Effect of Flotation Purification on Preparation of β—Hemihydrate Gypsum from Phosphogypsum

-

摘要:

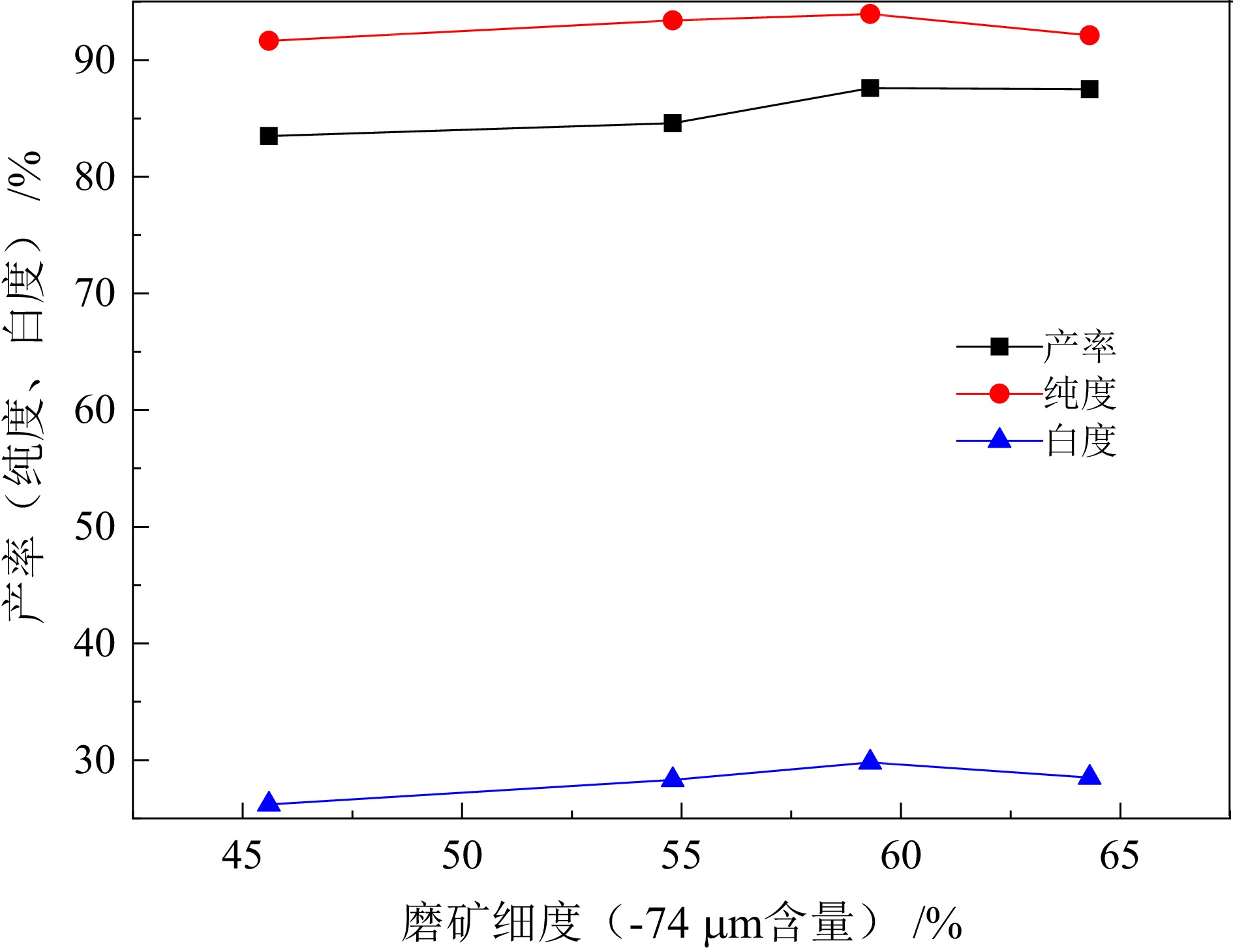

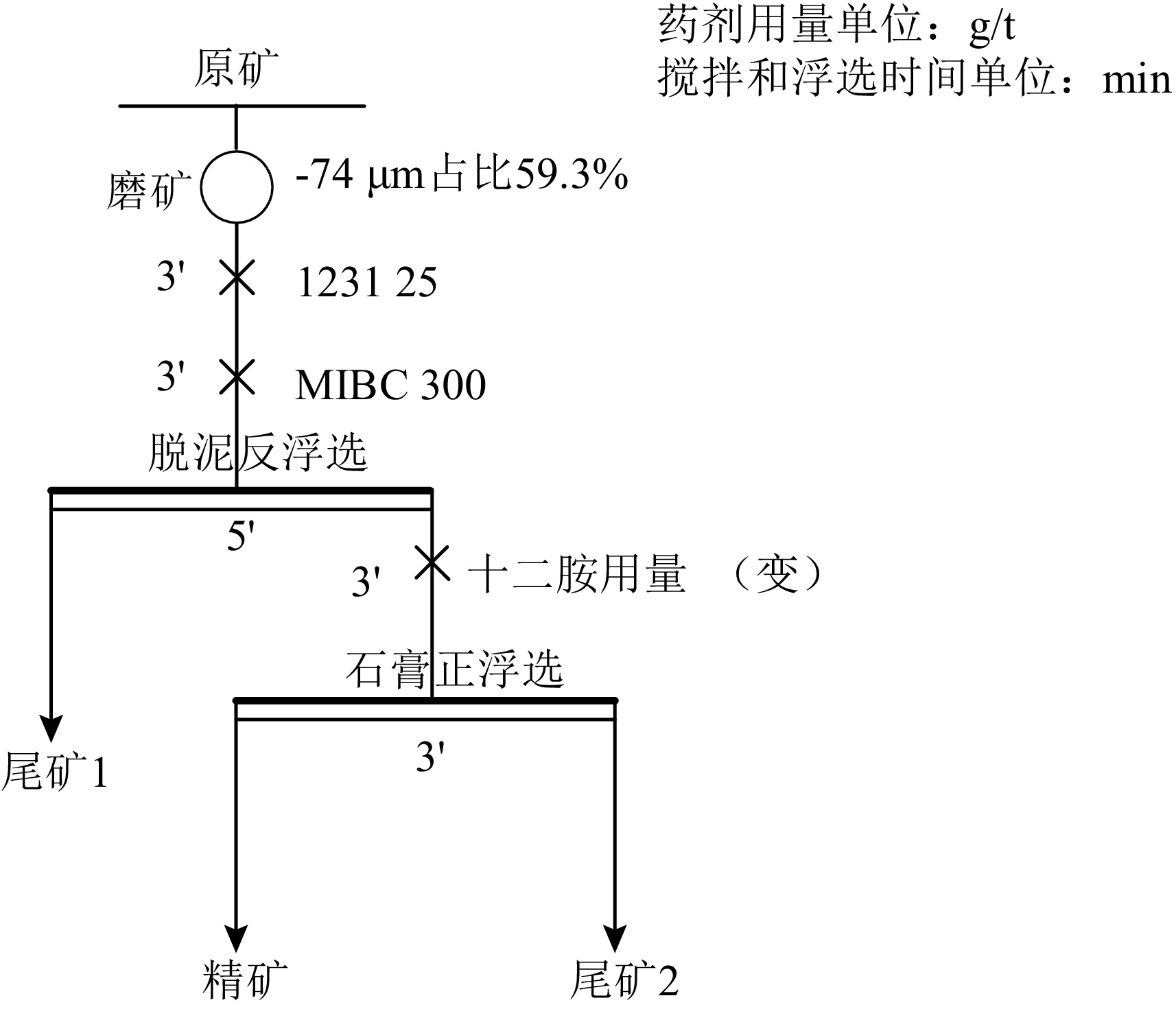

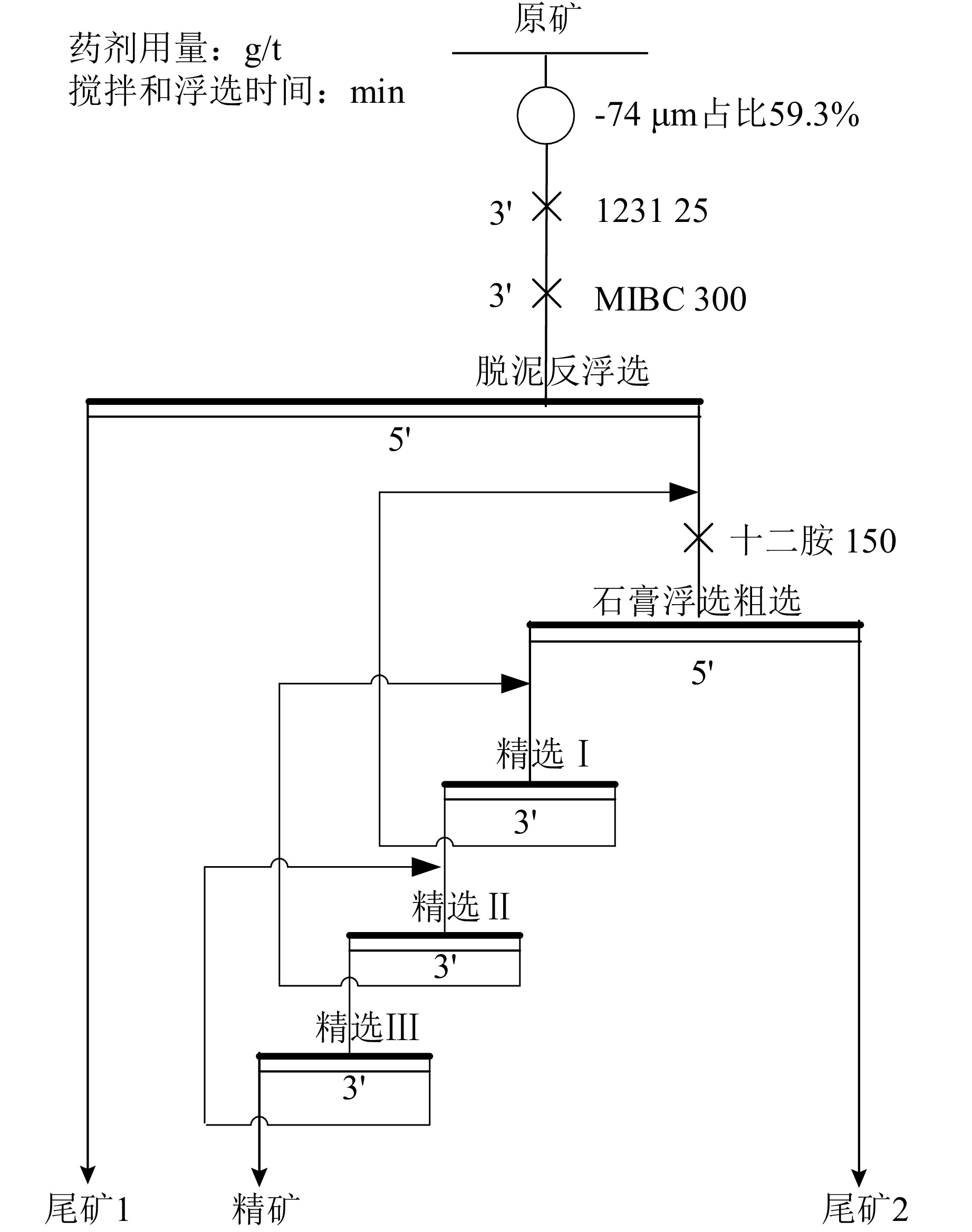

磷石膏是磷化工行业产生的大宗工业固废,其中的杂质会降低磷石膏制备β−半水石膏的性能。采用浮选法对磷石膏进行净化提纯,并对比净化前后磷石膏所制备β−半水石膏的性能。研究结果表明:采用甲基异丁基甲醇为起泡剂反浮选可脱除微细矿泥及有机杂质,采用十二胺可浮出二水石膏。闭路浮选精矿与磷石膏原矿相比,白度从19.4%提升到41.1%,纯度从73.12%提升到96.41%。利用磷石膏精矿制备β−半水石膏的2 h抗折强度、2 h抗压强度、3 d干抗压强度和原样制备的相比分别提升22.8%、14.1%、24.1%,白度从27.8%提升到46.3%。采用浮选净化能显著提高磷石膏制备β−半水石膏的性能。

Abstract:Phosphogypsum produced by phosphorus chemical industry is the bulk industrial solid waste. The impurities would reduce the performance of β−hemihydrate gypsum that was prepared from phosphogypsum. In this study, phosphogypsum was purified by flotation method, and the performance of β−hemihydrate gypsum prepared from phosphogypsum before and after purification was compared. The results showed that the fine slime and organic impurities were removed by reverse flotation with methyl isobutyl methanol as foaming agent, and the dihydrate gypsum was floated by dodecamine. Compared with phosphogypsum ore, the whiteness and purity of the concentrate increased from 19.4% to 41.1% and 73.12% to 96.41%, respectively. The 2−hour flexural strength, compressive strength and 3−day dry compressive strength of β−gypsum that was prepared from phosphogypsum concentrate were 22.8%, 14.1% and 24.1% higher than those was prepared from raw ore, respectively. Whiteness increased from 27.8% to 46.3%. Flotation purification can significantly improve the performance of phosphogypsum in β−gypsum preparation.

-

Key words:

- phosphogypsum /

- flotation /

- purification /

- β gypsum /

- strength

-

-

表 1 磷石膏原料化学成分XRF分析结果

Table 1. XRF analysis results of phosphogypsum raw ores

/% 元素 SO3 CaO SiO2 P2O5 Al2O3 Fe2O3 SrO K2O TiO2 BaO Na2O ZnO 含量 49.33 41.31 5.03 1.49 1.42 0.58 0.35 0.19 0.10 0.07 0.07 0.01 表 2 开路试验结果

Table 2. Results of open circuit test

产品名称 产率/% CaSO4·2H2O 纯度/% 白度/% 磷石膏精矿 41.25 94.37 40.5 中矿1 6.20 90.14 35.4 中矿2 11.75 91.36 36.1 中矿3 16.45 93.29 39.8 尾矿1 21.27 69.31 17.4 尾矿2 3.08 72.67 20.5 磷石膏原矿 100 73.12 19.4 表 3 闭路试验结果

Table 3. Results of close circuit test

产品 SO3/% CaO/% SiO2/% P2O5/% Al2O3/% Fe2O3/% 产率/% 白度/% 纯度/% 可溶磷含量/% 可溶氟含量/% 精矿 51.64 42.88 2.76 1.17 0.72 0.30 67.98 41.1 96.41 0.07 0.18 尾矿1 45.27 34.13 11.93 2.07 3.39 1.77 22.84 18.3 71.46 − − 尾矿2 48.70 38.12 4.51 2.81 2.51 0.89 9.18 18.7 74.83 − − 原矿 49.33 41.31 5.03 1.49 1.42 0.58 100 19.4 73.12 0.48 0.54 表 4 净化前后磷石膏制备建筑石膏块性能对比

Table 4. Properties comparison of β−hemihydrous gypsum blocks prepared by phosphogypsum before and after purification

性能 β−半水石膏

(原矿)β−半水石膏

(精矿)提升幅度/% 白度/% 27.8 46.3 66.5 2h抗折强度/MPa 2.67 3.28 22.8 2h抗压强度/MPa 8.11 9.25 14.1 3d干抗压强度/MPa 13.26 16.45 24.1 -

[1] 彭家惠, 彭志辉, 张建新, 等. 磷石膏中可溶磷形态、分布及其对性能影响机制的研究[J]. 硅酸盐学报, 2000, 28(4): 309−313.

PENG J H, PENG Z H, ZHANG J X, et al. Study on the form and distribution of water−soluble P2O5 in phosphogypsum and effective mechanism of properties[J]. Journal of the Chinese Ceramic Society, 2000, 28(4): 309−313.

[2] 董泽, 翟延波, 任志威, 等. 磷石膏建材资源化利用研究进展[J]. 无机盐工业, 2022, 54(4): 5−9.

DONG Z, ZHAI Y B, REN Z W, et al. Research progress on phosphogypsum utilization in building materials[J]. Inorganic Chemicals Industry, 2022, 54(4): 5−9.

[3] WU F, REN Y, QU G, et al. Utilization path of bulk industrial solid waste: a review on the multi−directional resource utilization path of phosphogypsum[J]. Journal of Environmental Management, 2022, 313: 0301−4797.

[4] 李铭, 梁欢, 随婕斐, 等. 我国磷石膏资源化利用进展及前景展望[J]. 磷肥与复肥, 2020, 35(7): 30−36.

LI M, LIANG H, SUI J F. Progress and prospect of comprehensive utilization of phosphogypsum in China[J]. Phosphate & Compound Fertilizer, 2020, 35(7): 30−36.

[5] 吴道丽. 磷石膏作为水泥缓凝剂的应用研究[J]. 环境科学导刊, 2008, 27(6): 76−77.

WU D L. Study on application of phosphogypsum as cement retarder[J]. Environmental science survey, 2008, 27(6): 76−77.

[6] CHERNYSHY. Recycling of radioactive phosphogypsum wastes[J]. Advances in the Toxicity of Construction and Building Materials, 2022, 10: 225−240.

[7] 李青霄, 张心会, 徐开东, 等. α石膏、β石膏、铁尾矿砂制备自流平砂浆及其性能研究[J]. 新型建筑材料, 2022, 49(9): 149−153.

LI Q X, ZHANG X H, XU K D, et al. Study on self−leveling mortar prepared by α, β gypsums and iron tailings sand and its properties[J]. New Building materials, 2022, 49(9): 149−153.

[8] 吴照洋, 张永兴, 张利珍, 等. β石膏相组成和杂质含量对其性能的影响[J]. 无机盐工业, 2021, 53(9): 67−71.

WU Z Y, ZHANG Y X, ZHANG L Z, et al. Effect of phase composition and impurity content of β−gypsum on its properties[J]. Inorganic Chemicals Industry, 2021, 53(9): 67−71.

[9] 杨敏, 钱觉时, 王智, 等. 杂质对磷石膏应用性能的影响[J]. 材料导报, 2007(6): 104−106.

YANG M, QIAN J S, WANG Z, et al. Effect of impurities on the working performance of phosphogypsum[J]. Materials Reports, 2007(6): 104−106.

[10] 杨敏. 杂质对不同相磷石膏性能的影响[D]. 重庆: 重庆大学, 2009.

YANG M, Effect of Impurities on the properties of phosphogypsum with different forms[D], Chongqing: Chongqing University, 2009.

[11] 张婧, 孟醒, 唐永波, 等. 磷石膏杂质处理及综合利用研究进展[J]. 磷肥与复肥, 2021, 36(9): 25−28.

ZHANG J, MENG X, TANG Y B, et al. Research progress of phosphogypsum impurity treatment and comprehensive utilization[J]. Phosphate & Compound Fertilizer, 2021, 36(9): 25−28.

[12] 黄照昊, 罗康碧, 李沪萍. 磷石膏中杂质种类及除杂方法研究综述[J]. 硅酸盐通报, 2016(5): 1504−1508.

HANG Z H, LUO K B, LI H P. Types of impurity in phosphogypsum and the method of removing impurity research review[J]. Bulletin of The Chinese Ceramic Society, 2016(5): 1504−1508.

[13] 董铭, 肖立华. 磷石膏制备建筑石膏的试验研究[J]. 云南化工, 2015, 42(3): 24−27.

DONG M, XIAO L H. Experimental study of producing gypsum powder with phosphogypsum[J]. Yunnan Chemical Technology, 2015, 42(3): 24−27.

[14] 耿庆钰. 磷石膏制备硫酸钙晶须[D]. 昆明: 昆明理工大学, 2017

GENG Q Y, Phosphorite preparation of calcium sulfate whiskers[D]. Kunming: Kunming University of Science and Technology, 2017

[15] 方竹堃. 磷石膏高效水洗净化处理技术[J]. 云南化工, 2023, 50(2): 114−116.

FANG Z K. High Efficiency water washing purification technology of phosphogypsum[J]. Yunnan Chemical Technology, 2023, 50(2): 114−116.

[16] 朱志伟, 何东升, 陈飞, 等. 磷石膏预处理与综合利用研究进展[J]. 矿产保护与利用, 2019(4): 19−25.

ZHU Z W, HE D S, CHEN F. Research progress on pretreatment and comprehensive utilization of phosphogypsum[J]. Conservation and Utilization of Mineral Resources, 2019(4): 19−25.

[17] 马林转, 宁平, 杨月红, 等. 磷石膏预处理工艺综述[J]. 磷肥与复肥, 2007, 22(3): 62−63.

MA L Z, NING P, YANG Y H. Review on the technology of phosphogypsum pretreatment[J]. Phosphate & Compound Fertilizer, 2007, 22(3): 62−63.

[18] 沈维云, 郑光明, 孙桦林, 等. 磷石膏提纯增白试验研究[J]. 磷肥与复肥, 2022, 37(2): 5−6.

SHEN W Y, ZHENG G M, SUN H L, et al. Experimental study on purification and whitening of phosphogypsum[J]. Phosphate & Compound Fertilizer, 2022, 37(2): 5−6.

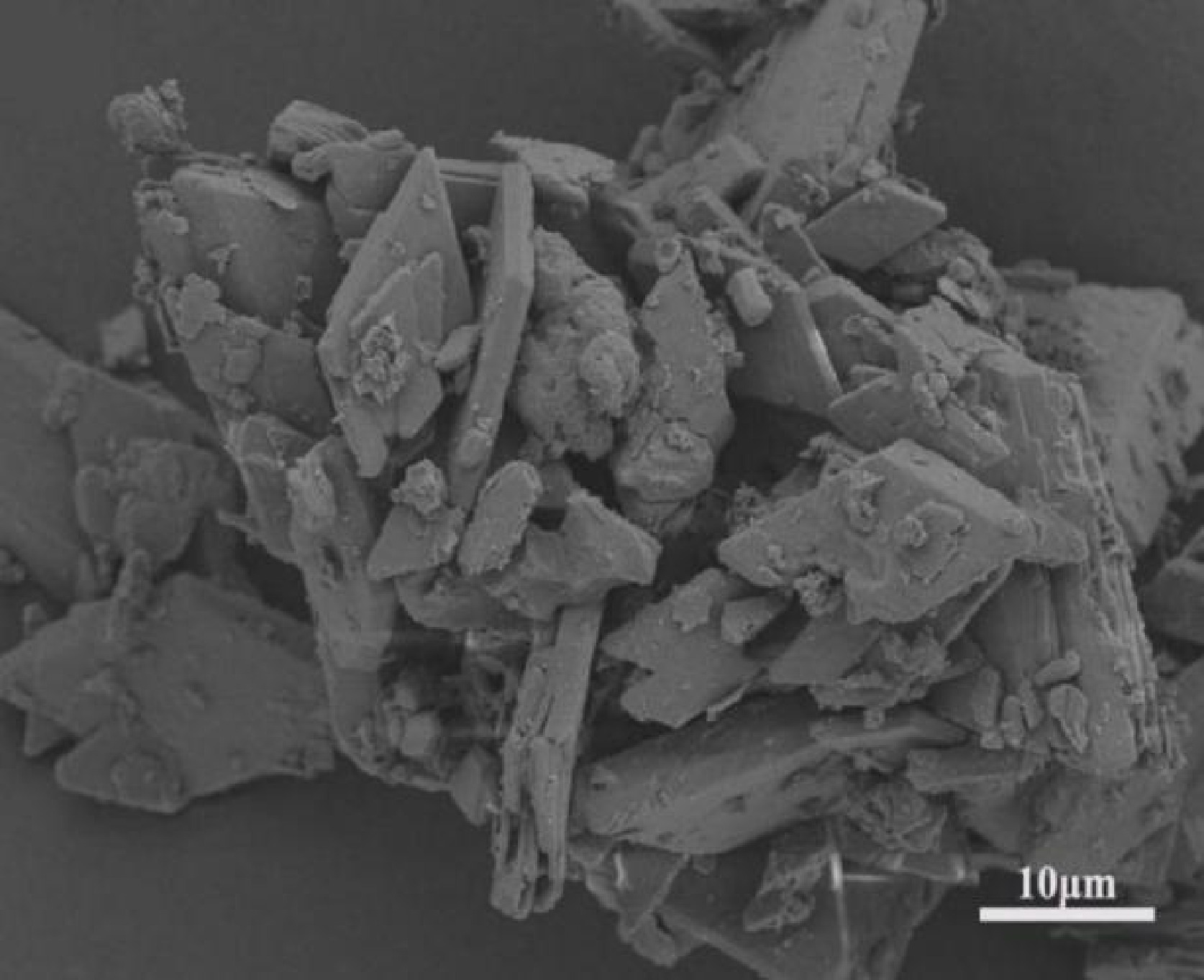

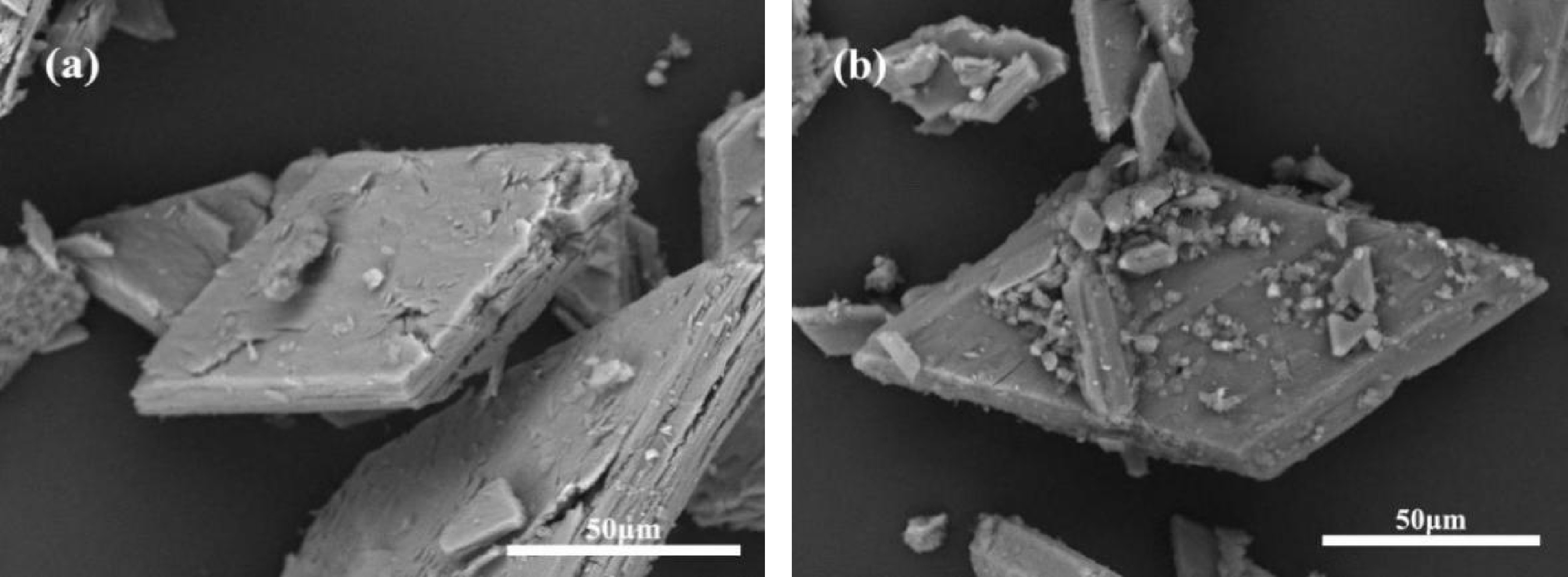

[19] 杜明霞, 王进明, 董发勤, 等. 磷石膏工艺矿物学特征与可选性关系研究[J]. 非金属矿, 2020, 43(6): 52−55.

DU M X, WANG J M, DONG F Q, et al. Technological mineralogical characteristics of phosphogypsum[J]. Non−Metallic Mines, 2020, 43(6): 52−55.

[20] 卢烁十, 孙传尧. 几种硫酸盐矿物可浮性的晶体化学研究[J]. 金属矿山, 2008, 383(5): 49−52.

LU S S, SUN C Y. Study on crystal chemistry of flotation ability of several sulfate minerals[J]. Metal Mine, 2008, 383(5): 49−52.

-

下载:

下载: