Research Progress of Flotation Foam State Informatization Based on the Background of Intelligent Beneficiation

-

摘要:

矿产资源是经济社会发展的基础,实现矿产资源高质量发展,利用信息化、数字化技术建设绿色、高效的智慧矿山是必要途径。智慧选矿是智慧矿山的组成部分,其实施基础是选矿过程的信息化和数字化。以泡沫浮选为切入点,梳理了泡沫状态信息化常用方法,在此基础上阐述了泡沫状态信息的数字化应用,探讨了浮选过程智能化的研发与推广方向,旨在推动智慧选矿领域先进技术的研究进程。

Abstract:Mineral resources are the foundation of social and economic development. According to the goal of realizing high−quality development of mineral resources in the new period of China, it is necessary to build green and highly efficient mines by using information and digital technology. Intelligent beneficiation is a part of intelligent mine, and its implementation is based on the informatization and digitalization of mineral processing. Taking foam flotation as an example, the common methods of foam state informatization were combed, and the digital applications of foam state information were further described, then the development and promotion direction of intelligent flotation process was discussed. The aim is to facilitate the advancement of the research process related to advanced technologies in the field of intelligent mineral processing.

-

Key words:

- intelligent beneficiation /

- flotation foam /

- informatization /

- digitization

-

-

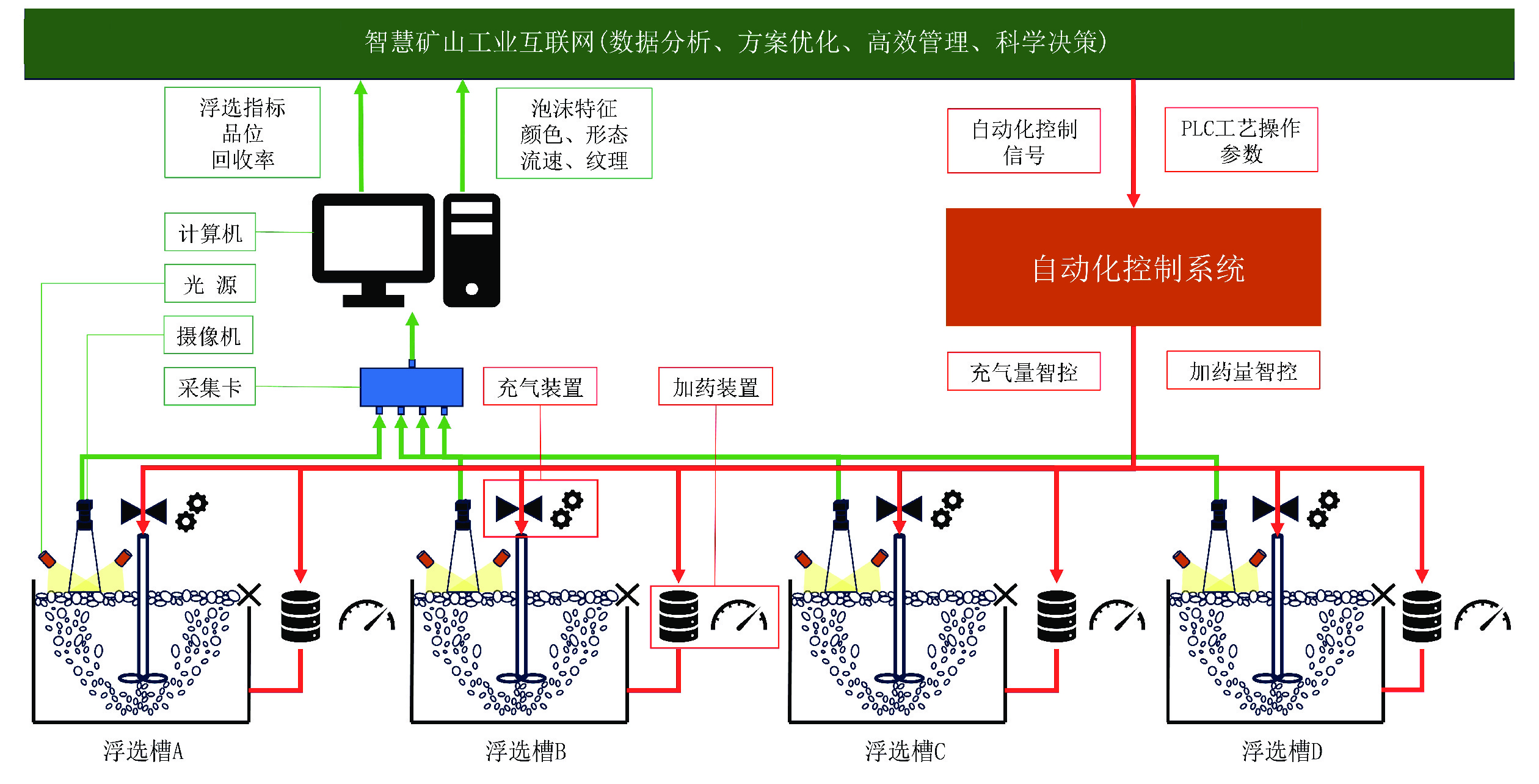

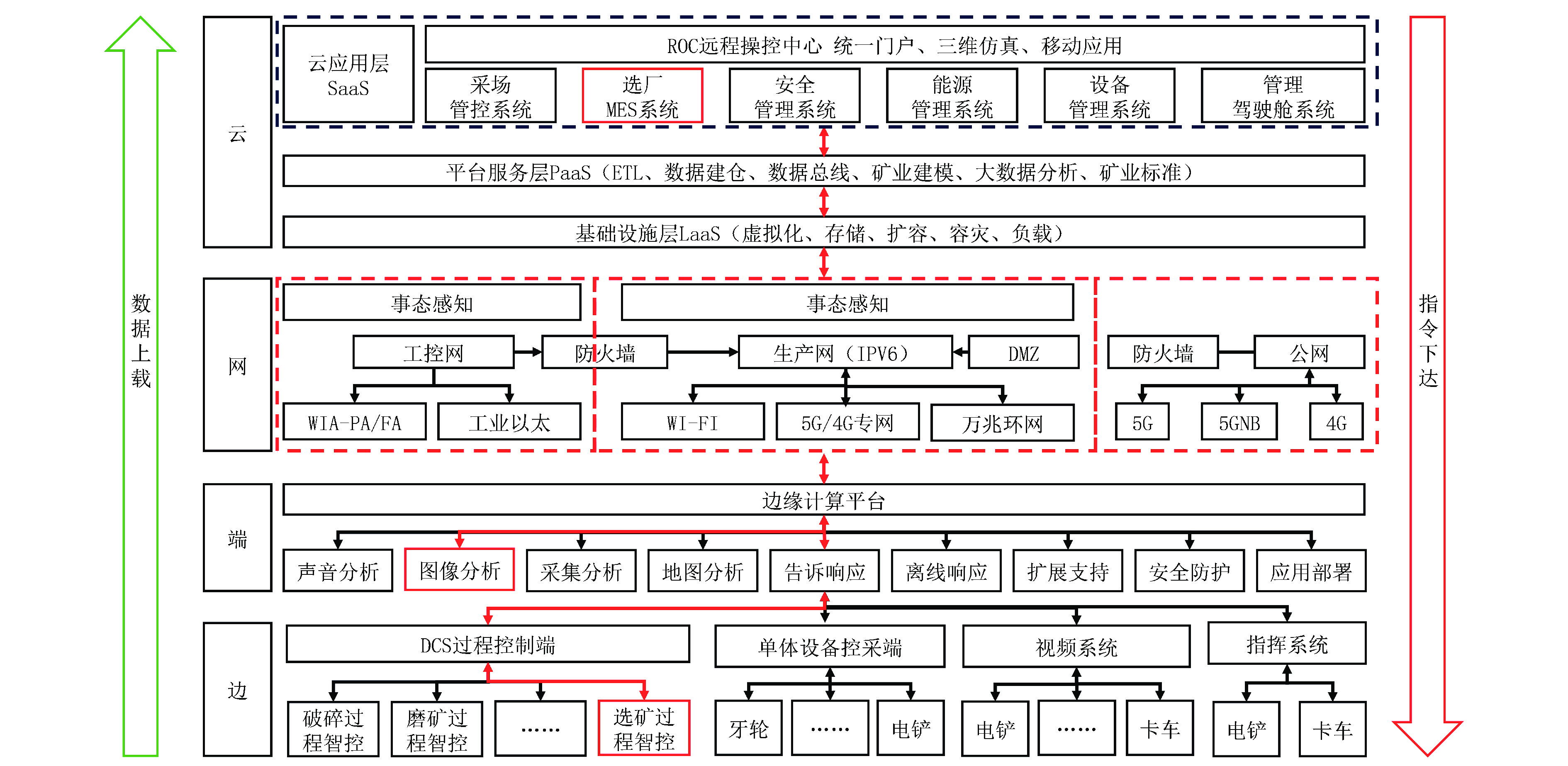

图 1 智慧选矿在智慧矿山体系中的定位[3]

Figure 1.

-

[1] 中国矿产资源报告2022[J]. 自然资源情报, 2023(1): 2.

China mineral resources report 2022[J]. Natural Resource Information, 2023(1): 2.

[2] 邵安林, 刘畅, 岳星彤, 等. 新时期我国矿产资源行业高质量发展路径[J]. 金属矿山, 2024(1): 2−6.

SHAO A L, LIU C, YUE X, et al. Path of high−quality development of China's mineral resources industry in the new era[J]. Metal Mine, 2024(1): 2−6.

[3] 柳小波, 张兴帆, 曲福明, 等. 我国冶金行业智慧矿山建设路径探索与实践[J]. 金属矿山, 2024(1): 45−54.

LIU X B, ZHANG X F, QU F M, et al. Exploration and engineering practice of the development path for smart mines in China′s metallurgical industry[J]. Metal Mine, 2024(1): 45−54.

[4] 中华人民共和国自然资源部. 智能矿山建设规范: DZ/T 0376—2021[S]. 北京: 地质出版社, 2021.

Ministry of Natural Resources of the People′s Republic of China. Specification for intelligent mine construction: DZ/T 0376—2021[S]. Beijing: Geology Press, 2021.

[5] 祝晋, 刘威, 高立强. 智能选矿厂的建设探索与实践[J]. 有色金属(选矿部分), 2023(1): 121−126.

ZHU J, LIU W, GAO L Q. Exploration and practice of intelligent concentrator construction[J]. Nonferrous Metals (Mineral Processing Section), 2023(1): 121−126.

[6] 刘道喜. 基于浮选泡沫图像颜色特征提取的矿浆品位建模及工程实现[D]. 沈阳: 东北大学, 2024.

LIU D X. Pulp grade modeling and engineering realization based on color feature extraction of flotation foam images[D]. Shenyang: Northeastern University, 2024.

[7] 李佳俊. 基于图像处理的辉铜矿浮选泡沫图像研究[D]. 黄石: 湖北师范大学, 2023.

LI J J. Study on froth image of chalcocite flotation based on image processing[D]. Huangshi: Hubei Normal University, 2023.

[8] MOOLMAN D W, AlRICH C, VAN DEVENTER J S J. The interpretation of flotation froth surfaces by using digital image analysis and neural networks[J]. Chemical Engineering Science, 1995, 50(22): 3501−3513. doi: 10.1016/0009-2509(95)00190-G

[9] MOOLMAN D W, ALRICH C, SCHMITZ G, et al. The interrelationship between surface froth characteristics and industrial flotation performance[J]. Minerals Engineering, 1996, 9(8): 837−854.

[10] HARGRAVE JM, MILES N J, HALL S T. The use of grey level measurement in predicting coal flotation performance[J]. Minerals Engineering, 1996, 9(6): 667−674. doi: 10.1016/0892-6875(96)00054-4

[11] WOODBURN E T, AUSTIN L G, STOCKTON J B. A froth based flotation kinetic model[J]. Chemical Engineering Research & Design, 1994, 72(2A): 211−226.

[12] VENTURA−MEDINA E, CILLIERS J J. Calculation of the specific surface area in flotation[J]. Minerals Engineering, 2000, 13(3): 265−275. doi: 10.1016/S0892-6875(00)00006-6

[13] VENTURA−MEDINA E, CILLIERS J J. A model to describe flotation performance based on physics of foams and froth image analysis[J]. International Journal of Mineral Processing, 2002, 67: 79−99. doi: 10.1016/S0301-7516(02)00038-8

[14] WANG W, BERGHOLM F, YANG B. Froth delineation based on image classification[J]. Minerals Engineering, 2003, 16: 1183−1192. doi: 10.1016/j.mineng.2003.07.014

[15] VINCENT L, SOLILLE P. Watershed in digital spaces: An efficient algorithm based immersion simulations[J]. IEEE Trans. PA−MI, 1991, 13(6): 583−598. doi: 10.1109/34.87344

[16] SAMEER H M, DEE J B, MARTIN C H. The use of the froth surface lamellae burst rate as a flotation froth stability measurement[J]. Minerals Engineering, 2012, 36(10): 152−159.

[17] XU C H, GUI W H, YANG C H, et al. Flotation process fault detection using output PDF of bubble size distribution[J]. Minerals Engineering, 2012, 26: 5−12. doi: 10.1016/j.mineng.2011.09.012

[18] CHEN X F, GUI W H, YANG C H, et al. Adaptive image processing for bubbles in flotation process[J]. Measurement & Control, 2011, 44(4): 121−125.

[19] HAMARNEH G, LI X. Watershed segmentation using prior shape and appearance knowledge[J]. Image & Vision Computing, 2009, 27(1): 59−68.

[20] GAO H, LIN W. Marker−based image segmentation relying on disjoint set union[J]. Signal Processing Image Communication, 2006, 21(2): 100−112. doi: 10.1016/j.image.2005.06.008

[21] GONZALEZ R C, WOODS R E. Woods digital image processing: 2nd edition[M]. Beijing: Publishing House of Electronics Industry, 2011.

[22] 林小竹, 谷莹莹, 赵国庆. 煤泥浮选泡沫图像分割与特征提取[J]. 煤炭学报, 2007(3): 304−308. doi: 10.3321/j.issn:0253-9993.2007.03.019

LIN X Z, GU Y Y, ZHAO G Q. Image segmentation and feature extraction of slime flotation foam[J]. Journal of China Coal Society, 2007(3): 304−308. doi: 10.3321/j.issn:0253-9993.2007.03.019

[23] 李怡. 铜浮选过程泡沫图像特征提取及工况识别方法研究[D]. 沈阳: 东北大学, 2019.

LI Y. Study on foam image feature extraction and working condition recognition method in copper flotation process[D]. Shenyang: Northeastern University, 2019.

[24] 周开军. 矿物浮选泡沫图像形态特征提取方法与应用[D]. 长沙: 中南大学, 2010.

ZHOU K J. Morphological feature extraction method and application of mineral flotation foam image[D]. Changsha: Central South University, 2010.

[25] 廖一鹏, 王卫星. 结合多尺度边缘增强及自适应谷底检测的浮选气泡图像分割[J]. 光学精密工程, 2016, 24(10): 2589−2600. doi: 10.3788/OPE.20162410.2589

LIAO Y P, WANG W X. Flotation bubble image segmentation combined with multi−scale edge enhancement and adaptive valley bottom detection[J]. Optics and Precision Engineering, 2016, 24(10): 2589−2600. doi: 10.3788/OPE.20162410.2589

[26] NING Z. An image segmentation algorithm for flotation foam of copper and molybdenum ore[J]. Computer Knowledge and Technology, 2014, 10(12): 2875−2877.

[27] 王宇龙. 基于机器视觉的煤泥浮选泡沫分类研究[D]. 太原: 太原理工大学, 2022.

WANG Y L. Study on classification of coal slime flotation foam based on machine vision[D]. Taiyuan: Taiyuan University of Technology, 2022.

[28] 温智平. 基于深度学习的煤泥浮选过程灰分预测与系统控制研究[D]. 徐州: 中国矿业大学, 2023.

WEN Z P. Research on ash prediction and system control of coal slime flotation process based on deep learning[D]. Xuzhou: China University of Mining and Technology, 2023.

[29] 胡椰清. 基于泡沫图像特征的钨浮选精矿品位预测研究[D]. 长沙: 中南大学, 2023.

HU Y Q. Prediction of tungsten flotation concentrate grade based on foam image features[D] . Changsha: Central South University, 2023.

[30] 陈宁, 黄璐, 桂卫华, 等. 泡沫图像统计建模与恒常颜色校正算法研究[J]. 控制理论与应用, 2016, 33(5): 613−620. doi: 10.7641/CTA.2016.50783

CHEN N, HUANG L, GUI W H, et al. Research on statistical modeling and constant color correction algorithm of foam image[J]. Control Theory and Applications, 2016, 33(5): 613−620. doi: 10.7641/CTA.2016.50783

[31] LIU J, GUI W, TANG Z, et al. Recognition of the operational statuses of reagent addition using dynamic bubble size distribution in copper flotation process[J]. Minerals Engineering, 2013, 45: 128−41. doi: 10.1016/j.mineng.2013.02.003

[32] 何桂春, 黄开启. 浮选指标与浮选泡沫数字图像关系研究[J]. 金属矿山, 2008, 37(8): 96−101.

HE G C, HUANG K Q. Study of the relation between flotation indexes and froth digital images[J]. Metal Mine, 2008, 37(8): 96−101.

[33] HARALICK R M, SHANMUGAM K, DINSTEIN I. Textural Features for Image Classification[J]. IEEE Transactions on Systems, Man and Cybernetics, 1973, 3(6): 610−621.

[34] 刘文礼, 路迈西, 王凡, 等. 煤泥浮选泡沫图像纹理特征的提取及泡沫状态的识别[J]. 化工学报, 2003, 54(6): 830−835. doi: 10.3321/j.issn:0438-1157.2003.06.025

LIU W L, LU M X, WANG F, et al. Extraction of textural feature and recognition of coal flotation froth[J]. Journal of Chemical Industry and Engineering, 2003, 54(6): 830−835. doi: 10.3321/j.issn:0438-1157.2003.06.025

[35] 程翠兰. 基于颜色与纹理特征的矿物浮选精选泡沫分类[D]. 长沙: 中南大学, 2011.

CHENG C L. Classification of mineral flotation foam based on color and texture characteristics[D]. Changsha: Central South University, 2011.

[36] 唐朝晖, 孙园园, 桂卫华, 等. 基于小波变换的浮选泡沫图像纹理特征提取[J]. 计算机工程, 2011, 37(18): 206−208. doi: 10.3969/j.issn.1000-3428.2011.18.069

TANG C H, SUN Y Y, GUI W H, et al. Texture feature extraction of flotation foam image based on wavelet transform[J]. Computer Engineering, 2011, 37(18): 206−208. doi: 10.3969/j.issn.1000-3428.2011.18.069

[37] 朱楚梅. 铝土矿精选泡沫图像纹理特征提取方法研究[D]. 长沙: 中南大学, 2013.

ZHU C M. Research on texture feature extraction method of bauxite foam image[D]. Changsha: Central South University, 2013.

[38] 马爱莲, 徐德刚, 谢永芳, 等. 基于复杂网络时空特性的泡沫图像动态纹理特征分析[J]. 化工学报, 2017, 68(3): 1023−1031.

MA A L, XU D G, XIE Y F, et al. Analysis of dynamic texture features of floatation froth images based on space−time characteristics of complex networks[J]. CIESC Journal, 2017, 68(3): 1023−1031.

[39] 牟学民, 刘金平, 桂卫华, 等. 基于SIFT特征配准的浮选泡沫移动速度提取与分析[J]. 信息与控制, 2011, 40(4): 525−531.

MOU X M, LIU J P, GUI W H, et al. Extraction and analysis of flotation foam movement velocity based on SIFT feature registration[J]. Information and Control, 2011, 40(4): 525−531.

[40] TANG Z, ZENG S, XIE Y, et al. Real−time froth velocity extraction of zinc flotation based on improved SURF[C]//proceedings of the 2018 Chinese Automation Congress (CAC), F, IEEE. 2018.

[41] 陈良琴, 王卫星. 基于气泡跟踪与相位相关的浮选表面气泡平移运动估计[J]. 四川大学学报(工程科学版), 2016, 48(5): 143−152.

CHEN L Q, WANG W X, Estimation of bubble translation motion on flotation surface based on bubble tracking and phase correlation[J]. Journal of Sichuan University (Engineering Science Edition), 2016, 48(5): 143−152.

[42] 卜显忠, 杨怡琳, 宛鹤. 基于浮选泡沫图像预测精矿品位的研究进展[J]. 金属矿山, 2024(2): 25−38.

BU X Z, YANG Y L, WAN H. Research progress of concentrate grade prediction based on flotation foam image[J]. Metal Mine, 2024(2): 25−38.

[43] LI Z M, GUI W H, ZHU J Y, Fault diagnosis method of flotation process based on deep learning and support vector machine[J]. Journal of Central South University, 2019, 26(9): 2504−2515.

[44] WANG X, SONG C, YANG C, et al. Process working condition recognition based on the fusion of morphological and pixel set features of froth for froth flotation[J]. Minerals Engineering, 2018, 128: 17−26. doi: 10.1016/j.mineng.2018.08.017

[45] 梁秀满, 田童, 刘文涛, 等. 基于泡沫图像特征融合的煤泥浮选工况识别[J]. 计算机仿真, 2021, 38(4): 385−389. doi: 10.3969/j.issn.1006-9348.2021.04.078

LIANG X M, TIAN T, LIU W T, et al. Coal slime flotation condition recognition based on foam image feature fusion[J]. Computer Simulation, 2021, 38(4): 385−389. doi: 10.3969/j.issn.1006-9348.2021.04.078

[46] 朱建勇, 黄鑫, 杨辉, 等. 基于稀疏化神经网络的浮选泡沫图像特征选择[J]. 控制与决策, 2021, 36(7): 1627−1636.

ZHU J Y, HUANG X, YANG H, et al. Feature selection of flotation froth image based on sparse neural network[J]. Control and Decision, 2021, 36(7): 1627−1636.

[47] 周开军, 阳春华, 牟学民, 等. 基于泡沫特征与LS−SVM的浮选回收率预测[J]. 仪器仪表学报, 2009, 30(6): 1295−1300. doi: 10.3321/j.issn:0254-3087.2009.06.034

ZHOU K J, YANG C H, MOU X M, et al. Prediction of flotation recovery rate based on foam characteristics and LS−SVM[J]. Chinese Journal of Scientific Instrument, 2009, 30(6): 1295−1300. doi: 10.3321/j.issn:0254-3087.2009.06.034

[48] 张海洋, 王旭, 王庆凯等. 镍浮选过程智能控制系统开发与应用[J]. 有色金属工程, 2024, 14(2): 77−84.

ZHANG H Y, WANG X, WANG Q K, et al. Development and application of intelligent control system for nickel flotation process[J]. Nonferrous Metals Engineering, 2024, 14(2): 77−84.

[49] 阳春华, 任会峰, 许灿辉, 等. 基于稀疏多核最小二乘支持向量机的浮选关键指标软测量[J]. 中国有色金属学报, 2011, 21(12): 3149−3154.

YANG C H, REN H F, XU C H, et al. Soft measurement of key flotation indexes based on Sparse multi−core least squares support vector machine[J]. The Chinese Journal of Non−Ferrous Metals, 2011, 21(12): 3149−3154.

[50] 张燕红, 刘俊, 陈冲等. 浮选智能控制系统在某钼矿选厂的应用[J]. 矿山机械, 2021, 49(9): 50−54. doi: 10.3969/j.issn.1001-3954.2021.09.012

ZHANG Y H, LIU J, CEHN C, et al. Application of flotation intelligent control system in a molybdenum ore separation plant[J]. Mining Machinery, 2021, 49(9): 50−54. doi: 10.3969/j.issn.1001-3954.2021.09.012

[51] 苏超, 王旭. 浮选流程智能控制系统开发与应用[J]. 铜业工程, 2019(4): 4−9. doi: 10.3969/j.issn.1009-3842.2019.04.003

SU C, WANG X. Development and application of flotation process intelligent control system[J]. Copper Engineering, 2019(4): 4−9. doi: 10.3969/j.issn.1009-3842.2019.04.003

-

下载:

下载: