Hydrogen−based Mineral Phase Transformation−low Intensity Magnetic Separation−reverse Flotation of an Iron Ore Abroad

-

摘要:

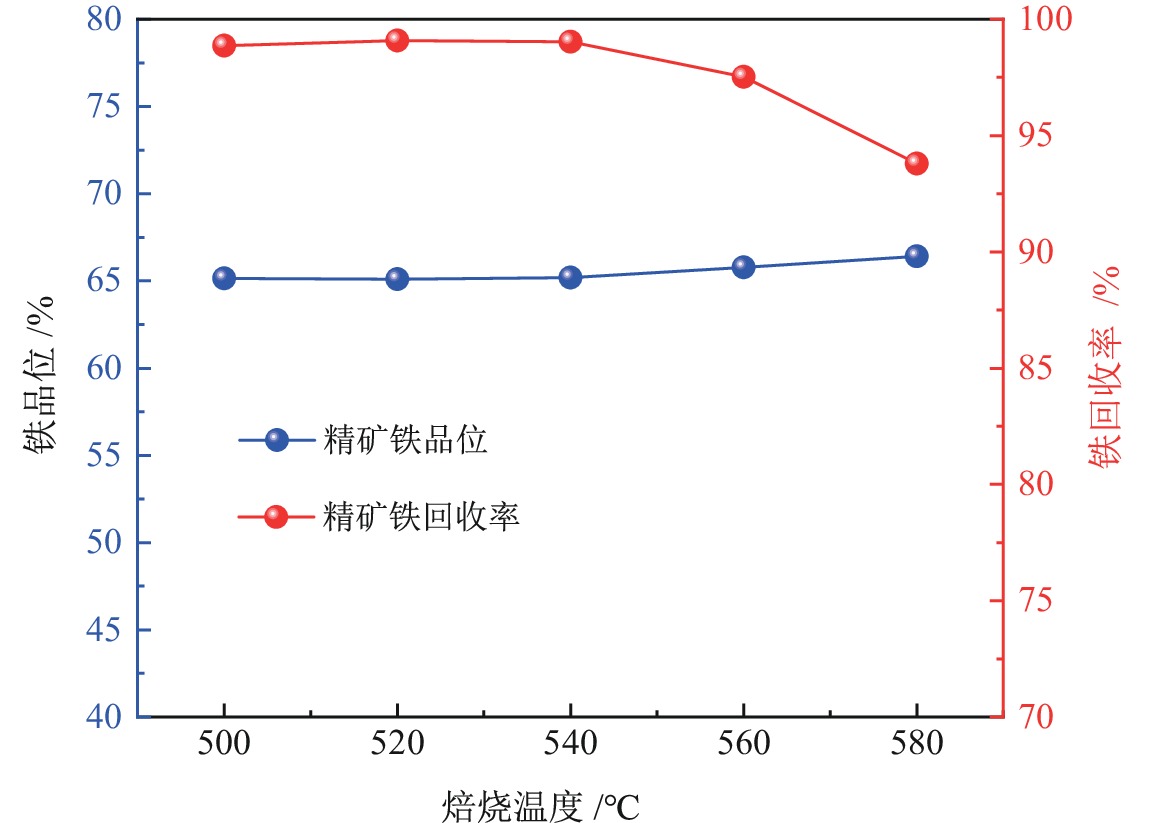

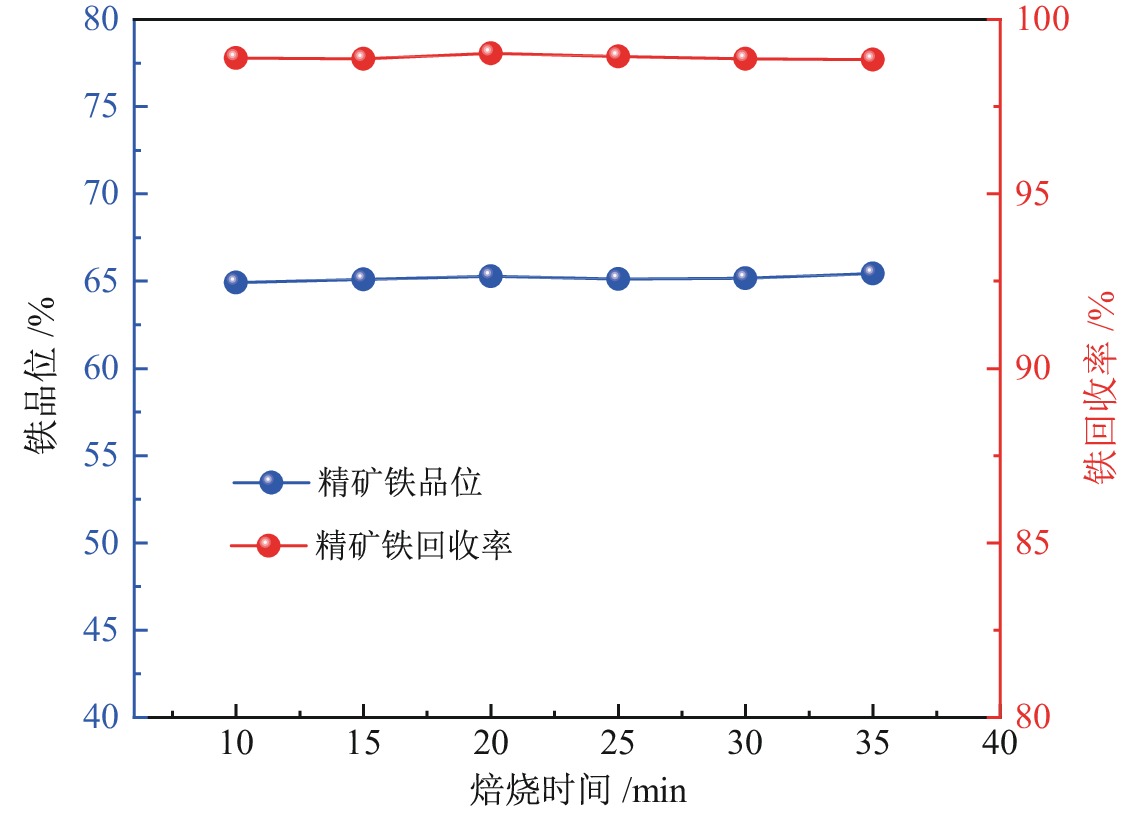

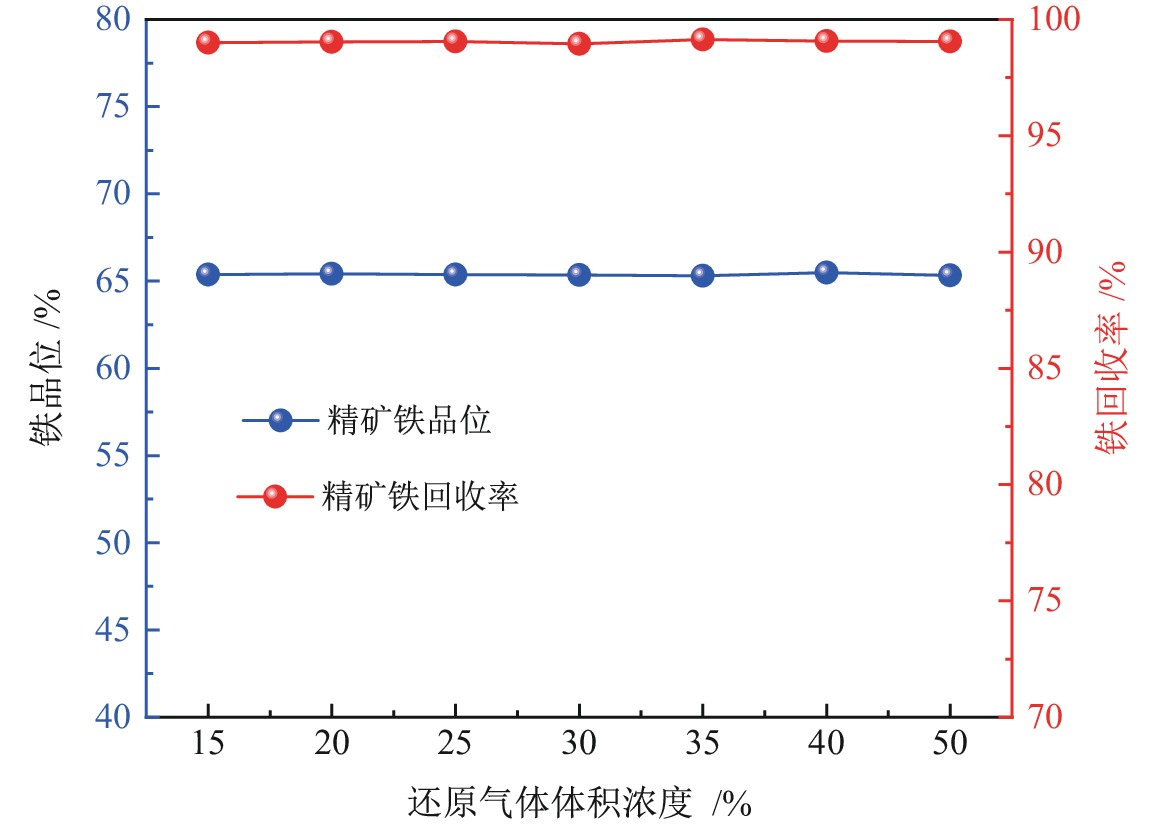

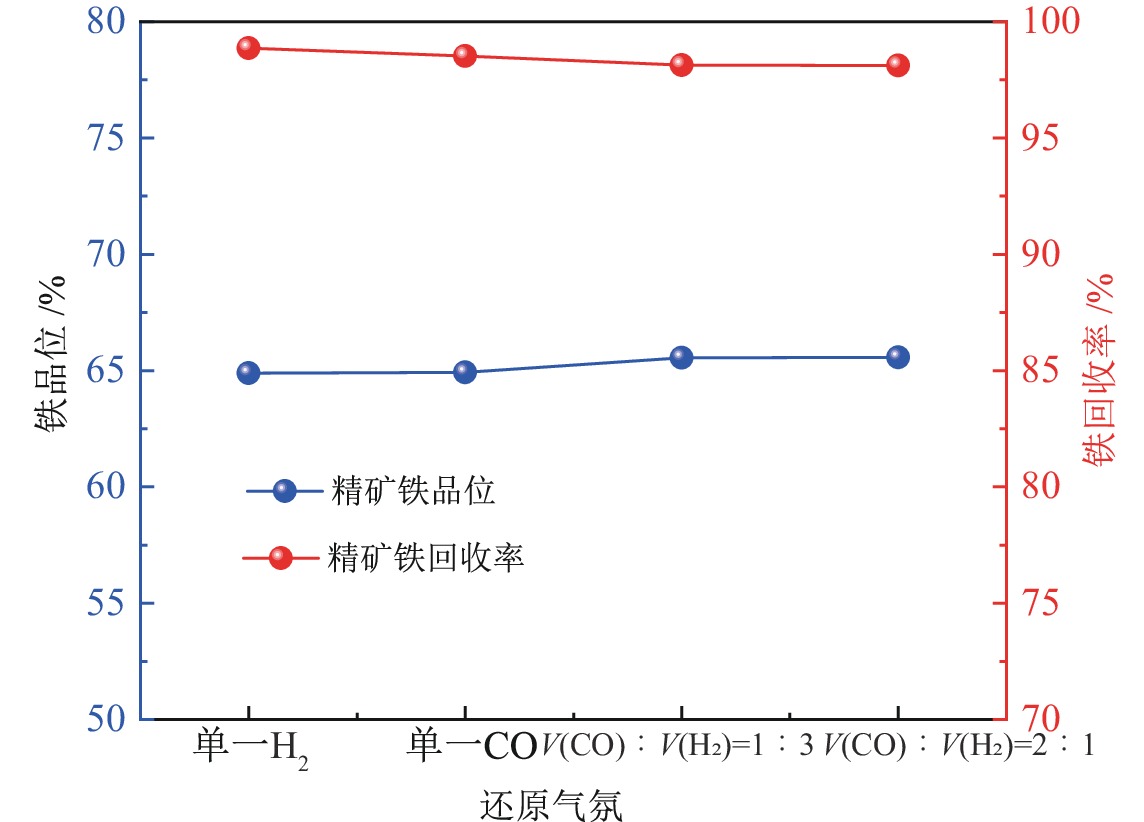

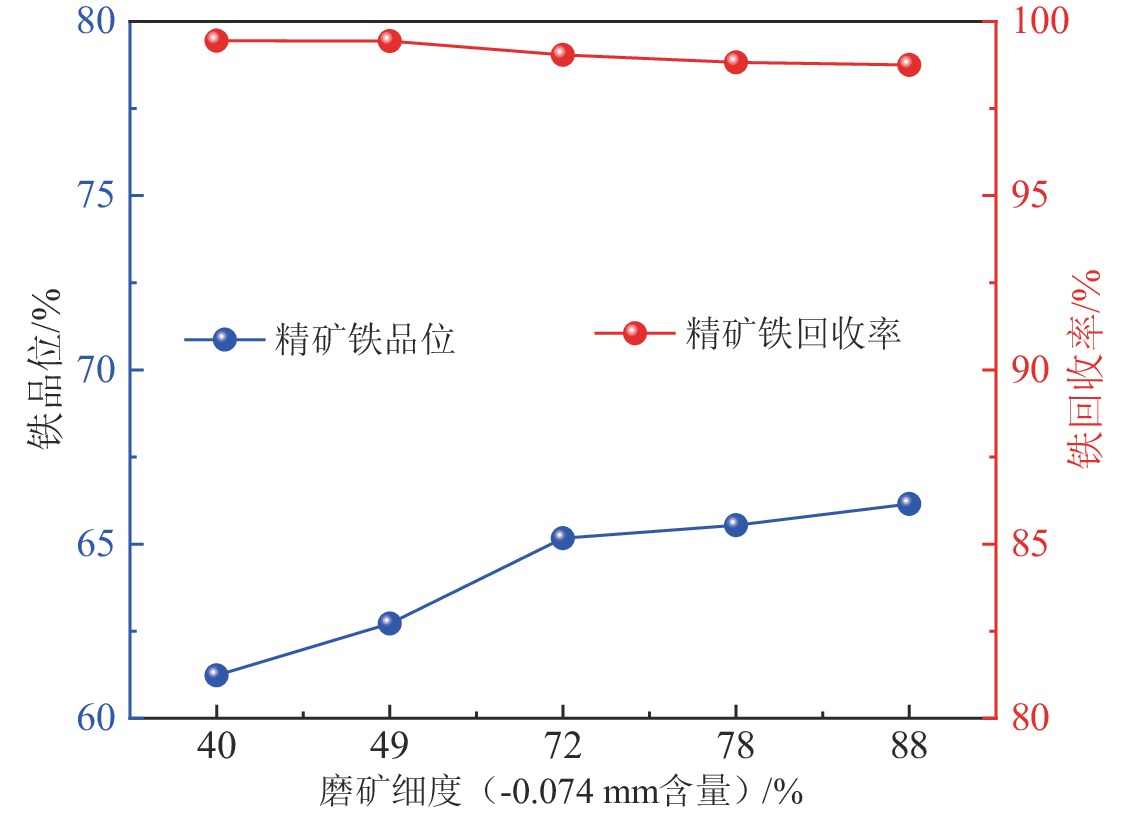

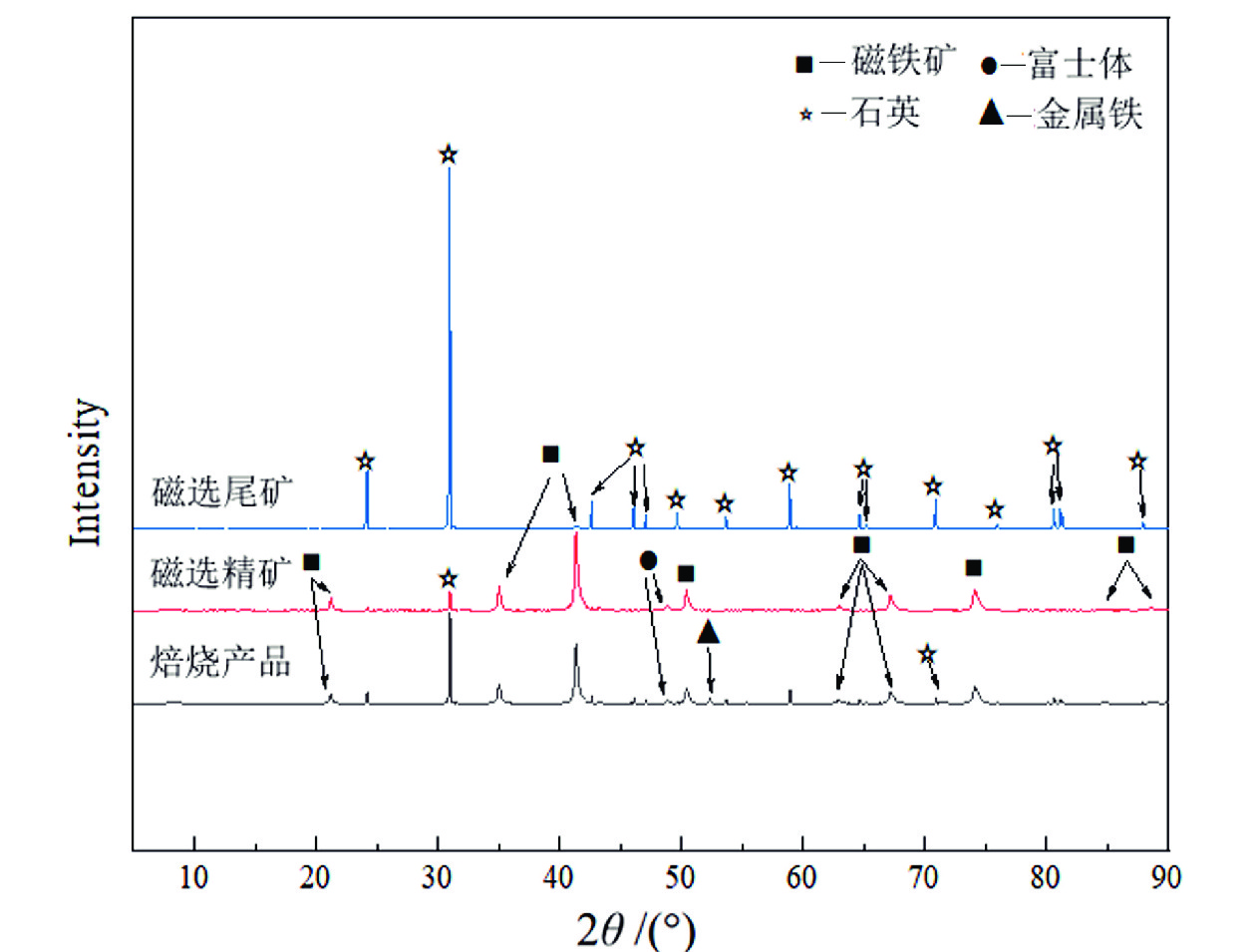

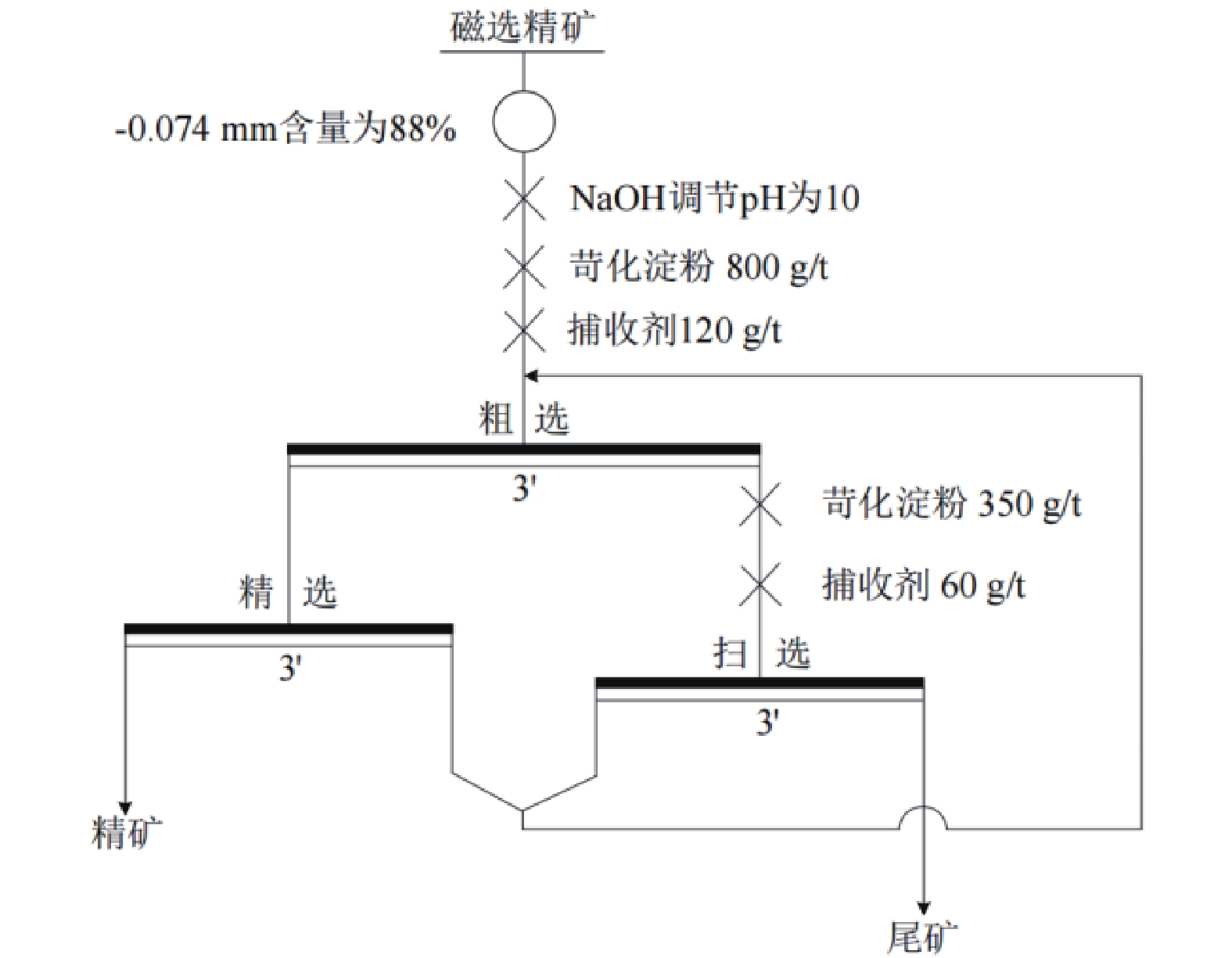

某铁矿铁品位为52.11%,铁主要以赤/褐铁矿的形式存在,占全铁的85.54%,主要脉石矿物为石英,含量为20.87%。为确定该矿石的合理利用工艺,进行了氢基矿相转化—弱磁选—反浮选实验研究。结果表明,在还原温度为540 ℃、还原时间为20 min、还原气体体积浓度为25%,还原气氛V(CO)∶V(H2)=1∶3,磨矿细度−0.074 mm含量占72%、磁场强度为

1600 Gs的条件下,可以得到磁选精矿铁品位65.55%、铁回收率98.14%的指标;磁选精矿中铁主要存在于磁性铁中,赤/褐铁矿的含量降为0.20%,说明原矿经氢基矿相转化后,弱磁性的赤/褐铁矿物被还原为强磁性的磁铁矿,在弱磁选过程中铁矿物得到有效回收。将磁选精矿磨细至−0.074 mm含量为88%,经一次粗选一次精选一次扫选反浮选实验可以获得铁品位68.47%、回收率97.48%(对原矿95.61%)的最终精矿,SiO2含量为3.06%,比原矿降低约18百分点。“氢基矿相转化—弱磁选—反浮选”工艺是处理该矿石的适宜工艺,具有巨大的经济、社会和环境效益,提升了矿产资源高质量利用能力、资源持续保障能力和市场风险防范能力。Abstract:China's iron ore is heavily dependent on imports. In order to solve the problem of import dependence, enterprises are actively searching for available iron ore resources and developing independent innovation technologies. The hydrogen−based mineral phase conversion technology uses hydrogen or hydrogen−rich gas as a reducing agent to chemically react the ore in a suspended state and at a certain temperature, so that the weakly magnetic iron minerals in the ore are converted into strong magnetic magnetite or maghemite, and then magnetic separation is performed using magnetic differences between minerals. The iron grade of an iron ore is 52. 11%. Iron mainly exists in the form of hematite/limonite, accounting for 85. 54% of total iron. The main gangue mineral is quartz, with a content of 20. 87%. In order to determine the reasonable utilization process of the ore, the experimental study of hydrogen−based mineral phase transformation−low intensity magnetic separation−reverse flotation was carried out. The results show that when the reduction temperature is 540 ℃, the reduction time is 20 min, the reduction gas volume concentration is 25%, the reduction atmosphere V(CO)∶V(H2)=1∶3, the grinding fineness −0. 074 mm content accounts for 72%, and the magnetic field strength is

1600 Gs, the magnetic concentrate iron grade is 65. 55%, and the iron recovery rate is 98. 14%. The iron in the magnetic separation concentrate mainly exists in the magnetic iron. Compared with the iron content in the magnetic iron of the raw ore, the iron content in the magnetic iron increases by about 58%, and the content of hematite/limonite decreases to 0. 20%, indicating that the weak magnetic hematite/limonite minerals are reduced to strong magnetic magnetite after the conversion of the raw ore by the hydrogen−based mineral phase, and the iron minerals are effectively recovered during the weak magnetic separation process. The magnetic separation concentrate was ground to −0. 074 mm content of 88%. After one roughing, one cleaning and one scavenging reverse flotation test, the final concentrate with iron grade of 68. 47% and recovery rate of 97. 48% was obtained. The SiO2 content was 3. 06%, which was about 18 percentage points lower than that of the raw ore. In this paper, through the process of ' hydrogen−based mineral phase transformation−low intensity magnetic separation−reverse flotation ', the experimental research on iron extraction and impurity reduction is completed. It is a suitable process for treating the ore. The process has great economic, social and environmental benefits, and improves the high−quality utilization of mineral resources. Ability, resource sustainability and market risk prevention capabilities. -

-

表 1 原矿化学多元素分析结果

Table 1. Results of chemical multi−element analysis of raw ore

/% 元素 TFe FeO Al2O3 SiO2 P S 含量 52.11 1.13 0.86 20.87 0.077 0.041 元素 K2O CaO MgO Na2O 烧失 含量 0.019 0.010 <0.01 0.003 5.61 表 2 原矿铁物相分析结果

Table 2. Iron phase analysis results of raw ore

/% 铁物相 磁性铁

中铁碳酸铁

中铁赤/褐铁

中铁硫化铁

中铁硅酸铁

中铁合计 含量 6.61 0.23 44.57 0.21 0.49 52.11 分布率 12.68 0.44 85.54 0.40 0.94 100.00 表 3 原矿中矿物组成及含量统计结果

Table 3. Statistical results of mineral composition and content in raw ore

/% 矿物类型 矿物名称 含量 合计 金属氧化物 钛铁矿 0.06 85.73 磁/赤铁矿 33.35 褐铁矿 52.32 脉石矿物 石英 13.45 14.27 白云母 0.01 绿泥石 0.01 高岭石 0.72 铝土矿 0.08 合计 100.00 100.00 表 4 磁选精矿主要元素分析结果

Table 4. Analysis results of main elements in magnetic concentrate

/% 元素 TFe FeO SiO2 烧失 含量 65.55 30.22 6.76 1.96 表 5 磁选尾矿主要元素分析结果

Table 5. Main element analysis results of magnetic separation tailings

/% 元素 TFe FeO SiO2 烧失 含量 2.15 0.49 89.50 0.65 表 6 磁选精矿铁物相分析结果

Table 6. Iron phase analysis results of magnetic concentrate

/% 铁物相 磁性铁

中铁碳酸铁

中铁赤/褐铁

中铁硫化铁

中铁硅酸铁

中铁合计 含量 64.41 0.57 0.20 0.09 0.28 65.55 分布率 98.26 0.87 0.31 0.14 0.42 100.00 表 7 磁选精矿矿物组成及含量

Table 7. Results of mineral composition and content of magnetic concentrate

/% 矿物类型 矿物名称 含量 小计 金属氧化物 钛铁矿 0.01 95.52 磁铁矿 66.83 磁赤铁矿 28.69 脉石矿物 石英 4.38 4.48 方解石 0.01 高岭石 0.08 铝土矿 0.02 合计 100.00 100.00 表 8 磁选精矿反浮选闭路实验结果

Table 8. Magnetic concentrate reverse flotation closed−circuit test results

/% 产品名称 产率 TFe品位 TFe回收率 SiO2品位 精矿 93.33 68.47 97.48 3.06 尾矿 6.67 24.69 2.52 58.53 给矿 100.00 65.55 100.00 6.76 -

[1] 赵立群, 王春女, 张敏, 等. 中国铁矿资源勘查开发现状及供需形势分析[J]. 地质与勘探, 2020, 56(3): 635−642.

ZHAO L Q, WANG C N, ZHANG M, et al. Current exploration status and supply−demand situation of iron ore resources in China mainland[J]. Geology and Exploration, 2022, 42(2): 67−73.

[2] 张玉成. 中国铁矿石进口布局多元化研究—基于分散依赖性风险视角[D]. 昆明: 云南财经大学, 2023: 11−16.

ZHANG Y C. The diversification of China's iron ore import layout study−based on the perspective of dispersed dependence risk[D]. Kun Ming: Yunnan University of Finance and Economics, 2023: 11−16.

[3] 温子龙. 2019年中国铁矿供需现状及未来发展建议[J]. 矿产资源研究, 2020(1): 28−30.

WEN Z L. China's iron ore supply and demand status and future development suggestions in 2019[J]. Research on Mineral Resources, 2020(1): 28−30.

[4] 周廷波, 魏晓彤, 孙永升, 等. 菱铁矿微波磁化焙烧磁选工艺及机理研究[J]. 金属矿山, 2023(6): 107−111.

ZHOU T B, WEI X T, SUN Y S, et al. Research on process and mechanism of microwave magnetization roasting and magnetic separation for siderite[J]. Metal Mine, 2023(6): 107−111.

[5] 韩跃新, 张强, 孙永升, 等. 难选铁矿石矿相转化清洁高效利用技术新进展[J]. 钢铁研究学报, 2022, 34(12): 1303−1313.

HAN Y X, ZHANG Q, SUN Y S, et al. Progress in phase transformation technology for clean and efficient utilization of refractory iron ore[J]. Journal of Iron and Steel Research, 2022, 34(12): 1303−1313.

[6] 郭磊, 陈宏超, 高鹏, 等. 白云鄂博中贫氧化矿预富集—氢基矿相转化试验研究[J]. 金属矿山, 2023(6): 96−100.

GUO L, CHEN H C, GAO P, et al. Study on pre−concentration and hydrogen−based phase transformation technology for medium−low grade oxidized ore of Baya Obo[J]. Metal Mine, 2023(6): 96−100.

[7] 曾永杰, 王星. 白云鄂博中贫氧化矿氢基矿相转化—磁选试验研究[J]. 包钢科技, 2023, 49(1): 12−16.

ZENG Y J, WANG X. Experimental Study on hydrogen−based mineral phase transformation−magnetic separation of medium−lean oxidized ore in Bayan Obo[J]. Science and Technology of Baotou Steel, 2023, 49(1): 12−16.

[8] 韩文杰, 朱一民, 李文博, 等. 海南石碌铁矿氢基矿相转化过程中的氢还原动力学和微观结构演变[J]. 钢铁研究学报, 2022, 34(12): 1352−1360.

HAN W J, ZHU Y M, LI W B, et al. Hydrogen reduction kinetics and microstructure evolution of Hainan Shilu iron ore during hydrogen−based ore phase transformation[J]. Journal of Iron and Steel Research, 2022, 34(12): 1352−1360.

[9] 张淑敏, 董再蒸, 袁帅, 等. 高铁低锰矿石氢基矿相转化分选试验研究[J]. 工程科学学报, 2023, 45(12): 1997−2004.

ZHANG S M, DONG Z Z, YUAN S, et al. Hydrogen−based phase transformation and separation of high iron and low manganese ores[J]. Chinese Journal of Engineering, 2023, 45(12): 1997−2004.

[10] 韩跃新, 张琦, 李艳军, 等. 海南石碌铁矿石氢基矿相转化新技术研究及应用[J]. 中国矿业大学学报, 2022, 51(3): 538−548.

HAN Y X, ZHANG Q, LI Y J, et al. Research and application of a new hydrogen−based phase transformation technology for Hainan−Shilu iron ore[J]. Journal of China University of Mining & Technology, 2022, 51(3): 538−548.

-

下载:

下载: