Orthogonal Experiment on Preparation of Lightweight Porous Ceramics from a Porphyry Copper Flotation Tailings in Mongolia

-

摘要:

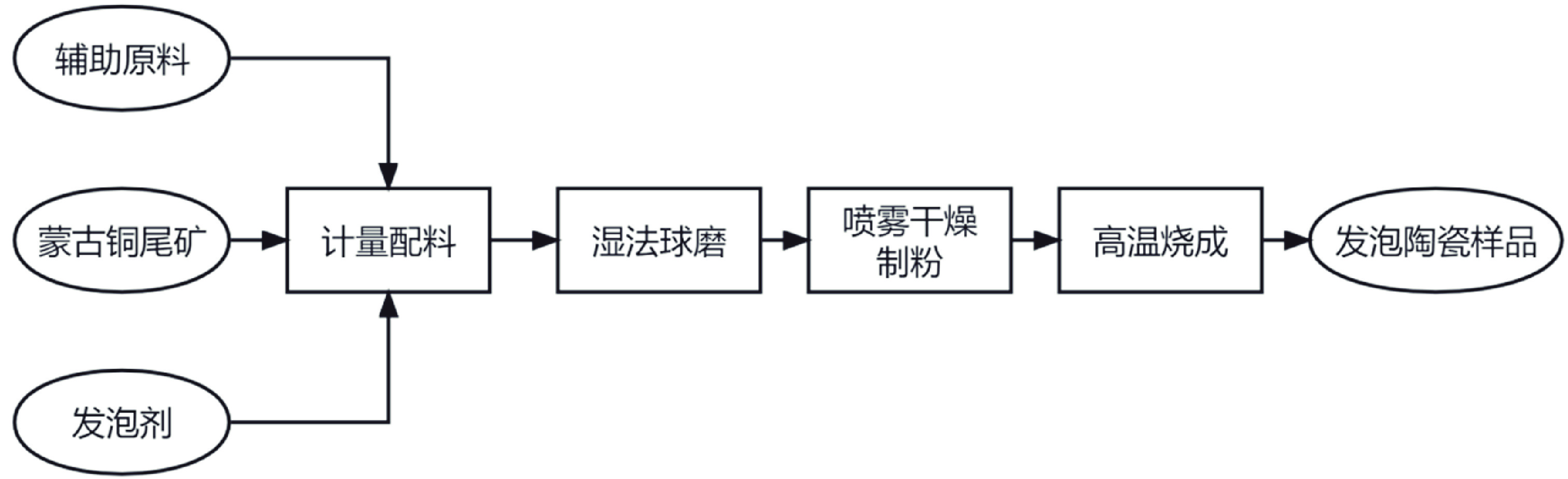

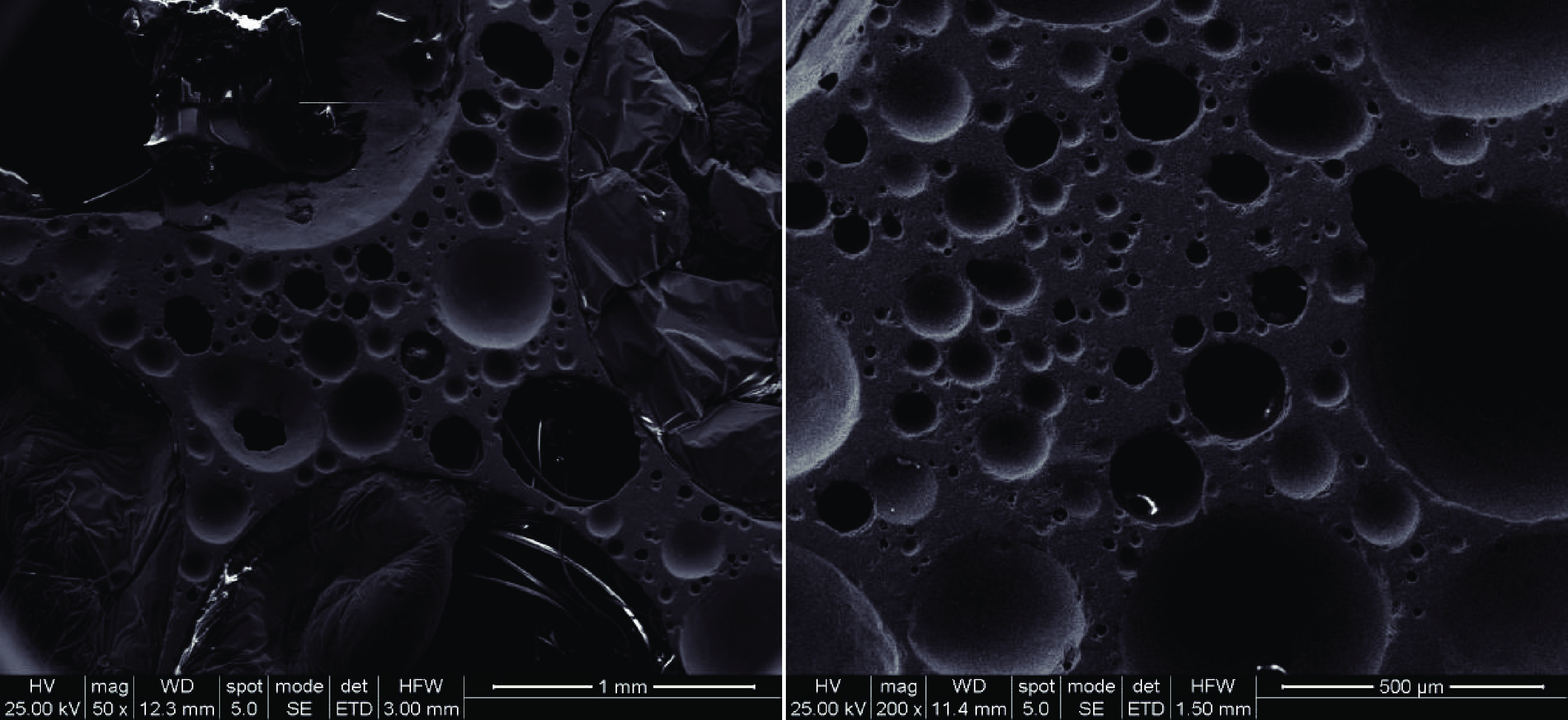

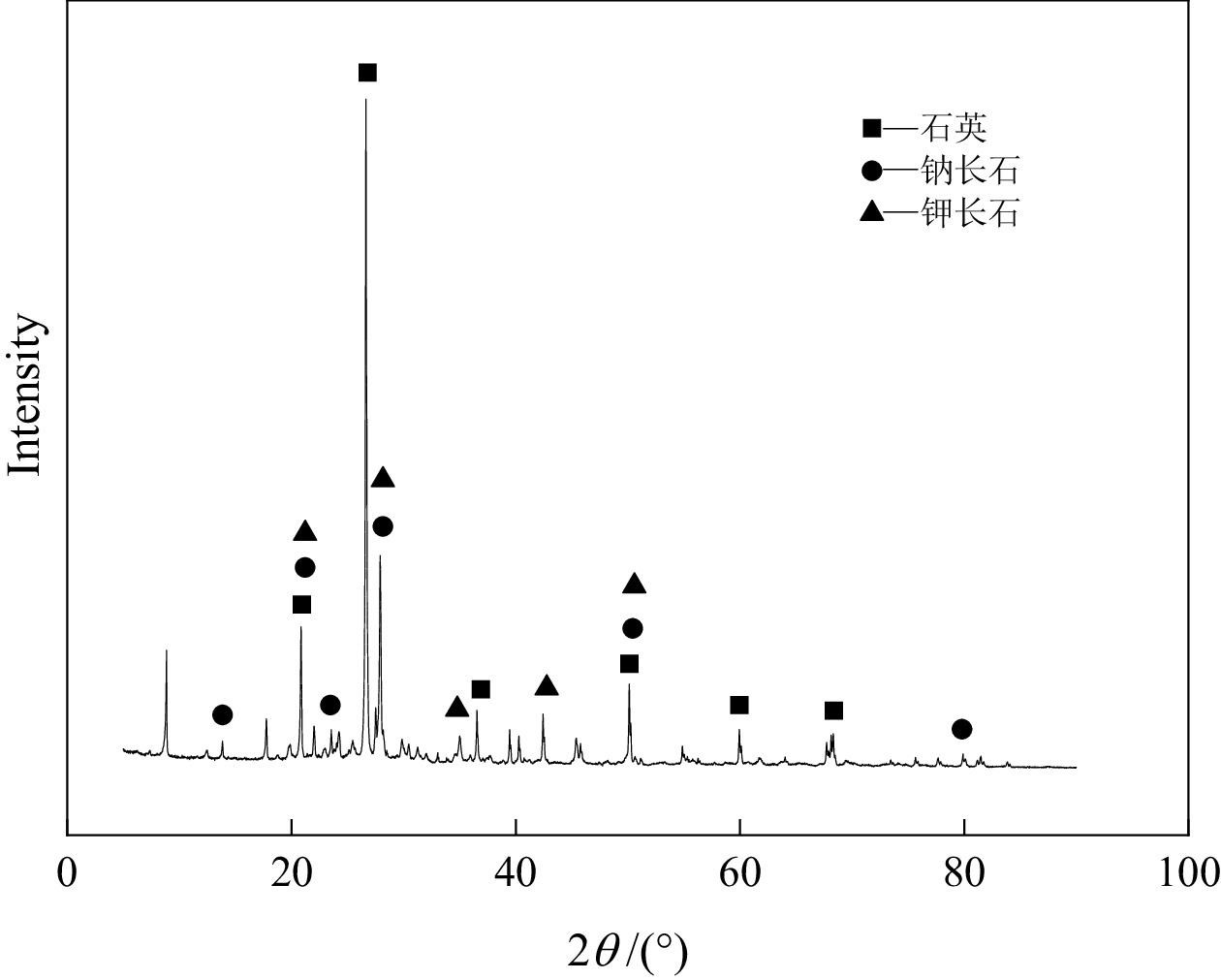

以蒙古国某典型斑岩型铜矿尾矿为主要原料,添加钠长石、高岭土、发泡剂SiC,制备轻质多孔陶瓷材料。通过正交实验研究了物料配比、粉磨时间、发泡剂种类、发泡剂用量和烧成温度对轻质多孔陶瓷表观密度和抗压强度的影响。当m(铜尾矿)∶m(钠长石)∶m(高岭土)为6.4∶2.7∶0.9、粉磨时间为15 min、发泡剂(SiC)掺量为0.1%、烧成温度为1180 ℃、保温时间为60 min时,获得的多孔陶瓷材料表观密度为580 kg/m3,抗压强度为4.90 MPa,软化系数为0.92。

Abstract:Lightweight porous ceramic materials is prepared from flotation tailings of a typical porphyry copper ore in Mongolia, albite, kaolin and foaming agent SiC. The effects of material ratio, grinding time, foaming agent type, foaming agent dosage and sintering temperature on the apparent density and compressive strength of lightweight porous ceramics are studied by orthogonal tests. When the ratio of m (copper tailings)∶m (albite)∶m (kaolin) is 6.4∶2.7∶0.9, the grinding time was 15min, the content of foaming agent (SiC) was 0.1%, the sintering temperature was 1180℃ and the holding time was 60min, the technological process was the best. At this time, the apparent density of porous ceramic material was 580 kg/m3, the compressive strength was 4.90 MPa and the softening coefficient was 0.92.

-

-

表 1 主要原料的X射线荧光光谱分析结果

Table 1. X−ray fluorescence spectrum analysis of copper tailings

/% 化学成分 SiO2 Al2O3 CaO MgO K2O Na2O Fe2O3 SO3 Loss 铜尾矿 67.74 15.73 0.67 0.95 3.68 3.72 2.70 2.38 1.36 钠长石 77.50 11.98 0.61 1.52 0.36 7.15 0.32 0.02 0.45 高岭土 45.71 40.32 0.77 0.66 2.53 0.18 7.27 0.16 2.14 表 2 发泡剂种类实验结果

Table 2. Test results of foaming agent types

试验编号 发泡剂种类 发泡剂用量/% 多孔陶瓷材料

表观密度/(kg·m−3)1 炭粉 5.0 2320 2 煤矸石 7.0 2551 3 纯碱 2.0 1900 4 氧化铁 4.0 2156 5 SiC 0.5 614 注:不同的发泡剂发泡能力有差异,因此发泡剂的用量有差别。 表 3 铜尾矿发泡陶瓷配方及工艺条件正交因素和水平

Table 3. Orthogonal factor and level table of formula and process conditions of copper tailings foamed ceramics

因素 铜尾矿

/%钠长石

/%高岭土

/%磨矿

时间/min发泡剂

掺量/%烧成

温度/℃1 50 20 5 10 0.1 1180 2 60 30 10 15 0.3 1200 3 70 40 15 20 0.5 1220 表 4 正交实验表L18(36)

Table 4. Orthogonal Experiment Table L18(36)

因素 尾矿

/wt%钠长石

/wt%高岭土

/wt%发泡剂

掺量/wt%磨矿

时间/min烧成

温度/℃实验1 50 20 5 0.1 10 1180 实验2 50 30 10 0.3 15 1200 实验3 50 40 15 0.5 20 1220 实验4 60 20 5 0.3 15 1220 实验5 60 30 10 0.5 20 1180 实验6 60 40 15 0.1 10 1200 实验7 70 20 10 0.1 20 1200 实验8 70 30 15 0.3 10 1220 实验9 70 40 5 0.5 15 1180 实验10 50 20 15 0.5 15 1200 实验11 50 30 5 0.1 20 1220 实验12 50 40 10 0.3 10 1180 实验13 60 20 10 0.5 10 1220 实验14 60 30 15 0.1 15 1180 实验15 60 40 5 0.3 20 1200 实验16 70 20 15 0.3 20 1180 实验17 70 30 5 0.5 10 1200 实验18 70 40 10 0.1 15 1220 表 5 发泡陶瓷材料配方及工艺正交实验结果

Table 5. Orthogonal experimental results of formula and process of foamed ceramic materials

水平 因素 性能测试结果 尾矿 钠长石 高岭土 发泡剂掺量 磨矿细度 烧成温度 表观

密度/(kg·m−3)抗压

强度/MPa1 1 1 1 1 1 1 204.01 0.47 2 1 2 2 2 2 2 301.79 2.29 3 1 3 3 3 3 3 188.53 0.29 4 2 1 1 2 2 3 319.36 1.60 5 2 2 2 3 3 1 980.43 4.58 6 2 3 3 1 1 2 729.63 7.29 7 3 1 2 1 3 2 571.47 8.39 8 3 2 3 2 1 3 404.44 1.41 9 3 3 1 3 2 1 279.34 1.07 10 1 1 3 3 2 2 199.65 0.63 11 1 2 1 1 3 3 707.03 3.82 12 1 3 2 2 1 1 315.73 2.42 13 2 1 2 3 1 3 432.99 2.32 14 2 2 3 1 2 1 825.35 15.59 15 2 3 1 2 3 2 382.71 1.51 16 3 1 3 2 3 1 337.09 4.04 17 3 2 1 3 1 2 430.02 3.74 18 3 3 2 1 2 3 756.98 13.78 表观密度 K1 319.46 344.09 387.08 632.41 419.47 490.32 K2 611.75 608.18 559.90 343.52 447.08 435.88 K3 463.22 442.15 447.45 418.49 527.88 468.22 极差 292.29 264.08 172.82 288.89 108.41 54.45 优方案 A1 B1 C1 D2 E1 F2 抗压强度 K1 1.65 2.91 2.03 8.22 2.94 4.70 K2 5.48 5.24 5.63 2.21 5.83 3.97 K3 5.41 4.39 4.88 2.11 3.77 3.87 极差 3.83 2.33 3.60 6.12 2.89 0.83 优方案 A2 B2 C2 D1 E2 F1 表 6 优化的产品性能测试结果

Table 6. Test results of optimal product performance

项目 抗压强度/MPa 表观密度/(kg·m−3) 软化系数 产品性能 4.90 580 0.92 标准要求 ≥3.50 ≤900 ≥0.80 -

[1] 姜葱葱, 董祎然, 黄世峰, 等. 基于原位发泡工艺的固废基发泡陶瓷研究进展[J]. 硅酸盐学报, 2022, 50(9): 2510−2526.

JIANG C C, DONG Y R, HUANG S F, et al. Research progress of solid waste-based foamed ceramics based on in-situ foaming process[J]. Journal of Silicate, 2022, 50(9): 2510−2526.

[2] 赵绘婷, 董龙浩, 谢梅竹, 等. 以煤矸石制备发泡陶瓷的研究[J]. 中国陶瓷工业, 2022, 29(3): 26−30.

ZHAO H T, DONG L H, XIE M Z, et al. Study on preparation of foamed ceramics from coal gangue[J]. China Ceramic Industry, 2022, 29(3): 26−30.

[3] 詹学武, 邢益强, 吴晓鹏, 等. 花岗岩废料基闭孔发泡陶瓷的正交试验研究[J]. 硅酸盐通报, 2020, 39(8): 2650−2655.

ZHAN X W, XING Y Q, WU X P, et al. Orthogonal experimental study on closed-cell foamed ceramics based on granite waste[J]. Silicate Bulletin, 2020, 39(8): 2650−2655.

[4] 徐娜, 王挺. 采用发泡-流延成型工艺制备多孔莫来石发泡陶瓷[J]. 耐火材料, 2020, 54(4): 330−333.

XU N, WANG T. Porous mullite foamed ceramics were prepared by foaming-tape casting process[J]. Refractory, 2020, 54(4): 330−333.

[5] 郭震, 严伟. 发泡陶瓷保温装饰一体板的研究与应用[J]. 新型建筑材料, 2020, 47(6): 114−116.

GUO Z, YAN W. Research and application of thermal insulation and decoration of integrated plate with foamed ceramics[J]. New building materials, 2020, 47(6): 114−116.

[6] 彭团儿, 李洪潮, 刘玉林, 等. 工业固废制备发泡陶瓷研究及应用进展[J]. 陶瓷, 2019(12): 9−22.

PENG T E, LI H C, LIU YU L, et al. Research and application progress of foamed ceramics prepared from industrial solid waste[J]. Ceramics, 2019(12): 9−22.

[7] 温晓庆, 王林俊, 毕晟, 等. 尾矿和发泡剂对发泡陶瓷板(砖)的性能影响[J]. 砖瓦, 2019(12): 47−50. doi: 10.16001/j.cnki.1001-6945.2019.12.009

WEN X Q, WANG L J, BI S, et al. Influence of tailings and foaming agent on properties of foamed ceramic board[J]. Brick and tile, 2019(12): 47−50. doi: 10.16001/j.cnki.1001-6945.2019.12.009

[8] 王玉文, 张士察, 钟路生, 等. 发泡陶瓷产业发展现状及前景[J]. 陶瓷, 2019(8): 9−12.

WANG Y W, ZHANG S C, ZHONG L S, et al. Development status and prospect of foamed ceramics industry[J]. Ceramics, 2019(8): 9−12.

[9] 熊灿光, 王慧, 曾令可. 利用抛光废渣制造发泡陶瓷[J]. 山东陶瓷, 2019, 42(3): 3−8. doi: 10.3969/j.issn.1005-0639.2019.03.001

XIONG C G, WANG H, ZENG L K. Making foamed ceramics from polishing waste residue[J]. Shandong Ceramics, 2019, 42(3): 3−8. doi: 10.3969/j.issn.1005-0639.2019.03.001

[10] 马子钧. 利用硅酸盐工业废(尾)矿制备发泡陶瓷的研究[D]. 北京: 北京工业大学, 2019.

MA Z J. Study on preparation of foamed ceramics from waste (tailings) ore of silicate industry [D]. Beijing : Beijing University of Technology, 2019.

[11] 杨航, 李伟光, 申士富, 等. 江西某铜尾矿制备发泡陶瓷的正交试验研究[J]. 铜业工程, 2019(2): 78−86.

YANG H, LI W G, SHEN S F, et al. Orthogonal experimental study on preparation of foamed ceramics from a copper tailings in Jiangxi[J]. Copper Engineering, 2019(2): 78−86.

-

下载:

下载: