Research and Molecular Dynamics Simulation of Efficient Flotation of Scheelite with Ternary Combined Collector Based on BHA

-

摘要:

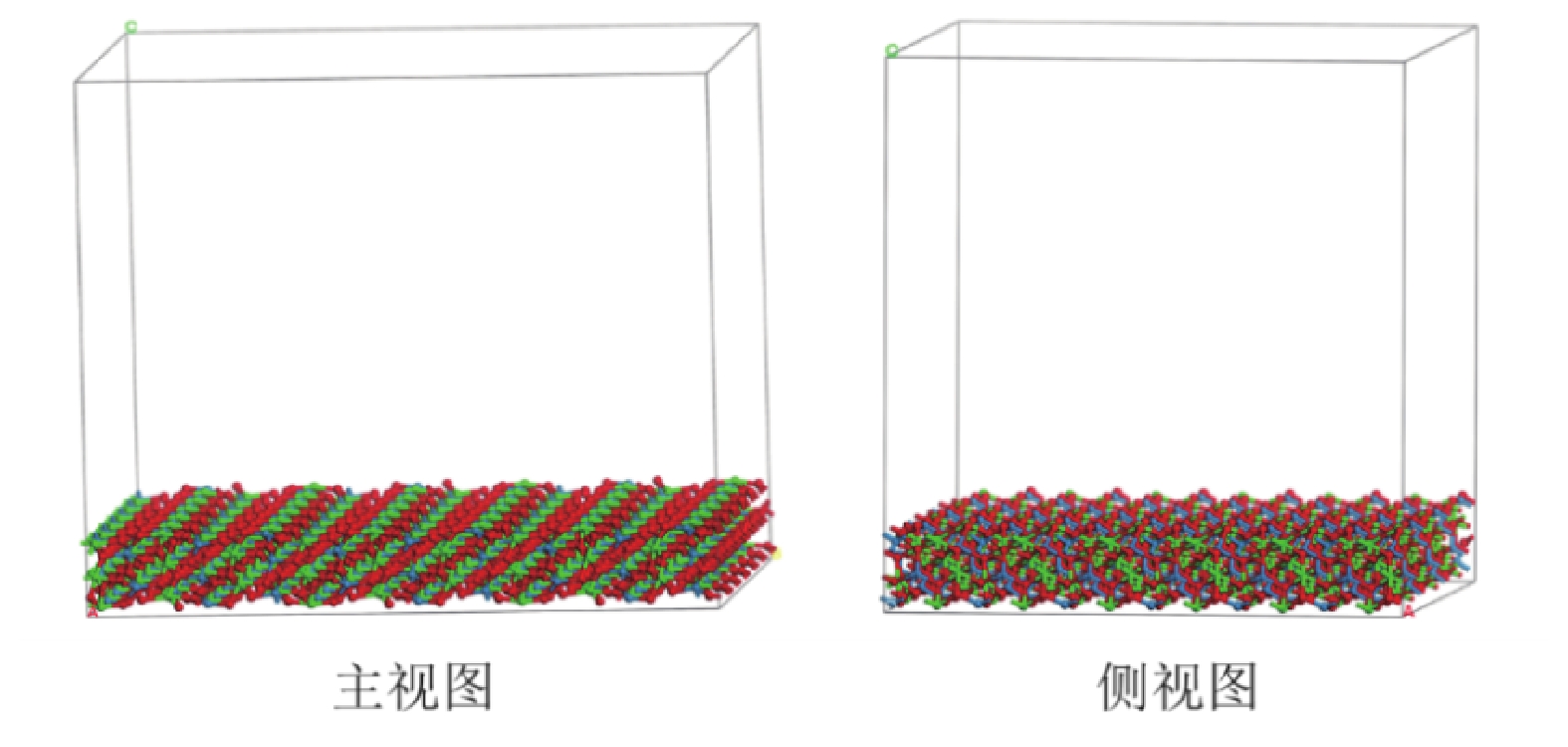

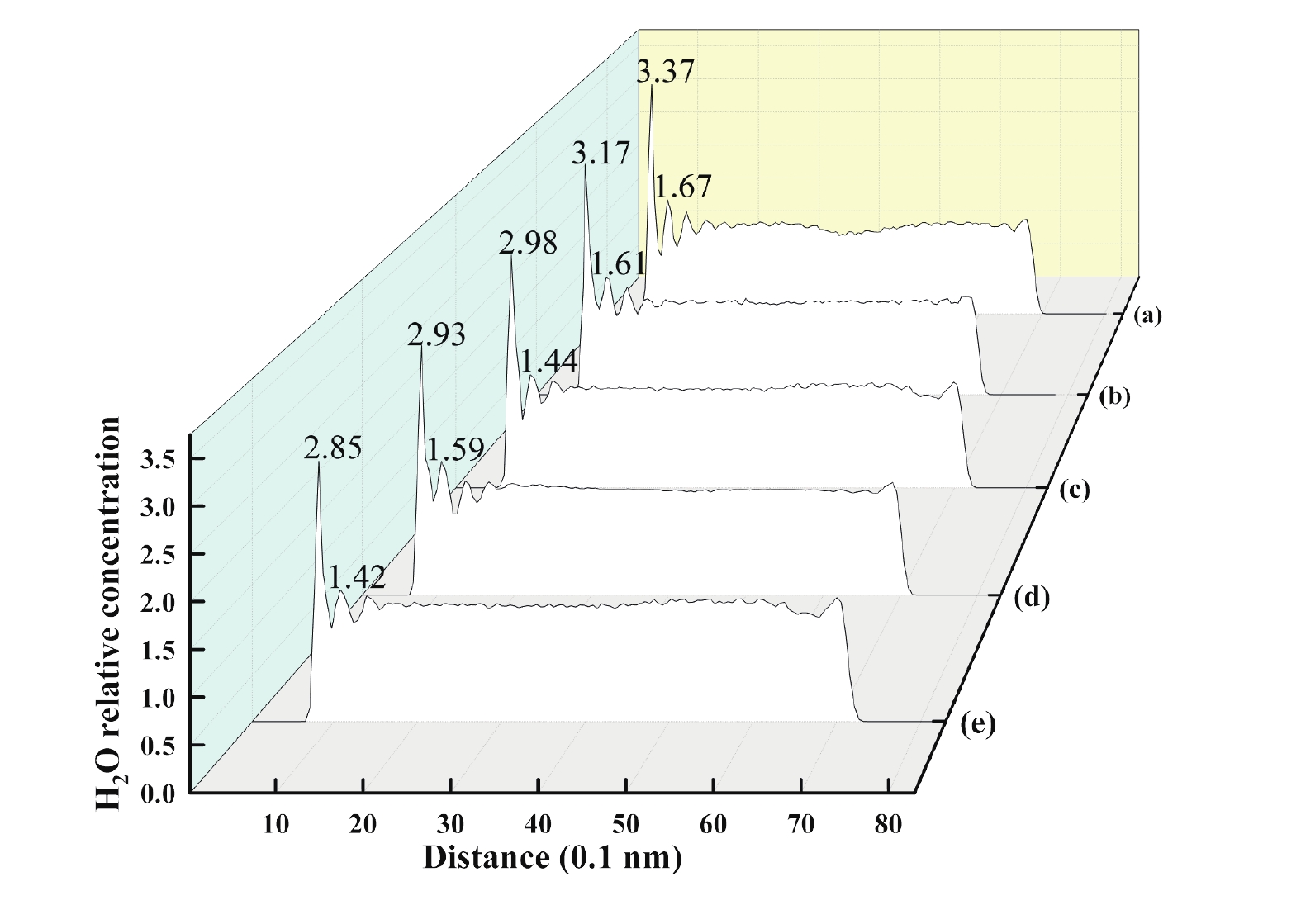

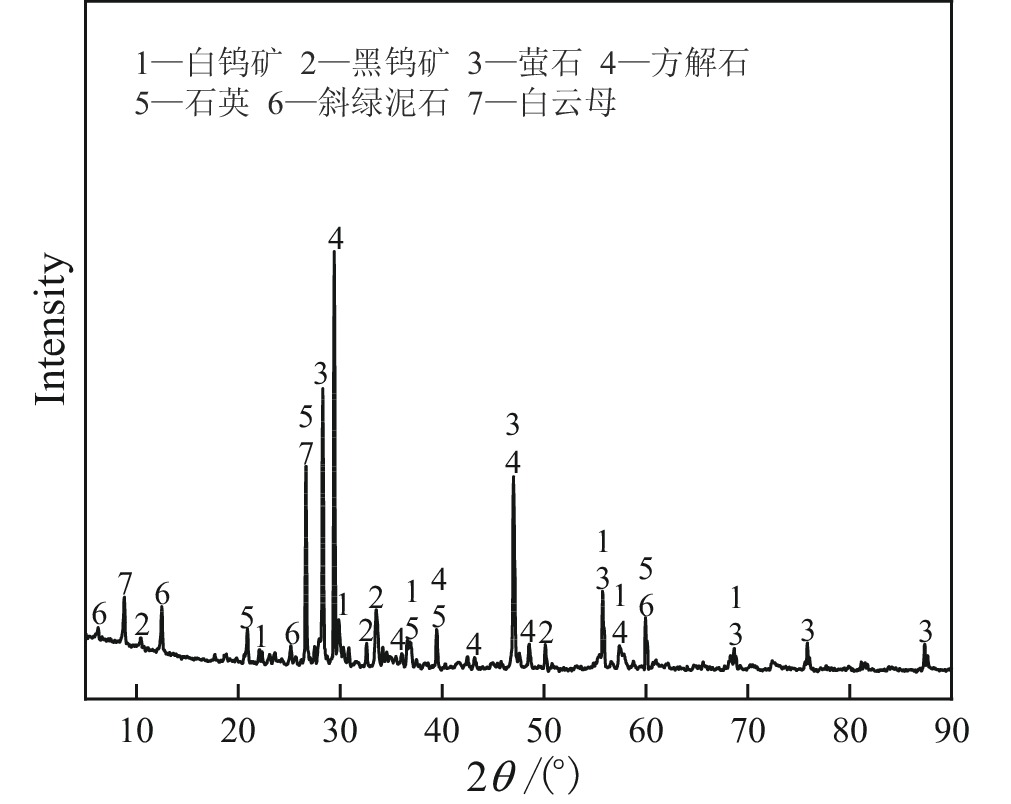

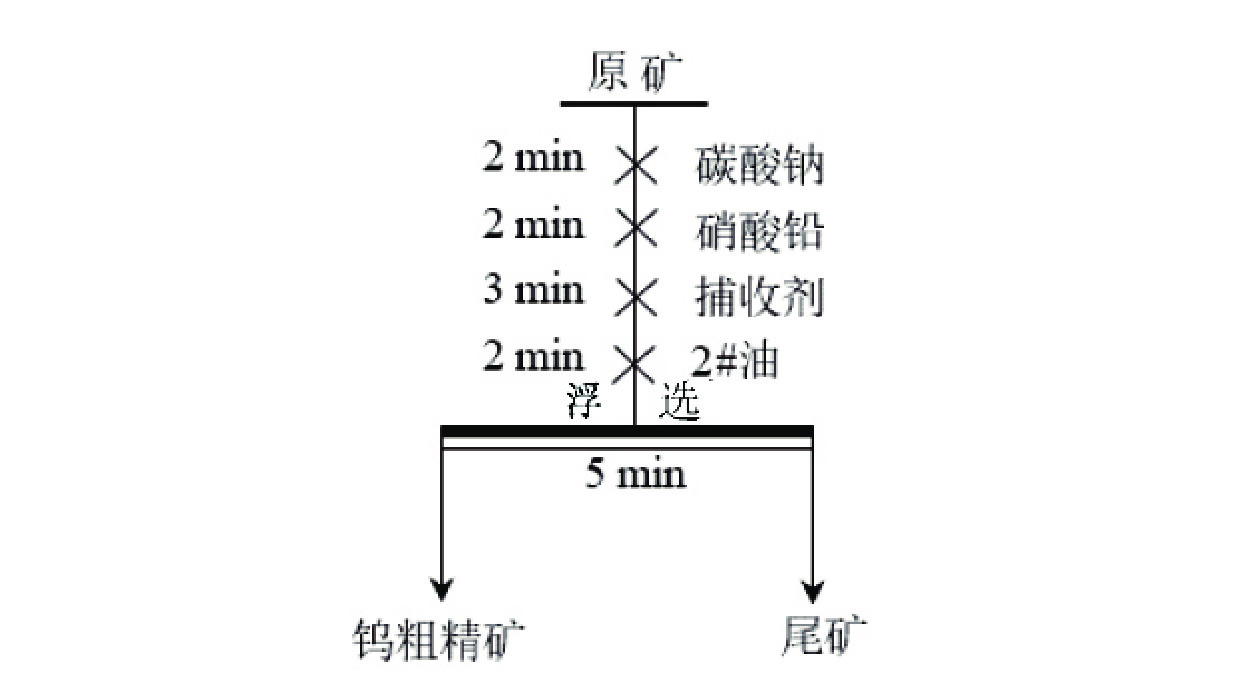

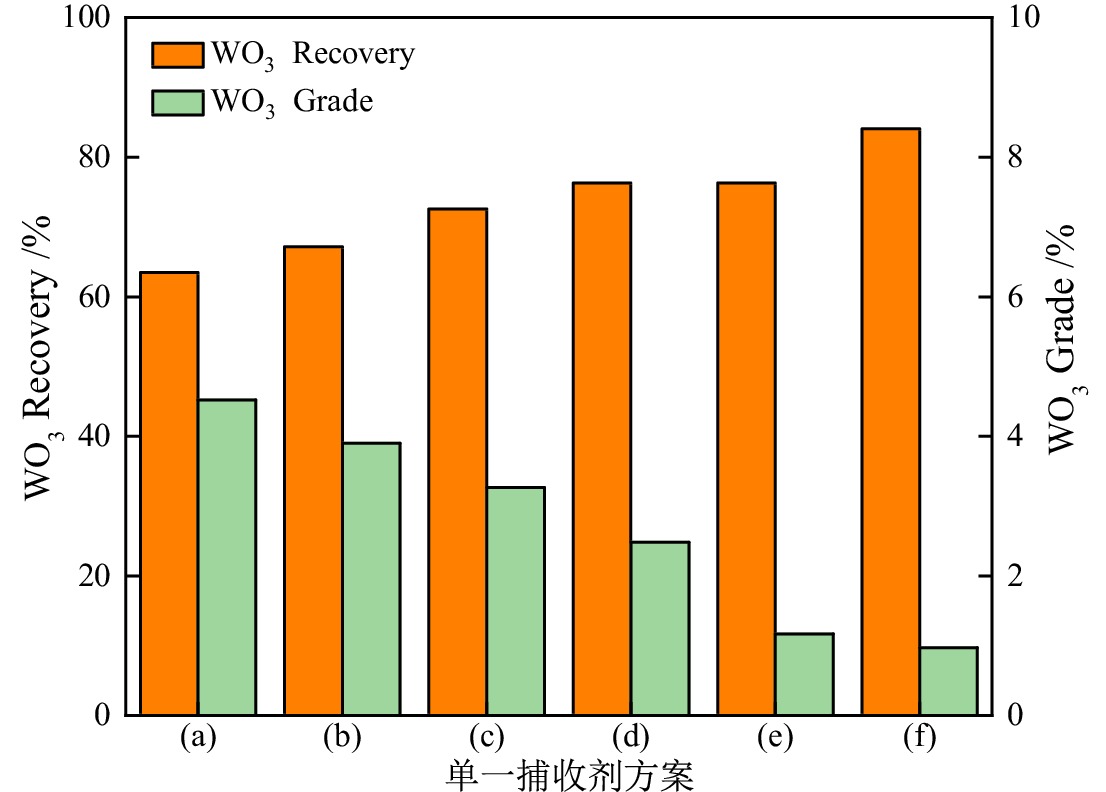

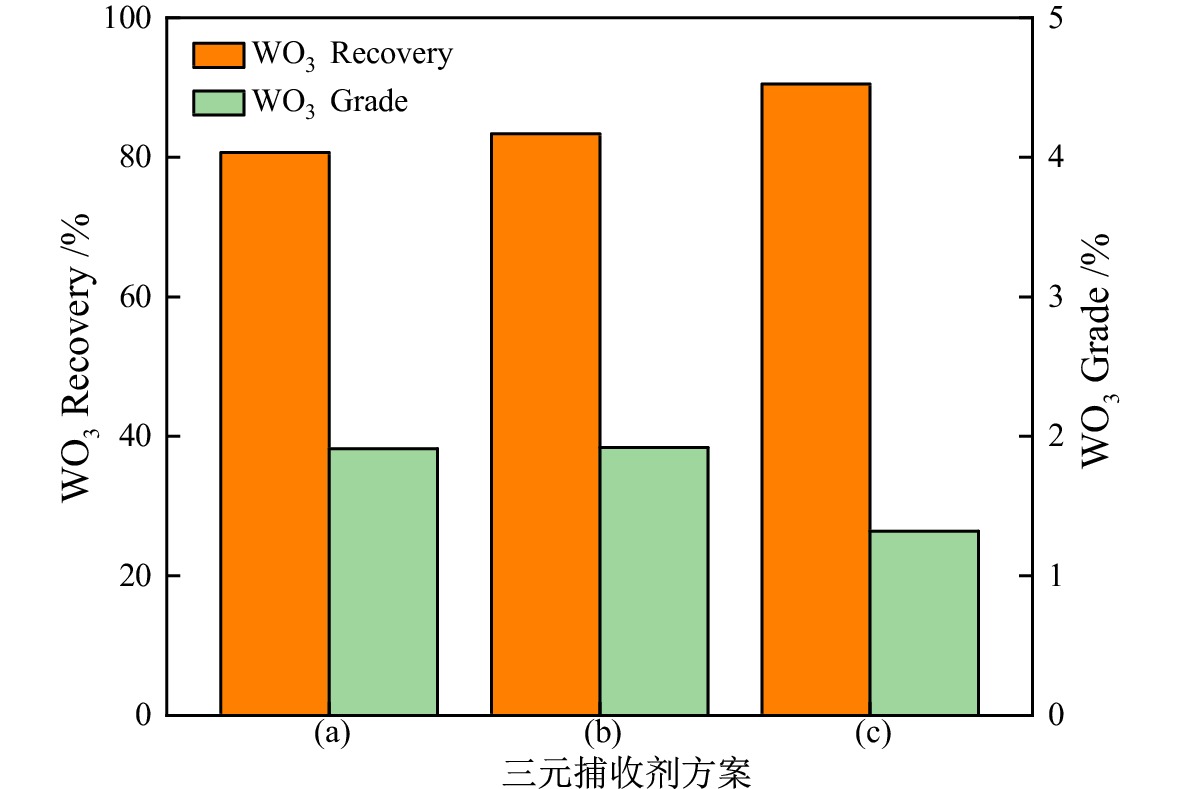

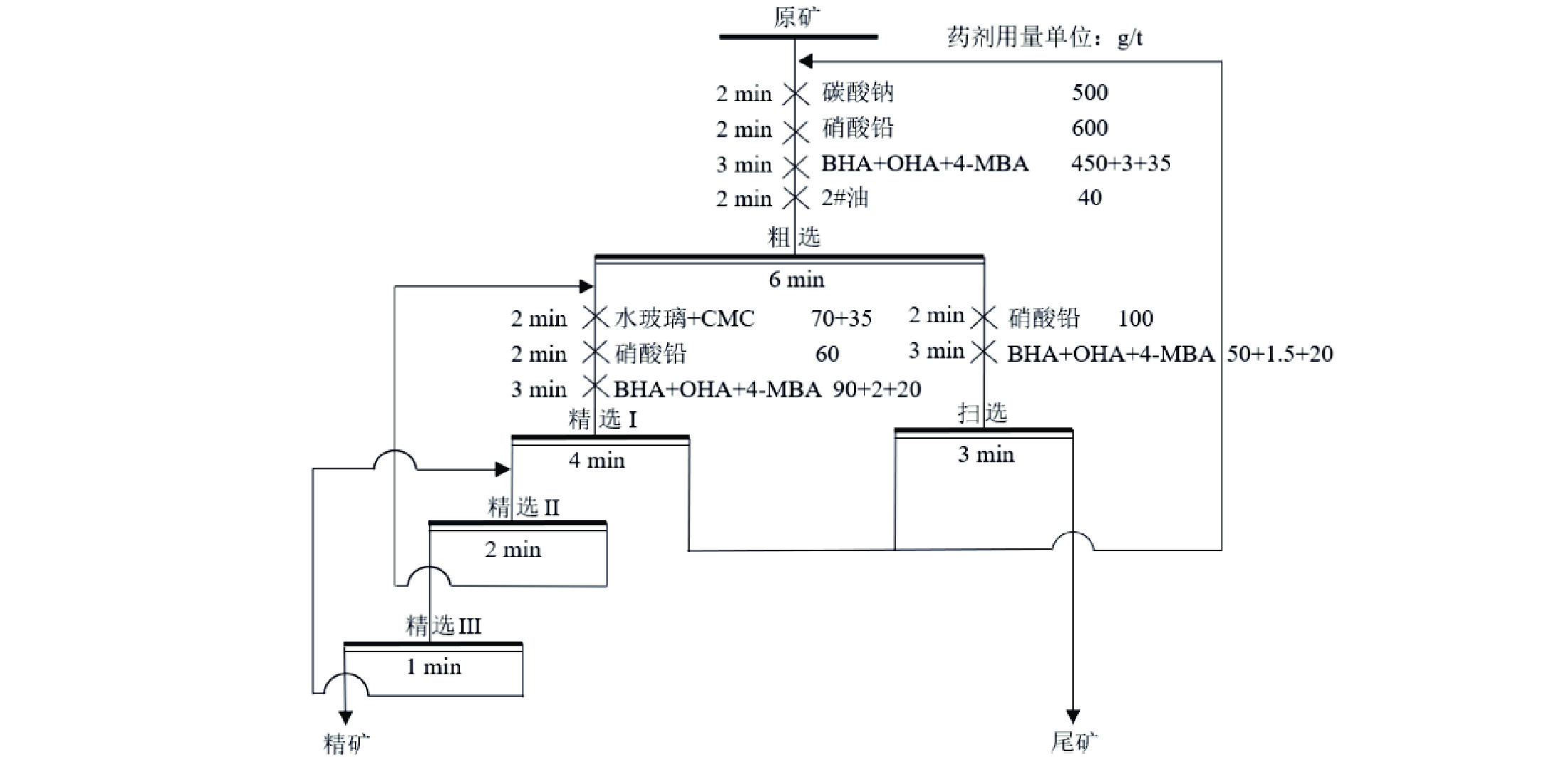

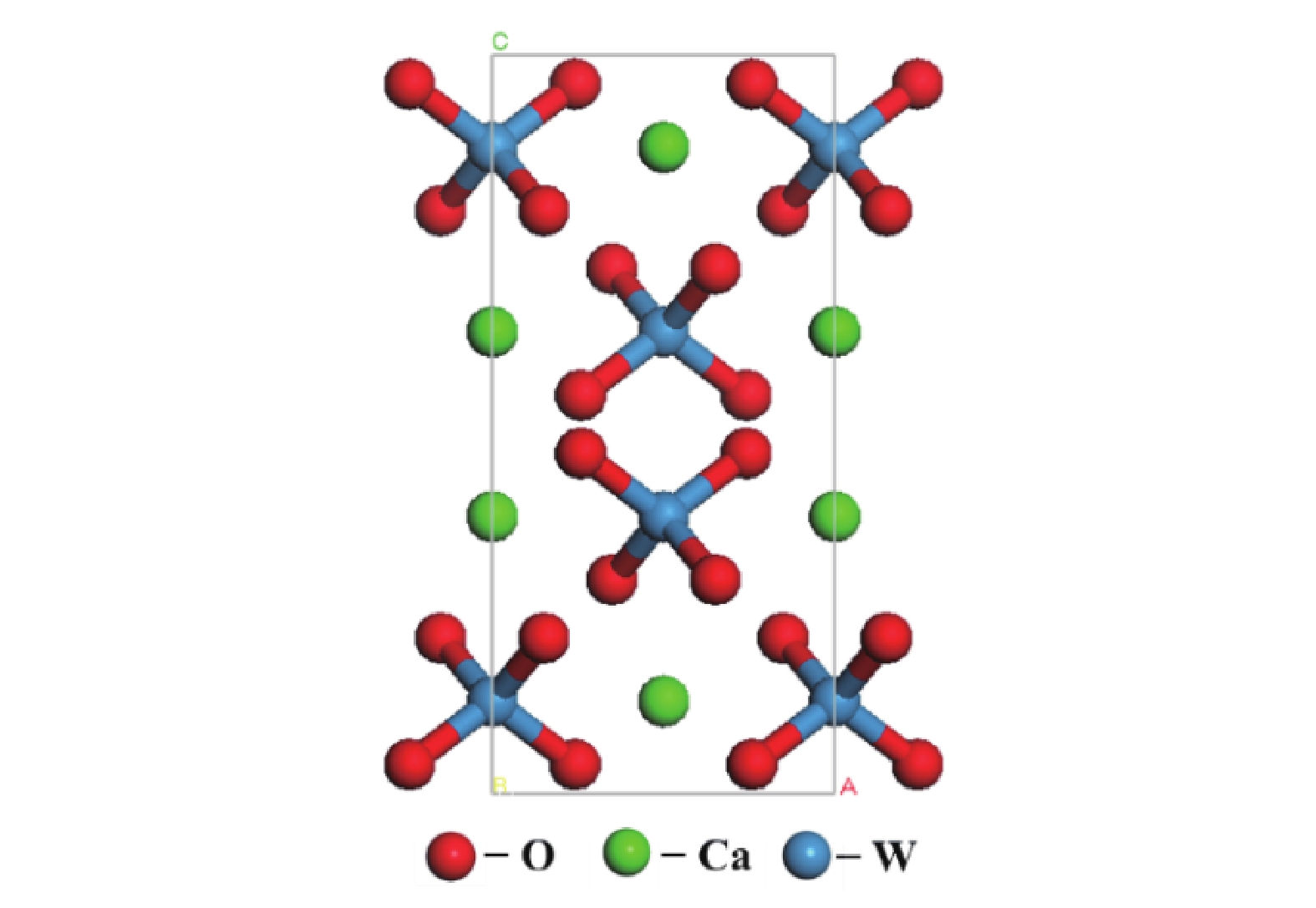

羟肟酸是常见的白钨矿浮选捕收剂,由于其价格高、用量大导致浮选成本偏高。为实现白钨矿的低成本高效浮选,提出一种降本增效的白钨矿浮选三元组合捕收剂:苯甲羟肟酸(BHA)+R−苯甲酸(4−MBA)+辛基羟肟酸(OHA)。采用分子动力学模拟计算方法证实了该组合捕收剂在白钨矿浮选体系中存在协同作用;同时,通过实际矿石浮选实验,进一步验证了组合捕收剂对白钨矿有着良好的捕收性能。分子动力学模拟结果表明,随着捕收剂种类的增加,白钨矿(112)表面水分子相对浓度也随之降低,矿物表面疏水性增强;当捕收剂体系为BHA+OHA+4−MBA的三元组合捕收剂时,白钨矿表面水分子相对浓度最低,表明该三元组合捕收剂间存在协同作用,使矿物表面表现出更强的疏水性。针对某复杂低品位白钨矿进行了浮选试验,结果表明,在BHA浮选白钨矿体系中加入BHA用量11.11%的4-MBA,有效提高了BHA对白钨矿的浮选效果,在保障回收率的同时,BHA用量约降低40%;而BHA用量2.22%的OHA与BHA组合后,白钨矿的浮选回收率约提高20百分点,同时改善了浮选泡沫层。在BHA+OHA+4−MBA的三元组合捕收剂体系中,综合了两种不同的协同作用效果,使钨粗精矿的品位与回收率均达到最佳值。在使用水玻璃与羧甲基纤维素(CMC)组合作为抑制剂,经一粗一扫三精的闭路浮选实验后得到WO3品位为28.55%、WO3回收率为72.04%的钨精矿;与现场使用苯甲羟肟酸单一捕收剂相比,钨精矿的品位与回收率分别提高了3百分点与4百分点左右,捕收剂用量降低了37.5%。在提高白钨矿回收率的同时显著降低了浮选药剂成本,实现了白钨矿的高效回收。

Abstract:The hydroxamic acid reagents are extremely pervasive in the collector of scheelite flotation. Due to its high price and large dosage, the flotation cost of scheelite is high. To achieve cost−effective and efficient flotation of scheelite, this study proposes a ternary combined collector for scheelite flotation: benzohydroxamic acid (BHA)+R−benzoic acid (4−MBA)+octyl hydroxamic acid (OHA). The synergistic effect of the combined collector in the scheelite flotation system was confirmed by molecular dynamics simulation. Meanwhile, it was further verified that the combined collector has good collection performance for scheelite through actual ore flotation experiments. Molecular dynamics simulation results indicate that as the variety of collector increases, the relative concentration of water molecules on the scheelite (112) surface decreases, enhancing hydrophobicity. The lowest relative concentration of water molecules on the scheelite surface was observed under the ternary combined collector system. This suggests a synergistic effect among the ternary combined collectors, resulting in a stronger hydrophobicity on the mineral surface. The flotation test was conducted on a complex low−grade scheelite ore. The results showed that the addition of 4−MBA at a dosage of 11.11% in the BHA flotation scheelite system effectively improved the flotation effect of BHA on the scheelite ore, while reducing the BHA dosage by approximately 37.5% while ensuring the flotation recovery. When OHA at a dosage of 2.22% was combined with BHA, the flotation recovery of scheelite ore increased by about 20%, and the flotation foam layer was improved. The best flotation effect was exhibited under the ternary combination of BHA+OHA+4−MBA. Using water glass and carboxymethyl cellulose (CMC) as depressants, a closed−circuit flotation test consisting of roughing, scavenging, and three stages of cleaning can obtain scheelite concentrate with a WO3 grade of 28.55% and a WO3 recovery of 72.04%. Compared to using benzohydroxamic acid as a single collector on site, the grade and recovery of scheelite concentrate increased by approximately 3% and 4%, respectively, while reducing the collector dosage by 37.5%. Therefore, the ternary combined collector can significantly reduce the cost of flotation reagent while improving the recovery of scheelite, and realize the efficient recovery of scheelite.

-

Key words:

- combined collector /

- scheelite /

- molecular dynamics simulation /

- flotation /

- BHA

-

-

表 1 优化前后白钨矿晶体的晶格参数

Table 1. Lattice parameters of scheelite crystal after geometric optimization

项目 a=b/nm c/nm α=β=γ/(°) Z 实验值[21] 0.5243 1.1376 90 4 优化值 0.5240 1.1371 90 4 表 2 白钨矿样品化学多元素分析结果

Table 2. Chemical multi−element analysis results of sample

/% 元素 WO3 Ca F S Si Al 含量 0.40 42.80 11.40 0.17 20.00 7.40 表 3 钨的物相分析结果

Table 3. Results of tungsten phase analysis

/% 钨相 白钨矿 黑钨矿 钨华 总钨 WO3 含量 0.35 0.04 0.01 0.40 WO3 分布率 85.89 10.64 3.47 100.00 表 4 闭路实验结果

Table 4. Results of closed−circuit test

产物名称 产率/% WO3品位/% WO3回收率/% 精矿 0.95 28.55 72.04 尾矿 99.05 0.11 27.96 共计 100.00 0.38 100.00 -

[1] YANG, X S. Beneficiation studies of tungsten ores – a review[J]. Minerals Engineering, 2018, 125: 111−119. doi: 10.1016/j.mineng.2018.06.001

[2] 王军. 高性能钨合金制备技术研究现状[J]. 有色金属材料与工程, 2019, 40(4): 53−60.

WANG J. Research status on preparation techniques of high−performance tungsten alloys[J]. Nonferrous Metal Materials and Engineering, 2019, 40(4): 53−60.

[3] 初阳. 钨合金的各种用途[J]. 有色金属材料与工程, 1982(1): 89−90.

CHU Y. The various uses of tungsten alloys[J]. Nonferrous Metal Materials and Engineering, 1982(1): 89−90

[4] U. S. Geological Survey. Mineral commodity summaries 2024[R/OL]. [2023−01−31].https://doi.org/10.3133/mcs2023.

[5] 殷俐娟. 我国钨资源现状与政策效应[J]. 中国矿业, 2009, 18(11): 1−3. doi: 10.3969/j.issn.1004-4051.2009.11.001

YIN L J. The status of tungsten resources and policy effects in China[J]. China Mining Magazine, 2009, 18(11): 1−3. doi: 10.3969/j.issn.1004-4051.2009.11.001

[6] 王明燕, 贾木欣, 肖仪武, 等. 中国钨矿资源现状及可持续发展对策[J]. 有色金属工程, 2014, 4(2): 76−80. doi: 10.3969/j.issn.2095-1744.2014.02.018

WANG M Y, JIA M X, XIAO Y W, et al. The current situation of tungsten resources in China and sustainable development strategies[J]. Nonferrous Metals Engineering, 2014, 4(2): 76−80. doi: 10.3969/j.issn.2095-1744.2014.02.018

[7] 赵可可, 戴惠新, 龚志辉, 等. 白钨矿浮选行为研究进展[J]. 有色金属(选矿部分), 2022(6): 155−164.

ZHAO K K, DAI H X, GONG Z H, et al. Research progress of scheelite flotation behavior[J]. Nonferrous Metals(Mineral Processing Section), 2022(6): 155−164.

[8] 李小康, 张英, 管侦皓, 等. 微细粒白钨矿浮选研究进展[J]. 矿产保护与利用, 2023, 43(2): 169−178.

LI X K, ZHANG Y, GUAN Z H, et al. Research status and prospect of flotation of fine scheelite[J]. Conservation and Utilization of Mineral Resources, 2023, 43(2): 169−178.

[9] KUPKA N, RUDOLPH M. Froth flotation of scheelite – a review[J]. International Journal of Mining Science and Technology, 2018, 28(3): 373−384. doi: 10.1016/j.ijmst.2017.12.001

[10] 卢颖, 孙胜义. 组合药剂的发展及规律[J]. 矿业工程, 2007(6): 42−44.

LU Y, SUN S Y. The development and the combined law of composite reagents[J]. Mining Engineering, 2007(6): 42−44.

[11] 刘明宝, 姚国超, 鲁力力, 等. 氧化矿和盐类矿物浮选捕收剂协同效应研究现状[J]. 矿物学报, 2022, 42(5): 649−658.

LIU M B, YAO G C, LU L L, et al. Recent status of researches on synergistic effect of floatation collector for oxidized ores and salt minerals[J]. Acta Mineralogica Sinica, 2022, 42(5): 649−658.

[12] 徐龙华, 田佳, 巫侯琴, 等. 组合捕收剂在矿物表面的协同效应及其浮选应用综述[J]. 矿产保护与利用, 2017(2): 107−112.

XU L H, TIAN J, WU H Q, et al. A review on the synergetic effect of the mixed collectors on mineral surface and its application in flotation[J]. Conservation and Utilization of Mineral Resources, 2017(2): 107−112.

[13] WANG L, HU Y, LIU J, et al. Flotation and adsorption of muscovite using mixed cationic–nonionic surfactants as collector[J]. Powder Technology, 2015, 276: 26−33. doi: 10.1016/j.powtec.2015.02.019

[14] 艾光华, 徐晓衣, 邬海滨, 等. 江西某低品位白钨矿选矿试验研究[J]. 有色金属工程, 2017, 7(1): 44−48.

AI G H, XU X Y, WU H B, et al. Experimental research on beneficiation of a low−grade scheelite in Jiangxi[J]. Nonferrous Metals Engineering, 2017, 7(1): 44−48.

[15] 黄发兰, 马英强, 印万忠, 等. 组合捕收剂浮选回收云南某白钨矿的选矿试验研究[J]. 有色金属(选矿部分), 2016(1): 78−82.

HANG F L, MA Y Q, YIN W Z, et al. Experimental study on scheelite flotation with combined collectors[J]. Nonferrous Metals(Mineral Processing Section), 2016(1): 78−82.

[16] 徐芮, 孙宁, 孙伟, 等. 分子动力学模拟在矿物浮选中的研究进展[J]. 中南大学学报(自然科学版), 2024, 55(1): 1−19.

XU R, SUN N, SUN W, et al. Research progress of molecular dynamics simulation in mineral flotation[J]. Journal of Central South University(Science and Technology), 2024, 55(1): 1−19.

[17] 郝海青, 李丽匣, 张晨, 等. 经典分子动力学模拟在矿物浮选研究中的应用[J]. 矿产保护与利用, 2018(3): 9−16.

HAO H Q, LI L X, ZHANG C, et al. Application of classic molecular dynamics simulations in minerals flotation[J]. Conservation and Utilization of Mineral Resources, 2018(3): 9−16.

[18] GAO Z Y, SUN W, HU Y H. New insights into the dodecylamine adsorption on scheelite and calcite: an adsorption model[J]. Minerals Engineering, 2015, 79: 54−61. doi: 10.1016/j.mineng.2015.05.011

[19] LIAO R P, WEN S M, LIU J, et al. Experimental and molecular dynamics simulation study on DDA/DDTC mixed collector co−adsorption on sulfidized smithsonite surfaces[J]. Minerals Engineering, 2024, 205: 108493. doi: 10.1016/j.mineng.2023.108493

[20] 汪聪, 邓建, 王建军, 等. 白钨矿晶体化学及浮选现状[J]. 金属矿山, 2021(6): 15−25.

WANG C, DENG J. WANG J J, et al. Crystal chemistry and flotation principle of scheelite[J]. Metal Mine, 2021(6): 15−25.

[21] GAO Z Y, HU Y H, SUN W, et al. Surface−charge anisotropy of scheelite crystals[J]. Langmuir, 2016, 32(25): 6282−6288. doi: 10.1021/acs.langmuir.6b01252

[22] LIAO R P, WEN S M, BAI S J, et al. Co−adsorption mechanism of isoamyl potassium xanthate and ammonium dibutyl dithiophosphate on sulfidized smithsonite in dodecylamine flotation system[J]. Separation and Purification Technology, 2024, 333: 125788.

-

下载:

下载: