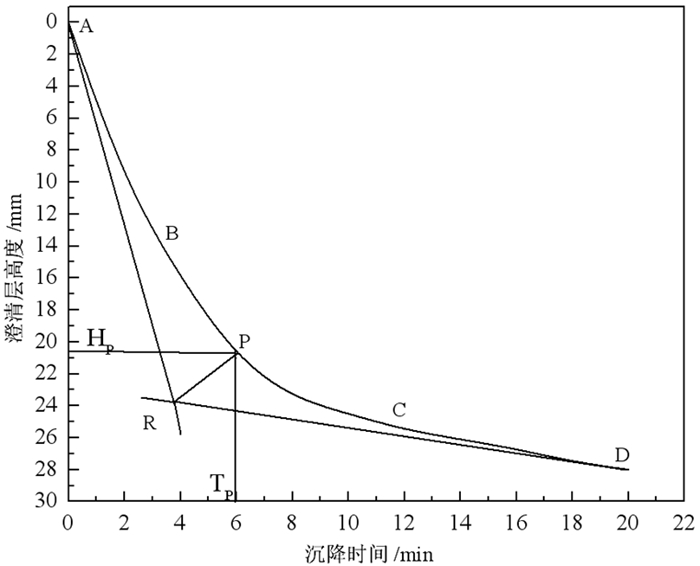

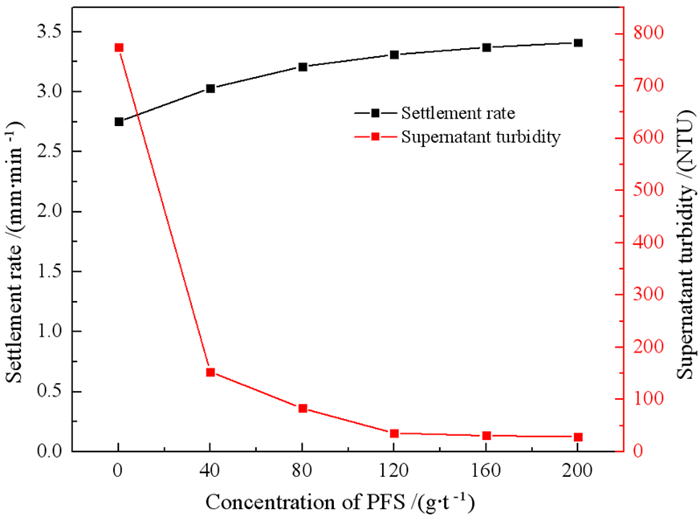

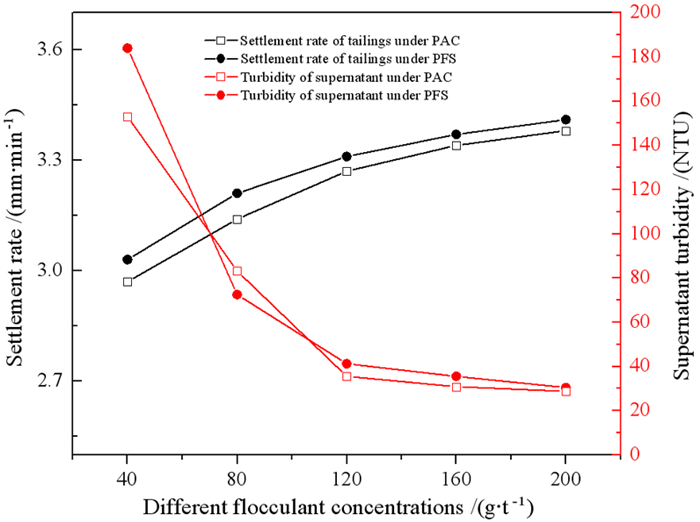

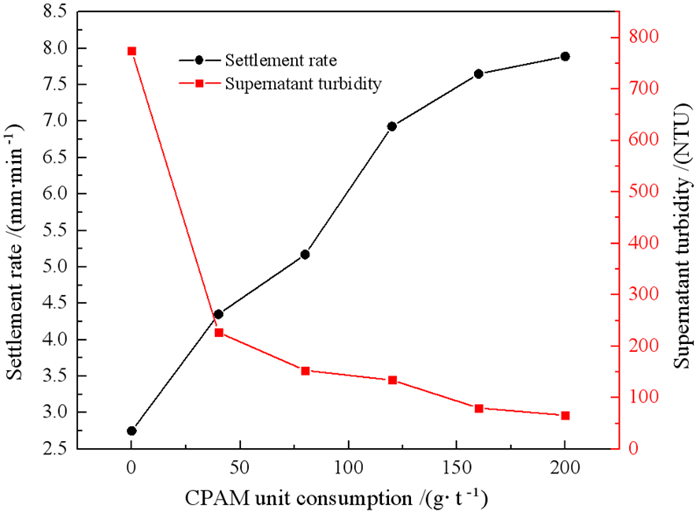

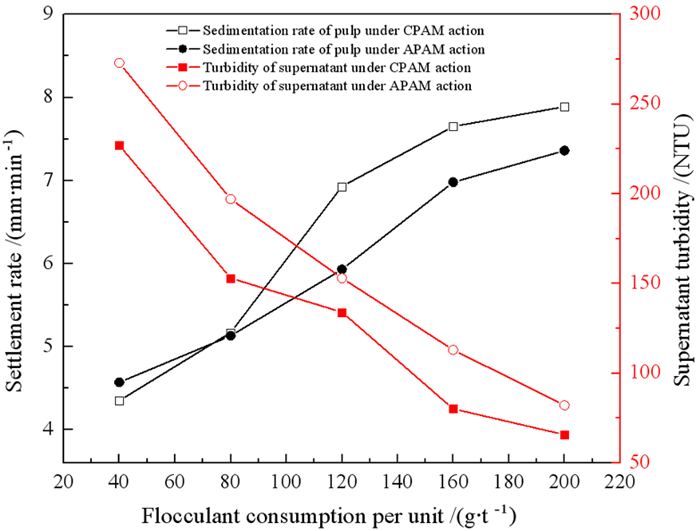

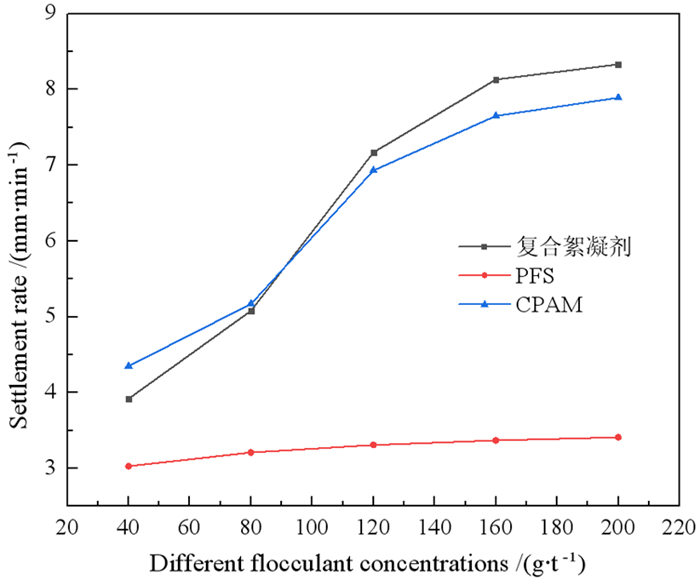

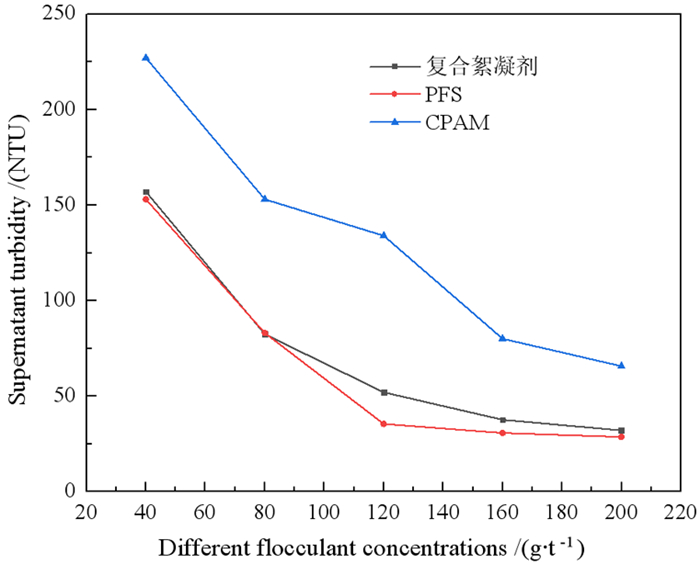

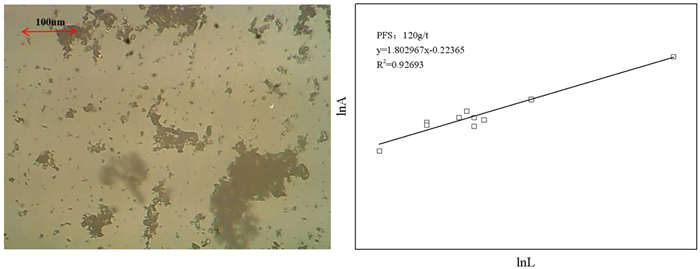

由于尾矿颗粒粒度细,沉降困难,尾矿的高效沉降浓缩已成为一个重要的课题。为了提高尾矿沉降速率和提升水质,分别考察了两种无机高分子絮凝剂和两种有机高分子絮凝剂的用量对尾矿絮凝浓缩的影响,根据絮凝效果,选择其中两种絮凝剂进行药剂复配、相应的絮凝沉降试验以及显微镜絮团图像分析,并讨论了絮凝机理,旨在揭示无机絮凝剂、有机絮凝剂以及复合絮凝剂在絮凝效果方面的关系。结果表明:针对硫化铅锌矿的浮选尾矿,无机絮凝剂在降低上清液浊度方面效果显著,聚合硫酸铁(PFS)在提升沉降速率方面优于聚合氯化铝(PAC);有机絮凝剂在提高沉降速率方面效果突出,阳离子聚丙烯酰胺(CPAM)在去除浊度方面明显优于阴离子聚丙烯酰胺(APAM);PFS-CPAM复合絮凝剂则在保证去除浊度效果的同时,极大提升了沉降速率,并优于两种单一絮凝剂。

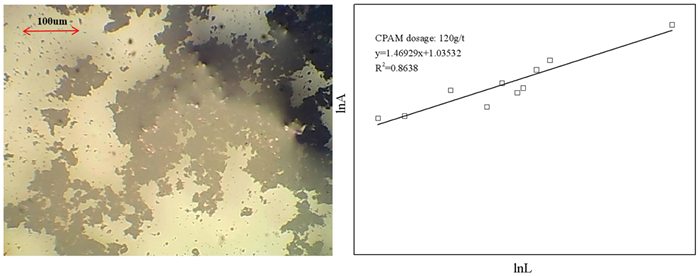

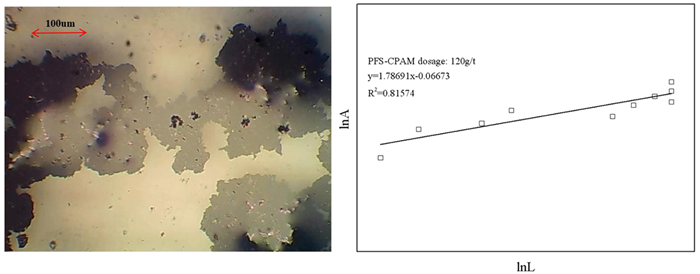

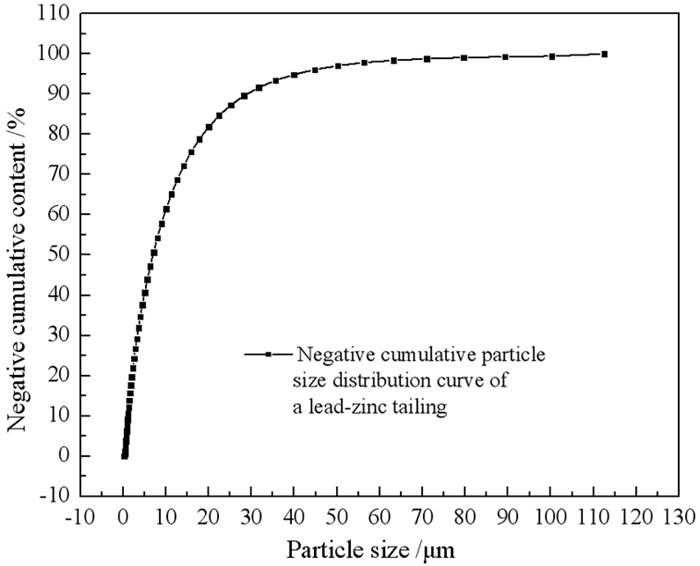

Abstract:Due to the fine particle size and difficult settlement of tailings, the efficient settlement and concentration of tailings has become an increasingly important topic.In order to improve the sedimentation rate and improve the water quality of tailings, research on two kinds of inorganic polymer flocculants, and the dosage of the two kinds of organic polymer flocculant effect on flocculation concentration tailings, according to the flocculation effect, two kinds of flocculants for drug distribution, the corresponding flocculation sedimentation experiment floccules and microscope image analysis, and discussed the flocculation mechanism, aims to reveal the inorganic flocculants, organic flocculants and composite flocculants on flocculation effect.The results show that for flotation tailings of lead-zinc sulfide ore, the inorganic flocculant has a significant effect on reducing the turbidity of supernant solution, and the polyferric sulfate (PFS) is better than the polyaluminum chloride (PAC) in improving the settling rate. Organic flocculants have a prominent effect on increasing the sedimentation rate, and cationic polyacrylamide (CPAM) is obviously better than anionic polyacrylamide (APAM) in removing turbidity. PFS-CPAM composite flocculant can not only ensure the turbidity removal effect, but also greatly improve the sedimentation rate, and is better than two single flocculants.

-

Key words:

- tailing settlement /

- inorganic flocculant /

- organic flocculant /

- composite flocculant

-

-

表 1 化学多元素分析结果

Table 1. Chemical multi-element result

成分 Pb Zn Cu Cd Hg Ge TFe SiO2 含量/% 0.82 0.40 0.009 8 0.001 1 0.000 2 0.000 7 7.53 27.23 成分 Al2O3 CaO MgO P As S C Ag 含量/% 4.64 21.28 1.58 0.031 0.10 7.46 5.38 6.88 注: Ag的单位为g/t。 表 2 样品中主要矿物的含量

Table 2. Contents of main minerals in the sample

矿物/% 黄铁矿 石英 方解石 白云石 云母 辉石 硅灰石 石膏 其他 含量/% 16.60 23.70 33.80 6.70 9.50 1.00 1.30 3.50 3.90 -

[1] 吴德礼, 朱申红, 王铮. 国内外矿山尾矿综合利用现状与思考[J]. 青岛建筑工程学院学报, 2001(4): 84-87, 91. doi: 10.3969/j.issn.1673-4602.2001.04.022 https://www.cnki.com.cn/Article/CJFDTOTAL-QDJG200104021.htm

[2] 谢锐, 王艳, 韩彬等. 都龙矿区尾矿高效浓缩脱水试验研究与应用[J]. 矿产综合利用, 2017(3): 99-102. doi: 10.3969/j.issn.1000-6532.2017.03.020 https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201703020.htm

[3] MA J, FU K, JIANG L, et al. Flocculation performance of cationic polyacrylamide with high cationic degree in humic acid synthetic water treatment and effect of kaolin particles[J]. Separation and Purification Technology, 2017, 181: 201-212. doi: 10.1016/j.seppur.2017.03.027

[4] 张正安, 廖义涛, 郑舒婷, 等. 絮凝剂分类及其水处理作用机理研究进展[J/OL]. 宜宾学院学报: 1-5[2019-06-20]. 20190507.001.

[5] 夏雄, 刘威, 许霞, 等. PSAF-CPAM高分子无机-有机复合絮凝剂表征及其对印染废水除磷效果分析[J]. 工业安全与环保, 2018, 44(3): 82-85. doi: 10.3969/j.issn.1001-425X.2018.03.021

[6] 杨开吉, 姚春丽. 高分子复合絮凝剂作用机理及在废水处理中应用的研究进展[J]. 中国造纸, 38(12). https://www.cnki.com.cn/Article/CJFDTOTAL-ZGZZ201912016.htm

[7] 姚彬, 张文存, 张玉荣等. 无机-有机高分子复合絮凝剂的研究进展[J]. 石化技术与应用, 2018, 36(5): 73-78. https://www.cnki.com.cn/Article/CJFDTOTAL-IZHM201805021.htm

[8] 王晓昌, 丹保宪仁. 絮凝体形态学和密度的探讨——Ⅰ. 从絮凝体分形构造谈起[J]. 环境科学学报, 2000, 20(3): 257-262. doi: 10.3321/j.issn:0253-2468.2000.03.001

[9] 赵亚伟. 赤铁矿絮凝形态特征及演化规律[D]. 唐山: 华北理工大学, 2020.

[10] 牛福生, 李卓林, 张晋霞. 微细粒赤铁矿絮凝体物理特性表征研究[J]. 矿产保护与利用, 2016(5): 73-78. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=a0039f02-d2b4-4c2f-9870-4bba398581dd

[11] 刘东京. 废水制备聚硅硫酸盐絮凝剂及絮凝体分形仿真模拟[D]. 南昌: 南昌大学, 2012.

[12] 陈婉琦. 细粒赤铁矿助沉团聚行为的研究[D]. 武汉: 武汉科技大学, 2016.

[13] 周兴龙, 张文彬, 王文潜. 量筒内进行矿浆沉降试验的方法[J]. 有色金属(选矿部分), 2005(5): 30-32, 25. doi: 10.3969/j.issn.1671-9492.2005.05.008 https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK200505008.htm

-

下载:

下载: