Experimental Study on Medium Optimization and Reduction of Semi−Autogenous Grinding Hard Stone Accumulation Based on Grinding Parameters

-

摘要:

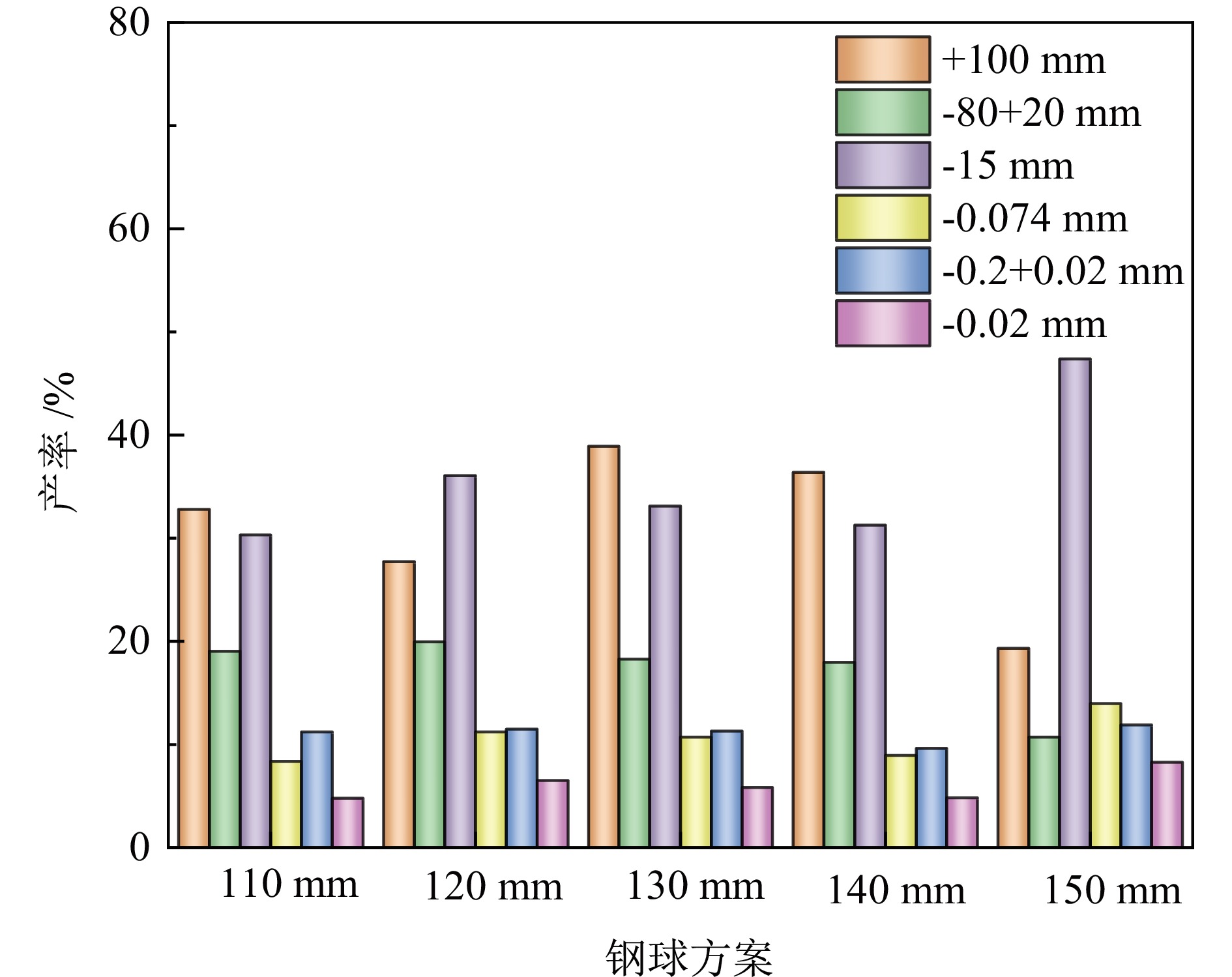

针对某大型钼矿存在半自磨机顽石积累、产能提升幅度有限等问题,在综合考虑不同测试方法下的碎磨参数及通过压载实验获得顽石粒级的基础上,运用修正后的Azzaroni公式进行钢球直径精确计算,并通过实验室实验进行合理性验证。研究结果表明:(1)三种测试方法获得的碎磨参数结果均表明了该矿石的难磨剥特性但在描述矿石抗冲击性能上仍有区别;(2)该矿石的顽石粒级为−80+20 mm;(3)半自磨机的最佳钢球方案为m(Φ130 mm)∶m(Φ110 mm)=1∶1。单一球径Φ130 mm中+100 mm充当自磨介质的矿石磨矿产品较选厂Φ120 mm钢球方案提高了11.17百分点,顽石含量降低了1.67百分点;混合球径m(Φ130 mm)∶m(Φ110 mm)=1∶1的+100 mm含量较单一球径Φ130 mm提高了1百分点,顽石含量降低了3.41百分点,验证了所计算的最大钢球直径方案的合理性,并采用混合球径方案获得了更优的磨矿效果。

Abstract:In response to the problems of hard rock accumulation and limited production capacity improvement in a large molybdenum mine using a semi−autogenous mill, the modified Azzaroni formula was used to accurately calculate the optimal steel ball diameter. Various crushing and grinding parameters obtained through different testing methods and compression experiments to measure hard rock particle size were incorporated into this calculation. The rationality was verified through laboratory experiments. The research results indicated that: (1) The crushing and grinding parameters obtained by the three testing methods consistently highlighted the difficult grinding and stripping characteristics of the ore, though variations in describing the impact resistance of the ore were observed; (2) The hard rock particle size of the ore was determined to be −80+20 mm; (3) The optimal steel ball scheme for a semi−autogenous mill was a 1∶1 mass ratio of 130 mm and 110 mm diameters. Using a single ball diameter of 130 mm with a 100 mm diameter as the self−grinding medium resulted in an 11.17% increase in production compared to the existing 120 mm ball diameter scheme in the selection plant, and a 1.67% decrease in the content of hard rock −80+20 mm. The content of+100 mm with a mixed ball diameter of 130 mm and 110 mm in a 1∶1 ratio increased by 1% compared to a single ball diameter of 130 mm, while the content of hard rock −80+20 mm decreased by 3.41%. This verified the accuracy of the calculated maximum steel ball diameter and achieved better grinding results using the mixed ball diameter scheme.

-

-

表 1 A×b值与矿石软硬对照表

Table 1. Comparison table of A×b values with ore softness and hardness

特性 极硬 硬 中硬 中 中软 软 极软 A×b <30 30~38 38~43 43~56 56~67 67~127 >127 表 2 邦德球磨功指数与矿石软硬程度对照表

Table 2. Comparison table of bond ball mill work index with ore softness and hardness

特性 软矿石 中矿石 中硬矿石 硬矿石 极硬矿石 Wib,/(kW·h·t−1) <8 8~14 14~20 20~25 >25 表 3 普氏硬度系数与矿石软硬程度对照表

Table 3. Comparison table of protodyakonov coefficient with ore hardness and softness

特性 极硬 很硬 坚硬 较硬 普通 较软 软层 松软 f 20 15 8~10 5~6 3~4 1.5~2 0.8~1 <1 表 4 碎磨特性参数

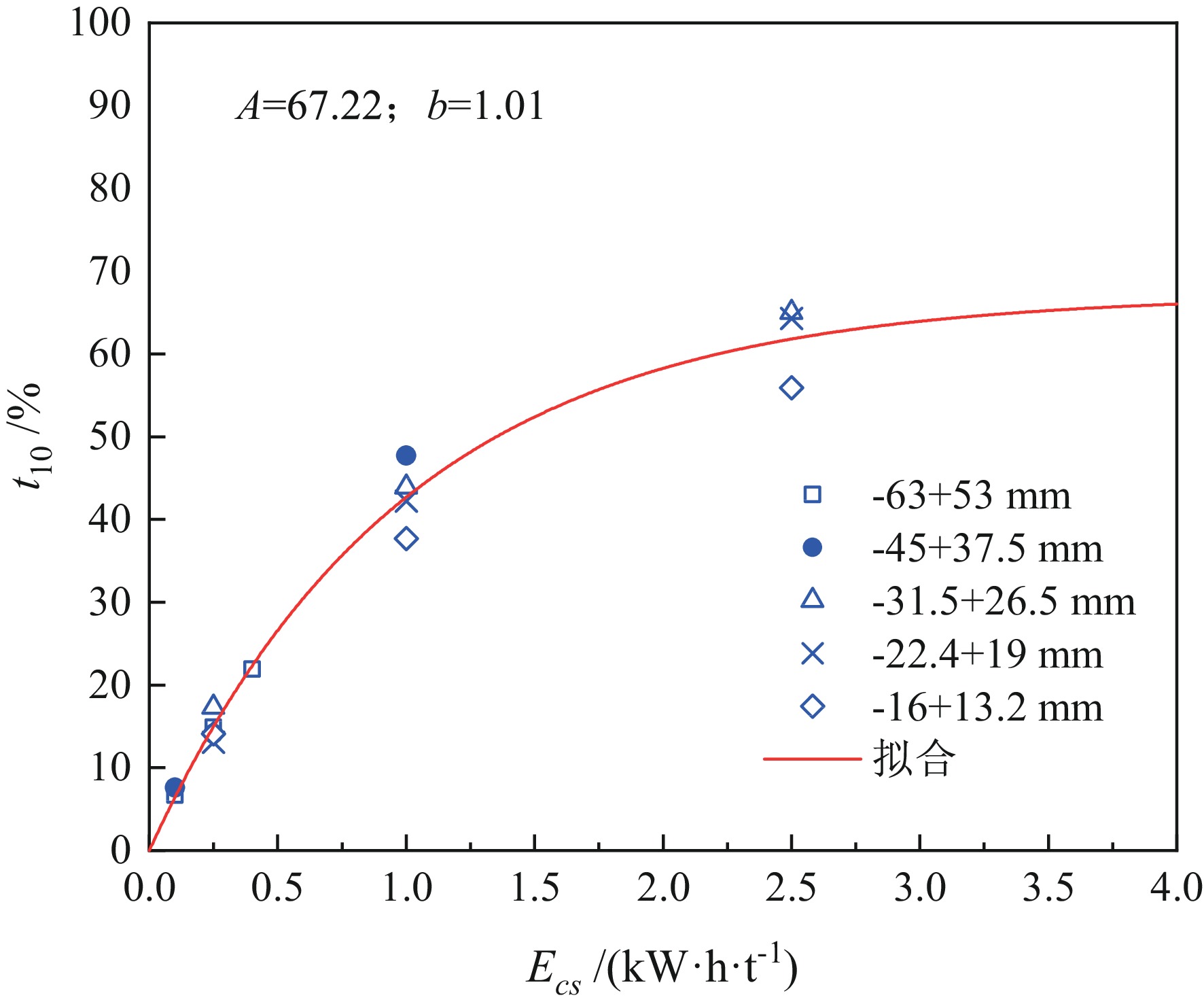

Table 4. Comminution characteristic parameters

参数 M fmat A b A*b ta Wib/(kW·h·t−1) 取值 96.54 0.17 67.22 1.01 67.89 0.36 16.27 表 5 力学性质测定结果

Table 5. Mechanical property measurement results

样品 抗压强度R/MPa 块体密度/(g·cm−3) 泊松比 345 104.00 2.59 / 360 185.00 2.63 / 375 77.50 2.62 0.34 390 90.60 2.59 0.25 435 137.00 2.63 / 均值 118.82 2.61 0.30 -

[1] A. GUPTA, D. S. YAN. Chapter 9 − autogenous and semi−autogenous mills[M]. Elsevier B. V. , 2006.

[2] 尤腾胜, 李兆峰, 何荣权. 半自磨系统顽石性质及其对系统产能的影响研究[J]. 中国矿山工程, 2023, 52(1): 72−77. doi: 10.3969/j.issn.1672-609X.2023.01.012

YOU T S, LI Z F, HE R Q. Research on the properties of hard stones in semi autogenous grinding systems and their impact on system capacity[J]. China Mining Engineering, 2023, 52(1): 72−77. doi: 10.3969/j.issn.1672-609X.2023.01.012

[3] 肖庆飞, 王国强, 杨芳, 等. 半自磨顽石做中矿再磨介质的应用研究[J]. 矿产保护与利用, 2017(3): 32−36.

XIAO Q F, WANG G Q, YANG F, et al. Research on the application of semi autogenous grinding refractory stone as a medium for intermediate ore re grinding[J]. Mineral Protection and Utilization, 2017(3): 32−36.

[4] 黄国智, 方启学, 任翔, 等. 全自磨半自磨磨矿技术[M]. 北京: 冶金工业出版社, 2018: 47−51.

HUANG G Z, FANG Q X, REN X, et al. Fully and semi autogenous grinding[M]. Beijing: Metallurgical Industry Press, 2018: 47−51.

[5] A. R. HASANKHOEI, M. MALEKI−MOGHADDAM, A. HAJI−ZADEH, et al. On dry SAG mills end liners: Physical modeling, DEM−based characterization and industrial outcomes of a new design[J]. Minerals Engineering, 2019, 141(C): 105835−105835.

[6] VOGEL L , PEUKERT W . Determination of material properties relevant to grinding by practicable labscale milling tests[J]. International Journal of Mineral Processing, 2004, 74: S329−S338.

[7] P. W. CLEARY, G. W. DELANEY, M. D. SINNOTT, et al. Inclusion of incremental damage breakage of particles and slurry rheology into a particle scale multiphase model of a SAG mill[J]. Minerals Engineering, 2018, 128: 92−105. doi: 10.1016/j.mineng.2018.08.026

[8] R. D. MORRISON, P. W. CLEARY. Using DEM to model ore breakage within a pilot scale SAG mill[J]. Minerals Engineering, 2004, 17(11): 1117−1124.

[9] P W. CLEARY, R. D. MORRISON, G. W. DELANEY. Incremental damage and particle size reduction in a pilot SAG mill: DEM breakage method extension and validation[J]. Minerals Engineering, 2018, 12856−68.

[10] 郜峰. 球磨机负荷监测软件平台的设计与开发[D]. 沈阳: 东北大学, 2010.

GAO F. Design and development of a ball mill load monitoring software platform [D]. Shenyang: Northeastern University, 2010.

[11] A GIBLETT, S MORRELL. Process development testing for comminution circuit design[J]. Minerals & Metallurgical Processing, 2016(4).

[12] 谭文才, 刘俊, 夏林, 等. 给料粒度分布对半自磨机的影响[J]. 矿山机械, 2019, 47(11): 36−40. doi: 10.3969/j.issn.1001-3954.2019.11.009

TANG W C, LIU J, XIA L, et al. The influence of feed particle size distribution on semi autogenous grinding machines[J]. Mining Machinery, 2019, 47(11): 36−40. doi: 10.3969/j.issn.1001-3954.2019.11.009

[13] 王越, 苏祥玉, 邓海轩, 等. 某钼矿快捷提高半自磨处理量的有效途径[J]. 矿冶, 2022, 31(2): 47−52. doi: 10.3969/j.issn.1005-7854.2022.02.008

WANG Y, SU X Y, DENG H X, et al. An effective way to quickly increase the semi autogenous grinding processing capacity of a molybdenum mine[J]. Mining and Metallurgy, 2022, 31(2): 47−52. doi: 10.3969/j.issn.1005-7854.2022.02.008

[14] 国宏臣, 肖庆飞, 李云啸, 等. 基于离散元法的多级配球提高半自磨机磨矿效率研究[J]. 矿产保护与利用, 2023, 43(4): 60−67.

GUO H C, XIAO Q F, LI Y X, et al. Research on improving the grinding efficiency of semi autogenous mills by multi−stage ball matching based on discrete element method[J]. Mineral Protection and Utilization, 2023, 43(4): 60−67.

[15] 谢浩松, 肖庆飞, 张志鹏, 等. 云南某金矿半自磨钢球尺寸优化及离散元仿真模拟分析[J]. 矿产保护与利用, 2023, 43(1): 57−65.

XIE H S, XIAO Q F, ZHANG Z P, et al. Size optimization and discrete element simulation analysis of semi autogenous grinding steel balls in a gold mine in Yunnan[J]. Mineral Protection and Utilization, 2023, 43(1): 57−65.

[16] 国宏臣, 周强, 肖庆飞, 等. 勒洛四面体与传统磨矿介质对料层冲击破碎特性的对比研究[J]. 矿产保护与利用, 2023, 43(5): 107−113.

GUO H C, ZHOU Q, XIAO Q F, et al. Comparative study on the impact crushing characteristics of material layers between Leluo tetrahedron and traditional grinding media[J]. Mineral Protection and Utilization, 2023, 43(5): 107−113.

[17] SHI F , KOJOVIC T . Validation of a model for impact breakage incorporating particle size effect[J]. International Journal of Mineral Processing, 2006, 82(3): 156−163.

[18] GROUP T & E C . From Single Particle Impact Behaviour to Modeling of Impact Mills[J]. Chemical Engineering & Technology: Industrial Chemistry −Plant Equipment −Process Engineering −Biotechnology, 2005, 28(10): 1077.

[19] 王国强, 刘建远, 朱阳戈, 等. 基于矿石碎磨特性的设备选型及能耗分析[J]. 矿山机械, 2022, 50(1): 29−33. doi: 10.3969/j.issn.1001-3954.2022.01.007

WANG G Q, LIU J Y, ZHU Y G, et al. Equipment selection and energy consumption analysis based on ore crushing and grinding characteristics[J]. Mining Machinery, 2022, 50(1): 29−33. doi: 10.3969/j.issn.1001-3954.2022.01.007

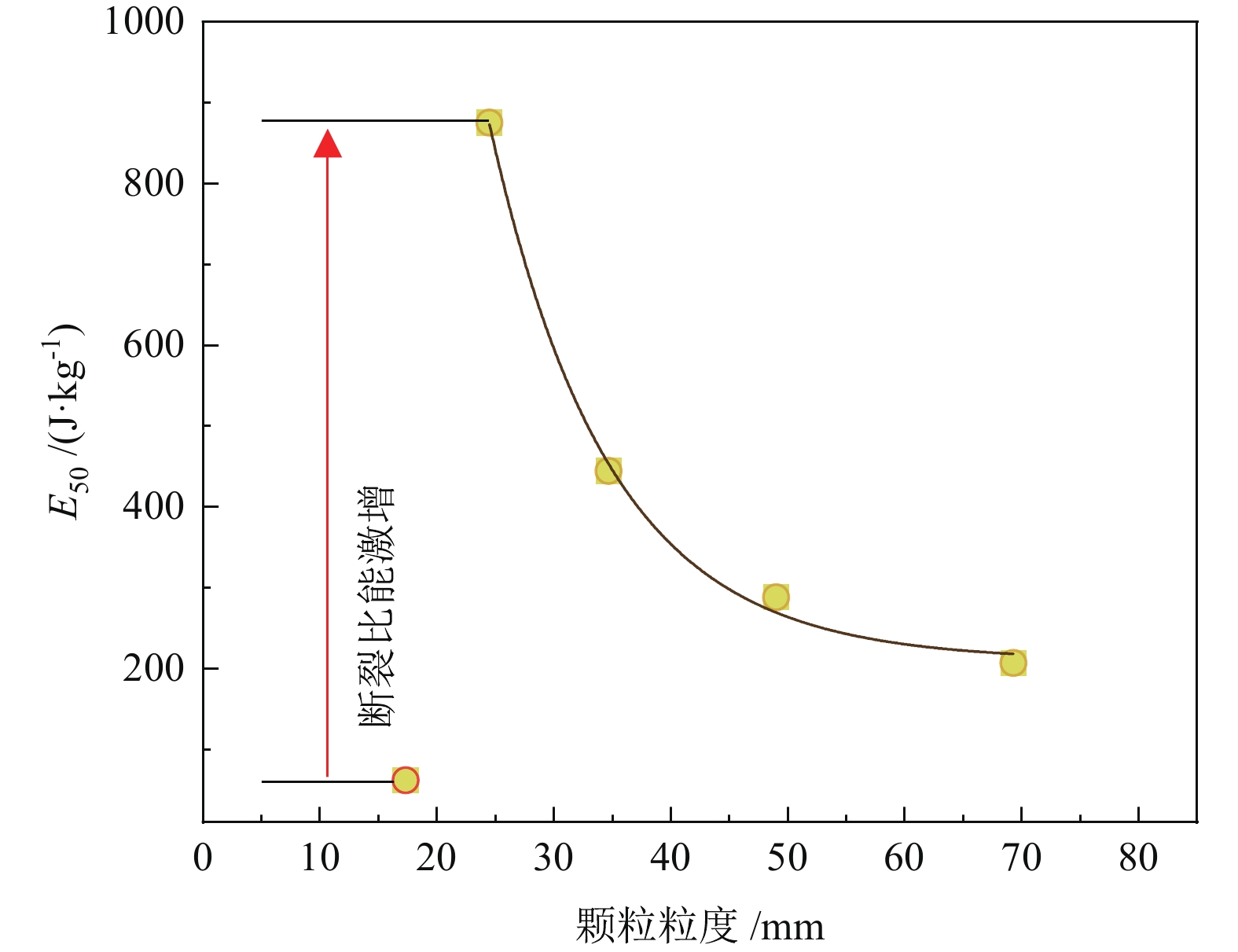

[20] 周强, 汪轶凡, 肖庆飞, 等. 不规则铜钼矿颗粒断裂强度分布实验研究[J]. 矿产保护与利用, 2023, 43(4): 33−42.

ZHOU Q, WANG Y F, XIAO Q F, et al. Experimental study on the distribution of fracture strength of irregular copper molybdenum ore particles[J]. Mineral Protection and Utilization, 2023, 43(4): 33−42.

[21] 周强, 肖庆飞, 潘永泰. 挤压作用下脆性物料断裂强度分布研究[J]. 中国矿业大学学报, 2022, 51(6): 1086−1095. doi: 10.3969/j.issn.1000-1964.2022.6.zgkydxxb202206005

ZHOU Q, XIAO Q F, PAN Y T. Research on the distribution of fracture strength of brittle materials under compression[J]. Journal of China University of Mining and Technology, 2022, 51(6): 1086−1095. doi: 10.3969/j.issn.1000-1964.2022.6.zgkydxxb202206005

[22] L. M TAVARES, R. P KING. Single−particle fracture under impact loading[J]. Elsevier B. V. , 1998.

[23] 骆忠, 肖庆飞, 方雨, 等. 基于钢球与矿石碰撞能量确定半自磨机钢球尺寸的方法: CN115138447A[P], 2022−10−04.

LUO Z, XIAO Q F, FANG Y, et al. Method for determining the size of steel balls in semi−automatic mills based on the collision energy between steel balls and ores: CN115138447A[P], 2022−10−04.

-

下载:

下载: