Research on the Influence of Loading Rate on the Failure Characteristics of Irregular Molybdenum Ores

-

摘要:

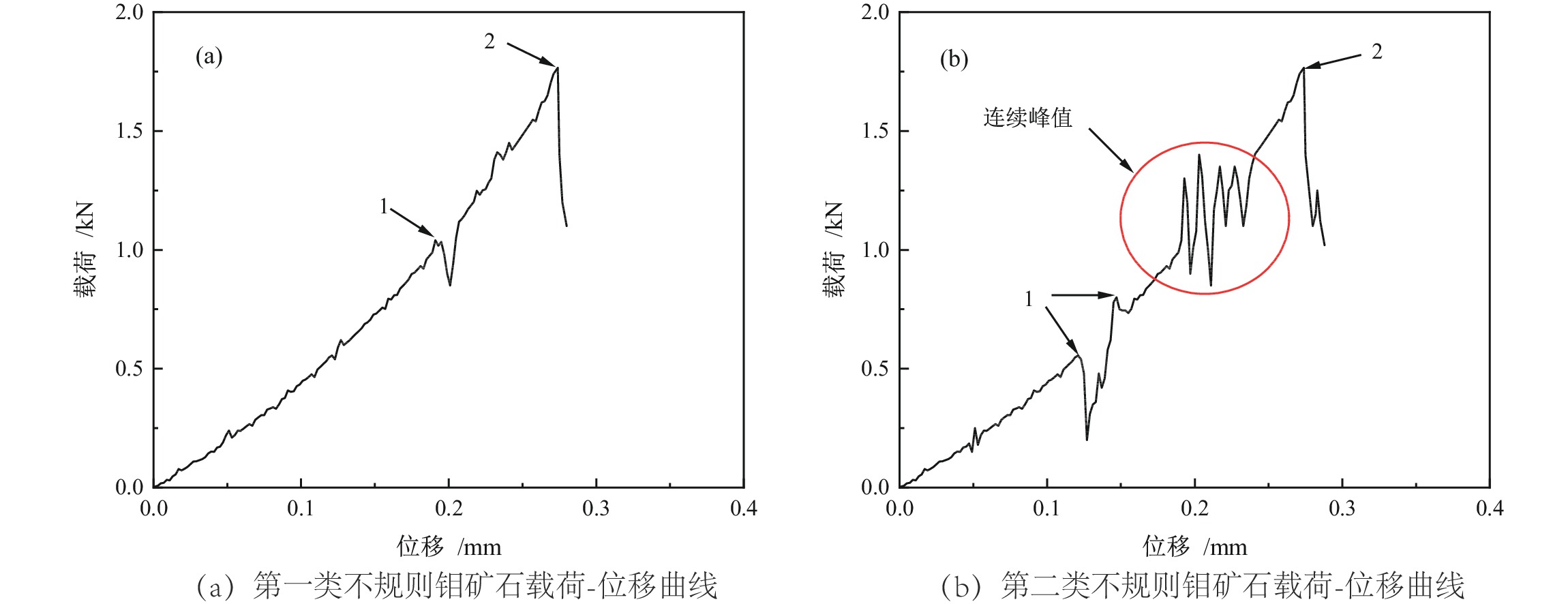

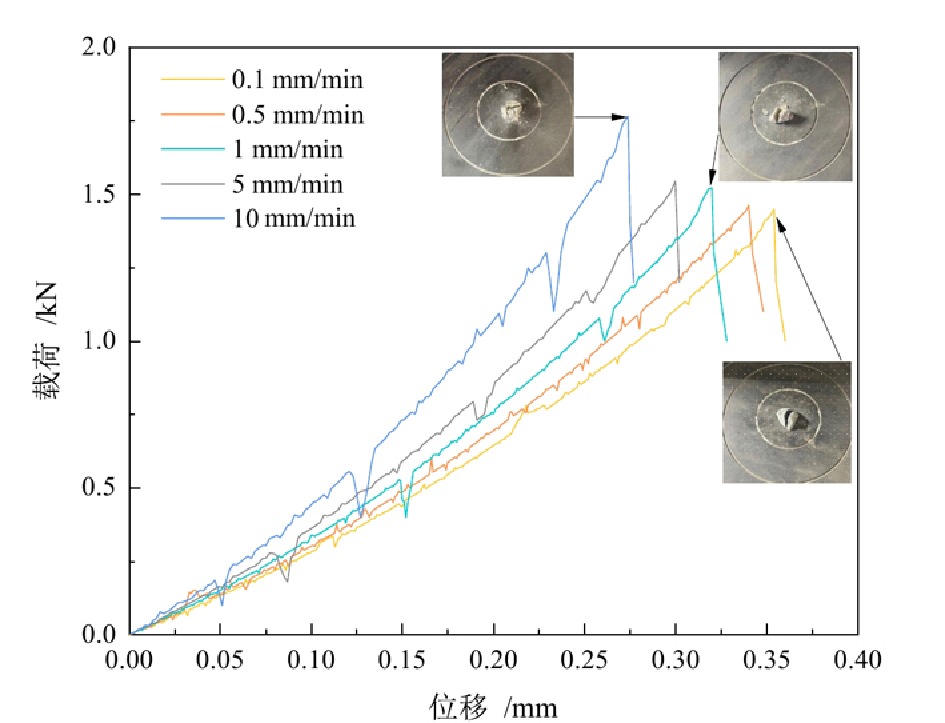

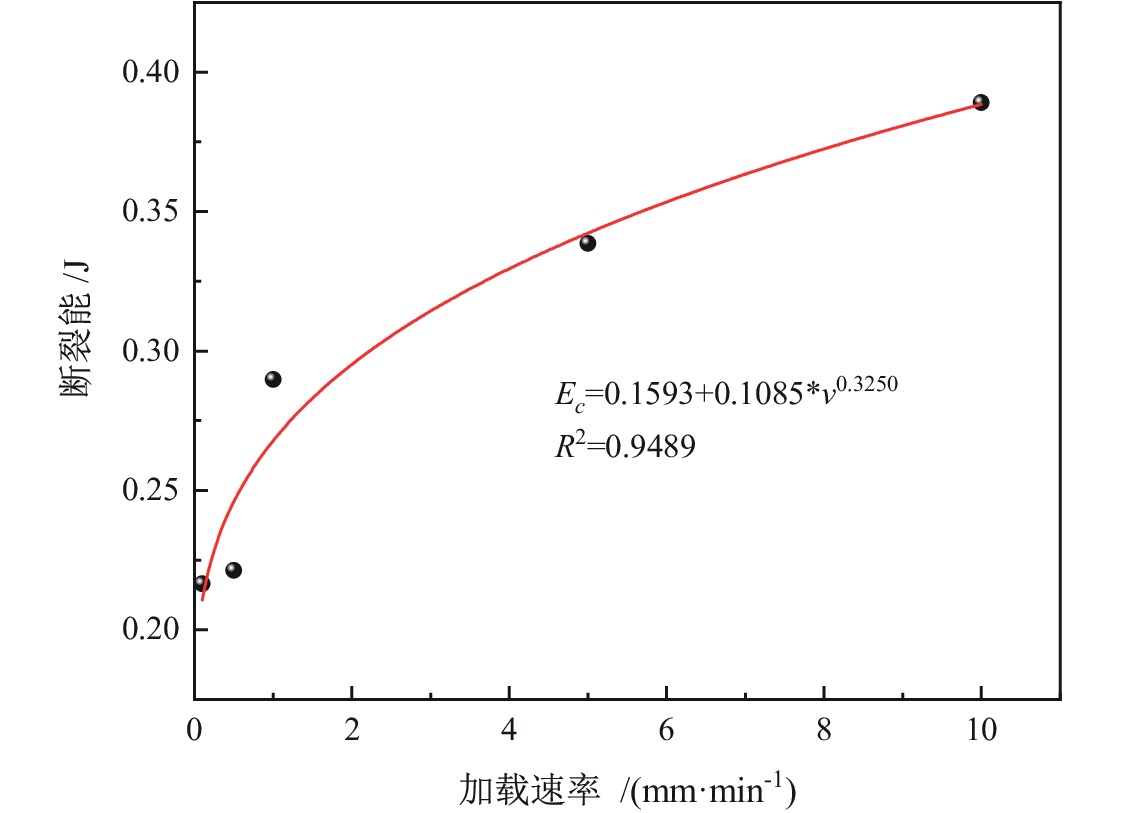

加载速率是影响矿石破碎特性的关键因素之一。为探究加载速率对不规则钼矿石破坏特性的影响,开展了不规则钼矿石在不同加载速率下的单轴压缩实验,系统研究了加载速率对钼矿石的破坏形态、载荷峰值、位移变化、断裂能、破碎强度及Weibull分布模型的影响。实验结果表明:随着加载速率增大,不规则钼矿石破坏程度愈剧烈,其载荷峰值呈现增大趋势,且在高加载速率下增加幅度更为显著,峰值位移(峰值强度对应位移)逐步减小;断裂能在低加载速率(0.1 mm/min和0.5 mm/min)时变化不显著,高加载速率(10 mm/min)时断裂能增加幅度较为显著;随着加载速率增加,不规则钼矿石的破碎强度表现为先急剧增大、后缓慢增加的变化趋势,近似满足幂函数关系;两参数Weibull分布模型可以较好地描述不规则钼矿石破碎强度分布,其中Weibull分布模量m为常数,与加载速率无关,特征强度σ0随着加载速率的增大呈现增大趋势。本论文研究结果进一步丰富和扩展了不规则矿石破碎的理论与方法。

-

关键词:

- 加载速率 /

- 不规则钼矿石 /

- 破碎强度 /

- 断裂能 /

- Weibull分布模型

Abstract:Loading rate is one of the key factors affecting the crushing characteristics of ore. In order to explore the influence of loading rate on the failure characteristics of irregular molybdenum ore, uniaxial compression experiments of irregular molybdenum ore at different loading rates were carried out. The effects of loading rate on the failure mode, peak load, displacement change, fracture energy, crushing strength and Weibull distribution model of molybdenum ore were systematically studied. The experimental results show that with the increase of loading rate, the damage degree of irregular molybdenum ore is more severe, the peak load shows an increasing trend, and the increase is more significant at high loading rate, and the peak displacement ( peak strength corresponding displacement ) gradually decreases. The fracture energy does not change significantly at low loading rates (0.1 mm/min and 0.5 mm/min), and the fracture energy increases significantly at high loading rates (10 mm/min). With the increase of loading rate, the crushing strength of irregular molybdenum ore increases sharply at first and then increases slowly, which approximately satisfies the power function relationship. The two-parameter Weibull distribution model can better describe the crushing strength distribution of irregular molybdenum ore. The modulus m of Weibull distribution is constant and has nothing to do with the loading rate. The characteristic strength σ0 increases with the increase of loading rate.The research results of this paper further enrich and expand the theory and method of irregular ore crushing.

-

-

表 1 通过两参数Weibull分布模型拟合得到的不规则钼矿石的各参数汇总

Table 1. Parameters of irregular molybdenum ore fitted by two-parameter Weibull distribution model are summarized

加载速率/(mm·min−1) m σ0/MPa R2 0.1 2.019 14.306 0.954 0.5 2.462 15.511 0.972 1 1.952 15.987 0.902 5 1.824 18.242 0.978 10 2.383 20.377 0.979 -

[1] 崔学茹. 功率控制在磨矿分级自动控制系统中的应用[J]. 有色金属(选矿部分), 2022(1): 120−123.

CUI X R. Application of power control in automatic control system of grinding and classification[J]. Nonferrous Metals(Mineral Processing Section), 2022(1): 120−123.

[2] 李晶, 叶红齐, 罗衡, 等. 静载荷作用下颗粒破碎的分形统计规律研究[J]. 金属矿山, 2016(8): 103−107.

LI J, YE H Q, LUO H, et al. Study on statistical fractal rule of particle breakage with static load[J]. Metal Mine, 2016(8): 103−107.

[3] 周强. 准静态压缩作用下脆性物料颗粒破碎特性研究[D]. 北京: 中国矿业大学, 2021.

ZHOU Q. Study on breakage characteristics of brittle granular materials under quasi−static compression[D]. Beijing: China University of Mining and Technology, 2021.

[4] 金爱兵, 朱东风, 孙浩, 等. 不同加载速率下的矿岩劈裂破坏特性试验研究[J]. 中南大学学报(自然科学版), 2023, 54(1): 269−279.

JIN A B, ZHU D F, SUN H, et al. Experimental study of ore−rock splitting failure characteristics at different loading rates[J]. Journal of Central South University(Science and Technology), 2023, 54(1): 269−279.

[5] 李福林, 杨健, 刘卫群, 等. 单轴压缩条件下泥岩加载速率变化效应研究[J]. 岩土力学, 2021, 42(2): 369−378.

LI F L, YANG J, LIU W Q, et al. Research on the effect of loading rate variation of mudstone under uniaxial compression conditions[J]. Rock and Soil Mechanics, 2021, 42(2): 369−378.

[6] 宋义敏, 邢同振, 邓琳琳, 等. 不同加载速率下岩石变形场演化试验研究[J]. 岩土力学, 2017, 38(10): 2773−2779+2788.

SONG Y M, XING T Z, DENG L L, et al. Experimental study of ore−rock splitting failure characteristics at different loading rates[J]. Rock and Soil Mechanics, 2017, 38(10): 2773−2779+2788.

[7] 尹白琳, 吝曼卿, 石明汉, 等. 不同加载速率对磷块岩破坏特性的影响研究[J]. 化工矿物与加工, 2023, 52(8): 26−31+38.

YIN B L, LIN M Q, SHI M H, et al. Study on the effect of loading rates on the failure characteristics of phosphate rock[J]. Industrial Minerals & Processing, 2023, 52(8): 26−31+38.

[8] 杨敬虎, 于翔. 加载速率影响抗拉强度的机理及其数值验证[J]. 煤炭学报, 2017, 42(S1): 51−59.

YANG J H, YU X. Mechanical explanation of loading rate impact on tensile strength and its numerical simulation analysis[J]. Journal of China Coal Society, 2017, 42(S1): 51−59.

[9] SHABNAM EBRAHIMI, BASHIR BEHJAT, MOHSEN KOUHI. The effect of loading rate on mixed mode Ⅰ/Ⅱ fracture behavior of adhesively bonded joints: Experimental and numerical approach[J]. Theoretical and Applied Fracture Mechanics, 2024, 131: 104420.

[10] XIAO W J, ZHANG D M, CAI Y, et al. Study on loading rate dependence of the coal failure process based on uniaxial compression test[J]. Pure and Applied Geophysics, 2020, 177(10): 4925−4941. doi: 10.1007/s00024-020-02513-0

[11] 吕志强. 加载速率对煤岩抗拉强度参数影响程度研究[J]. 煤炭技术, 2014, 33(10): 301−302.

LV Z Q. Study of loading speed influence on tensile strength parameter of coal rock[J]. Coal Technology, 2014, 33(10): 301−302.

[12] 周辉, 杨艳霜, 肖海斌, 等. 硬脆性大理岩单轴抗拉强度特征的加载速率效应研究−实验特征与机制[J]. 岩石力学与工程学报, 2013, 32(9): 1868−1875.

ZHOU H, YANG Y S, XIAO H B, et al. Research on loading rate effect of tensile strength property of hard brittle marble—test characteristics and mechanism[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(9): 1868−1875.

[13] 苏承东, 李怀珍, 张盛, 等. 应变速率对大理岩力学特性影响的试验研究[J]. 岩石力学与工程学报, 2013, 32(5): 943−950.

SU C D, LI H Z, ZHANG S, et al. Experimental investigation on effect of strain rate on mechanical characteristics of marble[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(5): 943−950.

[14] 徐秉权. 料层粉碎研究的进展[J]. 湖南有色金属, 1993(5): 278−283.

XU B Q. Progress in research on material layer crushing[J]. Hunan Nonferrous Metals, 1993(5): 278−283

[15] 王介强, 宋守志. 关于料层粉碎的理论研究[J]. 中国矿业, 1998(5): 48−50.

WANG J Q, SONG S Z. A theoretical study of particle bads comminution[J]. China Mining Magazine, 1998(5): 48−50.

[16] PARAPARI P S, PARIAN M, ROSENKRANZ J. Quantitative analysis of ore texture breakage characteristics affected by loading mechanism: fragmentation and mineral liberation[J]. Minerals Engineering, 2022, 182: 107561.

[17] 金子恒, 谢发祥, 蔡定鹏, 等. 不同加载速率下SAP混凝土断裂性能研究[J]. 硅酸盐通报, 2023, 42(10): 3546−3553.

JIN Z H, XIE F X, CAI D P, et al. Fracture performance of SAP concrete under different loading rates[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(10): 3546−3553.

[18] ANTONYUK S, TOMAS J, HEINRICH S. Breakage behaviour of spherical granulates by compress[J]. Chemical Engineering Science, 2005, 60(14): 4031−4044. doi: 10.1016/j.ces.2005.02.038

[19] 周强, 汪轶凡, 肖庆飞, 等. 不规则铜钼矿颗粒断裂强度分布实验研究[J]. 矿产保护与利用, 2023, 43(4): 33−42.

ZHOU Q, WANG Y F, XIAO Q F, et al. Experimental study of the strength distribution of irregular copper−molybdenum ore particles[J]. Conservation and Utilization of Mineral Resources, 2023, 43(4): 33−42.

[20] Y. HIRAMATSU, Y. OKA. Determination of the tensile strength of rock by a compression test of an irregular test piece[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1966, 3(2): 89−90.

[21] 黄俊宇. 冲击载荷下脆性颗粒材料多尺度变形破碎特性研究[D]. 合肥: 中国科学技术大学, 2016.

HUANG J Y. Dynamic multiscale deformation behavior and particle−breakage properties of granular materials subjected to impact loading[D]. Hefei: University of Science and Technology of China, 2016.

-

下载:

下载: