Investigation on Modification of Bentonite to Improve Performance for Civil Engineering Mud

-

摘要:

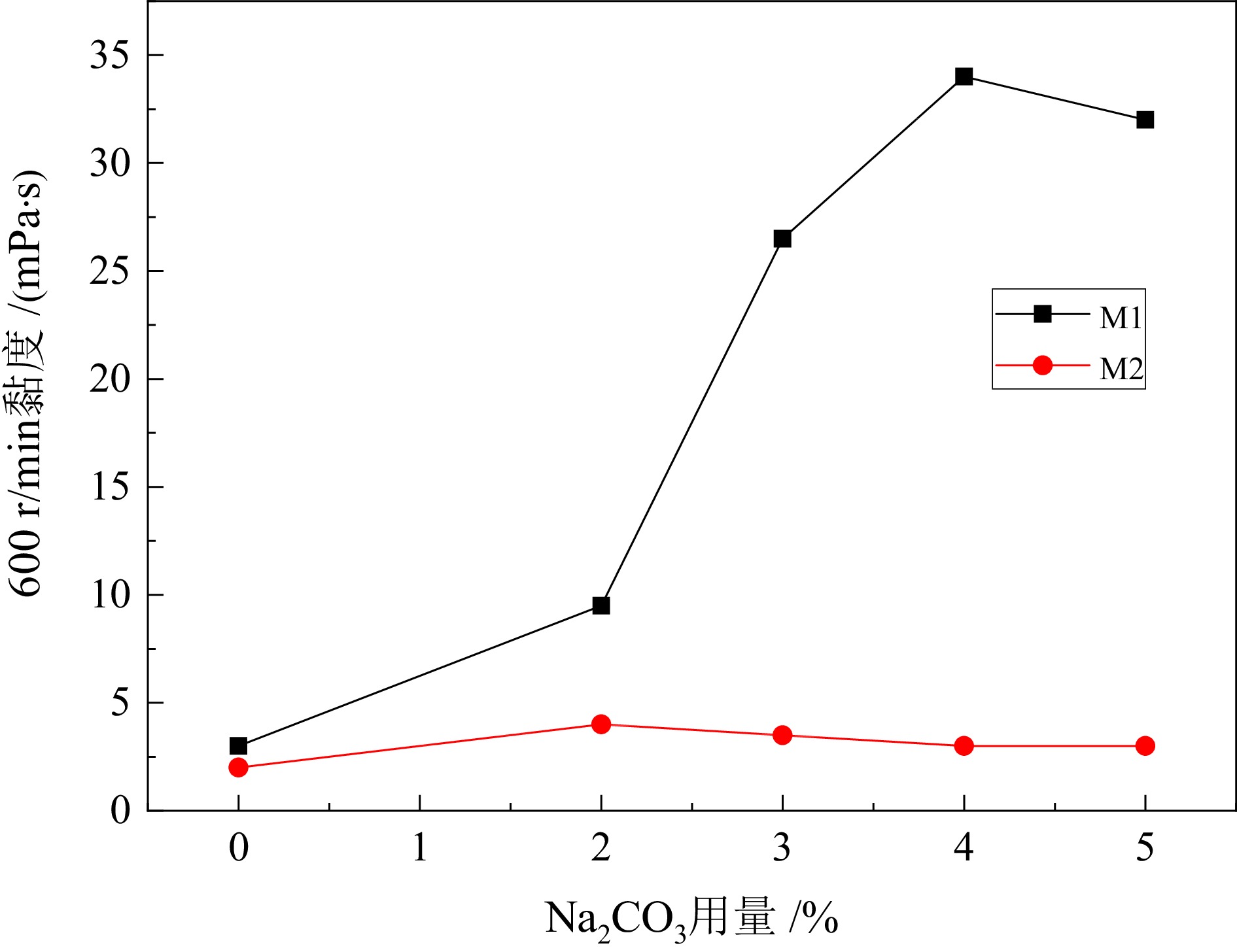

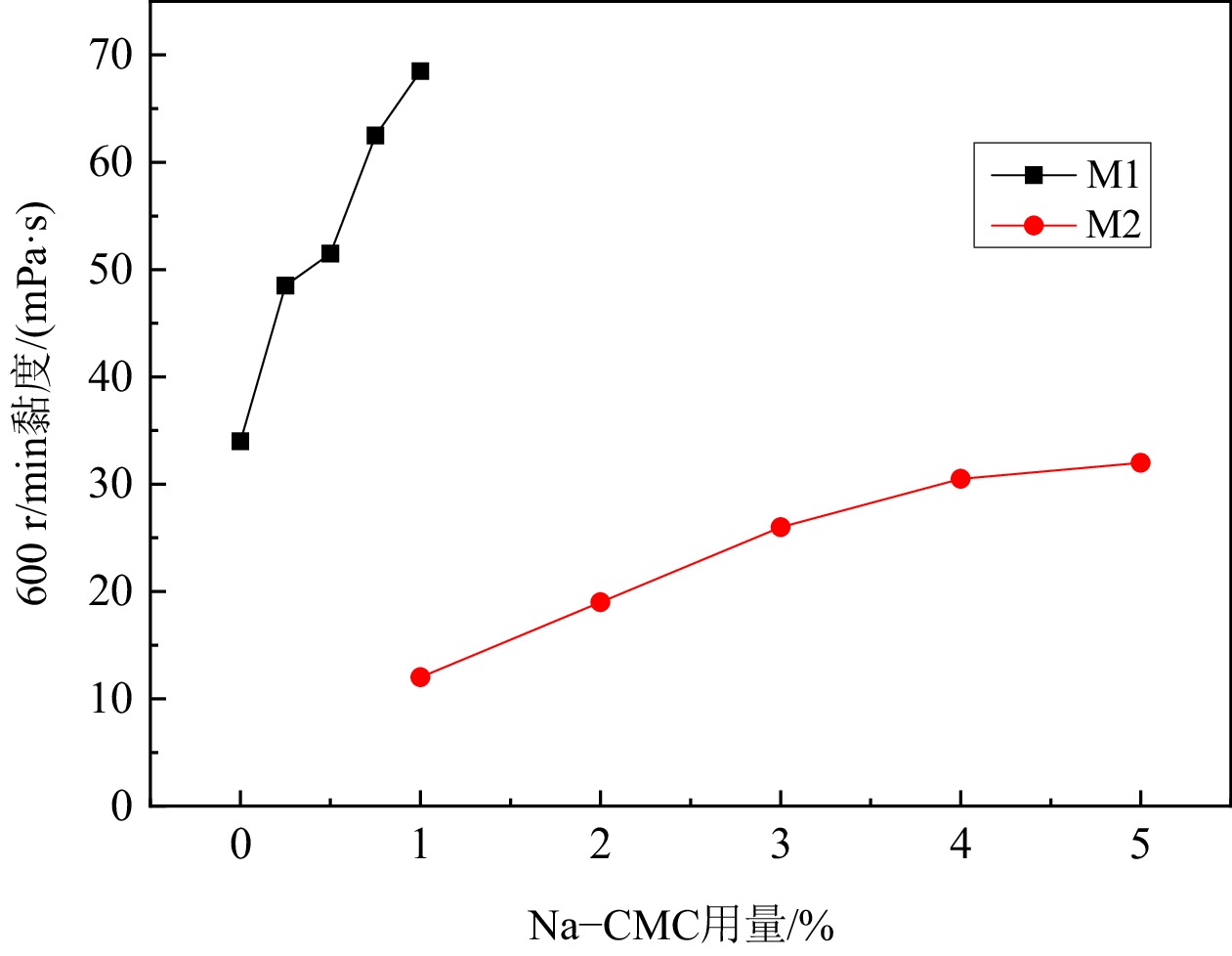

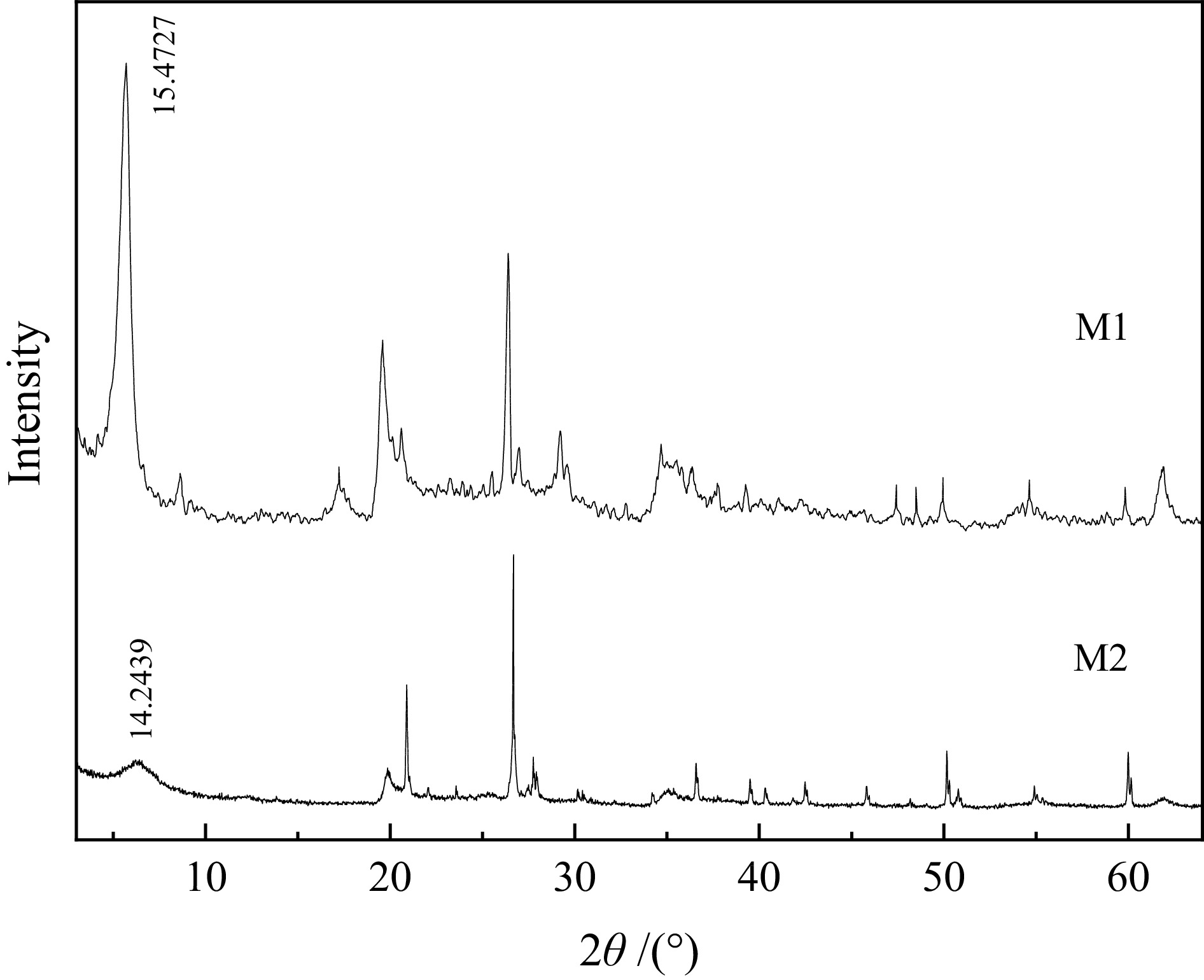

对河南洛阳吸蓝量为35.2 g/100 g和23.6 g/100 g的两种膨润土分别进行钠化改性和增效剂共混处理,制备土木工程泥浆用膨润土。系统研究了钠化剂、增效剂对膨润土泥浆性能的影响。研究结果表明,钠化改性对吸蓝量为35.2 g/100 g的高品位膨润土增黏效果更加显著,4% Na2CO3半干法改性可使高品位膨润土黏度由3 mPa·s提高到34 mPa·s。高品位膨润土钠化后添加0.75% Na−CMC共混可达到高黏膨润土标准。SPA和不同增效剂复配可以有效提高膨润土的黏度、降低滤失量和动塑比;0.2% SPA+1% PAC复配效果最好,可使吸蓝量为23.6 g/100 g的低品位膨润土达到中黏膨润土标准。

Abstract:Two kinds of bentonite with the ethylene blue adsorbed of 35.2 g/100 g and 23.6 g/100 g from Luoyang, Henan Province were Na−modified and mixed with synergists to develop civil engineering mud. The effects of sodium agent and synergists on the mud properties of bentonite were systematically studied. The results showed that the effect of Na−modification on the viscosity of high−grade bentonite with the ethylene blue adsorbed of 35.2 g/100 g was more significant, and the viscosity of high−grade bentonite was increased from 3 mPa·s to 34 mPa·s by 4% Na2CO3 semi−dry modification. The high−grade bentonite could reach the specification of high−viscosity bentonite after the Na−modification by addition of 0.75% Na−CMC. It was found that the combination of SPA and different synergists could effectively improve the viscosity and reduce the filtration loss and yield point/plastic viscosity ratio. The low−grade bentonite with the ethylene blue adsorbed of 23.6 g/100 g could reach the specification of medium−viscosity bentonite by addition of 0.2% SPA+1% PAC.

-

Key words:

- bentonite /

- mud /

- Na−modification /

- synergist

-

-

表 1 土木工程用膨润土的技术指标

Table 1. Specifications of bentonite for civil engineering

项目 指标 低黏膨润土 中黏膨润土 高黏膨润土 黏度(600 r/min)/(mPa·s) ≥ 12 ≥ 35 ≥ 60 动塑比/[Pa·(mPa·s)−1] ≤ 3.0 ≤ 1.5 ≤ 1.5 滤失量/cm3 ≤ 20.0 ≤ 15.0 ≤ 14.0 75 μm筛余/% ≤ 4.0 ≤ 2.0 ≤ 1.5 水分含量/% ≤ 13.0 ≤ 13.0 ≤ 13.0 表 2 Na−CMC用量对M1样品泥浆性能的影响

Table 2. Effect of Na−CMC dosage on the mud properties of sample M1

Na−CMC用量/% 0 0.25 0.5 0.75 1 黏度(600 r/min)/(mPa·s) 34 48.5 51.5 62.5 68.5 滤失量/cm3 13.6 11.0 11.0 10.8 10.0 动塑比/[Pa·(mPa·s)−1] 0.89 0.94 1.45 1.50 1.74 表 3 不同增效剂对M2样品泥浆性能的影响

Table 3. Effect of several synergists on the mud properties of sample M2

序号 增效剂 黏度(600 r/min)/

(mPa·s)滤失量/cm3 动塑比/

[Pa·(mPa·s)−1]1 0.3% APAM 16 19.6 1.00 2 0.5% APAM 22 18.2 0.83 3 1% APAM 29 16.8 1.42 4 0.3% PAC 25 17.6 0.79 5 0.5% PAC 28 17.6 0.75 6 1% PAC 35 16.2 0.94 7 0.3% XG 13 21.0 0.30 8 0.5% XG 23 18.6 0.83 9 1% XG 26 18.4 0.63 10 0.2% SPA 31 17.2 1.21 11 0.3% SPA 38 16.6 1.38 12 0.4% SPA 36 16.6 1.25 13 0.5% SPA 35 16.8 0.94 表 4 复配增效剂对M2样品泥浆性能的影响

Table 4. Effect of several compound synergists on the mud properties of sample M2

序号 复合增效剂 黏度(600 r/min)

/mPa·s滤失量

/cm3动塑比

/[Pa·(mPa·s)−1]1 0.2% SPA+0.3%Na−CMC 38 16.8 1.38 2 0.3% SPA+0.3%Na−CMC 51 17.2 1.83 3 0.3% SPA+0.4%Na−CMC 52 15.6 1.89 4 0.2% SPA+0.3% APAM 40 14.4 1.22 5 0.2% SPA+0.4% APAM 42 14.0 1.10 6 0.2% SPA+0.5% APAM 40 13.4 1.00 7 0.2% SPA+1.0% APAM 42 12.4 1.10 8 0.3% SPA+0.2% APAM 44 15.8 1.75 9 0.3% SPA+0.3% APAM 45 15.4 1.65 10 0.3% SPA+0.4% APAM 54 14.4 2.00 11 0.2% SPA+0.5% PAC 47 13.6 1.21 12 0.2% SPA+1.0% PAC 51 12.8 1.32 13 0.3% SPA+0.5% PAC 52 14.4 1.36 14 0.2% SPA+0.5% XG 42 18.4 1.63 15 0.2% SPA+1.0% XG 48 15.6 1.67 16 0.3% SPA+0.5% XG 50 16.2 1.78 -

[1] 余丽秀, 邵晨, 朱进, 等. 膨润土开发利用评估影响因素探讨[J]. 矿产保护与利用, 2018(6): 20−23.

YU L X, SHAO C, ZHU J, et al. Discussion on the influence factors of the development and utilization level of bentonite[J]. Conservation and Utilization of Mineral Resources, 2018(6): 20−23.

[2] 郑长文, 管俊芳, 郑佳敏, 等. 矿业领域膨润土应用的研究进展[J]. 矿产综合利用, 2020(3): 22−27.

ZHENG C W, GUAN J F, ZHENG J M, et al. Progress in the application of bentonite in mining industry[J]. Multipurpose Utilization of Mineral Resources, 2020(3): 22−27.

[3] DONG W X, PU X L, REN Y J, et al. Thermoresponsive bentonite for water−based drilling fluids[J]. Materials, 2019, 12(13): 2115−2134. doi: 10.3390/ma12132115

[4] 舒义勇, 周华安, 孙俊, 等. 原矿土钻井液室内评价与应用[J]. 钻井液与完井液, 2019, 36(4): 459−462.

SHU Y Y, ZHOU H A, SUN J, et al. Laboratory evaluation and application of a raw bentonite drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(4): 459−462.

[5] 彭超, 王震. 大直径深桩基施工中优质膨润土泥浆的运用[J]. 粘结, 2020, 42(4): 123−127.

PENG C, WANG Z. Application of high−quality bentonite mud in large−diameter deep pile foundation construction[J]. Adhesion, 2020, 42(4): 123−127.

[6] 祝启坤. 膨润土在土木工程中的应用与机理[J]. 化工矿产地质, 2003, 25(2): 99−102.

ZHU Q K. The application and mechanisms of bentonite in civil engineering[J]. Geology of Chemical Minerals, 2003, 25(2): 99−102.

[7] 鞠建英. 膨润土在土木工程中的应用[J]. 铁道建筑技术, 2004(3): 1−6.

JU J Y. The use of swelling soil in civil engineering[J]. Railway Construction Technology, 2004(3): 1−6.

[8] BORAH D, NATH H, SAIKIA H. Modification of bentonite clay & its applications: a review[J]. Reviews in Inorganic Chemistry, 2022, 42(3): 265−282. doi: 10.1515/revic-2021-0030

[9] KOTWICA K, SUFFNER H, ANDRAS A. Trenchless execution of microtunnels for municipal infrastructure in urbanized site – conception of a new solution[J]. Management Systems in Production Engineering, 2020, 28(4): 276−282. doi: 10.2478/mspe-2020-0039

[10] 王桂芳, 盘益任, 马少健, 等. 广西田东某钙基膨润土钠化改型试验[J]. 金属矿山, 2017(4): 87−90. doi: 10.3969/j.issn.1001-1250.2017.04.019

WANG G F, PAN Y R, MA S J, et al. Sodium modification study on a Ca−based bentonite from Tiandong, Guangxi[J]. Metal Mine, 2017(4): 87−90. doi: 10.3969/j.issn.1001-1250.2017.04.019

[11] KARAGüZEL C, çETINEL T, BOYLU F, et al. Activation of (Na, Ca)−bentonites with soda and MgO and their utilization as drilling mud[J]. Applied Clay Science, 2010, 48(3): 398−404. doi: 10.1016/j.clay.2010.01.013

[12] 雷华阳, 刘旭, 施福硕, 等. 顶管工程聚合物改性膨润土泥浆配比优化研究[J]. 岩土工程学报, 2021, 43(S2): 51−55. doi: 10.11779/CJGE2021S2012

LEI H Y, LIU X, SHI F S, et al. Proportional optimization of polymer−modified bentonite slurry in pipe jacking[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(S2): 51−55. doi: 10.11779/CJGE2021S2012

[13] 彭双磊, 冯雪钢, 田剑, 等. 国内钻井液增黏剂的研究与应用进展[J]. 广州化工, 2012, 40(12): 10−11.

PENG S L, FENG X G, TIAN J, et al. Progress in study and application of drilling fluid viscosifier at home[J]. Guangzhou Chemical Industry, 2012, 40(12): 10−11.

[14] 曹灿, 周风山, 张志磊, 等. 高造浆膨润土制备及其性能评价[J]. 地学前缘, 2013, 20(5): 220−226.

CAO C, ZHOU F S, ZHANG Z L, et al. Preparation and evaluation of high yield sodium−modified calcium base bentonite[J]. Earth Science Frontiers, 2013, 20(5): 220−226.

[15] ABU JDAYIL B, GHANNAM M, ALSAYYED A K, et al. The effect of biopolymer chitosan on the rheology and stability of Na−bentonite drilling mud[J]. Polymers, 2021, 13(19): 3361−3376. doi: 10.3390/polym13193361

[16] 黄志强, 冯东林. 生石灰膨润土泥浆土压盾构渣土改良试验研究[J]. 地下空间与工程学报, 2020, 16(1): 128−133.

HUANG Z Q, FENG D L. Soil improvement for earth pressure balance shields construction with lime bentonite clay[J]. Chinese Journal of Underground Space and Engineering, 2020, 16(1): 128−133.

[17] 李财富, 李本高, 汪燮卿. 国内水基钻井液降滤失剂研究现状[J]. 中外能源, 2013, 18(2): 39−44.

LI C F, LI B G, WANG X Q. Current research status of filtrate reducer for water−based drilling fluid in China[J]. Sino−Global Energy, 2013, 18(2): 39−44.

[18] 吴鑫磊, 闫丽丽, 王立辉, 等. 环保型钻井液用降滤失剂研究进展[J]. 钻井液与完井液, 2018, 35(3): 8−16.

WU X L, YAN L L, WANG L H, et al. Progress in the study of environmentally friendly drilling fluid filtration reducer[J]. Drilling Fluid & Completion Fluid, 2018, 35(3): 8−16.

[19] 王少帅, 张华. 纳米材料在钻井液封堵降滤失中的研究进展[J]. 广东化工, 2022, 49(19): 95−97.

WANG S S, ZHANG H. Research progress of nanomaterials in drilling fluid plugging and fluid loss reduction[J]. Guangdong Chemical Industry, 2022, 49(19): 95−97.

[20] HUANG Y F, ZHANG Y B, HAN G H, et al. Sodium−modification of Ca−based bentonite via semidry process[J]. Journal of Central South University of Technology, 2010, 17(6): 1201−1206. doi: 10.1007/s11771-010-0619-9

[21] 张太亮, 黄志宇, 莫军, 等. 膨润土改性作用机理及改性方法研究[J]. 钻采工艺, 2006, 29(6): 102−103.

ZHANG T L, HUANG Z Y, MO J, et al. Research on modification mechanism and method of bentonite[J]. Drilling & Production Technology, 2006, 29(6): 102−103.

[22] 王志强, 舒锋, 刘玉芹. 低品位膨润土矿制备土木工程泥浆土的研究[J]. 非金属矿, 2010, 33(4): 34−36.

WANG Z Q, SHU F, LIU Y Q. Study on preparation of civil engineering slurry clay from low−grade bentonite[J]. Non−Metallic Mines, 2010, 33(4): 34−36.

[23] 李鑫, 吴雪兰, 龙红明, 等. 高分子聚合物调控膨润土造浆性能及机理研究[J]. 硅酸盐通报, 2021, 40(7): 2256−2263.

LI X, WU X L, LONG H M, et al. Pulping properties and mechanism of bentonite controlled by polymer[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(7): 2256−2263.

-

下载:

下载: