Research Status of Underground Goaf Filling Technology in Solid Sylvite Mine

-

摘要:

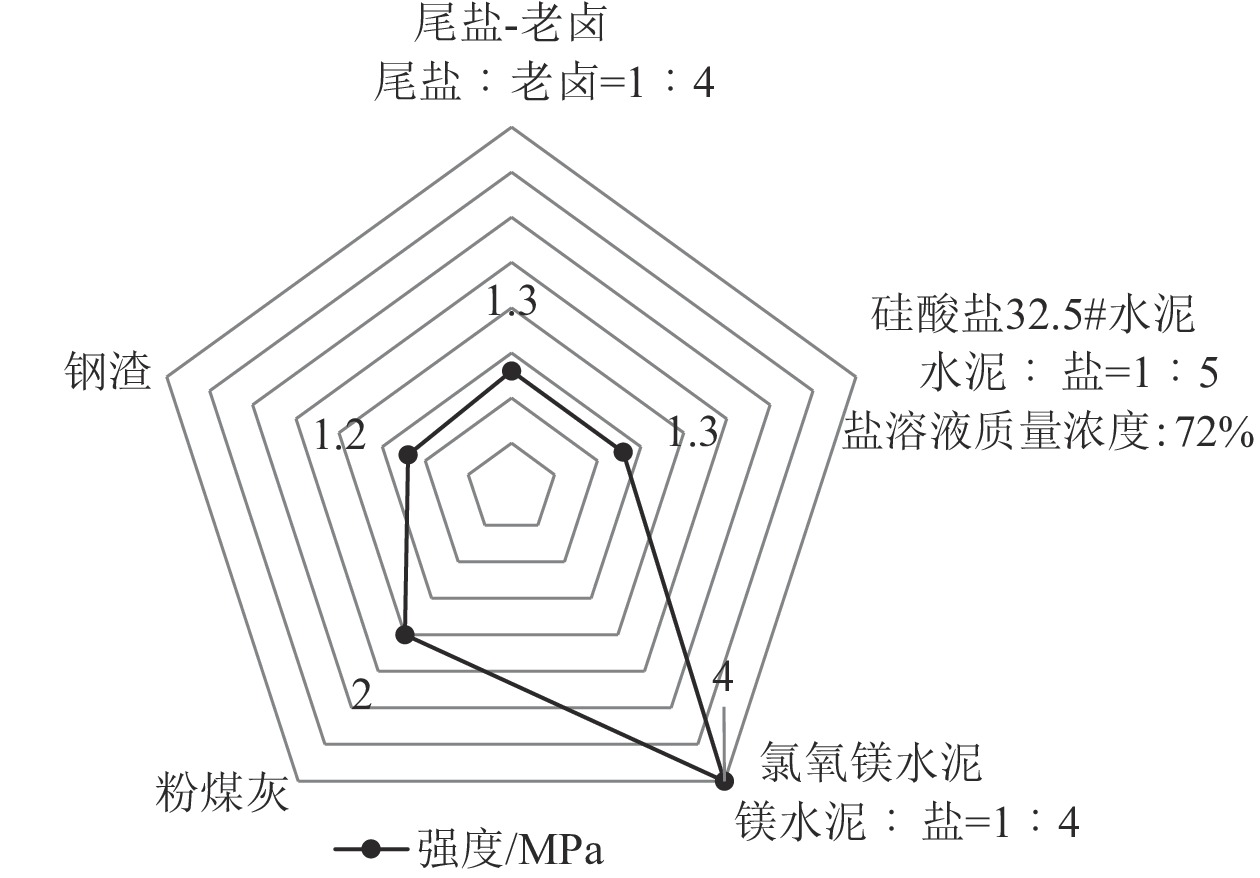

钾盐矿作为我国战略性非金属矿产,其安全高效开采直接关系到国家粮食安全和经济社会稳定。针对其地下开采遗留的采空区和选矿产生的固液尾废,总结了地下固体钾盐矿开采方法和充填方式的特点,系统介绍了不同充填胶凝材料的固结机理和研究进展,明确了胶凝材料配方及配比、尾废−胶结料固结体力学性能、胶结充填配套工艺等研究方向,为钾盐矿开发企业选择合适开采方式、充填方法和基于固液尾废的充填材料提供了参考。分析表明:低掺量氯氧镁水泥、粉煤灰、外加剂复合型胶凝材料,是现阶段实现地下固体钾盐矿山高效安全、低尾废排放、低成本充填开采的关键。

Abstract:Potassium salt as a strategic non−metallic mineral in China, its safe and efficient exploitation was directly related to national food security and economic and social stability. Aiming at the goaf left by underground mining and the solid−liquid tail waste generated by beneficiation, The characteristics of underground mining methods and filling methods of solid sylvite mines were summarized, besides generally introducing the cementation mechanism of different filling cementitious materials and the current research situation. The research directions covering cementitious material formula and proportion, mechanical properties of tailing−waste−colloid cement, and supporting technology of cementitious filling were clarified, so as to provide references for the potash mine developers to choose suitable mining methods, filling methods and solid−liquid tailing−waste−based filling materials. The analysis shows that the composite cementitious material with low dosage of magnesium chloride−oxygen cement, fly ash and additives is the key to realize the high efficiency and safety of solid potash underground mine which produces low tailing waste emission and low−cost of filling mining at the present stage.

-

Key words:

- solid sylvite deposit /

- backfilling of goaf /

- cementitious material

-

-

图 2 氯氧镁水泥3相水化物(a)和5相水化物(b)结构 [55]

Figure 2.

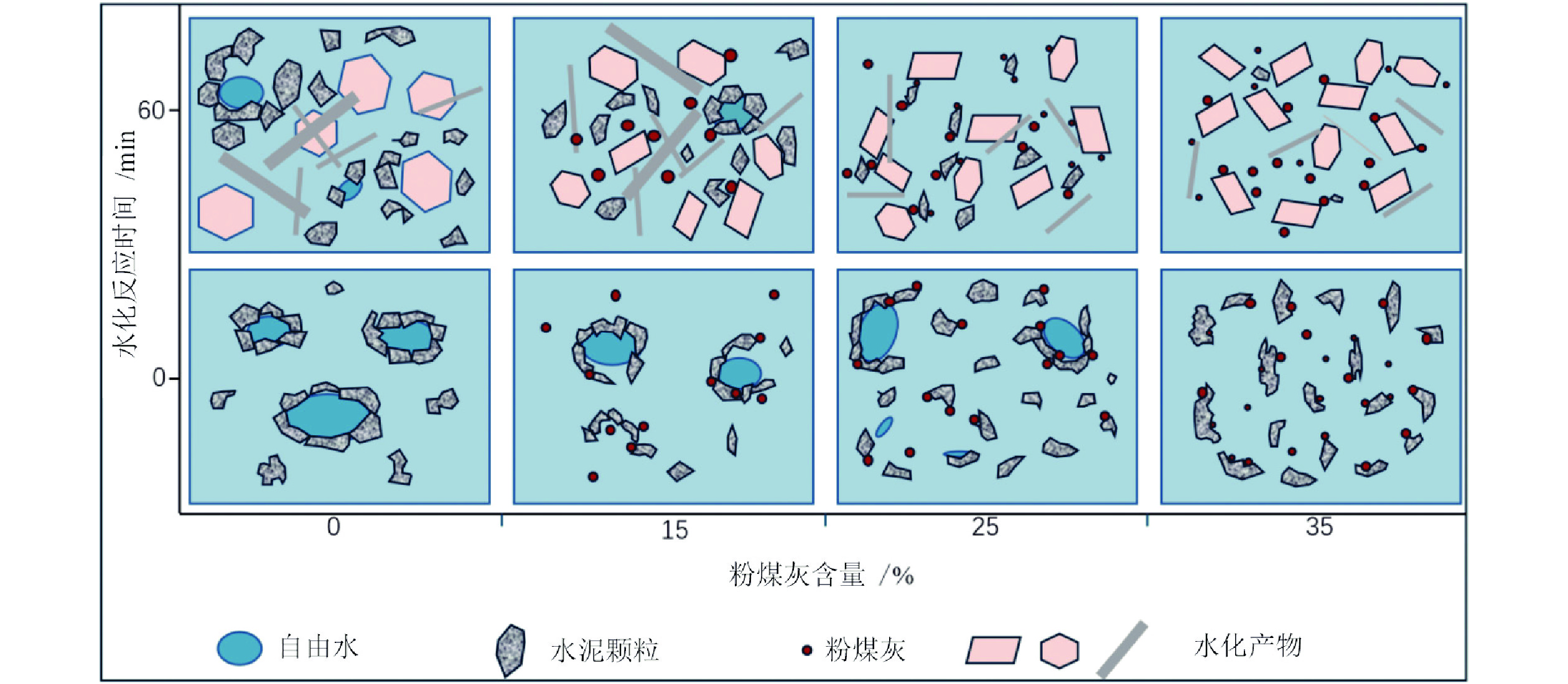

图 3 掺粉煤灰的氯氧镁水泥水化反应过程[67]

Figure 3.

-

[1] SHARMA P P, YADAV V, RAJPUT A, et al. Synthesis of chloride−free potash fertilized by ionic metathesis using four−compartment electrodialysis salt engineering[J]. ACS Omega, 2018, 3(6): 6895−6902.

[2] TüRK T, ÜçERLER Z, BURAT F, et al. Extraction of potassium from feldspar by roasting with CaCl2 obtained from the acidic leaching of wollastonite−calcite ore[J]. Minerals, 2021, 11(12): 1369.

[3] 熊增华, 王石军. 中国钾资源开发利用技术及产业发展综述[J]. 矿产保护与利用, 2020, 40(6): 1−7.

XIONG Z H, WANG S J. Overview of potassium resources exploitation & utilization technology and potash industry development[J]. Conservation and Utilization of Mineral Resources, 2020, 40(6): 1−7.

[4] 汪家铭. 我国海外钾盐资源开发及前景展望[J]. 中国石油和化工经济分析, 2010(9): 51−55.

WANG J M. Development and prospect of overseas potash resources in China[J]. China Petroleum and Chemical Economic Analysis, 2010(9): 51−55.

[5] 王石军. 全球钾肥产业发展现状与展望[J]. 磷肥与复肥, 2019, 34(10): 9−13. doi: 10.3969/j.issn.1007-6220.2019.10.004

WANG S J. Development status and prospect of potash fertilizer industry in the world[J]. Phosphate & Compound Fertilizer, 2019, 34(10): 9−13. doi: 10.3969/j.issn.1007-6220.2019.10.004

[6] SANTOS S, CASAGRANDE P, NADER P, et al. Technical feasibility study of the exploitation of seabed potassium salts by solution mining[J]. Journal of Materials Research and Technology, 2022, 16: 433−441.

[7] ZELEK S M, STADNICKA K M, TOBOŁA T, et al. Lattice deformation of blue halite from Zechstein evaporite basin: Kłodawa Salt Mine, Central Poland[J]. Mineralogy and Petrology, 2014, 108: 619−631.

[8] 白仟, 张寿庭, 袁俊宏, 等. 钾盐开采—加工技术及其对产业发展的影响[J]. 资源与产业, 2015, 17(3): 79−88.

BAI Q, ZHANG S T, YUAN J H, WANG Z G. Potash mining & processing technology and its influence on industrial development[J]. Resources & Industries, 2015, 17(3): 79−88.

[9] 常政, 袁小龙, 刘万平, 等. 察尔汗盐湖固体钾盐溶解对溶剂注入速率响应机制研究[J]. 地球学报, 2022, 43(3): 287−294. doi: 10.3975/cagsb.2022.021701

CHANG Z, YUAN X L, LIU W P. A study on the mechanism of influence of the dissolution of solid potassium salt in Qarhan Salt Lake to the rate of solvent injection[J]. Acta Geoscientica Sinica, 2022, 43(3): 287−294. doi: 10.3975/cagsb.2022.021701

[10] 董晓铭, 秦佳政, 张仂. 地下可溶性固体钾盐矿加工氯化钾新工艺探索[J]. 盐业与化工, 2015, 44(2): 18−20.

DONG X M, QIN J Z, ZHANG L. Exploration of new process for processing potassium chloride from underground soluble solid potash mine[J]. Journal of Salt Science and Chemical Industry, 2015, 44(2): 18−20.

[11] 王兴富, 王石军, 王罗海, 等. 柴达木低品位固体钾矿溶解转化实验及应用前景[J]. 化工矿产地质, 2019, 41(4): 299−305.

WANG X F, WANG S J, WANG L H, et al. Dissolution and transformation experiment of low−grade solid potash for Qaidam and its application prospect[J]. Geology of Chemical Minerals, 2019, 41(4): 299−305.

[12] CUI Z H, ZHAO Y J, ZHANG Y M, et al. Experimental study of lithium extraction in the solid−liquid conversion of low−grade solid potash ore[J]. Minerals, 2024, 14(1): 116.

[13] LI R Q, LIU C L, JIAO P C, et al. The present situation, existing problems, and countermeasures for exploitation and utilization of low−grade potash minerals in Qarhan Salt Lake, Qinghai Province, China[J]. Carbonates and Evaporites, 2020, 35(2): 34.

[14] RAJENDRAN V G. Corrosion inhibitor for potash solution mining [M]. Regina: The University of Regina (Canada), 2020.

[15] 王罗海, 王石军, 刘万平, 等. “固转液”技术应用及其对资源和环境的影响分析[J]. 化工矿产地质, 2020, 42(4): 378−381.

WANG L H, WANG S J, LIU W P, et al. The application of "Immersion dissolution and transformation method for solid potassium ore" and its impact on resources and environment[J]. Geology of Chemical Minerals, 2020, 42(4): 378−381.

[16] 魏东岩. 美国新墨西哥州钾盐矿床及其开发[J]. 化工矿产地质, 2001(1): 31−38.

WEI D Y. Potash deposit and its development of New Mexico of USA[J]. Industrial Minerals & Processin, 2001(1): 31−38.

[17] 王庐山. 博尔拜钾盐矿的地下开采[J]. 化工矿山技术, 1983(5): 57−58+49.

WANG L S. Underground mining at the Borbay Potash Mine[J]. Geology of Chemical Minerals, 1983(5): 57−58+49.

[18] 亓昭英, 谢鹏飞. 加拿大萨省钾盐资源与钾肥生产考察报告[J]. 云南化工, 2013, 40(6): 25−32. doi: 10.3969/j.issn.1004-275X.2013.06.006

QI Z Y, XIE P F. Inspection report on Canadian's potash resources and potash producers in Saskatchewan[J]. Yunnan Chemical Technology, 2013, 40(6): 25−32. doi: 10.3969/j.issn.1004-275X.2013.06.006

[19] 欧天明. 滇南勐野井钾盐矿床成因新解[J]. 云南地质, 2014, 33(1): 6−13. doi: 10.3969/j.issn.1004-1885.2014.01.002

OU T M. A new recognition of genesis of Mengyejing potash deposit in YunNan[J]. Yunnan Geology, 2014, 33(1): 6−13. doi: 10.3969/j.issn.1004-1885.2014.01.002

[20] 刘小力, 吴国平. 充填采矿技术在井采钾盐矿应用的探讨[J]. 采矿技术, 2013, 13(3): 1−2+27. doi: 10.3969/j.issn.1671-2900.2013.03.001

LIU X L, WU G P. Discussion on the application of in fill mining technology in shaft mining potash mine[J]. Mining Technology, 2013, 13(3): 1−2+27. doi: 10.3969/j.issn.1671-2900.2013.03.001

[21] 杨卉芃, 曹飞. 世界钾资源研究系列之一—资源概况及供需分析[J]. 矿产保护与利用, 2015(1): 75−78.

YANG H P, CAO F. Series study on potassium resources in world: General situation and analysis of supply and demand[J]. Conservation and Utilization of Mineral Resources, 2015(1): 75−78.

[22] 余建荣, 李成宝, 汪云川, 等. 老挝固体钾盐矿选矿设计的优化与创新—以开元500kt/a氯化钾项目为例[J]. 盐湖研究, 2019, 27(4): 28−36.

YU J R, LI C B, WANG Y C, et al. The optimization and innovation on design of KCl concentration plant in Laos: A case study from the 500 kt/a KCl production project in Laos Kaiyuan Mining Company[J]. Journal of Salt Lake Research, 2019, 27(4): 28−36.

[23] BILIBIO C, RETZ S, SCHELLERT C, et al. Drainage properties of technosols made of municipal solid waste incineration bottom ash and coal combustion residues on potash−tailings piles: A lysimeter study[J]. Journal of cleaner production, 2021, 279: 123442. doi: 10.1016/j.jclepro.2020.123442

[24] SAVON D Y, SHEVCHUK S, SHEVCHUK P. Reducing the impact of waste from potash industry on the environment[J]. Gorn Inform Anal Bull, 2016(8): 360−368.

[25] GOROSTIZA S, SAURI D. Naturalizing pollution: A critical social science view on the link between potash mining and salinization in the Llobregat river basin, northeast Spain[J]. Philosophical Transactions of the Royal Society B: Biological Sciences, 2019, 374(1764). DOI: 10.1098/rstb.2018.0006.

[26] ZIEMANN H, SCHULZ C J. Methods for biological assessment of salt−loaded running waters–fundamentals, current positions and perspectives[J]. Limnologica, 2011, 41(2): 90−95. doi: 10.1016/j.limno.2010.09.005

[27] 高新. 固体钾盐矿地下开采中的问题探讨和解决对策[J]. 采矿技术, 2016, 16(6): 1−2+6.

GAO X. Problem exploration and solution countermeasures in underground mining of solid potash mine[J]. Mining Technology, 2016, 16(6): 1−2+6.

[28] 朱明松. 老挝钾盐矿资源规模化开发的总体思路[J]. 云南化工, 2013, 40(6): 1−4.

ZHU M S. General idea of the scale of exploiting Laos potash resources[J]. Yunnan Chemical Technology, 2013, 40(6): 1−4.

[29] WANG J Q, ZHANG Q, Li M, et al. Effect of compressive behaviours of tail salt filling materials on roof deformation in potash mine[J]. Advances in Civil Engineering, 2021. DOI:10.1155/2021/6678258.

[30] 张超, 耿佃凯. 尾盐水力充填技术在老挝某固体钾盐矿的应用实践[J]. 中国矿业, 2020, 29(S2): 297−299.

ZHANG C, GENG D K. The application of hydraulic filling in Laos sylvite mine[J]. China Mining Magazine. 2020, 29(S2): 297−299.

[31] 郭雷, 翟建波, 施士虎, 等. 固体钾盐矿地下开采充填工艺研究[J]. 中国矿山工程, 2017, 46(3): 46−48+51.

GUO L, ZHAI J B, SHI S H, et al. Research on filling technology of underground mining of solid potash mine[J]. China Mine Engineering. 2017, 46(3): 46−48+51.

[32] 张声军, 石永奎, 李后蜀, 等. 矿山尾盐充填泵送试验研究[J]. 建筑机械化, 2012, 33(S1): 122−124.

ZHANG S J, SHI Y K, LI H S, et al. Experimental research on pumping the salts backfill the mine[J]. Construction Mechanization, 2012, 33(S1): 122−124.

[33] BODENSTEIN J, RAUCHE H A M, SCHREINER W, et al. Reduction of surface subsidence and brine inflow prevention in potash mines by subsequent backfilling[M]. Tailings and Mine Waste 2001. CRC Press, 2022: 171−176.

[34] 焦宏章, 王赟. 煤矿机械在固态钾盐地下开采中的应用研究[J]. 化工矿物与加工, 2014, 43(11): 31−33.

JIAO H Z, WANG Y. Study and application of coal mining equipment in the underground mining process of solid potash[J]. Industrial Minerals & Processing, 2014, 43(11): 31−33.

[35] 王作鹏, 金爱兵, 孙文斌, 等. 水砂—胶结充填隔离矿柱稳定性及宽度研究[J]. 金属矿山, 2024(3): 19−28.

WANG Z P, JIN A B, SUN W B, et al. Study on stability and width of isolated pillar between water sand backfill and cemented backfill[J]. Metal Mine, 2024(3): 19−28.

[36] 吴再海, 纪洪广, 姜海强, 等. 尾砂胶结含盐冻结充填体力学特性研究[J]. 岩土力学, 2020, 41(6): 1874−1880.

WU Z H, JI H G, JIANG H Q, et al. Study of mechanical properties of frozen saline cemented tailings backfill[J]. Rock and Soil Mechanics, 2020, 41(6): 1874−1880.

[37] 马慧, 关博文, 王永维, 等. 氯氧镁水泥胶凝材料的研究进展[J]. 材料导报, 2015, 29(15): 103−107.

MA H, GUAN B W, WANG Y W, et al. Research progress of magnesium oxychloride cement gelled material[J]. Materials Reports, 2015, 29(15): 103−107.

[38] 李国政, 李雨峰, 丁鹏, 等. 镁水泥与钾石盐尾矿胶结充填材料试验研究[J]. 中国矿山工程, 2010, 39(5): 23−25+37.

LI G Z, Li Y F, DING P, et al. Backfill test study on oxy−chloride magnesium cement and potash tailings[J]. China Mine Engineering, 2010, 39(5): 23−25+37.

[39] 李雨峰, 李国政. 钾盐尾矿充填数值模拟计算探讨[J]. 矿冶, 2013, 22(2): 24−28.

LI Y F, LI G Z. The numerical simulation of tailing filling for potash mines[J]. Mining and Metallurgy, 2013, 22(2): 24−28.

[40] 徐翔, 曾波. 老挝钾盐矿尾盐回填工程技术研究[J]. 云南化工, 2013, 40(6): 41−43.

XU X, ZENG B. Study on the tailings backfill technology of potash mine in Laos[J]. Yunnan Chemical Technology, 2013, 40(6): 41−43.

[41] 郭会仙, 王国栋, 曾波. 老挝钾盐矿尾盐回填试验研究[J]. 化工矿物与加工, 2015, 44(5): 24−26.

GUO H X, WANG G D, ZENG B. Experimental study on backfill of potash tail salt in Laos[J]. Industrial Minerals & Processing, 2015, 44(5): 24−26.

[42] 李永华, 朱孔金, 刘国举. 地下光卤石矿回填料浆制备与性能研究[J]. 化工矿物与加工, 2014, 43(9): 12−15.

LI Y H, ZHU K J, LIU G J. Research on preparation and properties of backfill slurry for underground carnallite[J]. Industrial Minerals & Processing, 2014, 43(9): 12−15.

[43] 姚俊耀, 李志立, 左迪. 条带开采嗣后充填法充填膏体强度设计及工程应用[J]. 采矿技术, 2019, 19(5): 27−29.

YAO J Y, LI Z L, ZUO D. Strength design and engineering application of filling paste by strip mining subsequent filling method[J]. Mining Technology, 2019, 19(5): 27−29.

[44] 高红波, 李涛. 老挝固体钾盐矿床开采尾矿低成本充填技术研究[J]. 中国矿业, 2020, 29(3): 140−143+148.

GAO H B, LI T. Study on low cost filling technology of tailings on Laos solid sylvite deposit mining[J]. China Mining Magazine, 2020, 29(3): 140−143+148.

[45] ERMOLOVICH E A, IVANNIKOV A L, KHAYRUTDINOV M M, et al. Creation of a nanomodified backfill based on the waste from enrichment of water−soluble ores[J]. Materials, 2022, 15(10): 3689. doi: 10.3390/ma15103689

[46] GONG W, WANG N, ZHANG N. Effect of fly ash and metakaolin on the macroscopic and microscopic characterizations of magnesium oxychloride cement[J]. Construction and Building Materials, 2021, 267: 120957. doi: 10.1016/j.conbuildmat.2020.120957

[47] HUANG Q, ZHENG W X, XIAO X Y, et al. Effects of fly ash, phosphoric acid, and nano−silica on the properties of magnesium oxychloride cement[J]. Ceramics International, 2021, 47(24): 34341−34351. doi: 10.1016/j.ceramint.2021.08.347

[48] MA C, CHEN G G, SHI J Y, et al. Improvement mechanism of water resistance and volume stability of magnesium oxychloride cement: A comparison study on the influences of various gypsum[J]. Science of the Total Environment, 2022, 829: 154546. doi: 10.1016/j.scitotenv.2022.154546

[49] 王雪, 王全, 张滨, 等. 钢渣作为钾盐矿充填料胶结剂的固化机理[J]. 工程科学学报, 2018, 40(10): 1177−1186.

WANG X, WANG Q, ZHANG B, et al. Hydration mechanism of using steel slag as binder for backfill materials in potash mines[J]. Chinese Journal of Engineering, 2018, 40(10): 1177−1186.

[50] 丁红霞, 吴国平, 苗润田. 钾盐矿尾矿充填技术研究[J]. 化工矿物与加工, 2016, 45(6): 44−46+50.

DING H X, WU G P, MIAO R T. Study on potash tailings filling technology[J]. Industrial Minerals & Processing, 2016, 45(6): 44−46+50.

[51] 王宇斌, 文堪, 王森, 等. 同离子效应对半水硫酸钙形貌的调控机理[J]. 高校化学工程学报, 2018, 32(6): 1444−1449. doi: 10.3969/j.issn.1003-9015.2018.06.027

WANG Y B, WEN K, WANG S, et al. Regulation mechanism of common ion effect on the morphology of calcium sulphate hemihydrate[J]. Journal of Chemical Engineering of Chinese Universities, 2018, 32(6): 1444−1449. doi: 10.3969/j.issn.1003-9015.2018.06.027

[52] 赖敏明, 徐先宝, 李响. 工业废盐的处理及其资源化研究进展[J]. 应用化工, 2023, 52(1): 215−218+222. doi: 10.3969/j.issn.1671-3206.2023.01.041

LAI M M, XU X B, LI X. Research progress on the treatment and resource utilization of industrial waste salt[J]. Applied Chemical Industry, 2023, 52(1): 215−218+222. doi: 10.3969/j.issn.1671-3206.2023.01.041

[53] 邓德华, 张传镁. 氯氧镁水泥水化物形成反应历程[J]. 华南建设学院西院学报, 1996(2): 22−29.

DENG D H, ZHANG C M. Reaction history of hydrate formation in magnesium chloride cement[J]. Journal of South China Construction University, 1996(2): 22−29.

[54] 余海燕, 胡林童. 氯氧镁水泥研究新进展[J]. 天津城建大学学报, 2021, 27(3): 161−167+184.

YU H Y, HU L T. New progress in research of magnesium oxychloride cement[J]. Journal of Tianjin Chengjian University, 2021, 27(3): 161−167+184.

[55] WALLING S A, PROVIS J L. Magnesia−based cements: A journey of 150 years, and cements for the future?[J]. Chemical reviews, 2016, 116(7): 4170−4204. doi: 10.1021/acs.chemrev.5b00463

[56] ZHENG W X, XIAO X Y, CHANG C G, et al. Characterizing properties of magnesium oxychloride cement concrete pavement[J]. Journal of Central South University, 2019, 26(12): 3410−3419. doi: 10.1007/s11771-019-4263-8

[57] TANG S W, HU Y, REN W, et al. Modeling on the hydration and leaching of eco−friendly magnesium oxychloride cement paste at the micro−scale[J]. Construction and Building Materials, 2019, 204: 684−690. doi: 10.1016/j.conbuildmat.2019.01.232

[58] 李国栋. 粉煤灰的结构、形态与活性特征[J]. 粉煤灰综合利用, 1998(3): 37−40.

LI G D. Characteristics of structure, shape and activity of fly ash[J]. Fly Ash Comprehensive Utilization, 1998(3): 37−40.

[59] RAO B K, REDDY M A K, RAO A V. Effect of flyash as cement replacement material and pore filling material in concrete[J]. Materials Today: Proceedings, 2022, 52: 1775−1780. doi: 10.1016/j.matpr.2021.11.444

[60] YIN B, KANG T, KANG J T, et al. Analysis of active ion−leaching behavior and the reaction mechanism during alkali activation of low−calcium fly ash[J]. International Journal of Concrete Structures, 2018, 12: 1−13.

[61] 时雅倩, 关渝珊, 葛伟哲, 等. 粉煤灰建材化增值利用: 最新技术与未来展望[J/OL]. 煤炭学报, 1−19. [2024−04−05]. https://doi.org/10.13225/j.cnki.jccs.ZZ23.1224.

SHI Y Q, GUAN Y S, GE W Z, et al. Value−added utilization of pulverized fuel ash as construction materials: state−of−the−art technologies and future prospects[J/OL]. Journal of China Coal Society, 1−19[2024−04−05]. https://doi.org/10.13225/j.cnki.jccs.ZZ23.1224.

[62] 饶运章, 王炳文, 熊正明, 等. 高盐卤矿山提高尾砂胶结充填体强度的研究[J]. 矿业研究与开发, 2004(S1): 170−173.

RAO Y Z, WANG B W, XIONG Z M, et al. Study on improving the strength of tailings cemented fill in high salt brine mines[J]. Mining Research and Development, 2004(S1): 170−173.

[63] 阎培渝. 粉煤灰在复合胶凝材料水化过程中的作用机理[C]//《硅酸盐学报》创刊50周年暨中国硅酸盐学会2007年学术年会. 北京: 2007.

YAN P Y. Mechanism of fly ash's effects during hydration process of composite binder[C]//50th Anniversary of the Journal of Silicates and 2007 Annual Conference of the Chinese Society of Silicates, Beijing: 2007.

[64] TEMUUJIN J, RIESSEN A V, WILLIAMS R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes[J]. Journal of Hazardous Materials, 2009, 167(1/2/3): 8.

[65] 赵华, 王永维, 关博文, 等. 粉煤灰对氯氧镁水泥早期性能的影响[J]. 材料导报, 2015, 29(18): 117−121+135.

ZHAO H, WANG Y W, GUAN B W, et al. Effect of fly ash on early properties of magnesium oxychloride cement[J]. Materials Reports, 2015, 29(18): 117−121+135.

[66] 薛伟, 张斌斌. 粉煤灰掺量对氯氧镁水泥保温材料的改性研究[J]. 混凝土, 2018(11): 67−70.

XUE W, ZHANG B B. Thermal insulation material of magnesium oxychloride cement dosage of fly ash modification research[J]. Concrete, 2018(11): 67−70.

[67] WU J H, CHEN H X, GUAN B W, et al. Effect of fly ash on rheological properties of magnesium oxychloride cement[J]. Journal of Materials in Civil Engineering, 2019, 31(3): 04018405.1−04018405.10. DOI: 10.1061/(ASCE)MT.1943-5533.0002597

[68] CASTRO−SUAREZ J R, COLPAS−CASTILLO F, TARON−DUNOYER A. Chemical and morphologic characterization of sylvite (KCl) mineral from different deposits used in the production of fertilizers[J]. Agronomy, 2023, 13(1): 52.

[69] SEGNI R, VIEILLE L, LEROUX F, et al. Hydrocalumite−type materials: 1. Interest in hazardous waste immobilization[J]. Journal of Physics and Chemistry of Solids, 2006, 67(5/6): 1037−1042. doi: 10.1016/j.jpcs.2006.01.081

[70] HOURI B, LEGROURI A, BARROUG A, et al. Removal of chromate ions from water by Anionicc CLAYS[J]. Journal de Chimie Physique et de Physico−Chimie Biologique, 1999, 96(3): 455−463.

-

下载:

下载: