Improvement of High Gradient Magnetic Separator with Horizontal Magnetic Field and Its Application for Ilmenite in Panxi Region

-

摘要:

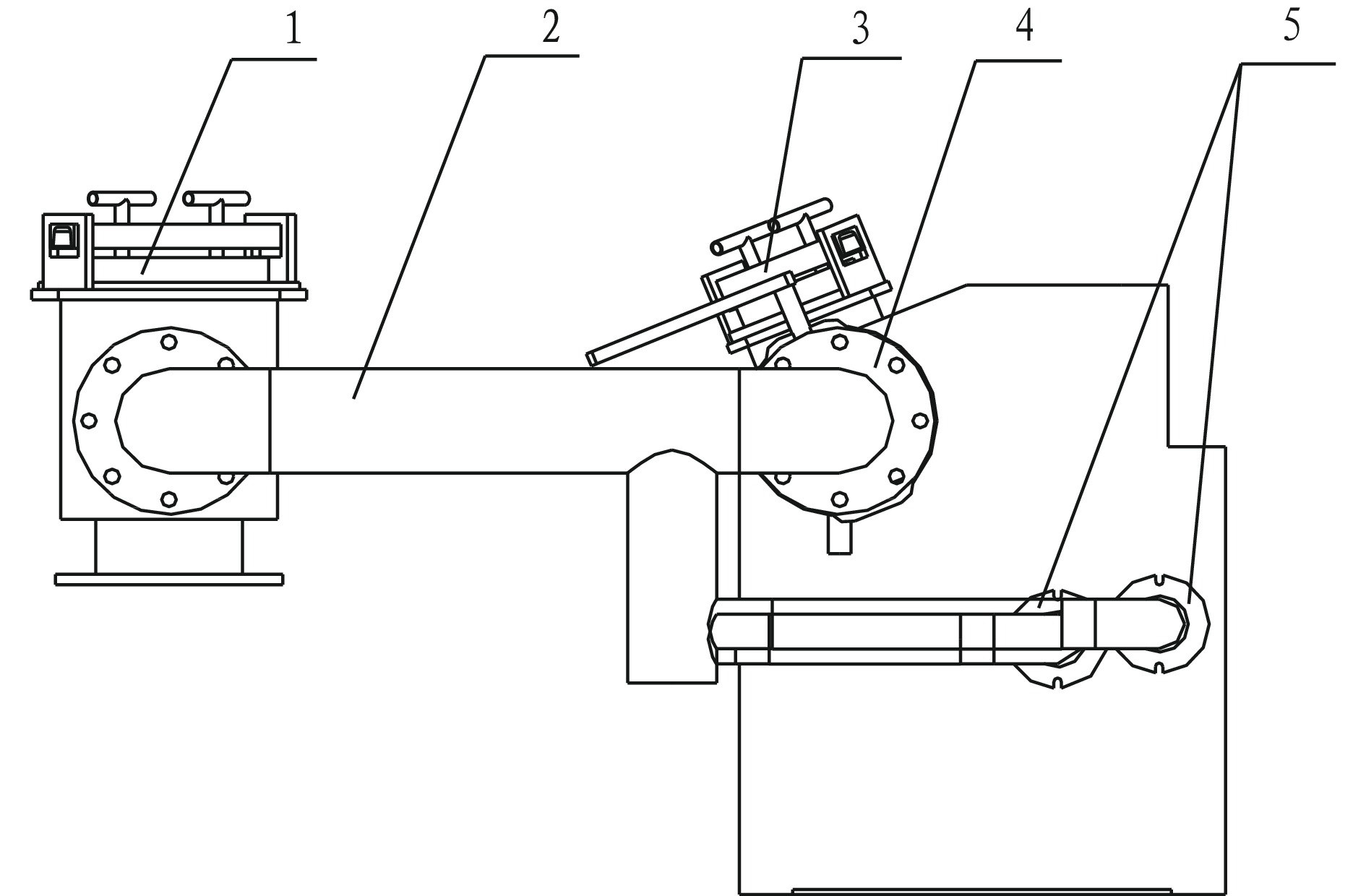

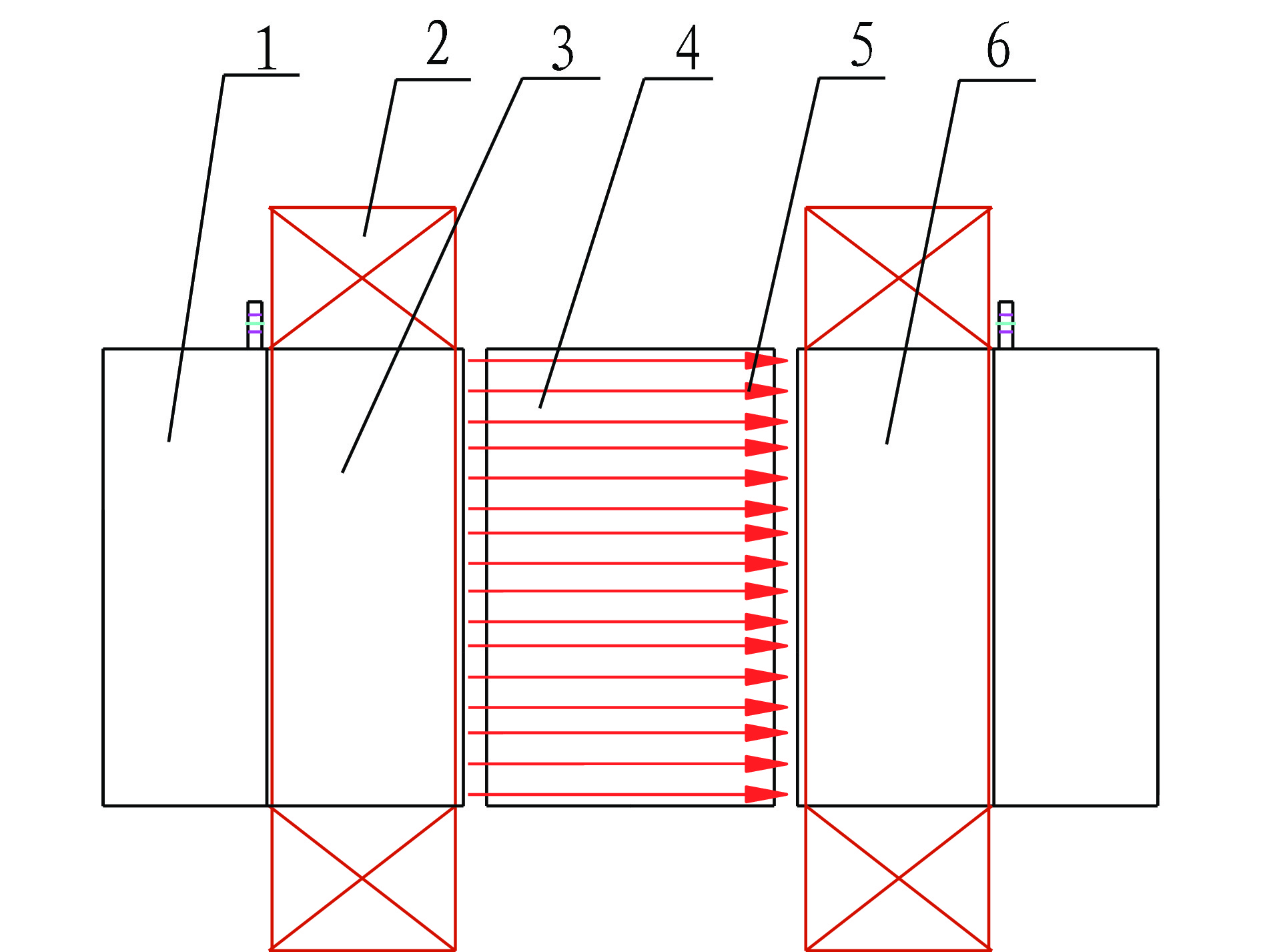

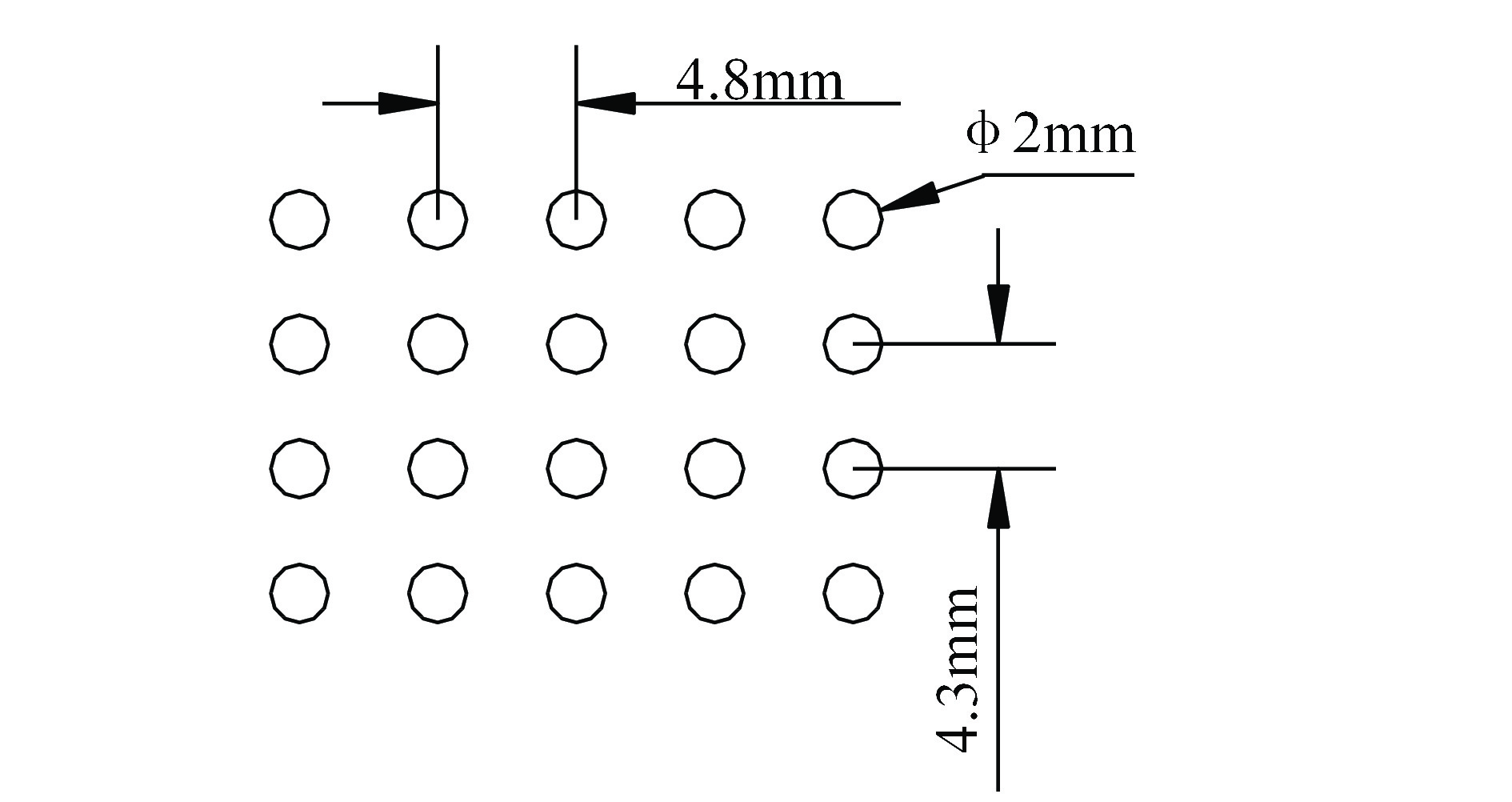

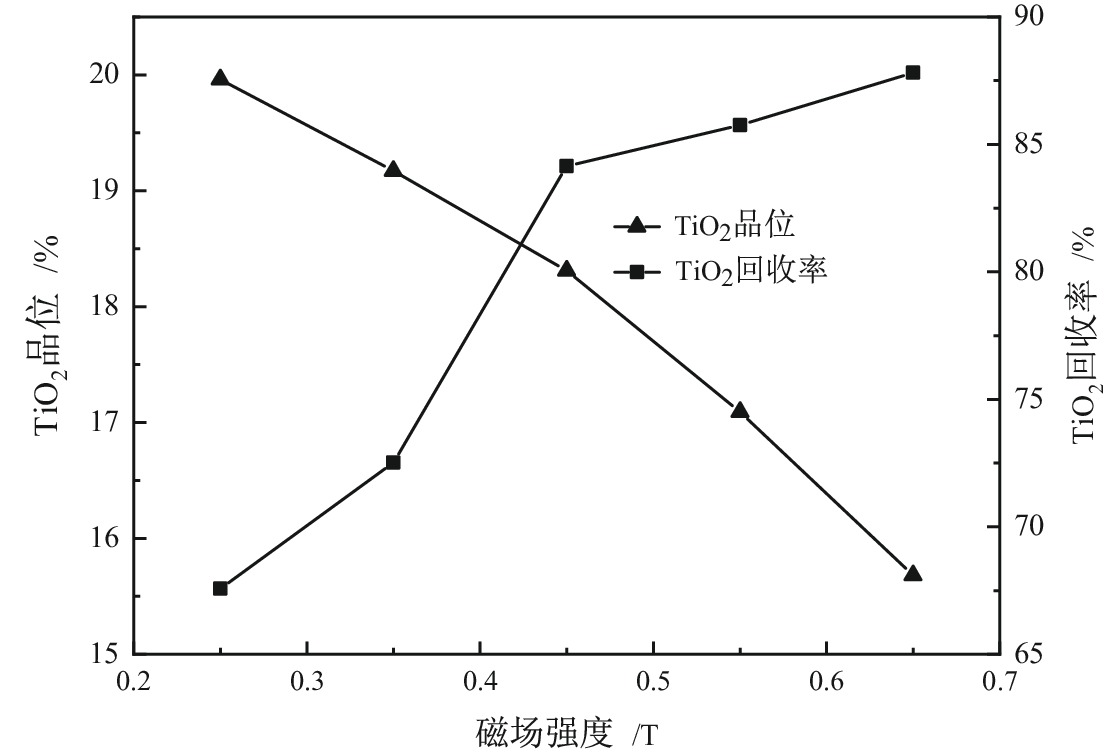

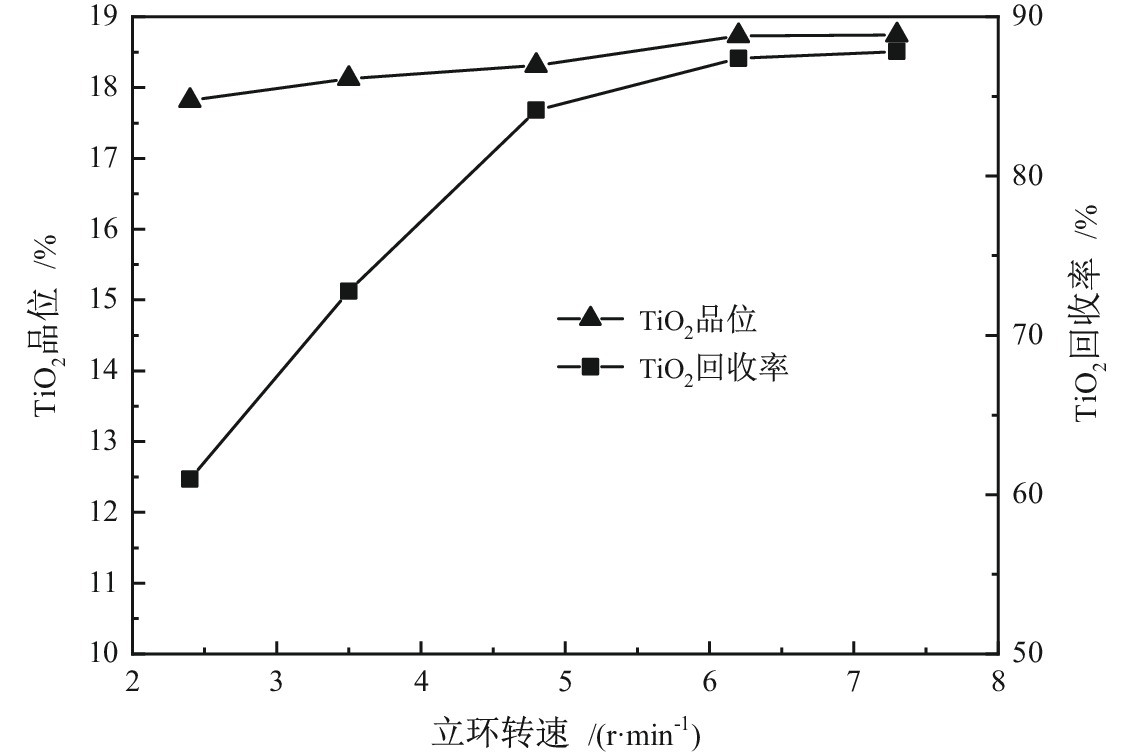

水平磁场高梯度磁选机具有磁系不易腐蚀、磁介质不易堵塞等特点,用于钛铁矿粗选效果良好,但该型设备受磁系间距限制,分选环宽度、磁介质体积量较小,影响处理量,且激磁能耗高,需要对其进行改进,提高处理量、降低能耗。以SSS−Ⅱ−2750水平磁场高梯度磁选机为基础,对其分选环系统进行了改进,在磁系高度方向增加分选环厚度,并分成内外双层环,并对内层环配置粗介质棒的介质盒以吸附粗粒、强磁性目的矿物,对外层环配置细介质棒的介质盒以吸附细粒、微细粒磁性较弱的目的矿物,可实现梯级分选,同时,内外环均配置卸矿装置,分层卸矿,可有效保障目的矿物的卸矿效率。在攀西地区某选钛厂钛铁矿一段粗选工序考察其效果,在磁场强度0.45 T、立环转速6.2 r/min、冲程10 mm、冲次120 r/min、给矿量160 t/h、原矿TiO2品位10.42%的条件下,改进后的水平磁场高梯度磁选机可获得TiO2品位18.55%、回收率85.78%的钛粗精矿。与改进前磁选机、垂直磁场高梯度磁选机相比,其钛粗精矿品位与其他两种设备相近,但回收率分别高8.43、13.63百分点,分选效果好,同时改进后的水平磁场高梯度磁选机的激磁能耗在三种设备中最低,为0.49 kW·h/t,表明该设备处理量大且能耗低,实现了设备改进目的。

Abstract:The High Gradient Magnetic Separator (HGMS) with a horizontal magnetic field has many characteristics, including resistance to corrosion of the magnetic system and a low propensity for the magnetic medium to become blocked. Consequently, the HGMS has a significant effect on the rough separation of ilmenite. However, the limited spacing of the magnetic system, the narrow width of the sorting ring, and the small volume of the magnetic medium result in low processing capacity and high energy consumption. Therefore, equipment improvements are necessary to enhance the processing capacity and reduce energy consumption. Based on the SSS−II−2750 horizontal magnetic field HGMS, the separation ring system was enhanced. The thickness of the separation ring was increased in the height direction of the magnetic system, and the inner and outer double rings were divided. The medium box equipped with a coarse medium rod in the inner ring adsorbed coarse grain and strong magnetic target minerals, while the medium box with a fine medium rod in the outer ring adsorbed fine grain and micro−fine grain with weak magnetic target minerals, achieving cascade sorting. At the same time, both inner and outer rings were equipped with ore unloading devices to realize layered ore unloading, effectively improving the ore unloading rate of the target minerals. The effect of the first stage roughing process of ilmenite in a titanium separation plant in the Panxi area was investigated. The improved HGMS with a horizontal magnetic field yielded titanium crude concentrates with a TiO2 grade of 18.55% and a recovery of 85.78%, under conditions of a magnetic field strength of 0.45 T, vertical ring speed of 6.2 r/min, stroke length of 10 mm, stroke frequency of 120 r/min, ore feed rate of 160 t/h, and raw ore TiO2 grade of 10.42%. Compared with the pre−improvement and vertical magnetic field, the improved HGMS achieved a similar titanium crude concentrate grade but increased the recovery rate by 8.43 and 13.63 percentage points, respectively. The improved HGMS with a horizontal magnetic field demonstrated a good sorting effect, and the lowest excitation energy consumption among the three devices (0.49 kWh/t). The research indicated that the improved equipment has a large processing capacity and low energy consumption, achieving the objective of equipment enhancement.

-

Key words:

- horizontal magnetic field /

- HGMS /

- ilmenite /

- magnetic separation

-

-

表 1 给矿主要元素分析结果

Table 1. Main element analysis results of feading

/% 元素 TFe TiO2 V2O5 S CaO MgO Al2O3 SiO2 含量 21.55 10.42 0.20 0.39 4.76 6.27 18.74 32.63 表 2 给矿粒级筛分结果

Table 2. Sieve analysis results of feading

粒级/mm 产率/% TiO2品位/% TiO2分布率/% +0.30 13.89 5.28 7.04 −0.30+0.20 18.68 9.36 16.78 −0.20+0.10 31.84 11.36 34.71 −0.10+0.074 7.45 14.31 10.23 −0.074 28.14 11.57 31.24 合计 100.00 10.42 100.00 表 3 给矿主要矿物组成

Table 3. Main mineral component results of feading

/% 矿物名称 钛铁矿 钒钛磁铁矿 褐铁矿 磁黄铁矿 黄铁矿 含量 14.98 0.41 0.81 0.67 0.24 矿物名称 黄铜矿 绿帘石 橄榄石 钛普通辉石 角闪石 含量 0.04 0.52 17.17 5.05 7.09 矿物名称 绿泥石 斜长石 石英 尖晶石 其他 含量 6.28 24.62 21.68 0.37 0.07 表 4 钛在给矿中的赋存状态

Table 4. Equilibrium distribution of TiO2 in feading

/% 矿物名称 含量 TiO2品位 TiO2分布率 钛铁矿 14.98 52.64 75.68 钒钛磁铁矿 0.41 11.14 0.44 褐铁矿 0.81 1.93 0.15 磁黄铁矿 0.67 / / 非磁性脉石(斜长石、

石英等)46.41 2.43 10.82 磁性脉石(橄榄石、

辉石、角闪石等)37.72 3.57 12.91 合计 100.00 10.42 100.00 表 5 不同冲程、冲次条件下钛粗精矿指标

Table 5. Concentrate indexes under different stroke and punching conditions

冲程/mm 冲次/(r·min−1) 产品 产率/% TiO2品位/% TiO2回收率/% 0 0 钛粗精矿 48.63 18.73 87.38 尾矿 51.37 2.56 12.62 给矿 100.00 10.42 100.00 10 120 钛粗精矿 47.68 18.95 86.70 尾矿 52.32 2.65 13.30 给矿 100.00 10.42 100.00 10 270 钛粗精矿 42.76 19.22 78.86 尾矿 57.24 3.85 21.14 给矿 100.00 10.42 100.00 20 120 钛粗精矿 44.69 19.12 82.01 尾矿 55.31 3.39 17.99 给矿 100.00 10.42 100.00 20 270 钛粗精矿 40.25 19.67 75.98 尾矿 59.75 4.19 24.02 给矿 100.00 10.42 100.00 表 6 三种磁选设备对比实验研究结果

Table 6. Test results for three types of HGMS

设备类型 产品 产率/% TiO2品位/% TiO2回收率/% 设备激磁功耗/(kW·h·t−1) 改进后的SSS−Ⅱ−2750 钛粗精矿 48.18 18.55 85.78 0.49 尾矿 51.82 2.86 14.22 给矿 100.00 10.42 100.00 未改进的SSS−Ⅱ−2750 钛粗精矿 43.28 18.75 77.35 0.78 尾矿 56.72 4.19 22.65 给矿 100.00 10.49 100.00 某垂直磁系高梯度磁选机 钛粗精矿 44.74 16.45 72.15 0.55 尾矿 55.26 5.14 27.85 给矿 100.00 10.20 100.00 -

[1] 熊大和. SLon立环脉动高梯度磁选机在多种金属矿选矿中的应用[J]. 矿产保护与利用, 2013(6): 51−56.

XIONG D H. The application of SLon VPHGMS for processing several metallic ores[J]. Conservation and Utilization of Mineral Resources, 2013(6): 51−56.

[2] 赵明, 黄雪平, 王丰雨. SSS新型高梯度磁选机的改进[J]. 金属矿山, 2011(4): 134−136.

ZHAO M, HUANG X P, WANG F Y. Development of SSS type high gradient magnetic separator[J]. Metal Mine, 2011(4): 134−136.

[3] 吴城材, 张超达, 钟森林, 等. ZQS型周期式高梯度磁选机在非金属矿除杂提质中的应用[J]. 材料研究与应用, 2017, 11(1): 47−50.

WU C C, ZHANG C D, ZHONG S L, et al. Application of ZQS−type circle high gradient magnetic separator in ironremoval purification of non−metallic mine[J]. Materials Research and Application. 2017, 11(1): 47−50.

[4] 熊大和. SLon−3000高梯度磁选机的研制与应用[J]. 金属矿山, 2013(12): 100−104.

XIONG D H. Development and application of SLon−3000 vertical ring and pulsating high gradient magnetic separator[J]. Metal Mine, 2013(12): 100−104.

[5] 洪家凯. Slon立环脉动高梯度磁选机在金属矿选矿中的应用[J]. 矿产保护与利用, 1997(6): 20−22.

HONG J K. Application of Slon veritic−ring pulsating HGMS in dressing of metallic ores[J]. Conservation and Utilization of Mineral Resources, 1997(6): 20−22.

[6] 王丰雨, 杨招君, 罗荣飞, 等. 采用ZQS高梯度磁选机提高超细粒级(−38μm)钛铁矿回收效果[J]. 金属矿山, 2019(8): 93−97.

WANG F Y, YANG Z J, LUO R F, et al. Recovery increase of −38 μm ultra fine ilmenite using ZQS high gradient magnetic separator[J]. Metal Mine, 2019(8): 93−97.

[7] 刘建国, 张军, 汤玉和. 重、磁预选工艺在几种典型钛铁矿选矿工艺中的应用[J]. 矿产保护与利用, 2018(1): 96−100.

LIU J G, ZHANG J, TANG Y H. Application of gravity and magnetic preconcentration process in the mineral processing of several typical ilmenite ores[J]. Conservation and Utilization of Mineral Resources, 2018(1): 96−100.

[8] 李萌, 白丽梅, 谢杰. 从黑山铁矿中回收钛铁矿的试验研究[J]. 矿产保护与利用, 2013(4): 29−32.

LI M, BAI L M, XIE J. Experimental study on flotation of ilmenite from Heishan iron ore[J]. Conservation and Utilization of Mineral Resources, 2013(4): 29−32.

[9] 闫伟平, 李维斯, 杨耀辉, 等. 攀西地区超微细粒级钛铁矿资源选矿工艺研究[J]. 矿产综合利用, 2023(4): 55−61.

YAN W P, LI W S, YANG Y H, et al. Research on mineral processing technology of ultrafine ilmenite resources in Panzhihua−Xichang area[J]. Multipurpose Utilization of Mineral Resources, 2023(4): 55−61.

[10] 汤玉和. SSS−Ⅱ湿式双频脉冲双立环高梯度磁选机的研制[J]. 金属矿山, 2004(3): 37−39.

TANG Y H. Development of SSS−Ⅱ wet type double frequency pulsation double vertical ring high gradient magnetic separator[J]. Metal Mine, 2004(3): 37−39.

[11] 赵明, 何健全, 许丽敏. SSS−Ⅱ型立环脉动高梯度磁选机磁介质棒排布方式的研究[J]. 矿山机械, 2009, 37(19): 97−99.

ZHAO M, HE J Q, XU L M. Research on the arrangement style of magnetic rod of the SSS−Ⅱ type vertical ring and pulsating high gradient magnetic separator[J]. Mining & Processing Equipment, 2009, 37(19): 97−99.

[12] 张军. SSS−Ⅱ高梯度磁选机回收微细粒钛铁矿的研究[J]. 材料研究与应用, 2012, 6(3): 195−197.

ZHANG J. Research on recycling micro−grained ilmenite using SSS−Ⅱ HGMS [J]. Materials Research and Application, 2012, 6(3): 195−197.

[13] 王丰雨, 谭世国, 赵明, 等. SSS−Ⅱ水平磁系场高梯度磁选机及其在密地选钛厂的应用[J]. 金属矿山, 2014(2): 122−126.

WANG F Y, TAN S G, ZHAO M, et al. Development of SSS−Ⅱ horizontal magnetic field high gradient magnetic separator and its application in Panzhihua Midi titanium plant[J]. Metal Mine, 2014(2): 122−126.

[14] 张军, 汤玉和, 李文博. SSS−Ⅱ型高梯度磁选机在承德钛铁矿生产中的应用[J]. 有色金属(选矿部分), 2011年(增刊1): 174−176+183.

ZHANG J, TANG Y H, LI W B. Application of SSS−Ⅱ high gradient magnetic separator in Chengde Ti−Fe mine[J]. Nonferrous Metals (Mineral Processing Section), 2011 (Supplement 1): 174−176+183.

[15] 胡厚勤, 张红英. 水平磁系高梯度磁选机回收攀西钛铁矿试验研究[J]. 钢铁钒钛, 2019, 40(6): 73−76+128. doi: 10.7513/j.issn.1004-7638.2019.06.015

HU H Q, ZHANG H Y. Experimental study on the recovering ilmenite from Iron tailings in Panzhihua−Xichang area by high gradient magnetic separator with a horizontal magnetic system[J]. Iron Steel Vanadium Titanium, 2019, 40(6): 73−76+128. doi: 10.7513/j.issn.1004-7638.2019.06.015

[16] 孟聪, 李丽匣, 申帅平, 等. 某钛铁矿分级磁选分级浮选试验研究[J]. 矿产保护与利用, 2017(1): 59−63.

MENG C, LI L X, SHEN S P, et al. Experiments on classified magnetic separation−classified flotation for a ilmenite[J]. Conservation and Utilization of Mineral Resources, 2017(1): 59−63.

[17] 邓建, 杨耀辉, 严伟平, 等. 攀西某超微细粒物料中钛铁矿选矿回收实验研究[J]. 矿产综合利用, 2023(1): 27−34.

DENG J, YANG Y H, YAN W P, et al. Recovery of ilmenite from an ultrafine fine particle material in Panxi[J]. Multipurpose Utilization of Mineral Resources, 2023(1): 27−34.

[18] 杨永涛, 张渊, 张俊辉. 四川某钒钛磁铁矿选铁尾矿选钛试验研究[J]. 矿产保护与利用, 2012(2): 32−36. doi: 10.3969/j.issn.1001-0076.2012.02.009

YANG Y T, ZHANG Y, ZHANG J H. Experimental research on ilmenite beneficiation for tailings after titanomagnetite recovery from a vanadic titanomagnetite ore in Sichuan[J]. Conservation and Utilization of Mineral Resources, 2012(2): 32−36. doi: 10.3969/j.issn.1001-0076.2012.02.009

[19] 张松, 文书明, 刘建, 等. 微细粒钛铁矿选矿技术研究进展[J]. 矿产保护与利用, 2019, 39(1): 131−137.

ZHANG S, WEN S M, LIU J, et al. Research on mineral processing status of fine ilmenite[J]. Conservation and Utilization of Mineral Resources, 2019, 39(1): 131−137.

[20] 王丽娟, 张超达, 陈俊明, 等. 反式水平磁场立环高梯度磁选机的研制及应用[J]. 现代矿业, 2017(6): 165−166+170. doi: 10.3969/j.issn.1674-6082.2017.06.047

WANG L J, ZHANG C D, CHEN J M, et al. Development and application of reverse horizontal magnetic field vertical ring high gradient magnetic separator[J]. Modern Mining, 2017(6): 165−166+170. doi: 10.3969/j.issn.1674-6082.2017.06.047

[21] 徐少华, 林恬盛. 立环高梯度磁选机线圈的冷却方式与特点[J]. 现代矿业, 2017(4): 222−224. doi: 10.3969/j.issn.1674-6082.2017.04.065

XU S H, LIN T S. Cooling method and characteristics of coil of vertical ring high gradient magnetic separator[J]. Modern Mining, 2017(4): 222−224. doi: 10.3969/j.issn.1674-6082.2017.04.065

[22] 宁宇, 储炜, 李明晶. 水平磁系高梯度磁选机精矿管堵塞原因分析与改造[J]. 现代矿业, 2020(5): 182−184. doi: 10.3969/j.issn.1674-6082.2020.05.055

NING Y, CHU W, LI M J. Cause analysis and transformation of concentrate pipe blockage of horizontal magnetic system high gradient magnetic separator[J]. Modern Mining, 2020(5): 182−184. doi: 10.3969/j.issn.1674-6082.2020.05.055

-

下载:

下载: