Experimental Study on Flotation of Skarn Scheelite in Gejiu City, Yunnan Province with a New Hydroxamic Acid Collector

-

摘要:

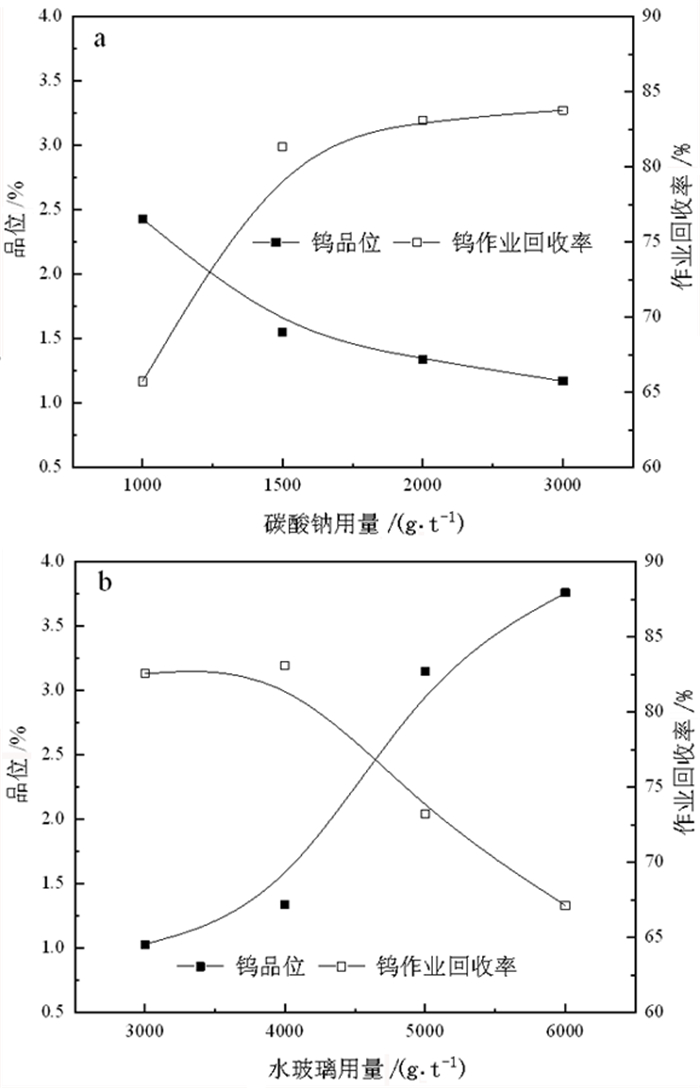

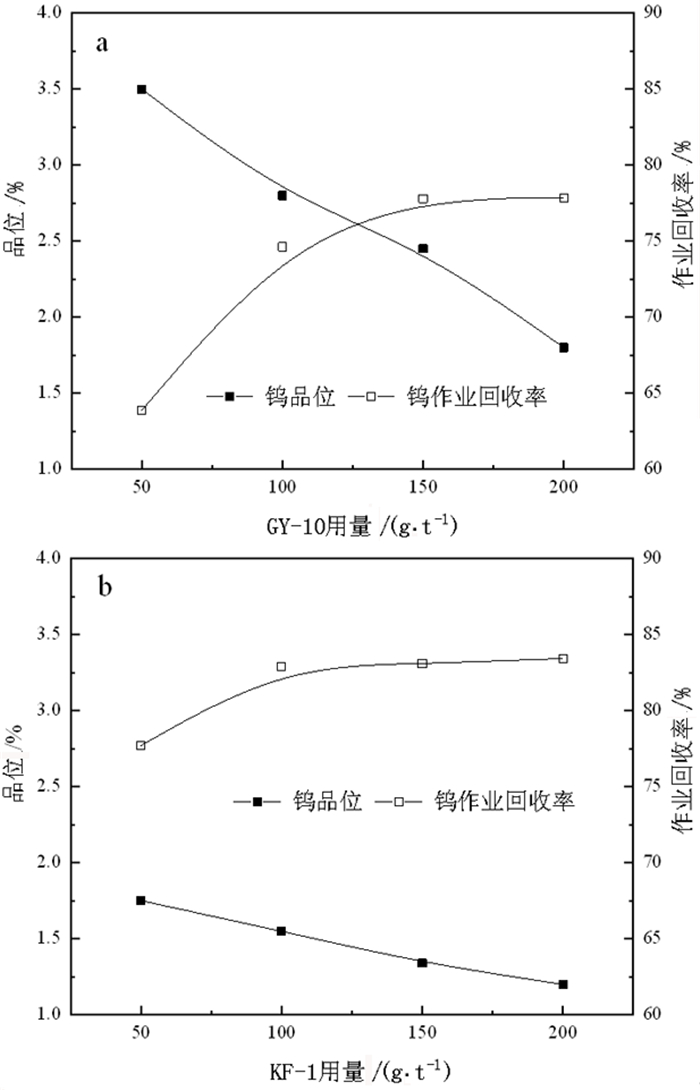

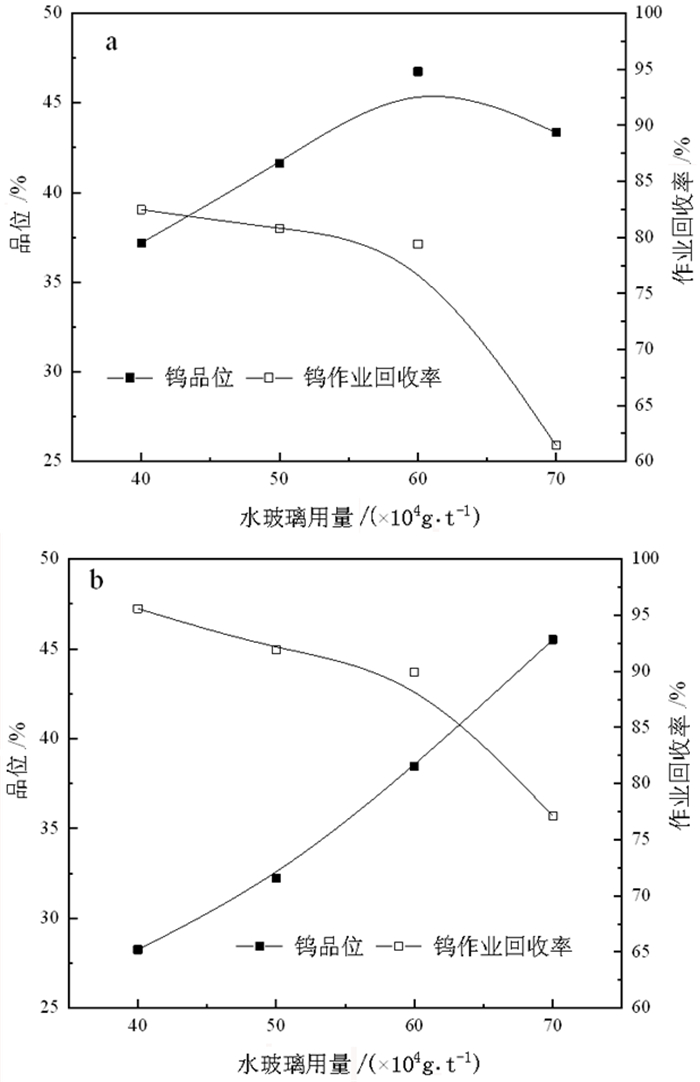

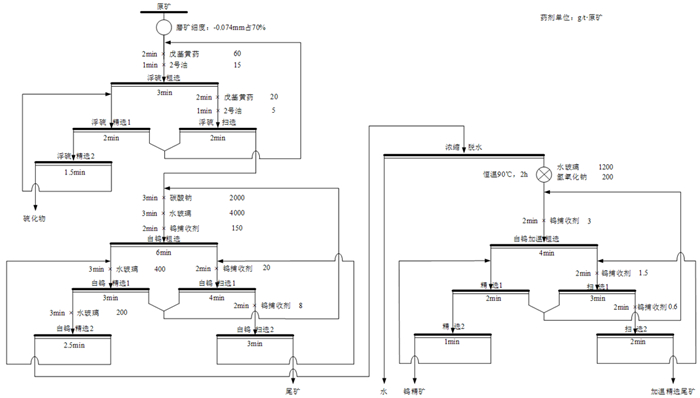

以云南个旧卡房矽卡岩型白钨矿为研究对象,针对原工艺GY-10捕收剂浮选体系下钨总回收率偏低的问题,为提高钨资源综合利用水平,应用新型白钨矿捕收剂KF-1进行了选矿试验研究。结果表明,脱硫浮选后,钨常温粗选碳酸钠、水玻璃和捕收剂用量分别为2 000 g/t、4 000 g/t和150 g/t,钨加温精选温度为85 ℃,保温时间为1 h,钨加温精选氢氧化钠、水玻璃和捕收剂用量分别为200 g/t、1 200 g/t和3 g/t,最终获得了钨精矿品位55.65%、钨回收率为77.35%的技术指标,与GY-10相比,钨总回收率提高了14百分点,实现了卡房矽卡岩型白钨矿的高效综合利用。

Abstract:In order to improve the comprehensive utilization level of tungsten resources, a new collector KF-1 was used to recover the skarn scheelite ore in Kafang mining area, Gejiu City, Yunnan Province. The results show that after the desulfurization flotation, the roughing tests at room temperature have been conducted, and the dosage of sodium carbonate, sodium silicate and collector has been determined as 2 000 g/t, 4 000 g/t and 150 g/t, respectively. Then after heating the coarse concentrate to 85 ℃ and holding for 1 h, the cleaning tests have been conducted, and the dosage of sodium hydroxide, sodium silicate and collector has been determined as 200 g/t, 1 200 g/t and 3 g/t, respectively. Finally, a tungsten concentrate assaying 55% WO3 with tungsten recovery of 77% has been obtained. Compared with GY-10, the total recovery of tungsten has been increased by 14%, and the efficient comprehensive utilization of skarn scheelite in Kafang mining area has been realized.

-

Key words:

- scheelite /

- flotation /

- collector /

- heating flotation /

- calcite

-

-

表 1 矿石主要元素分析结果

/% Table 1. Analysis results of main elements of the ore

成分 WO3 Cu S Al2O3 CaO SiO2 MgO 含量 0.20 0.086 0.76 4.06 25.74 39.12 1.66 表 2 主要矿物组成测定结果

/% Table 2. Determination results of the main mineral composition

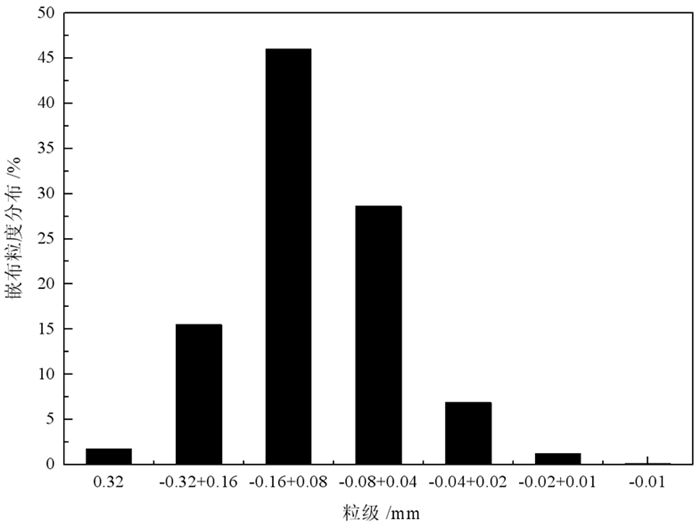

矿物 含量 矿物 含量 矿物 含量 白钨矿 0.256 黑云母 2.258 绿泥石 0.185 黑钨矿 微量 绢云母 0.588 方解石 13.947 黄铜矿 0.099 透辉石 37.26 白云石 0.283 黄铁矿 0.650 钙铁榴石 16.771 菱铁矿 0.134 磁黄铁矿 0.974 钙铝榴石 4.014 磁铁矿 0.103 石英 4.261 绿帘石 0.423 褐铁矿 0.195 长石 6.564 阳起石 0.541 钛铁矿 0.027 硅灰石 2.589 角闪石 3.749 榍石 0.342 表 3 不同磨矿细度下白钨矿单体解离度测定结果

/% Table 3. Determination results of the dissociation degree of scheelite monomer under different grinding fineness

磨矿细度(-0.074 mm含量) 50 60 70 80 单体解离度 75.12 80.45 91.65 93.19 表 4 脱硫流程试验结果

/% Table 4. Test results of the desulfurization process

产品名称 产率 品位 回收率 WO3 S WO3 S 硫化物 1.97 0.18 35.46 1.77 92.23 选钨给矿 98.03 0.20 0.06 98.23 7.77 给矿 100.00 0.20 0.76 100.00 100.00 表 5 钨常温粗选闭路试验结果

/% Table 5. Closed-circuit test results of the tungsten roughing at room temperature

钨捕收剂 产品名称 作业产率 WO3品位 WO3作业回收率 GY-10 钨粗精矿 1.96 7.79 76.48 尾矿 98.04 0.049 23.52 给矿 100.00 0.20 100.00 KF-1 钨粗精矿 2.77 6.20 86.34 尾矿 97.23 0.029 13.66 给矿 100.00 0.20 100.00 表 6 钨加温精选闭路试验结果

/% Table 6. Closed-circuit test results of the tungsten heating fine selection

钨捕收剂 产品名称 作业产率 WO3品位 WO3作业回收率 GY-10 钨精矿 9.52 69.35 84.68 加温精选尾矿 90.48 1.32 15.32 给矿 100.00 7.79 100.00 KF-1 钨精矿 10.25 55.65 91.11 加温精选尾矿 89.75 0.62 8.89 给矿 100.00 6.26 100.00 表 7 综合试验指标对比结果

/% Table 7. Comparison results of comprehensive test indexes

钨捕收剂 产品名称 产率 WO3品位 WO3回收率 GY-10 钨精矿 0.18 69.35 63.59 加温精选尾矿 1.74 1.32 11.50 硫化物 1.97 0.18 1.78 尾矿 96.11 0.048 23.13 原矿 100.00 0.20 100.00 KF-1 钨精矿 0.28 55.65 77.35 加温精选尾矿 2.44 0.62 7.55 硫化物 1.97 0.18 1.77 尾矿 95.31 0.028 13.33 原矿 100.00 0.20 100.00 -

[1] 方维萱, 郭玉乾, 贾润幸, 等. 论云南个旧锡铜钨三稀金属矿集区叠加成矿系统与垂向构造岩相学结构的关系[J]. 地质力学学报, 2021, 27(4): 557-584. https://www.cnki.com.cn/Article/CJFDTOTAL-DZLX202104005.htm

FANG W X, GUO Y Q, JIA R X, et al. On relationship between the superimposed mineralization systems and the zoning patterns of vertical tectonic lithofacies in the Gejiu concentration area of Sn-Cu-W and three rare metals in Yunnan[J]. Journal of Geomechanics, 2021, 27(4): 557-584. https://www.cnki.com.cn/Article/CJFDTOTAL-DZLX202104005.htm

[2] 姚建伟, 袁经中, 汪泰. 云锡卡房铜硫浮选尾矿中细粒锡石的回收[J]. 金属矿山, 2015(7): 159-163. doi: 10.3969/j.issn.1001-1250.2015.07.036

YAO J W, YUAN J Z, WANG T. Recovery of fine cassiterite from flotation tailings of copper-sulfide in Kafang, Yun[J]. Metal Mine, 2015(7): 159-163. doi: 10.3969/j.issn.1001-1250.2015.07.036

[3] 邱显扬. 矽卡岩锡矿床伴生低品位难选多金属分离技术与应用[R]. 广州: 广州有色金属研究院, 2012.

QIU X Y. Low-grade refractory polymetallic separation technology associated with skarn tin deposit and its application[R]. Guangzhou: Guangzhou Institute of Nonferrous Metals, 2012.

[4] 姚艳清, 胡真, 李汉文, 等. 某钨铜多金属共生矿资源综合利用研究[J]. 有色金属(选矿部分), 2021(3): 69-74+142. doi: 10.3969/j.issn.1671-9492.2021.03.012

YAO Y Q, HU Z, LI H W, et al. Study on comprehensive utilization of Tungsten-Copper polymetallic ore resources[J]. Nonferrous Metals(Mineral Processing Section), 2021(3): 69-74+142. doi: 10.3969/j.issn.1671-9492.2021.03.012

[5] 冷文华, 朱龙华, 冯其明. 钨矿物浮选研究进展[J]. 矿产保护与利用, 1999(5): 33-36. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=281ffb5c-af75-4d1c-a020-f991dfb9c31f

LENG W H, ZHU L H, FENG Q M. A review on the Flotation of Tungsten Minerals[J]. Conservation and Utilization of Mineral Resources, 1999(5): 33-36. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=281ffb5c-af75-4d1c-a020-f991dfb9c31f

[6] 郭玉武, 王全亮, 魏党生, 等. 云南某低品位白钨矿常温浮选工艺研究[J]. 矿产保护与利用, 2015(3): 29-33. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=31321e65-bd75-4c91-84ec-996ae780eb7f

GUO Y H, WANG Q L, WEI D S, et al. Normal temperature flotation of a low grade scheelite ore from Yunnan[J]. Conservation and Utilization of Mineral Resources, 2015(3): 29-33. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=31321e65-bd75-4c91-84ec-996ae780eb7f

[7] 王纪镇, 印万忠, 程雅芝, 等. 白钨矿浮选中方解石对磷酸钠抑制性能的影响及机理研究[J]. 矿产保护与利用, 2018(3): 77-80. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=61dd52af-7826-4b9f-9f94-31992e2c5290

WANG J Z, YIN W Z, CHENG Y Z, et al. The mechanism and effect of calcite on the depressing effect of sodium phosphate in the scheelite flotation[J]. Conservation and Utilization of Mineral Resources, 2018(3): 77-80. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=61dd52af-7826-4b9f-9f94-31992e2c5290

[8] 邓丽红, 周晓彤. 新型捕收剂R31浮选低品位白钨矿的研究[J]. 矿产保护与利用, 2007(4): 19-22. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=8c4c2a23-48d4-45ba-a22d-fcde32a6d54c

DENG L H, ZHOU X T. Flotation studies on low-grade scheelite with R31 as collector[J]. Conservation and Utilization of Mineral Resources, 2007(4): 19-22. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=8c4c2a23-48d4-45ba-a22d-fcde32a6d54c

[9] 李英霞, 王国生. 广东某白钨矿选矿的试验研究[J]. 矿产保护与利用, 2012(2): 20-22. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=59724b8c-0b0c-4151-956f-90fd5a1944f9

LI Y X, WANG G S. Mineral processing experimental on a scheelite ore in Guangdong Province[J]. Conservation and Utilization of Mineral Resources, 2012(2): 20-22. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=59724b8c-0b0c-4151-956f-90fd5a1944f9

[10] 郭蔚, 冯博, 钟志刚, 等. 白钨矿与含钙脉石浮选抑制剂研究进展[J]. 矿产保护与利用, 2017(4): 113-118. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=a72bebe9-925d-4bb9-bff0-8f59fe0ac5c6

GUO W, FENG B, ZHONG Z G, et al. Research progress on the depressants for flotation separation of scheelite and calcium-bearing gangue[J]. Conservation and Utilization of Mineral Resources, 2017(4): 113-118. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=a72bebe9-925d-4bb9-bff0-8f59fe0ac5c6

-

下载:

下载: