Mineralogical Analysis of Copper-Lead-Zinc Mixed Concentrate and Study on Separation Efficiency

-

摘要:

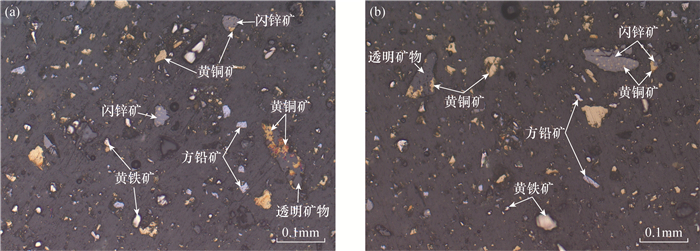

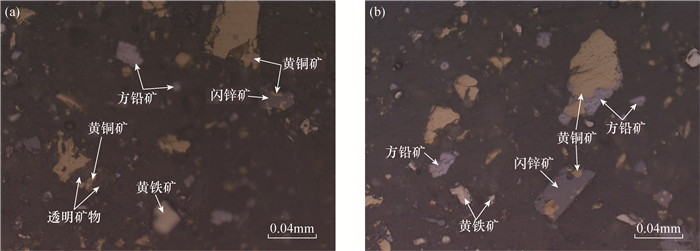

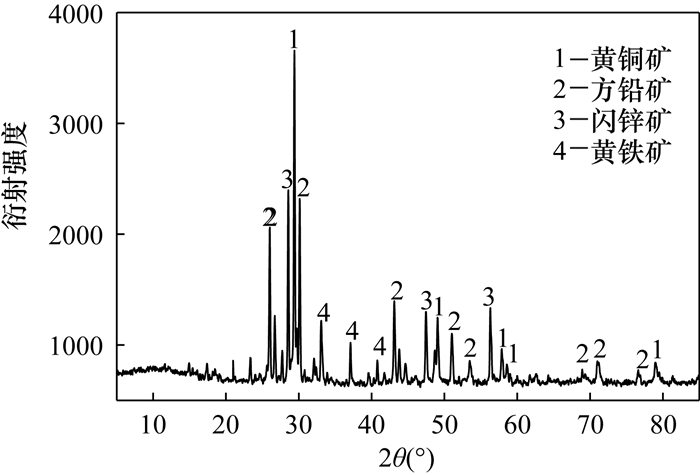

中国云南省有大量的铜铅锌多金属硫化矿资源,该类矿产资源的高效选矿分离是影响企业经济效益的主要问题之一。针对云南迪庆地区的硫化混合精矿,该混合精矿铜、铅、锌三种有价金属共存,分离难度较大,导致其产品难以销售或冶炼。本文采用化学分析、X射线衍射法和矿物解离度分析(MLA)等多种检测方法,对该混合精矿的主要元素含量、矿物组成、物相组成、主要目的矿物的嵌布特性和单体解离度等进行分析研究。研究结果表明,该混合精矿的粒度较细,各矿物之间存在一定的相互连生或包裹现象,目的矿物黄铜矿、方铅矿和闪锌矿的单体解离度中等偏低,为69.28%~70.56%。初步预测该混合精矿中铜、铅和锌的理论选矿分离效率依次为71.63%、62.97%和72.72%。根据实验分析结果,本文提出进一步提高该混合精矿的磨矿细度促使金属矿物充分解离,是提升铜、铅、锌各矿物选矿分离效率的关键途径。

Abstract:BACKGROUND There are large amounts of copper-lead-zinc polymetallic sulfide ore resources in Yunnan Province, China, but the efficient separation of these resources remains a major problem.

OBJECTIVES To improve the separation efficiency of valuable minerals in mixed concentrates.

METHODS In this study, the major elemental content, phase composition, mineral composition, particle size characteristics, and monomer liberation degree of a mixed concentrate were analyzed using a variety of modern detection methods such as chemical analysis, X-ray diffraction, and mineral liberation analysis (MLA).

RESULTS The results showed that the mixed concentrate had fine particles, and some minerals occurred as intergrowths or inclusions. The monomer liberation degree of the target minerals chalcopyrite, galena, and sphalerite was medium to low, ranging from 69.28% to 70.56%. It was preliminarily predicted that the theoretical separation efficiencies of copper, lead, and zinc in the mixed concentrate were 71.63%, 62.97% and 72.72%, respectively.

CONCLUSIONS Improving the grinding fineness of mixed concentrates to promote the full liberation of metal minerals is a key way to improve the separation efficiency of copper, lead, and zinc minerals.

-

-

表 1 混合精矿样品化学成分分析结果

Table 1. Analytical results of components in mixed concentrates

化学成分 含量(%) 化学成分 含量(%) Cu 11.94 SiO2 5.42 Pb 15.78 Al2O3 0.53 Zn 7.18 MgO 0.50 S 28.21 CaO 1.95 Sn 0.42 TFe 27.45 Ag 669×10-4 As 0.24 表 2 混合精矿主要矿物组成

Table 2. Main mineral compositions of mixed concentrates

矿物名称 分子式 含量(%) 黄铜矿 CuFeS2 34.33 黄铁矿 FeS2 17.91 方铅矿 PbS 18.22 闪锌矿 ZnS 11.01 菱铁矿 FeCO3 3.96 白云石 Ca(Mg, Fe)(CO3)2 2.30 方解石 CaCO3 3.13 石英 SiO2 4.80 高岭石 Al2Si2O5(OH)4 1.34 其他 / 3.00 合计 / 100.00 表 3 混合精矿中铜、铅、锌物相分析

Table 3. Analytical results of copper, lead and zinc phases in mixed concentrates

铜矿物 含量(%) 分布率(%) 硫化铜 11.85 98.75 游离氧化铜 0.10 0.83 结合氧化铜 0.03 0.25 胆矾 0.02 0.17 总计 12.00 100.00 铅矿物 含量(%) 分布率(%) 方铅矿 9.26 62.40 白铅矿 2.76 18.60 铅矾 2.66 17.92 铅铁钒及其他 0.16 1.08 总计 14.84 100.00 锌矿物 含量(%) 分布率(%) 硫化锌 7.10 93.67 氧化锌 0.40 5.28 锌铁尖晶石及其他 0.07 1.05 总计 7.58 100.00 表 4 混合精矿粒度分布分析结果

Table 4. Analytical results of particle size distribution for mixed concentrates

混合精矿粒级(mm) 产率(%) 品位(%) 金属分布率(%) Cu Pb Zn Cu Pb Zn +0.045(+325目) 3.57 9.49 1.61 2.39 3.13 0.40 1.33 -0.045~+0.038(-325~+400目) 1.83 8.84 1.32 2.25 1.49 0.16 0.64 -0.038~+0.023(-400目~+600目) 58.32 16.26 14.28 7.543 87.50 57.67 68.45 -0.023~+0.019(-600目~+800目) 32.16 2.36 17.39 5.36 7.00 38.73 26.87 -0.019(-800目) 4.12 2.31 10.64 4.21 0.88 3.04 2.71 合计 100.00 10.84 14.44 6.42 100.00 100.00 100.00 表 5 黄铜矿、方铅矿、闪锌矿的解离度特征

Table 5. Liberation characteristics of chalcopyrite, galena and sphalerite

矿物名称 解离度 解离水平 区间解离度(%) 累计解离度(%) 黄铜矿 100% 完全解离 69.28 69.28 75% < x < 100% 3/4解离~完全解离 12.72 75.51 50% < x≤75% 1/2解离~3/4解离 8.57 84.08 25% < x≤50% 1/4解离~1/2解离 8.28 92.36 0%≤x≤25% 未解离~1/4解离 7.64 100.00 方铅矿 100% 完全解离 70.56 70.56 75% < x < 100% 3/4解离~完全解离 10.18 75.91 50% < x≤75% 1/2解离~3/4解离 5.04 80.95 25% < x≤50% 1/4解离~1/2解离 6.20 87.15 0%≤x≤25% 未解离~1/4解离 12.85 100.00 闪锌矿 100% 完全解离 70.34 70.34 75% < x < 100% 3/4解离~完全解离 17.91 83.79 50% < x≤75% 1/2解离~3/4解离 5.92 89.70 25% < x≤50% 1/4解离~1/2解离 5.17 94.87 0%≤x≤25% 未解离~1/4解离 5.13 100.00 -

[1] 熊丽青. 试分析地质工作中的地质实验测试技术[J]. 世界有色金属, 2020(14): 216-217. doi: 10.3969/j.issn.1002-5065.2020.14.099

Xiong L Q. Testing technology of geological experiment in geological analysis[J]. World Nonferrous Metals, 2020(14): 216-217. doi: 10.3969/j.issn.1002-5065.2020.14.099

[2] 温利刚, 贾木欣, 王清, 等. 基于扫描电子显微镜的自动矿物学新技术——BPMA及其应用前景[J]. 有色金属(选矿部分), 2021(2): 12-23. doi: 10.3969/j.issn.1671-9492.2021.02.003

Wen L G, Jia M M, Wang Q, et al. New automatic mineralogy technology based on scanning electron microscope-BPMA and its application prospect[J]. Nonferrous Metals (Mineral Processing Section), 2021(2): 12-23. doi: 10.3969/j.issn.1671-9492.2021.02.003

[3] 张然, 叶丽娟, 党飞鹏, 等. 自动矿物分析技术在鄂尔多斯盆地砂岩型铀矿矿物鉴定和赋存状态研究中的应用[J]. 岩矿测试, 2021, 40(1): 61-73. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.202005130071

Zhang R, Ye L J, Dang F P, et al. Application of automatic mineral analysis technology in mineral identification and occurrence state study of sandstone type uranium deposits in Ordos Basin[J]. Rock and Mineral Analysis, 2021, 40(1): 61-73. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.202005130071

[4] 曾广圣, 欧乐明. X射线衍射-扫描电镜等技术研究秘鲁铜硫矿石选矿工艺矿物学特征[J]. 岩矿测试, 2019, 38(2): 160-168. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201804130042

Zeng G S, Ou L M. Mineralogical characteristics of mineral processing technology of Peruvian copper sulfur ore by X-ray diffraction and scanning electron microscopy[J]. Rock and Mineral Analysis, 2019, 38(2): 160-168. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201804130042

[5] Dieye M, Lichtervelde M V, Ndiaye A A, et al. Mine-ralogical characterization of heavy mineral concentrates from Senegalese great cost by using QEMSCAN and SEM[J]. International Journal of Geosciences, 2020, 11(12): 800-817. doi: 10.4236/ijg.2020.1112041

[6] Little L, Becker M, Wiese J, et al. Auto-SEM particle shape characterisation: Investigating fine grinding of UG2 ore[J]. Minerals Engineering, 2015, 82: 92-100. doi: 10.1016/j.mineng.2015.03.021

[7] 高倩倩, 刘杨, 杨艳芳, 等. MLA与偏光显微镜在工艺矿物学研究中的应用对比[J]. 矿业工程, 2018(4): 39-40. https://www.cnki.com.cn/Article/CJFDTOTAL-GWKS201804013.htm

Gao Q Q, Liu Y, Yang Y F, et al. Application comparison of MLA and polarizing microscope in process mineralogy research[J]. Mining Engineering, 2018(4): 39-40. https://www.cnki.com.cn/Article/CJFDTOTAL-GWKS201804013.htm

[8] 陈江安, 邱廷省, 余文. MLA自动检测技术在直接还原铁工艺矿物学研究中的应用[J]. 矿产综合利用, 2018(1): 86-91. doi: 10.3969/j.issn.1000-6532.2018.01.019

Chen J A, Qiu T S, Yu W. Application of MLA automatic detection technology in direct reduction iron process mineralogy research[J]. Mineral Comprehensive Utilization, 2018(1): 86-91. doi: 10.3969/j.issn.1000-6532.2018.01.019

[9] 白旭, 林伊琳, 文书明, 等. 非洲赞比亚难选混合铜矿工艺矿物学研究[J]. 有色金属(选矿部分), 2021(3): 15-20. doi: 10.3969/j.issn.1671-9492.2021.03.003

Bai X, Lin Y L, Wen S M, et al. Study on process mineralogy of refractory mixed copper ore in Zambia, Africa[J]. Nonferrous Metals (Mineral Processing Section), 2021(3): 15-20. doi: 10.3969/j.issn.1671-9492.2021.03.003

[10] 胡海祥, 李广. MLA在广东斑岩型锡石矿嵌布特征及赋存状态研究中的应用[J]. 过程工程学报, 2019, 19(5): 1006-1013. https://www.cnki.com.cn/Article/CJFDTOTAL-HGYJ201905018.htm

Hu H X, Li G. The application of MLA in the study of dissemination characteristics and occurrence of porphyry cassiterite deposits in Guangdong[J]. Acta Process Engineering, 2019, 19(5): 1006-1013. https://www.cnki.com.cn/Article/CJFDTOTAL-HGYJ201905018.htm

[11] Daley T, Opuni K B, Raj E, et al. Monitoring the process of formation of ZnO from ZnO using combined XRD/XAS technique[J]. Journal of Physics: Condensed Matter, 2021, 33(26): 264002. doi: 10.1088/1361-648X/abfb91

[12] Isabel B. Monte Carlo simulations of electron-sample interactions at phase boundaries and implications for automated mineralogy[J]. Minerals Engineering, 2020, 155: 106451. doi: 10.1016/j.mineng.2020.106451

[13] 鱼博, 王宇斌, 王妍, 等. 某铜铅锌多金属硫化矿工艺矿物学研究[J]. 中国钼业, 2021, 45(1): 34-38. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMY202101014.htm

Yu B, Wang Y B, Wang Y, et al. Process mineralogy of a copper lead zinc polymetallic sulfide ore[J]. China Molybdenum Industry, 2021, 45(1): 34-38. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMY202101014.htm

[14] 何丽, 范超, 田颖, 等. X射线粉晶衍射法结合运用于岩矿鉴定的薄弱部分——隐晶质岩石[J]. 中国锰业, 2017, 35(6): 132-135. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMM201706037.htm

He L, Fan C, Tian Y, et al. The weak part of X-ray powder diffraction in rock and mineral identification: Cryptocrystalline rocks[J]. China's Manganese Industry, 2017, 35(6): 132-135. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMM201706037.htm

[15] 杜丽娟. 滇西北羊拉铜矿床热液体系演化与成矿机制研究[D]. 北京: 中国科学院大学, 2017.

Du L J. Hydrothermal system evolution and metallogenic mechanism of Yangla copper deposit in Northwest Yunnan[D]. Beijing: University of Chinese Academy of Sciences, 2017.

[16] 刘榕鑫, 朱坤, 谢海云, 等. 云南斑岩型多金属金矿的嵌布特征及赋存状态研究[J]. 岩矿测试, 2018, 37(4): 404-410. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201710200169

Liu R X, Zhu K, Xie H Y, et al. Study on the distribution characteristics and occurrence state of porphyry polymetallic gold deposits in Yunnan Province[J]. Rock and Mineral Analysis, 2018, 37(4): 404-410. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201710200169

[17] 孙晓华, 付强, 应永朋, 等. 青海某低品位铜铅锌银多金属矿工艺矿物学研究[J]. 有色金属(选矿部分), 2020(5): 5-10. doi: 10.3969/j.issn.1671-9492.2020.05.002

Sun X H, Fu Q, Ying Y P, et al. Process mineralogy of a low grade Cu Pb Zn Ag polymetallic ore in Qinghai[J]. Nonferrous Metals (Mineral Processing Section), 2020(5): 5-10. doi: 10.3969/j.issn.1671-9492.2020.05.002

[18] 刘守信, 师伟红. 新疆某低品位铜铅锌多金属硫化矿浮选分离试验研究[J]. 有色金属(选矿部分), 2021(2): 93-97. doi: 10.3969/j.issn.1671-9492.2021.02.015

Liu S X, Shi W H. Experimental study on flotation separation of a low grade copper-lead-zinc polymetallic sulfide ore in Xinjiang[J]. Nonferrous Metals (Mineral Processing Section), 2021(2): 93-97. doi: 10.3969/j.issn.1671-9492.2021.02.015

[19] 肖炜, 田小松. 云南迪庆铜铅锌硫化矿浮选分离研究[J]. 矿产综合利用, 2020, 18(1): 65-70. doi: 10.3969/j.issn.1000-6532.2020.01.014

Xiao W, Tian X S. Study on flotation separation of Diqing copper lead zinc sulfide ore in Yunnan[J]. Mineral Comprehensive Utilization, 2020, 18(1): 65-70. doi: 10.3969/j.issn.1000-6532.2020.01.014

[20] 吴继宗, 谢海云, 田小松, 等. 高硫铜锌矿的全混浮-再磨脱硫及铜锌分离[J]. 有色金属工程, 2019, 9(7): 65-71. doi: 10.3969/j.issn.2095-1744.2019.07.011

Wu J Z, Xie H Y, Tian X S, et al. Desulfurization and separation of copper and zinc from high sulfur copper zinc ores by total flotation regrinding[J]. Nonferrous Metals Engineering, 2019, 9(7): 65-71. doi: 10.3969/j.issn.2095-1744.2019.07.011

[21] 曾令明, 欧乐明. 某硫化锌矿浮选新工艺及工艺矿物学特性分析[J]. 中国有色金属学报, 2018, 28(9): 1867-1875. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201809017.htm

Zeng L M, Ou L M. Analysis of new flotation process and process mineralogical characteristics of a zinc sulfide ore[J]. Acta Nonferrous Metals of China, 2018, 28(9): 1867-1875. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201809017.htm

[22] Pszonka J, Schulz B, Sala D. Application of mineral liber-ation analysis (MLA) for investigations of grain size distribution in submarine density flow deposits[J]. Marine and Petroleum Geology, 2021, 129: 105109. doi: 10.1016/j.marpetgeo.2021.105109

[23] Huimin W U, Junping W, Shuang Z. Application of MLA system in analysis of non-metallic inclusions of stainless steel[J]. Physical Testing and Chemical Analysis (Part A: Physical Testing), 2020, 56(7): 18-21. http://en.cnki.com.cn/Article_en/CJFDTotal-LHJW202007005.htm

[24] Al-Khirbash S A. Mineralogical characterization of low-grade nickel laterites from the North Oman Mountains: Using mineral liberation analyses-scanning electron microscopy-based automated quantitative mineralogy[J]. Ore Geology Reviews, 120: 1034229. http://www.sciencedirect.com/science/article/pii/S0169136819301386

[25] 荆晓雷, 郑桂兵, 任爱军, 等. 低品位铜铅锌铁复杂多金属资源清洁高效综合利用技术研究与应用[J]. 世界有色金属, 2018(10): 126-128. https://www.cnki.com.cn/Article/CJFDTOTAL-COLO201810068.htm

Jing X L, Zheng G B, Ren A J, et al. Research and application of clean and efficient comprehensive utilization technology of low grade copper, lead, zinc and iron complex polymetallic resources[J]. World Nonferrous Metals, 2018(10): 126-128. https://www.cnki.com.cn/Article/CJFDTOTAL-COLO201810068.htm

[26] 吴中贤, 陶东平. 云南某胶磷矿AMICS工艺矿物学研究及其难选机理探讨[J]. 工程科学学报, 2021, 43(4): 503-511. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202104006.htm

Wu Z X, Tao D P. Research on AMICS process mineralogy of a collophanite in Yunnan and discussion on its refractory mechanism[J]. Chinese Journal of Engineering, 2021, 43(4): 503-511. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD202104006.htm

[27] Mafra C, Bouzahzah H, Stamenov L, et al. Insights on the effect of pyrite liberation degree upon the acid mine drainage potential of sulfide flotation tailings[J]. Applied Geochemistry, 2020, 123(2): 104774. http://www.sciencedirect.com/science/article/pii/S0883292720302663

[28] Xie H Y, Liu Y H, Rao B, et al. Selective passivation behavior of galena surface by sulfuric acid and a novel dlotation separation method for copper-lead sulfide ore without collector and inhibitor[J]. Separation and Purification Technology, 2021, 267: 118621. doi: 10.1016/j.seppur.2021.118621

[29] Kursunoglu S, Top S, Kaya M. Recovery of zinc and lead from Yahyali non-sulphide flotation tailing by sequential acidic and sodium hydroxide leaching in the presence of potassium sodium tartrate[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(12): 3367-3378. doi: 10.1016/S1003-6326(20)65468-1

[30] Xie H Y, Sun S, Wu J Z, et al. A case study of enhanced sulfidization flotation of lead oxide ore: Influence of depressants[J]. Minerals, 2020, 10(2): 95. http://www.researchgate.net/publication/338760320_A_Case_Study_of_Enhanced_Sulfidization_Flotation_of_Lead_Oxide_Ore_Influence_of_Depressants

-

下载:

下载: