Experiment Study on Preparation of Graphene by Extracting Graphite from Graphite Tailings in Luobei

-

摘要:

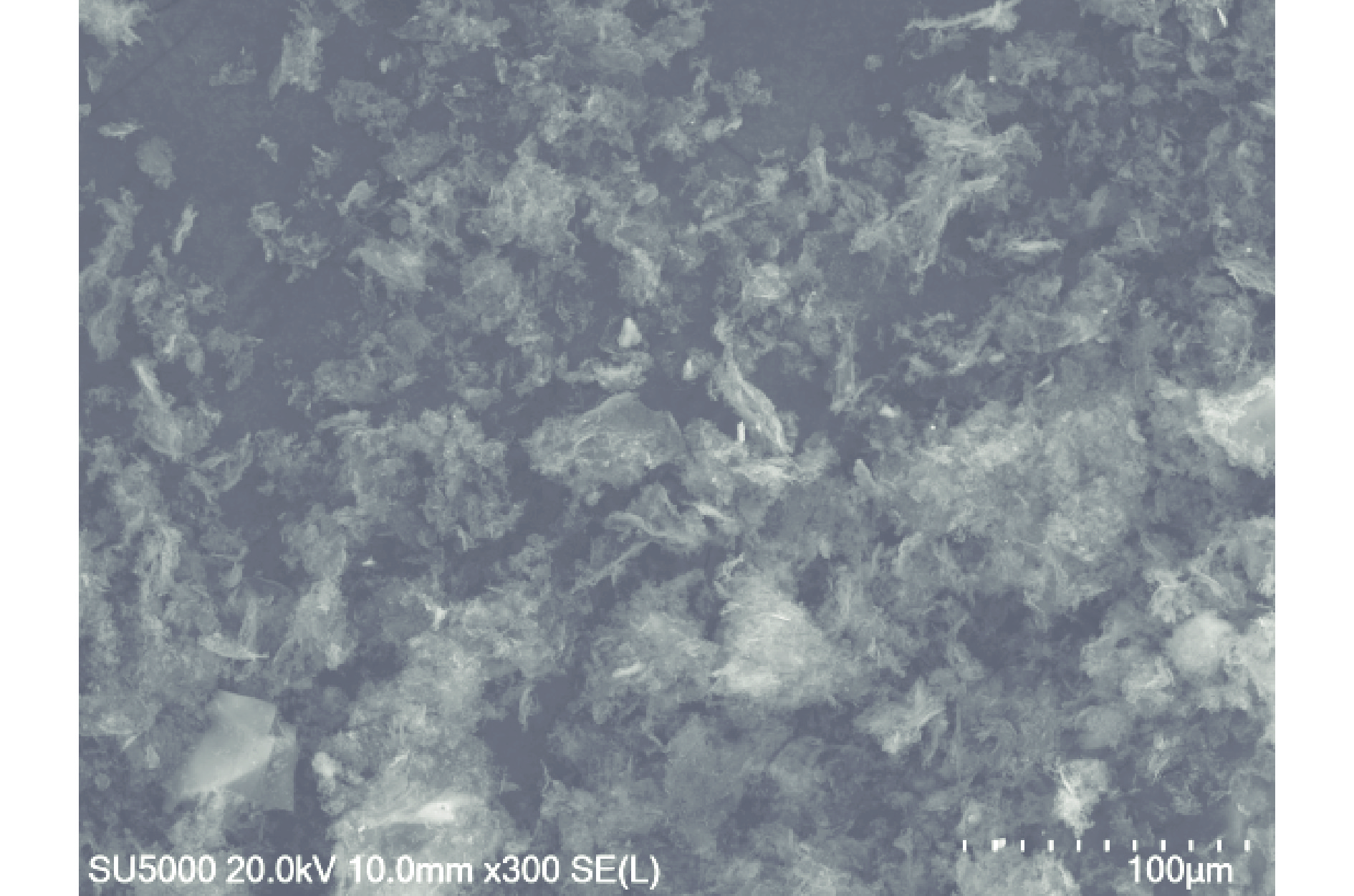

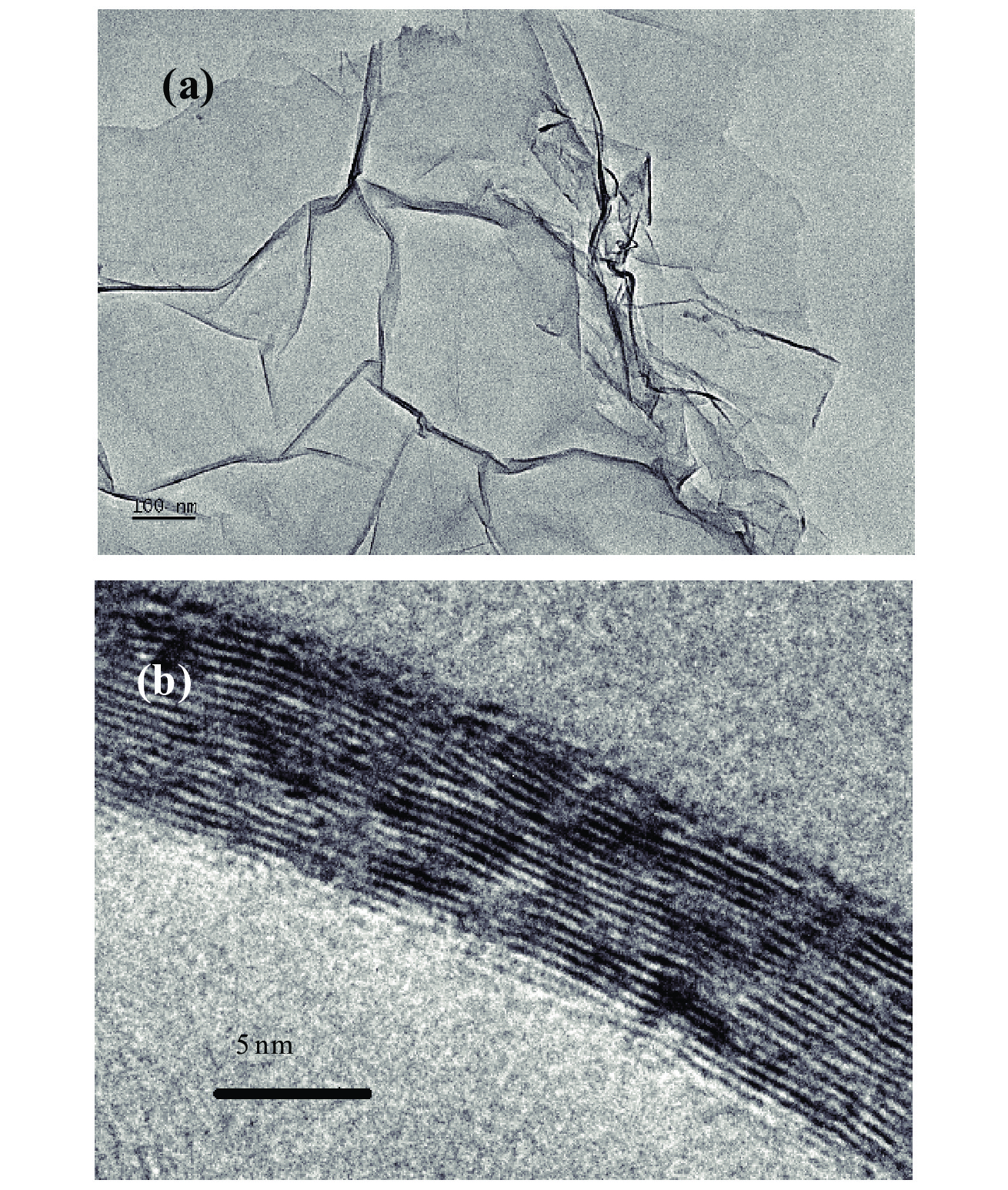

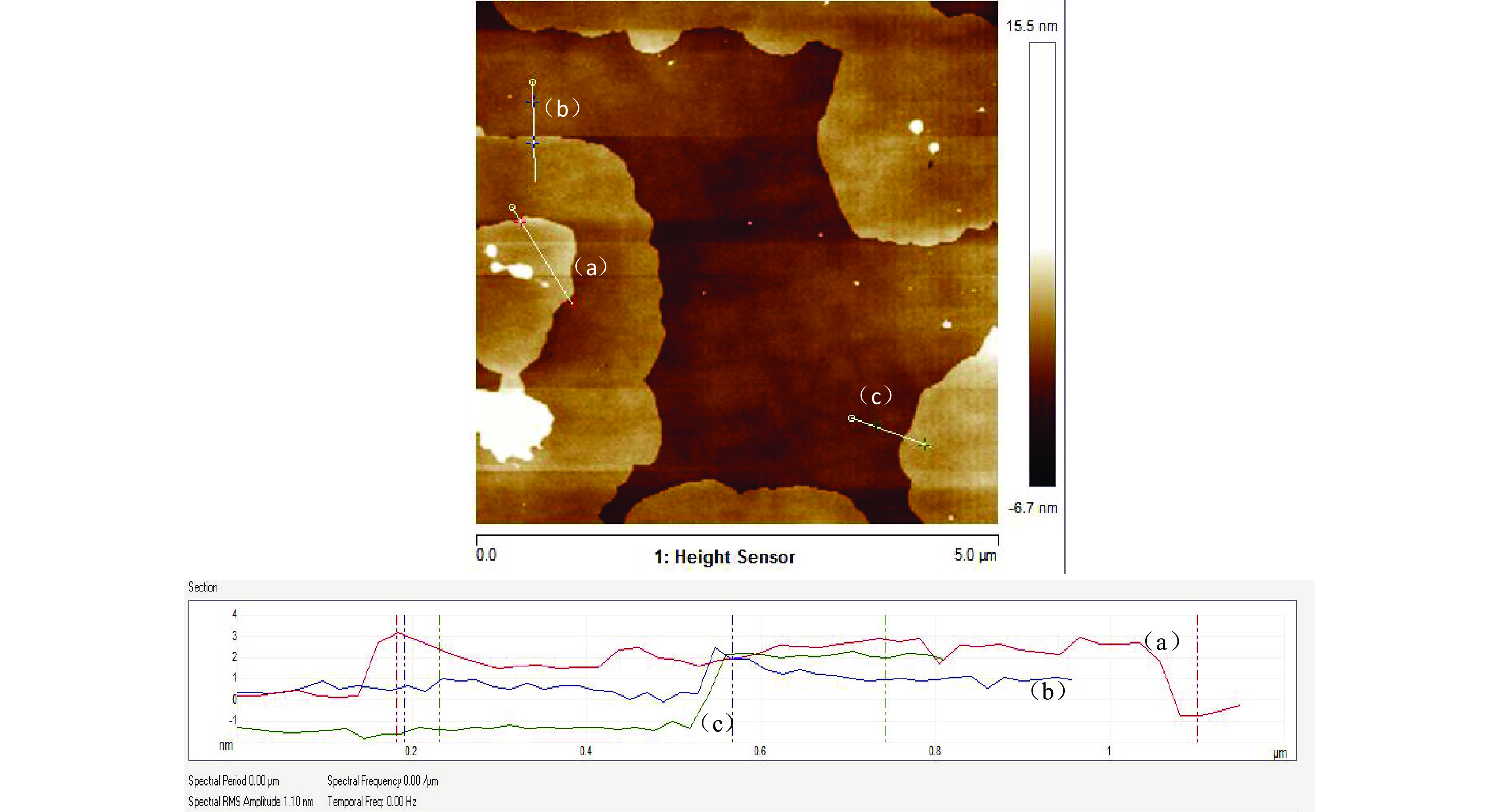

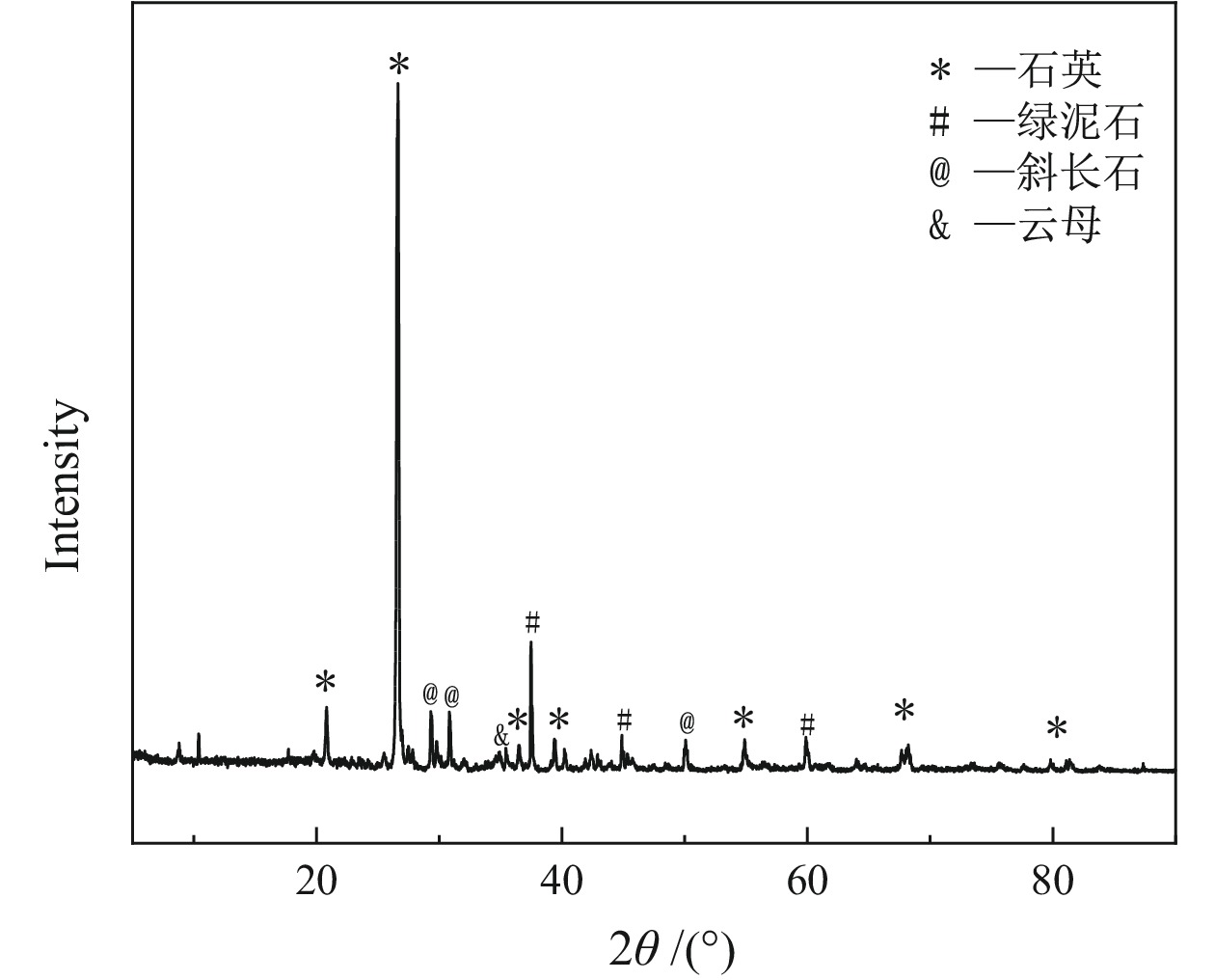

石墨烯独特的结构特性与优异的理化性质,使其具有广阔的应用前景。以萝北某石墨尾矿为对象,采用粉碎、超声剥离、重力沉降,提取石墨尾矿中石墨微纳米片,然后进行提纯剥离制备石墨烯。结果表明,研磨获得d50为2.5 µm左右的尾矿颗粒,超声剥离处理6 min,重力沉降进行石墨富集,获得石墨微片碳含量最高达9.72%,石墨回收率达80.01%,石墨微片经提纯后得到固定碳含量为98.1%、层数约为20层左右的石墨微纳米片。采用高压微射流均质机进行剥离制备多层石墨烯,石墨微片、水及分散剂配比为0.2 mg∶1 mL∶0.001 mg,高压微射流均质机的压力80 MPa,进行高压分散循环25次后,剥离得到的石墨烯片厚度在10层以下、片径在3 μm以上,制成具有较高晶体质量的石墨烯。石墨尾矿制备石墨烯既有利于拓展石墨烯原料范围又有利于实现石墨尾矿的资源化利用。

Abstract:Graphene showns promising prospects due to its unique structural characteristics and excellent physicochemical properties. In this paper, graphite tailings in Luobei were taken as the research object, and graphite nano/microsheets were extracted from graphite tailings by grinding, ultrasound and gravitational settlement, followed by purification and exfoliation to prepare graphene. The results showed that the tailings particles with d50 of about 2.5µm were obtained by grinding, ultrasonic stripping was performed for 6 min, and the graphite was enriched by gravitational settlement. The yield of recycled graphite microsheets was 9.72%, and the recovery rate was 80%. After purification, graphite nano/microsheets were obtained with fixed carbon content of 98.1% and about 20 layers. Finally, the high pressure microjet homogenizer was used to exfoliate and prepare multi−layer graphene. The ratio of graphite nano/microsheets, water and dispersant was 0.2 mg∶1 mL∶0.001 mg, and the pressure of the high pressure microjet homogenizer was 80 Mpa. After 25 high−pressure dispersion cycles, the thickness of the graphene sheets was less than 10 layers and the diameter of the sheets was more than 3 μm to produce graphene with high crystal quality. The preparation of graphene from graphite tailings not only expands the range of graphene raw materials but also realizes the resource utilization of graphite tailings.

-

-

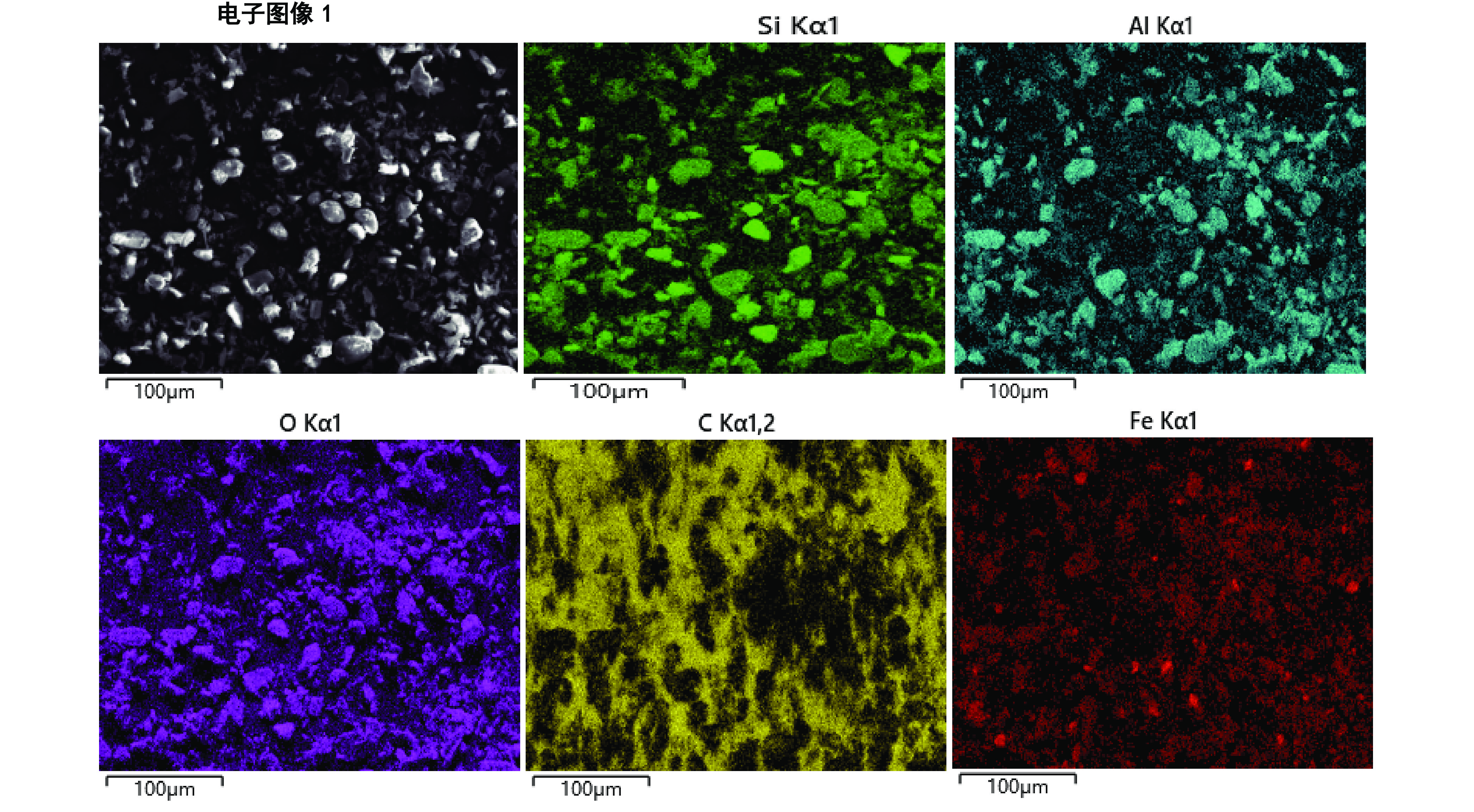

表 1 石墨尾矿化学成分

Table 1. Chemical composition of graphite tailings

/% 元素 SiO2 Fe3O4 FeS Al2O3 K2O Na2O CaO MgO TiO2 C 含量 60.36 5.15 3.28 11.92 2.64 0.47 7.10 0.50 0.04 2.21 表 2 相同静置时间5 min对过渡层产率、碳含量及石墨微片回收率影响

Table 2. Effect of the same rest time 5 min on transition layer yield, carbon content and graphite sheet yield

超声时间/min 沉降产率/% 固定碳含量/% 石墨微片回收率/% 0 10.31 8.68 40.52 2 14.33 9.30 60.33 4 15.62 9.67 68.39 6 18.19 9.72 80.01 8 18.79 9.41 80.02 10 18.91 9.47 80.13 -

[1] 祝雯霞, 亢建华, 张丹仙. 石墨资源成矿规律与浮选技术研究现状[J]. 矿物学报, 2023, 43(3): 97−415.

ZHU W X, KANG J H, ZHANG D X. Status of researches on the metallogenic regularity and flotation technology of graphite resources[J]. Acta Mineralogica Sinica, 2023, 43(3): 397−415.

[2] 梁文博, 张凌燕, 邱杨率, 等. 缅甸某地大鳞片石墨矿选矿试验研究[J]. 非金属矿, 2022, 45(6): 74−79.

LIANG W B, ZHANG L Y, QIU Y S, et al. Experimental research on beneficiation of large flake graphite ore in a certain place in myanmar[J]. Non−metallic Mines, 2022, 45(6): 74−79.

[3] 康文泽, 卢万里, 张宝成. 超声对萝北石墨浮选不同段数浮选效果的影响[J]. 矿产综合利用, 2024, 45(3): 43−49.

KANG W Z, LU W L, ZHANG B C. The effectof ultrasound on graphite flotation of different stages of Luobei[J]. Multipurpose Utilization of Mineral Resources, 2024, 45(3): 43−49.

[4] 丁会敏, 唐诗洋, 杨光, 等. 石墨尾矿综合利用现状[J]. 化学工程师, 2024, 38(1): 57−60.

DING H M, TANG S Y, YANG G, et al. Current situation of comprehensive utilization of graphite tailings[J]. Chemical Engineer, 2024, 38(1): 57−60.

[5] WANG Y P, VOULGARIS G, LI Y, et al. Sediment resuspension, flocculation, and setting in a macrotidal estuary[J]. Journal of Geophysical Resea rch Oceans, 2013, 118(10): 5591−5608. doi: 10.1002/jgrc.20340

[6] 邓旭, 孙刚臣, 张喜伟. 铝尾矿泥浆中微米级细颗粒自然沉降规律研究[J]. 河北地质大学学报, 2022, 45(6): 77−81.

DENG X, SUN G C, ZHANG X W. Study on natural settlement law of micron fine particles in aluminum tailing slime[J]. Journal of Hebei GEO University, 2022, 45(6): 77−81.

[7] 金智涛, 郑建国, 张君, 等. 颗粒形状对珊瑚砂和石英砂沉降影响的试验研究[J]. 海洋通报, 2021, 40(4): 447−454.

JIN Z T, ZHENG J G, ZHANG J, et al. Experimental study on the influence of particle shape on the settlementof coral sand and quartz sand[J]. Marine Science Bulletin, 2021, 40(4): 447−454.

[8] 唐杰平, 陈德志, 李高聪. 实验室内细颗粒泥沙沉降速度与悬沙浓度关系评估[J]. 海洋技术学报, 2023, 42(5): 86−93.

TANG J P, CHEN D Z, LI G C. Evaluation of the relationship between settling velocity and suspended sediment concentration for fine sediment in laboratory[J]. Journal of Ocean Technology, 2023, 42(5): 86−93.

[9] 尉琳琳, 李可可, 刘臻, 等. 以神东烟煤为原料制备石墨烯及其表征[J/OL]. 洁净煤技术, 1-9 [2024-02-21]. http://kns.cnki.net/kcms/detail/11.3676.td.20231121.1510.002.html.

WEI L L, LI K K, LIU Z, et al. Preparation and characterization of graphene from shendong bitu-minous coal[J/OL]. Clean Coal Technology, 1-9 [2024-02-21]. http://kns.cnki.net/kcms/detail/11.3676.td.20231121.1510.002.html.

[10] H. L. POH, F. SANEK, A. AMBROSI. Graphenes prepared by staudenmaier, hofmann and hummers methods with consequent thermal exfoliation exhibit very different electrochemical properties[J]. Nanoscale, 2012, 4: 3515−3522. doi: 10.1039/c2nr30490b

[11] KRISHNAMOORTHY K, VEERAPANDIAN M, YUN K, et al. The chemical and structural analysis of graphene oxide with different degrees of oxidation[J]. Carbon, 2013, 53: 38−49. doi: 10.1016/j.carbon.2012.10.013

-

下载:

下载: