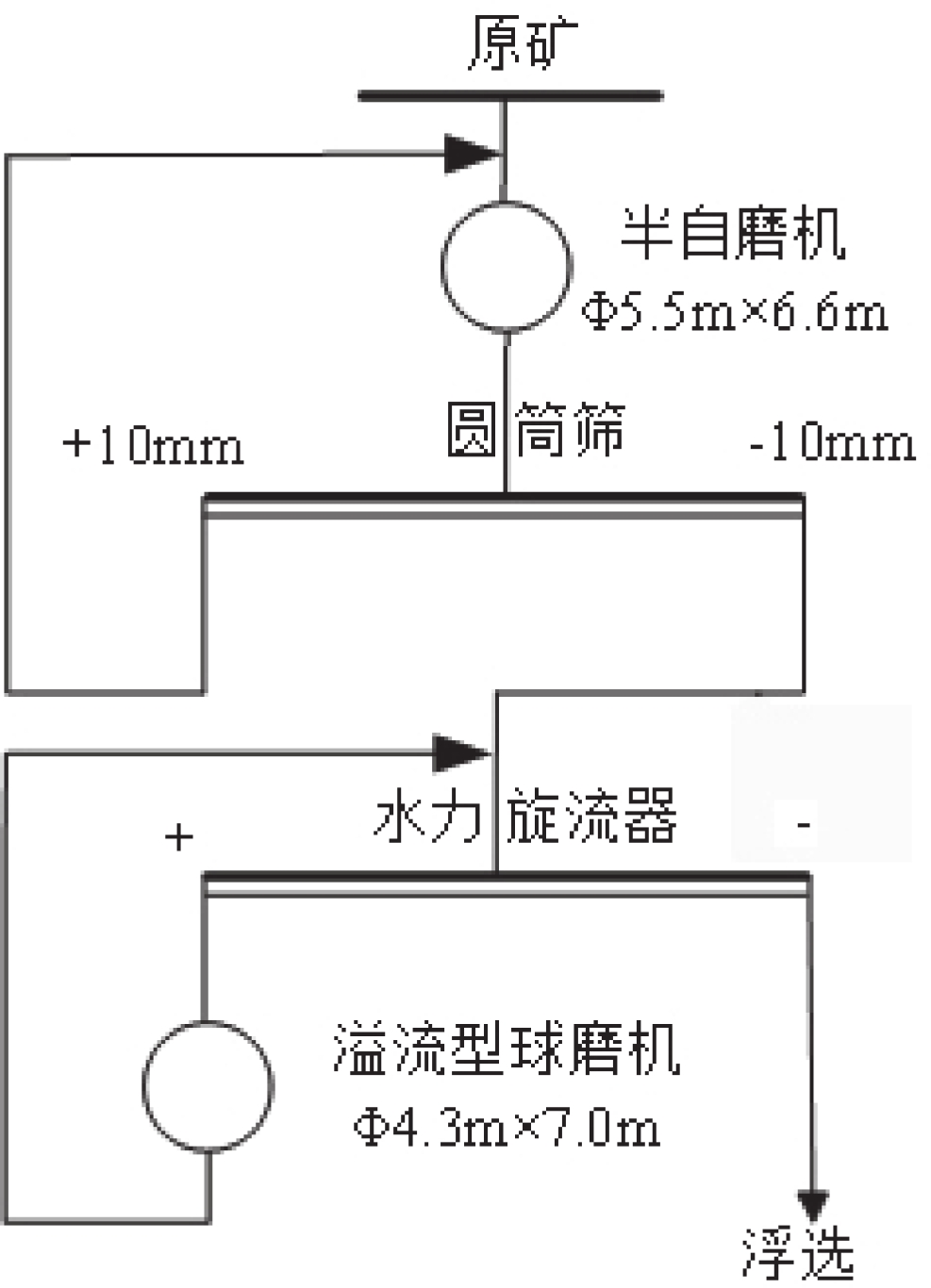

Optimization of Steel Ball Size and Discrete Element Simulation Analysis of a Semi-autogenous Grinding Gold Mine in Yunnan

-

摘要:

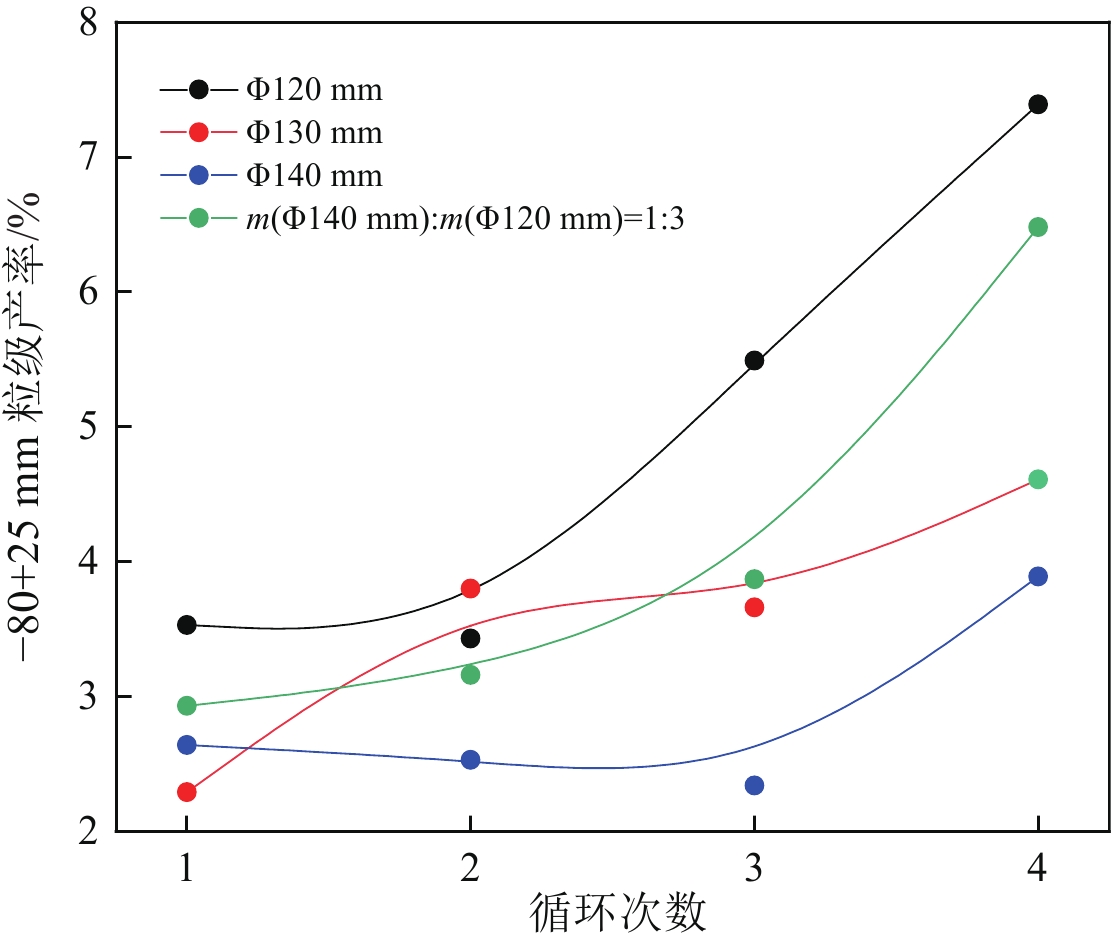

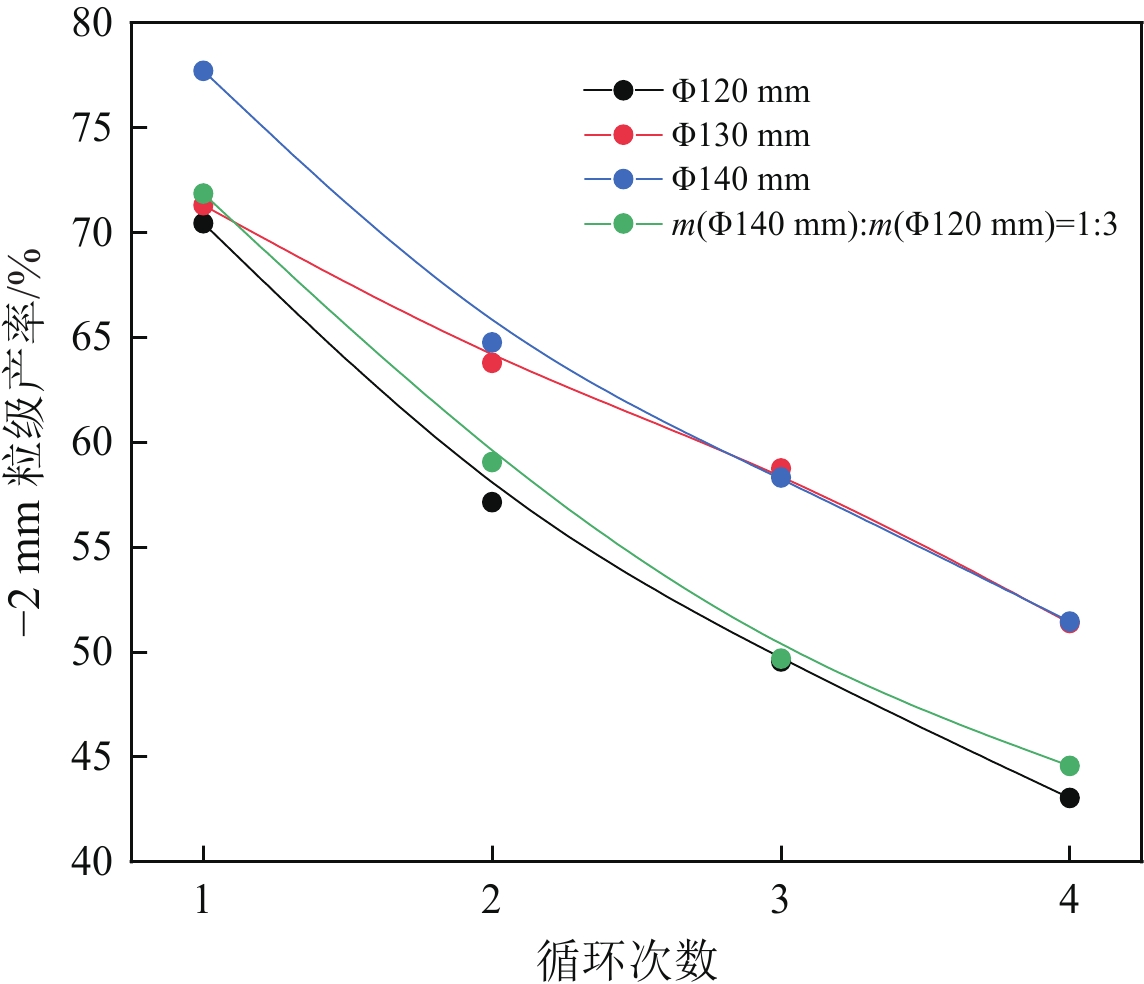

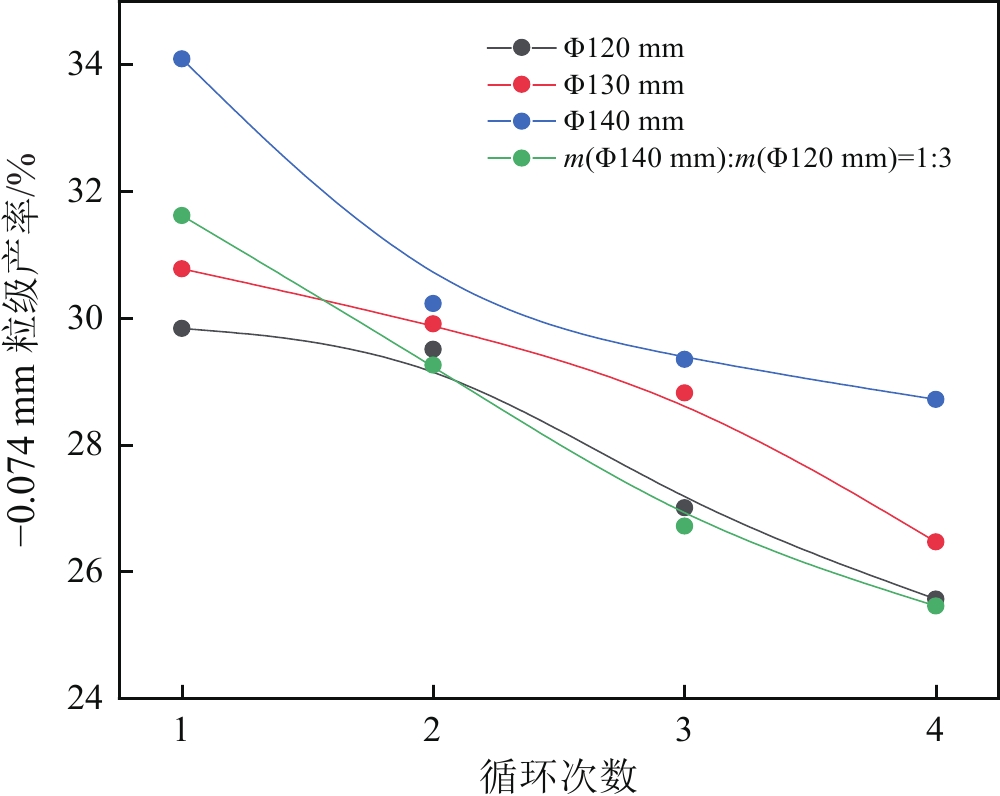

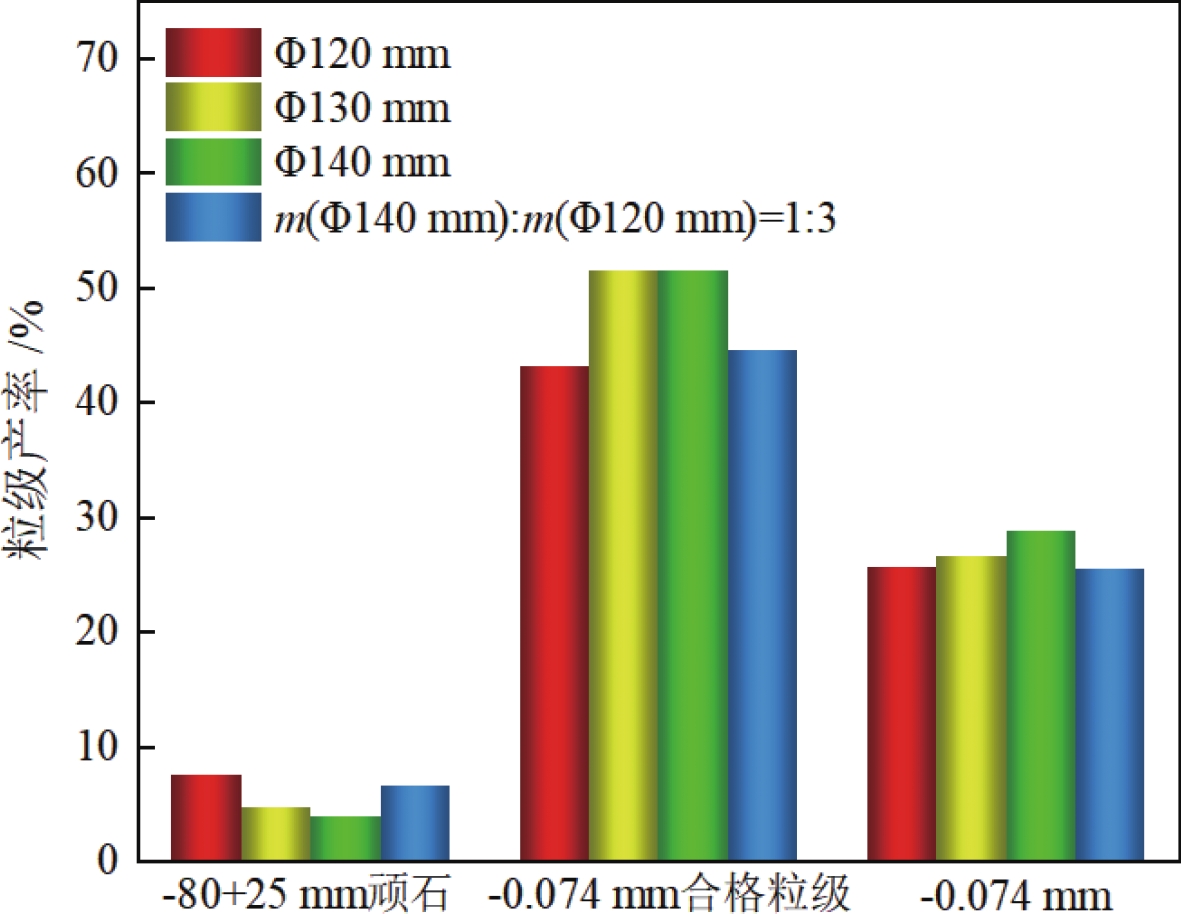

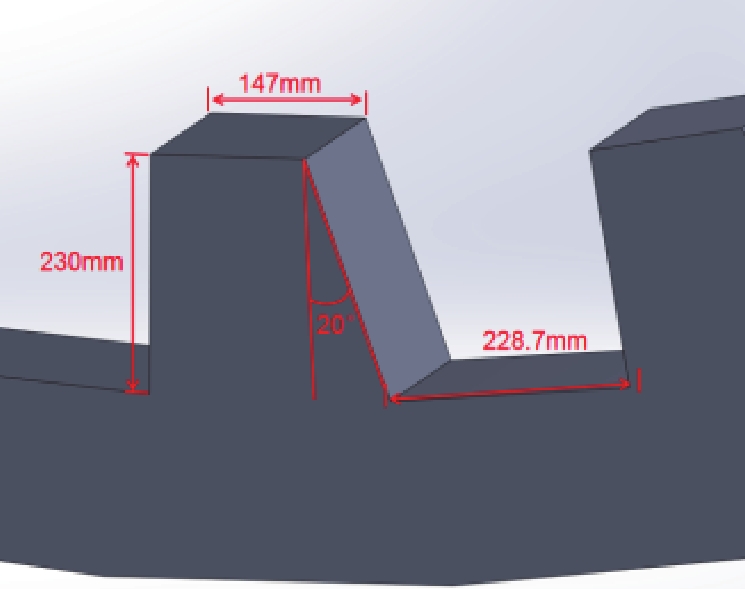

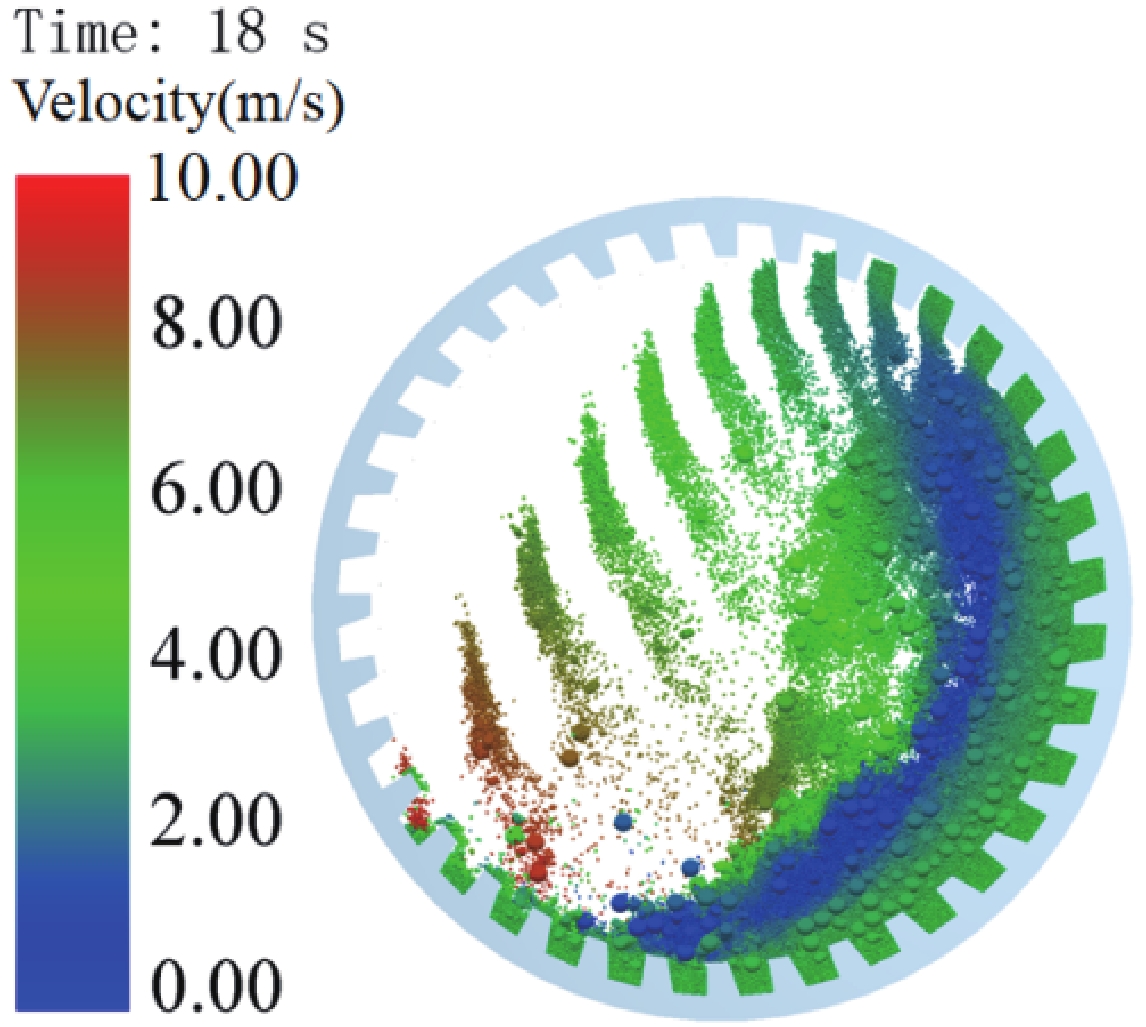

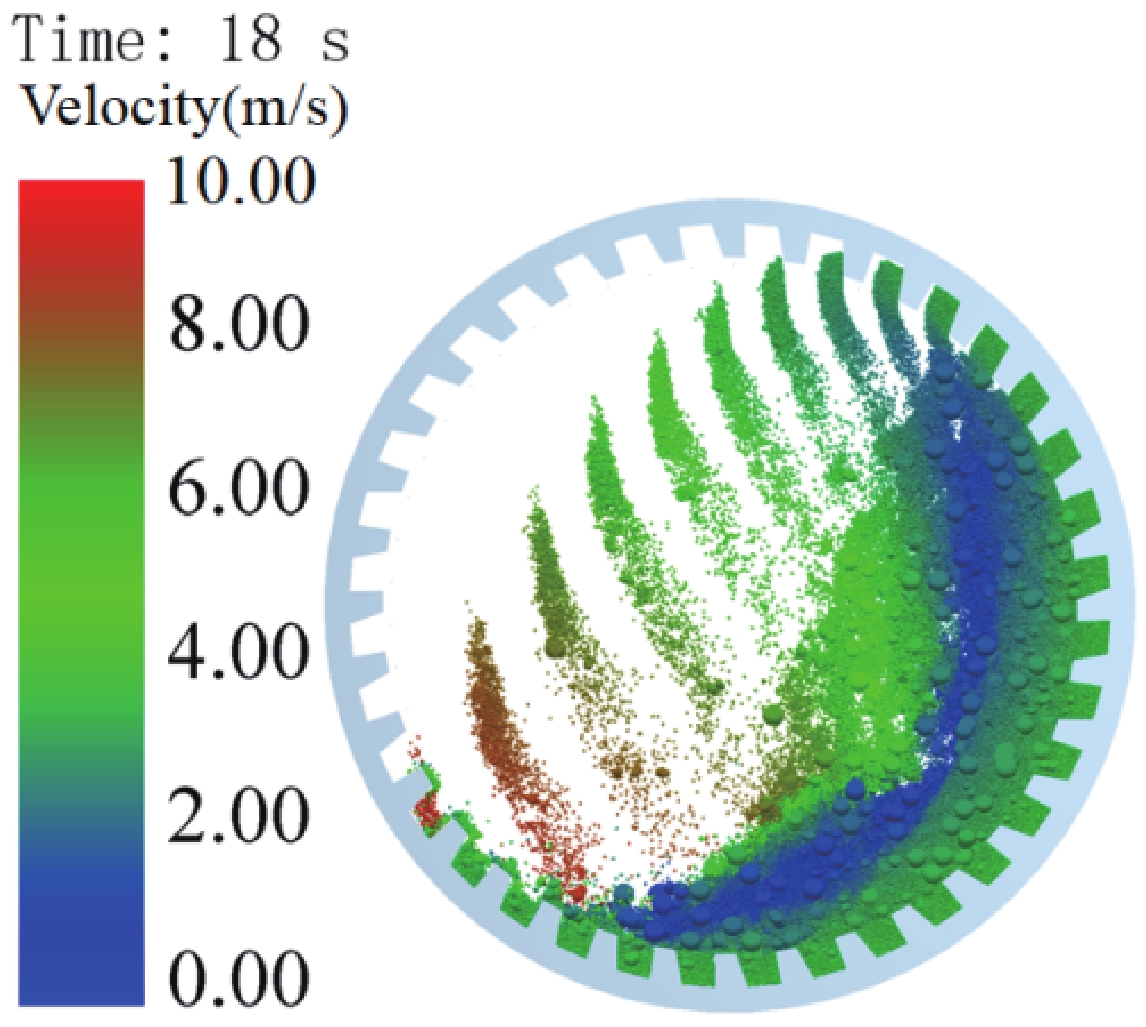

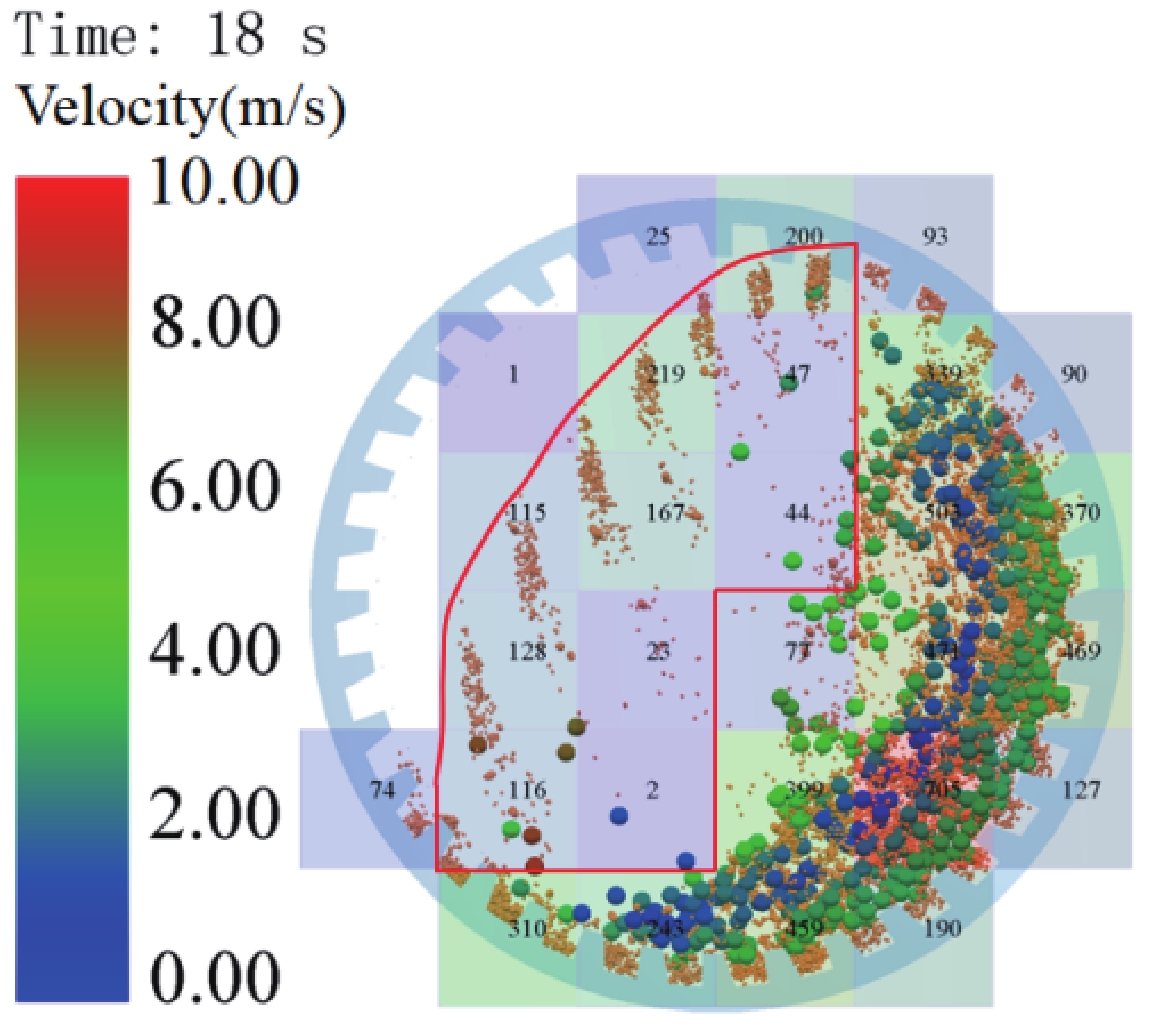

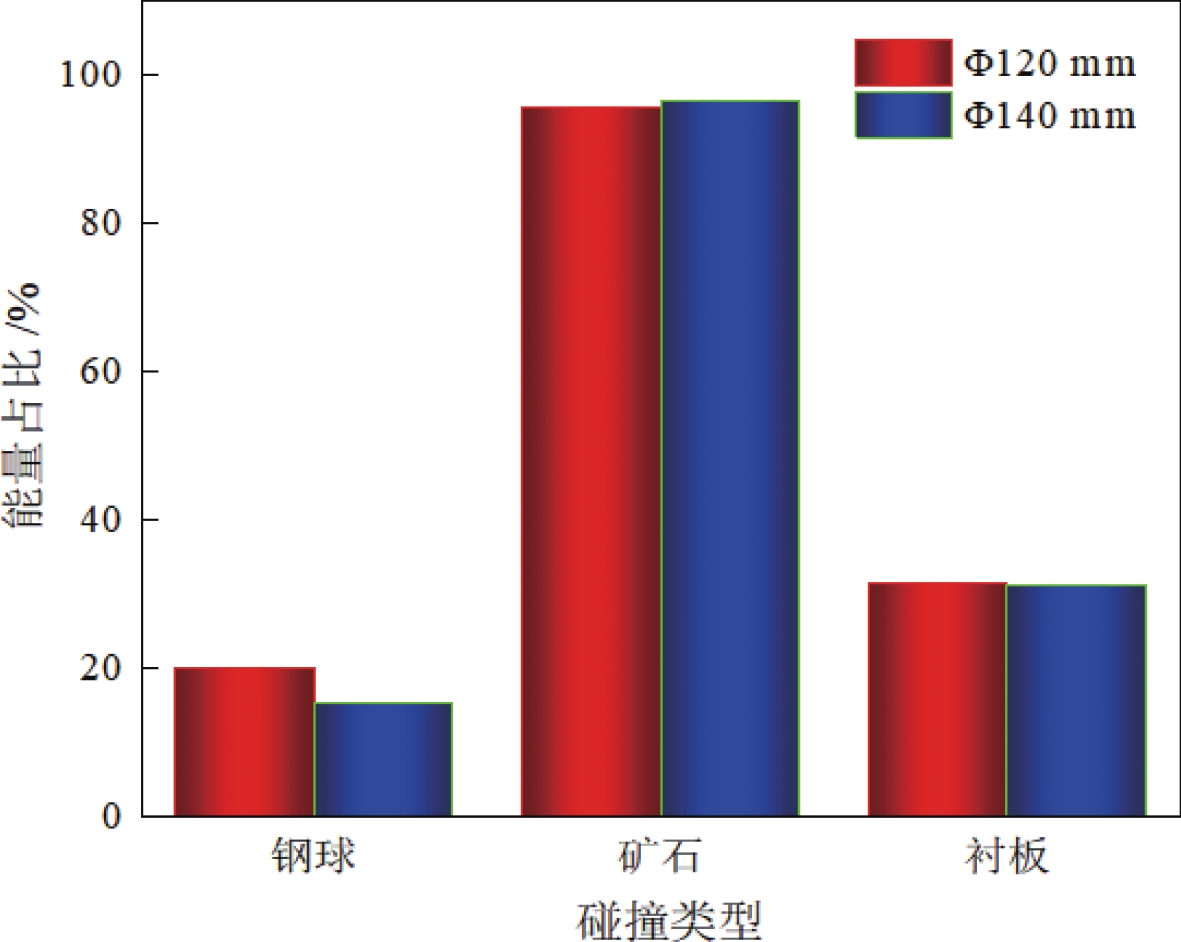

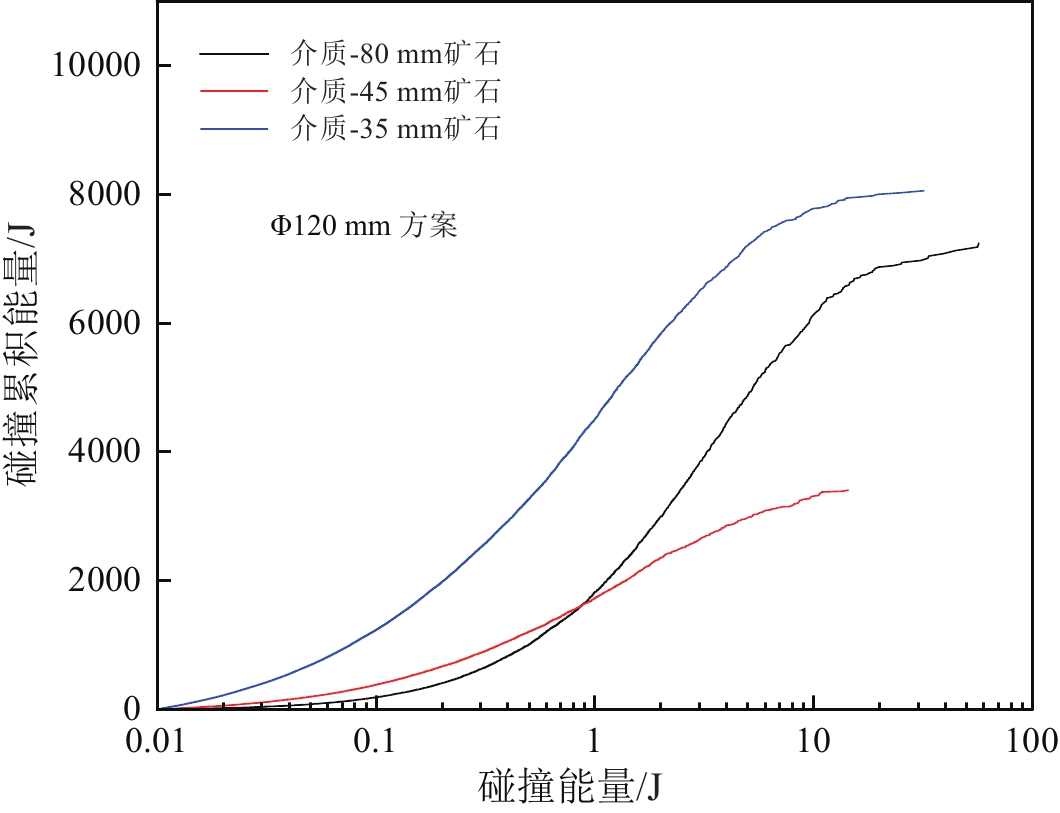

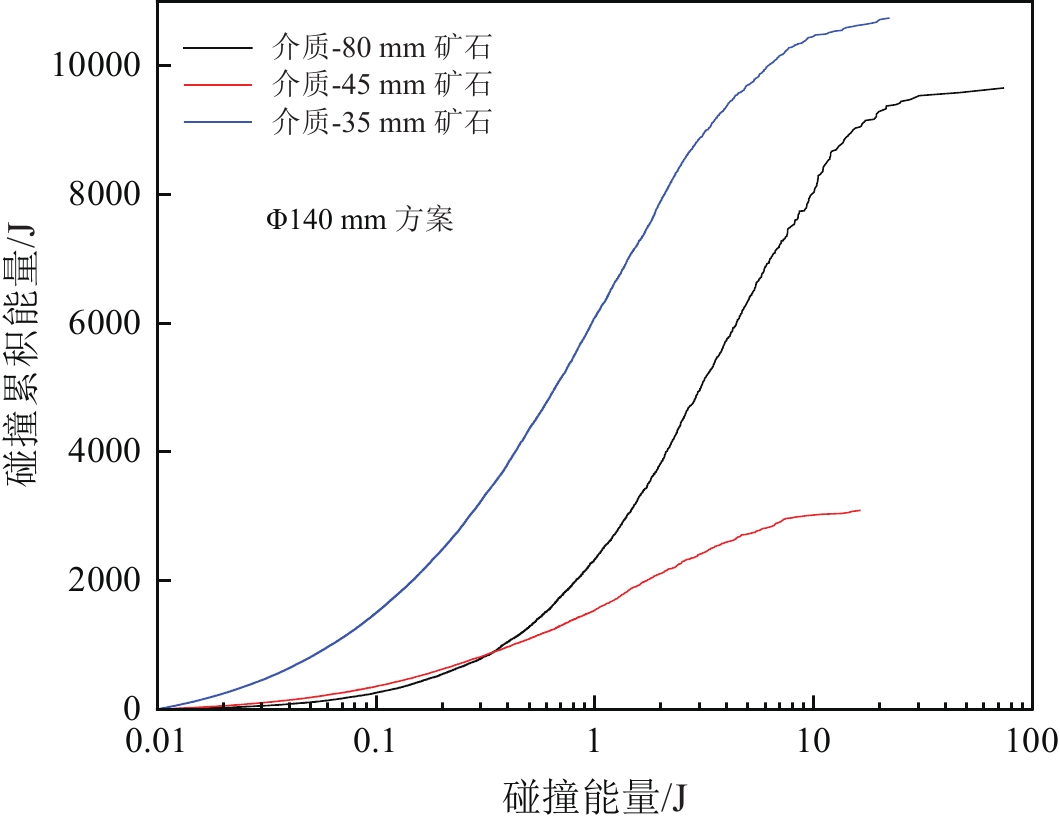

针对云南某金矿半自磨顽石(−80+25 mm)累积严重的问题,在分析矿石力学特性和给矿粒度组成的基础上,根据段氏球径半理论公式计算确定理论最佳钢球尺寸,以钢球尺寸为单一变量,进行实验室磨矿循环试验对比不同方案磨矿指标,并通过离散元仿真模拟分析进行验证。研究结果表明:该矿石平均普氏硬度较大,中等偏硬,同时存在脆性及韧性较大的矿石;在磨矿循环过程中推荐Φ140 mm方案的顽石积累积趋势最小,4次循环后,顽石产率最低,为3.89%,较现场Φ120 mm方案降低3.50百分点,−2 mm合格粒级及−0.074 mm粒级产率最高,分别较现场Φ120 mm方案提高8.40和3.15百分点。推荐Φ140 mm方案较现场Φ120 mm方案顽石颗粒运动状态更活跃,碰撞能量分布更合理,介质对顽石单次碰撞比能耗及高能碰撞频次更高。从磨矿试验和离散元模拟仿真试验验证了推荐Φ140 mm方案半自磨降低顽石累积的有效性。

Abstract:To address the problem of the serious accumulation of hard rock (-80+25 mm) in semi-autogenous grinding mill of a gold mine in Yunnan, The theoretical optimum size of steel ball was calculated by Duan's semi-theoretical formula of ball diameter which was based on the determination of mechanical properties and particle size of ore feed. The grinding cycle test was carried out with the steel ball size as a single variable, and grinding effect was verified by discrete element simulation analysis. The results showed that the average platts hardness of the ore is relatively large, which is medium to hard, and there are relatively large brittleness and toughness at the same time. The recommended Φ140 mm scheme had the lowest tendency to accumulate hard rock during the grinding cycle test. After 4 cycles, the hard rock yield was the lowest at 3.89%, 3.50 percentage points lower than the on-site Φ120 mm scheme, while the −2 mm pass grade and −0.074 mm grade yield were the highest, 8.40 and 3.15 percentage points higher than the on-site Φ120 mm scheme respectively. The recommended Φ140mm scheme was more active than the on-site Φ120 mm scheme in terms of hard rock particle motion, more reasonable collision energy distribution, and higher energy consumption and frequency of high-energy collision for single collision of hard rock by the media. The effectiveness of the recommended Φ140 mm scheme for semi-autogenous grinding to reduce hard rock accumulation was verified from grinding tests and discrete element simulation tests.

-

Key words:

- gold ore /

- grinding /

- semi-autogenous grinding /

- hard rock accumulation /

- steel ball size /

- discrete element method

-

-

表 1 矿石的力学性质测定结果

Table 1. The determination of mechnical properties of ores

矿块编号 1 2 3 4 5 平均值 密度/(g·cm−3) 3.69 4.45 3.43 3.56 4.17 3.86 单轴抗压强度σ压/MPa 148.00 94.70 81.93 83.17 73.80 96.32 静弹性模量E/104 MPa 9.03 12.60 7.45 10.80 2.33 8.44 泊松比μ 0.21 0.24 0.24 0.38 0.26 0.27 表 2 半自磨给矿粒度组成

Table 2. Particle size of ore feed in semi-autogenous grinding mill

级别/mm 产率/% 筛上累积产率/% 筛下累积产率/% +200 0.87 0.87 100 200~150 17.33 18.2 99.13 150~120 11.39 29.59 81.8 150~100 6.32 35.91 70.41 100~80 4.2 40.11 64.09 80~45 6.2 46.31 59.89 45~35 2.6 48.91 53.69 35~25 5.81 54.72 51.09 -25 45.28 100 45.28 总计 100 表 3 磨矿对比试验方案

Table 3. Scheme of grinding comparison test

钢球方案 平均

尺寸/mm钢球

个数钢球

质量/kg矿石

质量/kgΦ140 mm 140 3 33.62 43.96 Φ130 mm 130 4 35.89 46.93 m(Φ140 mm)∶m(Φ120 mm)=1∶3 125 1:3 32.38 42.34 Φ120 mm 120 5 35.29 46.15 表 4 离散元颗粒模型个数

Table 4. Number of particle model in discrete element simulation

颗粒 质量比例/% 个数 200 mm矿石 18.20 13 150 mm矿石 11.39 54 120 mm矿石 6.32 96 100 mm矿石 4.20 122 80 mm矿石 6.20 257 45 mm矿石 2.60 876 35 mm矿石 5.81 10889 25 mm矿石 45.28 113043 现场方案(Φ120 mm) 100.00 477 推荐方案 (Φ140 mm) 100.00 295 表 5 离散元仿真接触参数

Table 5. Contact parameters in discrete element simulation

颗粒模型 恢复系数 静摩擦系数 滚动摩擦系数 钢球-钢球 0.70 0.25 0.03 钢球-矿石 0.40 0.50 0.05 矿石-矿石 0.35 0.68 0.30 表 6 半自磨机中不同类型碰撞能量分布

Table 6. Energy distribution of different collision types in semi-autogenous mill

钢球方案 总能量/J 对钢球/J 对矿石/J 对衬板/J Φ120 mm 625830.46 125364.80 598198.00 197037.21 Φ140 mm 606109.90 92641.99 585131.95 188377.13 表 7 两种钢球方案下顽石碰撞比能耗对比

Table 7. Comparison of specific energy consumption of stubborn stone collision in two steel ball schemes

统计数据 单次最大比能耗/(J·kg−1) ≥10 J/kg比能耗频次 顽石粒级 80 mm 45 mm 30 mm 80 mm 45 mm 30 mm Φ120 mm 55.07 77.94 225.73 61 301 1791 Φ140 mm 71.26 88.50 254.74 65 186 2465 -

[1] 段希祥, 肖庆飞. 碎矿与磨矿[M]. 北京: 冶金工业出版社, 2012.

DUAN X X, XIAO Q F. Ore crushing and grinding [M]. Beijing: Metallurgical Industry Press, 2012.8

[2] 黄治国, 方启学, 任翔, 等. 全自磨半自磨磨矿技术[M]. 北京: 冶金工业出版社, 2018

HUANG Z G, FANG Q X, REN X et al. Full autogenous grinding and semi-autogenous grinding technology [M]. Beijing: Metallurgical Industry Press, 2018.

[3] 宗路, 李旭, 蔡改贫, 等. 基于响应曲面法的半自磨机磨矿能耗研究[J]. 化工矿物与加工, 2018, 47(4): 18−21+53. doi: 10.16283/j.cnki.hgkwyjg.2018.04.006

ZONG L, LI X, CAI G P, et al. Study on energy consumption of semi-autogenous mill grinding based on response surface method[J]. Chemical Minerals and Processing, 2018, 47(4): 18−21+53. doi: 10.16283/j.cnki.hgkwyjg.2018.04.006

[4] 尹自信. 球磨机铁矿石颗粒破碎及粒度分布行为研究[D]. 徐州: 中国矿业大学, 2020.

YIN Z X. Study of iron ore particle crushing and particle size distribution behavior in ball mill[D]. Xuzhou: China University of Mining and Technology, 2020.

[5] 赵元, 马华庆, 赵永志. 研磨介质形状对球磨机特性影响的DEM模拟研究[J]. 矿山机械, 2020, 48(5): 38−45.

ZHAO Y, MA H Q, ZHAO Y Z. DEM simulation study on the effect of grinding media shape on ball mill characteristics[J]. Mining Machinery, 2020, 48(5): 38−45.

[6] YU X P, XU N, ZHEN C Z, et al. Friction and wear of liner and grinding ball in iron ore ball mill[J]. Tribology International, 2017, 115: 506-517.

[7] CLEARY P W, DELANEY G W, SINNOTT M D, et al. Inclusion of incremental damage breakage of particles and slurry rheology into a particle scale multiphase model of a SAG mill[J]. Minerals Engineering, 2018, 128: 92−105. doi: 10.1016/j.mineng.2018.08.026

[8] CLEARY P W, MORRISON R D, DELANEY G W. Incremental damage and particle size reduction in a pilot SAG mill: DEM breakage method extension and validation[J]. Minerals Engineering, 2018, 128: 56−68. doi: 10.1016/j.mineng.2018.08.021

[9] CLEARY P W, MORRISON R D. Understanding fine ore breakage in a laboratory scale ball mill using DEM[J]. Minerals Engineering, 2011, 24: 352−366. doi: 10.1016/j.mineng.2010.12.013

[10] 乔文存, 姬建钢, 董节功, 等. 半自磨流程的优化措施研究[J]. 矿山机械, 2014, 42(7): 91−96. doi: 10.16816/j.cnki.ksjx.2014.07.024

QIAO W C, JI J G, DONG J G, et al. Research on optimization measures of semi-autogenous grinding process[J]. Mining & Processing Machinery, 2014, 42(7): 91−96. doi: 10.16816/j.cnki.ksjx.2014.07.024

[11] WANG M H, YANG R Y, YU A B. DEM investigation of energy distribution and particle breakage in tumbling ball mills[J]. Powder Technology, 2012, 223: 83−91. doi: 10.1016/j.powtec.2011.07.024

[12] WEERASEKARA N S, POWELL M S, CLEARY P W, et al. The contribution of DEM to the science of comminution[J]. Powder Technology, 2013, 248: 3−24. doi: 10.1016/j.powtec.2013.05.032

[13] 付开进. 大型半自磨机磨矿性能仿真及参数优化[D]. 长春: 吉林大学, 2016.

FU K J. Grinding performance simulation and parameter optimization of large semi-self-grinding mill [D]. Changchun: Jilin University, 2016.

[14] WEERASEKARA N S, LIU L X, POWELL M S. Estimating energy in grinding using DEM modelling[J]. Minerals Engineering, 2016, 85: 23−33. doi: 10.1016/j.mineng.2015.10.013

[15] 曲迪, 刘万华, 杨玉巍, 等. 基于离散元的半自磨机运行参数研究[J]. 矿业研究与开发, 2016, 36(2): 96−99. doi: 10.13827/j.cnki.kyyk.2016.02.022

QU D, LIU W H, YANG Y W, et al. Research on operation parameters of semi-autogenous mill based on discrete element[J]. Mining Research and Development, 2016, 36(2): 96−99. doi: 10.13827/j.cnki.kyyk.2016.02.022

[16] RODRIGUEZ V A, CARVALHO R M D, TAVARES L M. Insights into advanced ball mill modelling through discrete element simulations, Minerals Engineering, 2018, 127: 48-60.

[17] 张谦, 肖庆飞, 王旭东, 等. 改善新疆某铜镍矿半自磨机顽石积累[J]. 过程工程学报, 2020, 20(9): 1089−1096. doi: 10.12034/j.issn.1009-606X.219347

ZHANG Q, XIAO Q F, WANG X D, et al. Improvement of refractory rock accumulation in a semi-autocycle mill in Xinjiang[J]. Chinese Journal of Process Engineering, 2020, 20(9): 1089−1096. doi: 10.12034/j.issn.1009-606X.219347

[18] 武煜凯, 肖庆飞, 高志勇. 多级配球降低半自磨中顽石积累及改善磨矿效果试验[J]. 稀有金属, 2022, 46(5): 673−680. doi: 10.13373/j.cnki.cjrm.XY20120018

WU Y K, XIAO Q F, GAO Z Y. Experimental study on reducing the accumulation of refractory stones in semi-autogenous grinding and improving the grinding effect[J]. Rare Metals, 2022, 46(5): 673−680. doi: 10.13373/j.cnki.cjrm.XY20120018

[19] 王肖江. 基于离散元法的武山铜矿半自磨介质优化研究[D]. 昆明: 昆明理工大学, 2017.

WANG X J. Research on medium optimization of semi-autogenous grinding in Wushan opper mine based on discrete element method [D]. Kunming: Kunming University of Science and Technology, 2017.

[20] 王俊. 基于离散单元法的半自磨机工作性能研究[D]. 赣州: 江西理工大学, 2015.

WANG J. Research on performance of semi-autogenous mill based on discrete element method [D]. Ganzhou: Jiangxi University of Science and Technology, 2015.

[21] 何智文. 黄金选矿厂湿式半自磨机磨矿效率提升方法分析与实施[D]. 济南: 山东大学, 2018.

HE Z W. Analysis and implementation of grinding efficiency improvement method of wet semi-autogenous mill in gold concentrator [D]. Jinan: Shandong University, 2018.

-

下载:

下载: