Synergistic Mechanism of Mixed Anionic/cationic Collectors at Gas-liquid Interface in Lepidolite Flotation

-

摘要:

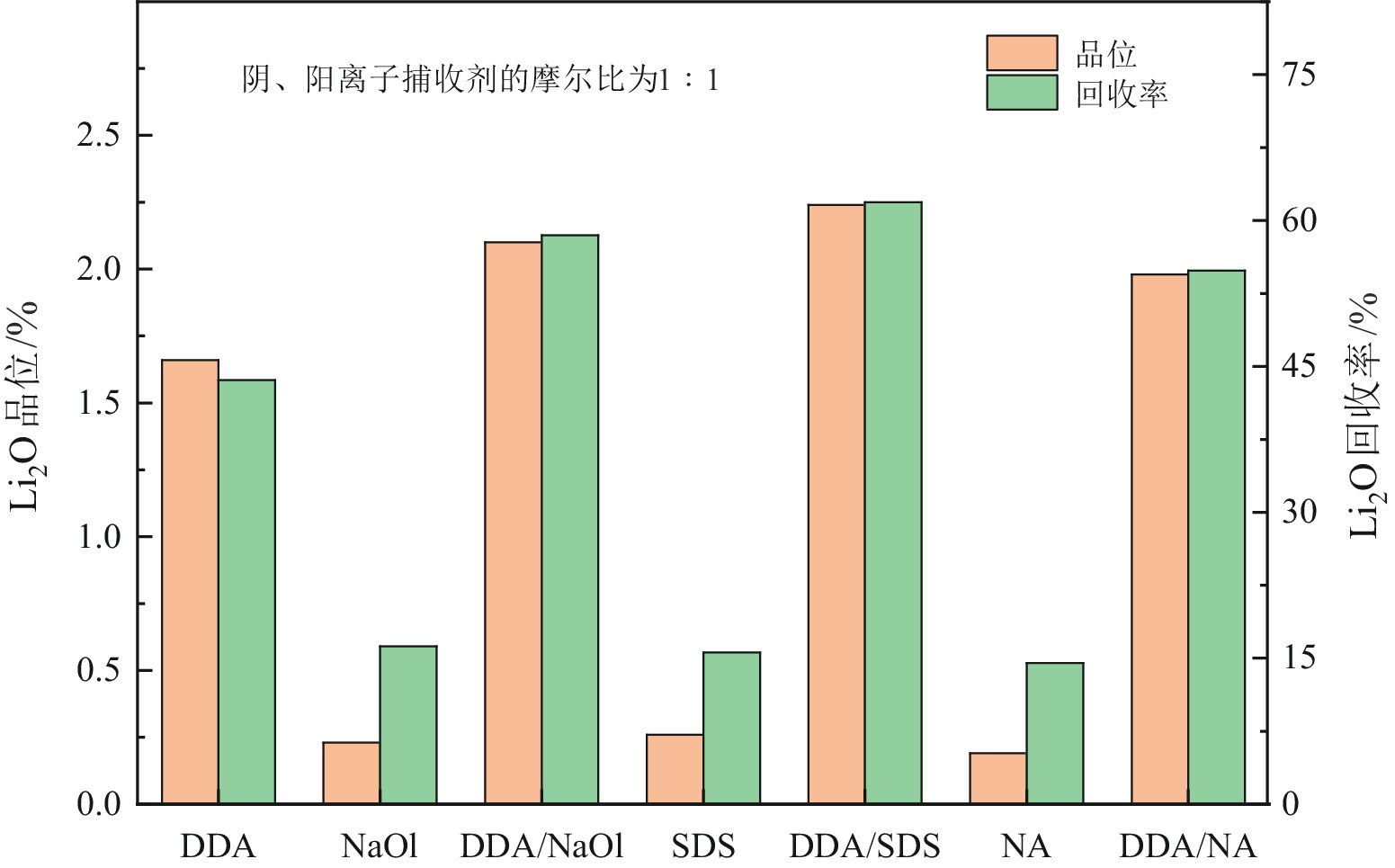

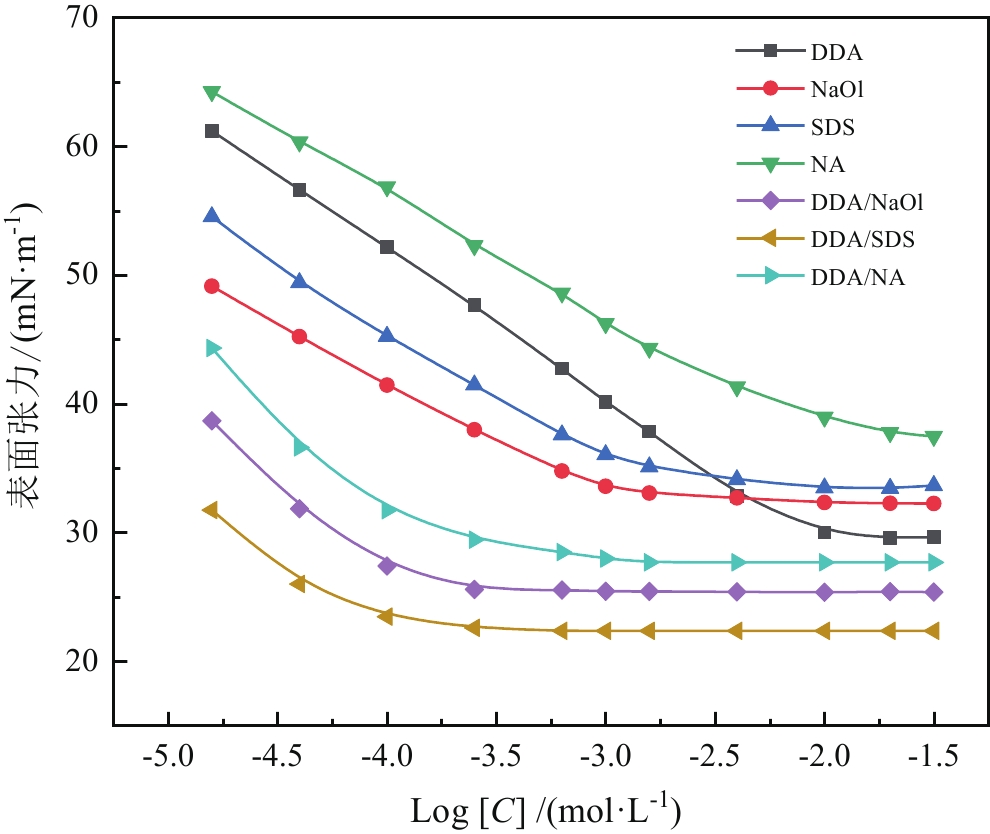

以某含Li2O 1.09%的锂云母矿石为研究对象,将三种阴离子捕收剂油酸钠(NaOl)、十二烷基磺酸钠(SDS)和环烷酸钠(NA)分别与阳离子捕收剂十二胺(DDA)进行复配,借助浮选试验、表面张力、泡沫物化性质测试及协同作用参数计算等手段,从气-液界面研究了阴/阳离子组合捕收剂在锂云母浮选中的协同作用机理。浮选结果表明,三种阴/阳离子组合捕收剂对锂云母的浮选效果均优于单一捕收剂,且当DDA与SDS摩尔比为1∶1时达到最佳浮选效果,精矿中Li2O品位和回收率分别为2.24%和61.88%。而此时浮选泡沫的稳定性达到最低,有利于锂云母的浮选,其浮选泡沫层的高度、半衰期和含水量分别为33 mm,86 s和48.72%。结合表面张力和协同作用参数计算结果可知,在阴/阳离子组合捕收剂体系中,由于正、负电荷相互吸引,致使阴离子捕收剂插入到DDA之间的空隙中,两种捕收剂通过静电力和碳链间的疏水缔合作用相互交织。而由于磺酸基较强的电负性,其降低DDA之间静电斥力的能力更强。相比DDA/NaOl和DDA/NA,DDA/SDS在气-液界面的饱和吸附值增加,捕收剂分子所占的平均最小面积减小,因而表现出更高的表面活性,展现出对锂云母更好的捕收能力及选择性。

Abstract:A lepidolite ore containing 1.09% Li2O was taken as the research object. Three anionic collectors (sodium oleate (NaOl), sodium dodecyl sulfonate (SDS) and sodium naphthenate (NA)) were combined with cationic collector (dodecylamine (DDA)), respectively, and the synergistic mechanism of mixed anionic/cationic collectors on lepidolite flotation was studied from the perspective of the gas-liquid interface by means of flotation experiment, surface tension, physicochemical property of foam and activity coefficient. The flotation results showed that the flotation performance of these three mixed anionic/cationic collectors was better than that of a single collector. When the molar ratio of DDA to SDS was 1∶1, the flotation performance was the best, and the grade and recovery of Li2O of the concentrate were 2.24% and 61.88% respectively. Meanwhile, the stability of flotation foam was the lowest, which was conducive to lepidolite flotation. The height, half-life and water content of the flotation foam were 33 mm, 86 s and 48.72% respectively. The results of surface tension and activity coefficient showed that the anionic collectors were inserted into the gaps between DDA cations and intertwined each other by electrostatic force and hydrophobic association between carbon chains in the mixture systems. Due to the strong electronegativity, the sulfonic groups had a stronger ability to neutralize the positive charges carried by the amine groups. Compared with DDA/NaOl and DDA/NA, the saturation adsorption value of DDA/SDS at the gas-liquid interface increased, and the average minimum area per molecule decreased, showing higher surface activity and better collection ability and selectivity for lepidolite.

-

-

表 1 锂云母原矿化学元素分析结果

Table 1. Chemical composition of lepidolite ore

化学成分 Li2O SiO2 Al2O3 Na2O K2O Fe2O3 MgO CaO 其他 含量/% 1.09 67.95 17.37 1.63 3.12 0.55 0.28 3.04 3.34 表 2 锂云母原矿主要矿物组成及含量

Table 2. Main mineral composition and content of lepidolite ore

矿物 锂云母 石英 钾长石 钠长石 高岭石 黄玉 其他 含量/% 33.82 36.39 6.27 2.15 12.48 4.02 4.87 表 3 阴/阳离子组合捕收剂摩尔比对浮选泡沫性质的影响

Table 3. Influence of the molar ratio of mixed collector on foam properties

捕收剂种类 DDA与阴离子捕收剂的摩尔比 泡沫层高度/mm 泡沫半衰期/s 泡沫含水量/% DDA — 62 267 74.52 DDA/NaOl 2∶1 43 124 55.19 1∶1 37 99 52.30 1∶2 34 107 54.72 DDA/SDS 2∶1 39 109 51.68 1∶1 33 86 48.72 1∶2 30 95 50.73 DDA/NA 2∶1 45 130 59.53 1∶1 38 103 55.92 1∶2 35 110 56.75 表 4 不同阴/阳离子组合捕收剂的表面和热力学性质

Table 4. Surface and thermodynamic properties of different mixed cationic/anionic collectors

捕收剂种类 CMC/(mol·L−1) γCMC/(mN·m−1) Γmax/(mol·m−2) Amin/nm2  /(kJ·mol−1)

/(kJ·mol−1)DDA 8.91×10−3 29.88 0.85×10−6 1.95 −11.62 NaOl 1.98×10−3 32.25 1.04×10−6 1.60 −15.17 SDS 7.97×10−3 34.25 0.91×10−6 1.83 −12.56 NA 1.74×10−2 37.71 0.83×10−6 2.00 −9.87 DDA/NaOl 0.32×10−3 25.68 2.24×10−6 0.74 −19.61 DDA/SDS 0.49×10−3 22.31 2.55×10−6 0.65 −18.57 DDA/NA 3.06×10−3 27.52 1.89×10−6 0.88 −14.11 表 5 不同阴/阳离子组合捕收剂的协同作用参数

Table 5. Synergism parameters for mixed collectors at different mole ratios

捕收剂种类 xca xcam  /(mol·L−1)

/(mol·L−1) /(mol·L−1)

/(mol·L−1) /(mol·L−1)

/(mol·L−1)βm

DDA/NaOl 0.5 0.44 8.91×10−3 1.98×10−3 0.32×10−3 −5.71 0.17 DDA/SDS 0.5 0.50 8.91×10−3 7.97×10−3 0.49×10−3 −5.80 0.23 DDA/NA 0.5 0.54 8.91×10−3 1.74×10−2 3.06×10−3 −2.49 0.59 -

[1] 马哲, 李建武. 中国锂资源供应体系研究: 现状、问题与建议[J]. 中国矿业, 2018, 27(10): 1−7.

MA Z, LI J W. Analysis of China’s lithium resources supply system: status, issues and suggestions[J]. China Mining Magazine, 2018, 27(10): 1−7.

[2] 雷晓力, 胡永达, 杜轶伦. 我国锂供需形势分析及对策建议[J]. 中国矿业, 2016, 25(S1): 25−26.

LEI X L, HU Y D, DU Z L. Analysis on the supply and demand trend of lithium and recommended management strategies in China[J]. China Mining Magazine, 2016, 25(S1): 25−26.

[3] TIAN J, XU L H, DENG W, et al. Adsorption mechanism of new mixed anionic/cationic collectors in a spodumene-feldspar flotation system[J]. Chemical Engineering Science, 2017, 164: 99−107. doi: 10.1016/j.ces.2017.02.013

[4] 徐龙华, 田佳, 巫侯琴, 等. 组合捕收剂在矿物表面的协同效应及其浮选应用综述[J]. 矿产保护与利用, 2017(2): 107−112.

XU L H, TIAN J, WU H Q, et al. A review on the synergetic effect of the mixed collectors on mineral surface and its application in flotation[J]. Conservation and Utilization of Mineral Resources, 2017(2): 107−112.

[5] WEI Q, FENG L Q, Dong L Y, et al. Selective co-adsorption mechanism of a new mixed collector on the flotation separation of lepidolite from quartz[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 612: 125973−125982. doi: 10.1016/j.colsurfa.2020.125973

[6] HANUMANTHA R, ANTTI B, FORSSBERG K. Flotation of mica minerals and selectivity between muscovite and biotite while using mixed anionic/cationic collectors[J]. Mining, Metallurgy & Exploration, 1990, 7(3): 127−132.

[7] XU L H, HU Y H, TIAN J, et al. Synergistic effect of mixed cationic/anionic collectors on flotation and adsorption of muscovite[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2016, 492: 181−189. doi: 10.1016/j.colsurfa.2015.11.003

[8] 王林林, 朱灵燕, 刘跃龙, 等. 阴/阳离子混合捕收剂用于中低品位锂云母的浮选试验研究[J]. 有色金属(选矿部分), 2019(3): 86−92.

WANG L L, ZHU L Y, LIU Y L, et al. Flotation of low grade lepidolite using mixed cationic/anionic collectors[J]. Nonferrous Metals (Mineral Processing), 2019(3): 86−92.

[9] CUI H R, CAO G Q, ZHU S Q, et al. Foaming performance evaluation of frother emulsions in the slime flotation: foamability, foam stability, and foam flow[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 638: 128310−128317. doi: 10.1016/j.colsurfa.2022.128310

[10] BAI Y, CUI W S, GAO Y J, et al. Synergistic mechanism of mixed cationic/anionic collectors on lepidolite flotation from the perspective of improving the performance of flotation foam[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 656: 130354−130364. doi: 10.1016/j.colsurfa.2022.130354

[11] BAI Y, LI C X, AN H Y, et al. Flotation and molecular dynamics simulation of muscovite with mixed anionic/cationic collectors[J]. Physicochemical Problems of Mineral Processing, 2020, 56(2): 312−323.

[12] 邓海波, 张刚, 任海洋, 等. 季铵盐和十二胺对云母类矿物浮选行为和泡沫稳定性的影响[J]. 非金属矿, 2012, 35(6): 23−25. doi: 10.3969/j.issn.1000-8098.2012.06.008

DENG H B, ZHANG G, REN H Y, et al. Influence of quaternary ammonium salt and dodecylamine on the flotation behavior and froth stability of mica minerals[J]. Non-Metallic Mines, 2012, 35(6): 23−25. doi: 10.3969/j.issn.1000-8098.2012.06.008

[13] WANG L, LIU R Q, HU Y H, et al. Adsorption of mixed DDA/Naol surfactants at the air/water interface by molecular dynamics simulations[J]. Chemical Engineering Science, 2016, 155: 167−174. doi: 10.1016/j.ces.2016.08.012

[14] HOLLAND P, RUBINGH D. Mixed surfactant systems[M]. New York: Marcel Dekker, 1992.

[15] 王淀佐. 浮选剂作用原理及应用[M]. 北京: 冶金工业出版社, 1982.

WANG D Z. Function principles and applications of flotation agent[M]. Beijing: Metallurgical Industry Press, 2012.

[16] ROSEN M, MILTON J. Surfactants and interfacial phenomena[M]. New York: John Wiley& Sons, 2012.

-

下载:

下载: