Study on Gravity and Magnetic Separation Process of an Iron-containing Low-grade and High Slime Tin Ore in Changning

-

摘要:

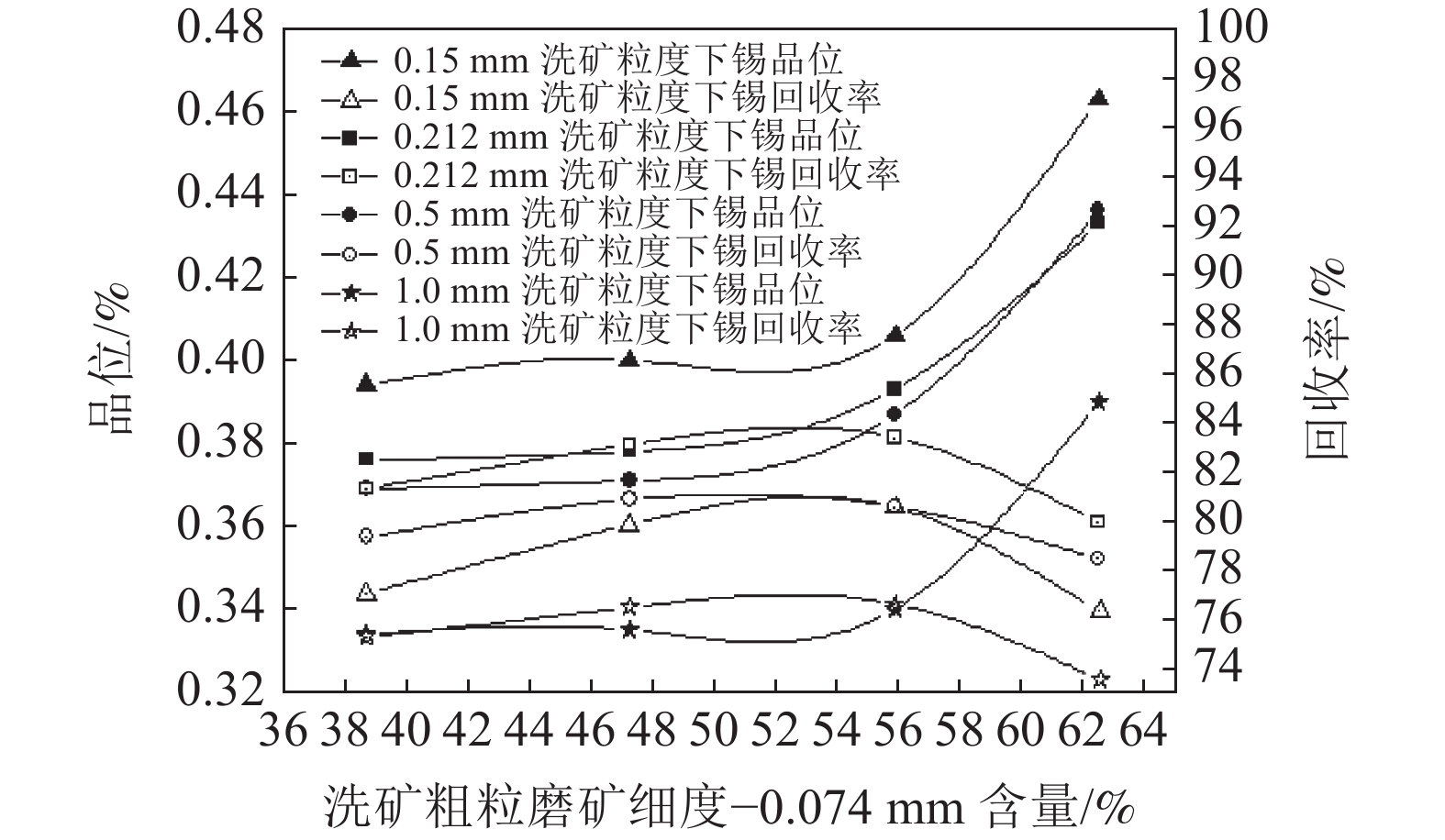

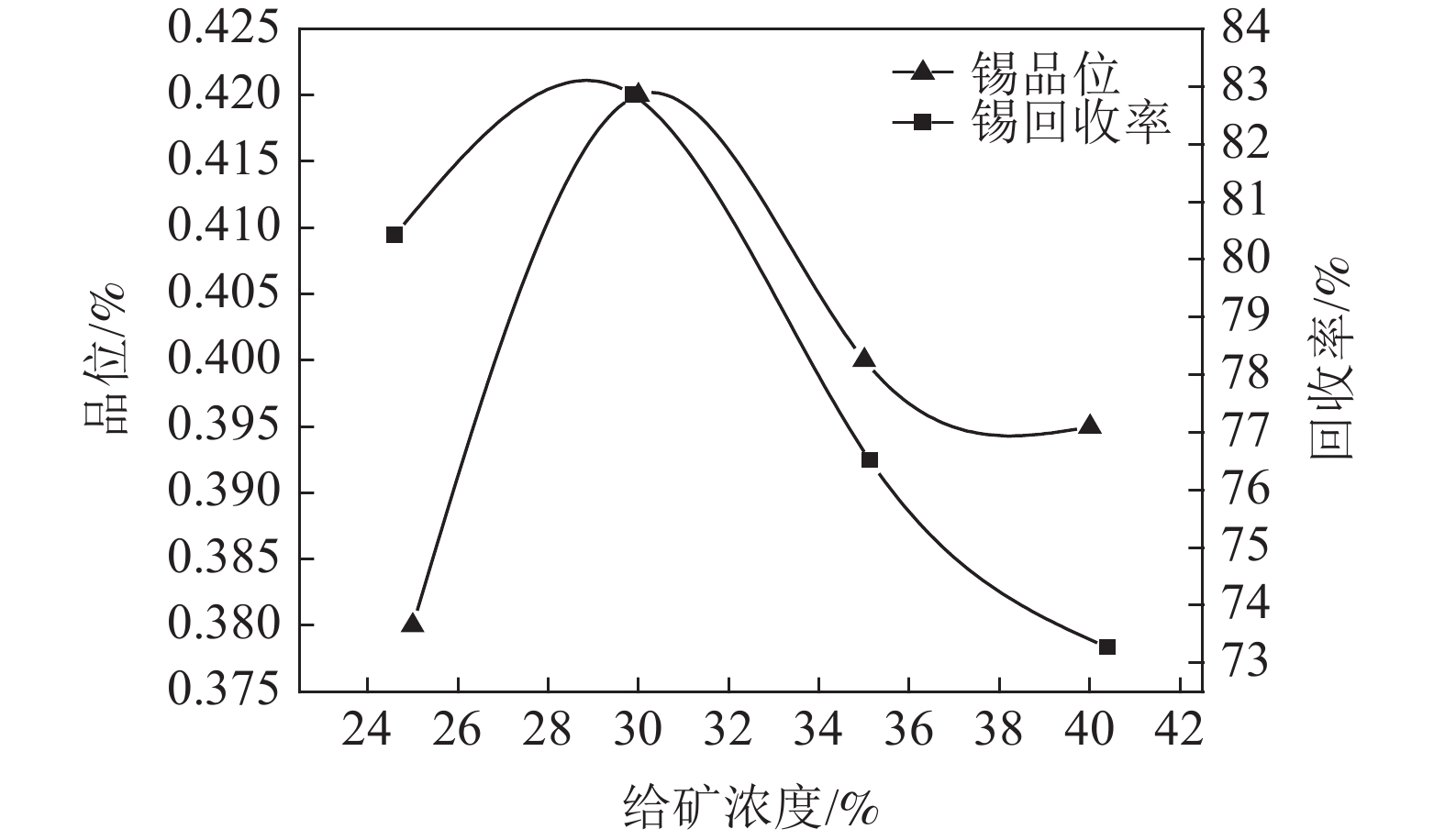

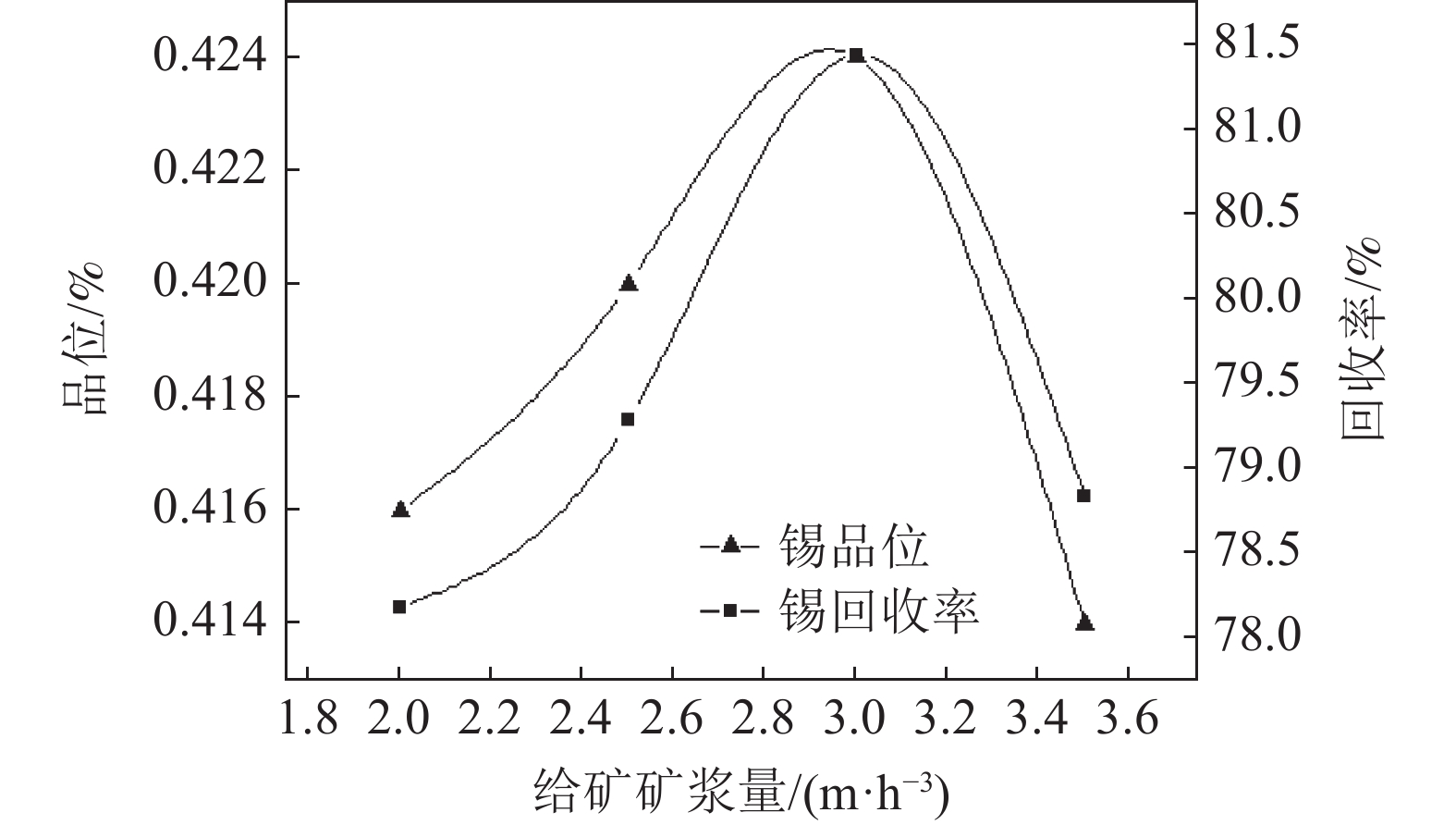

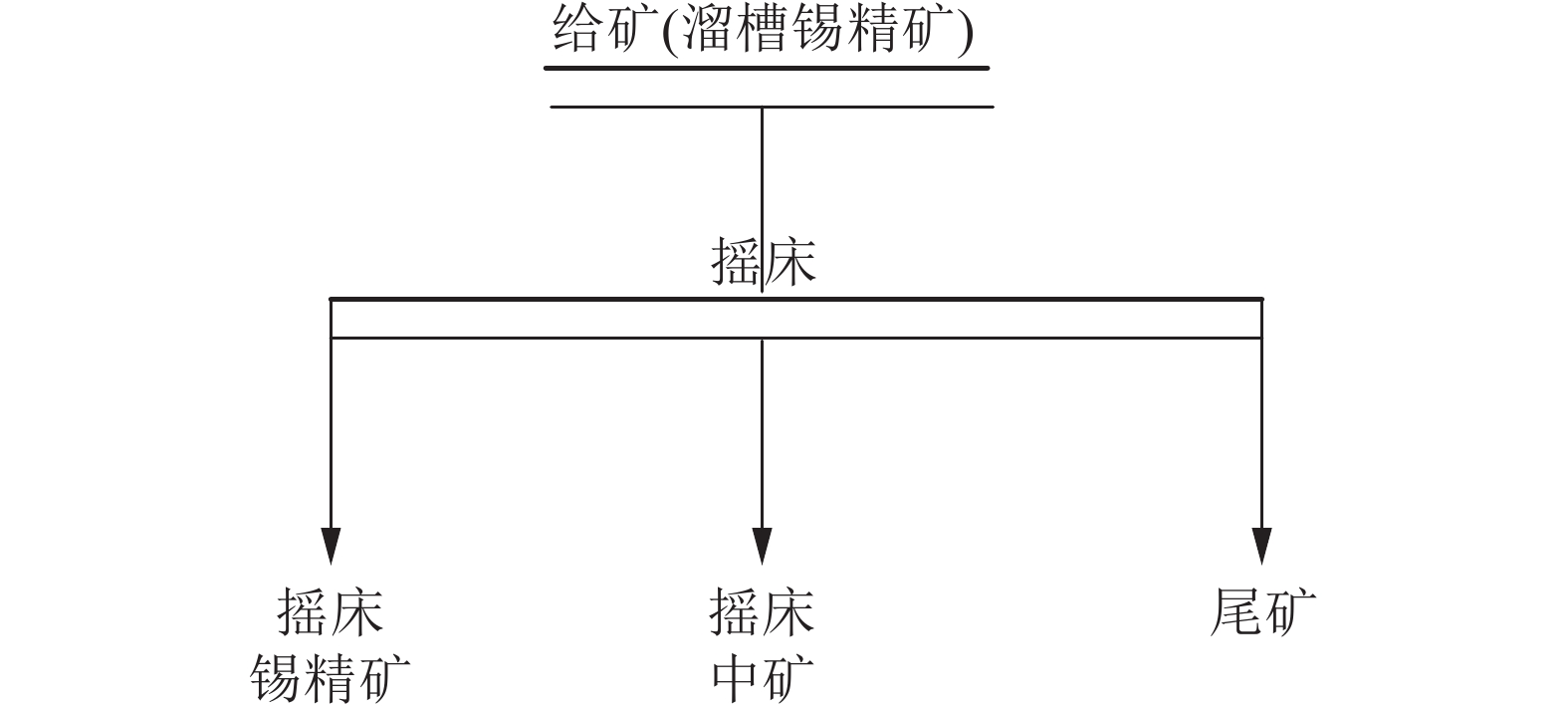

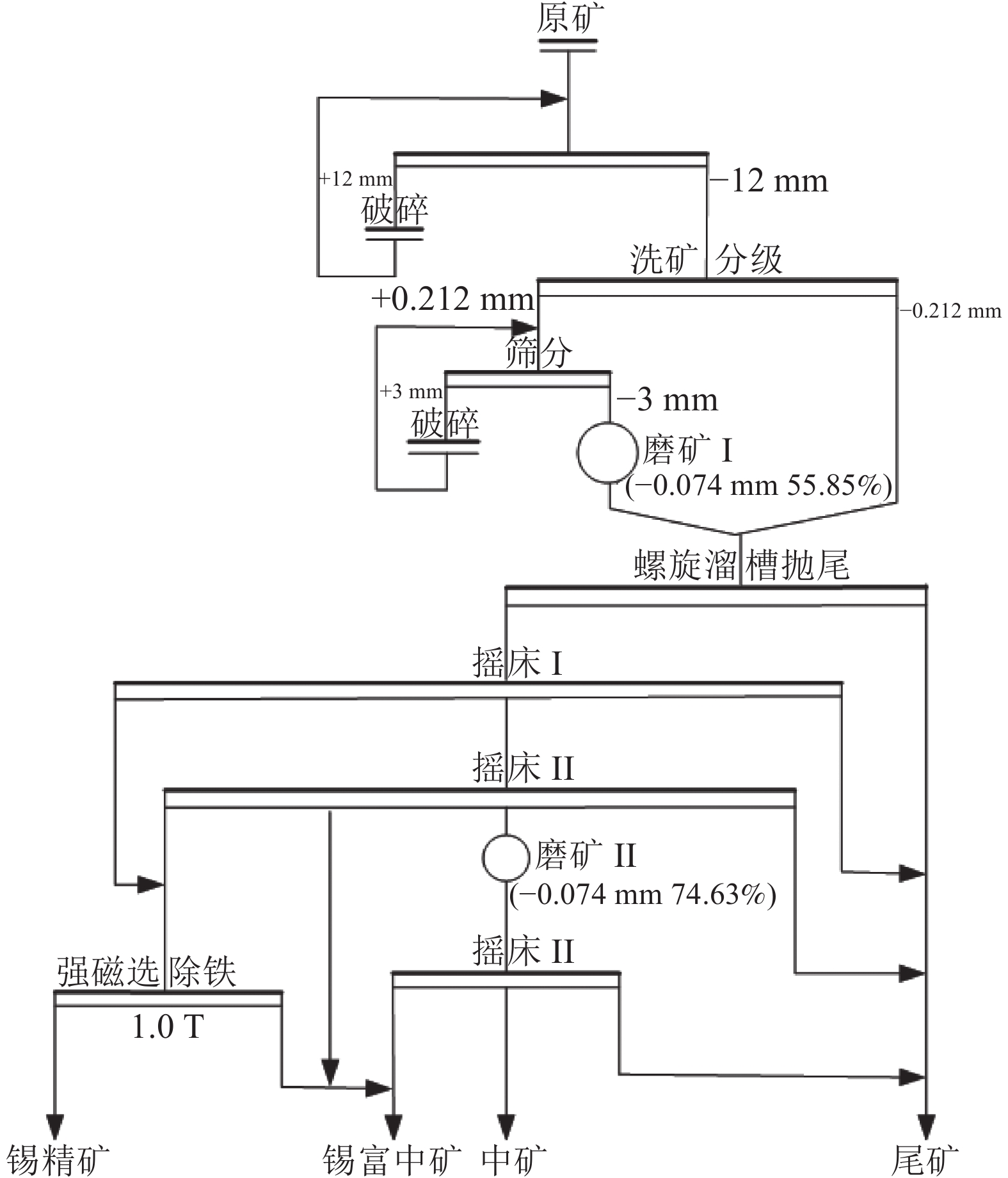

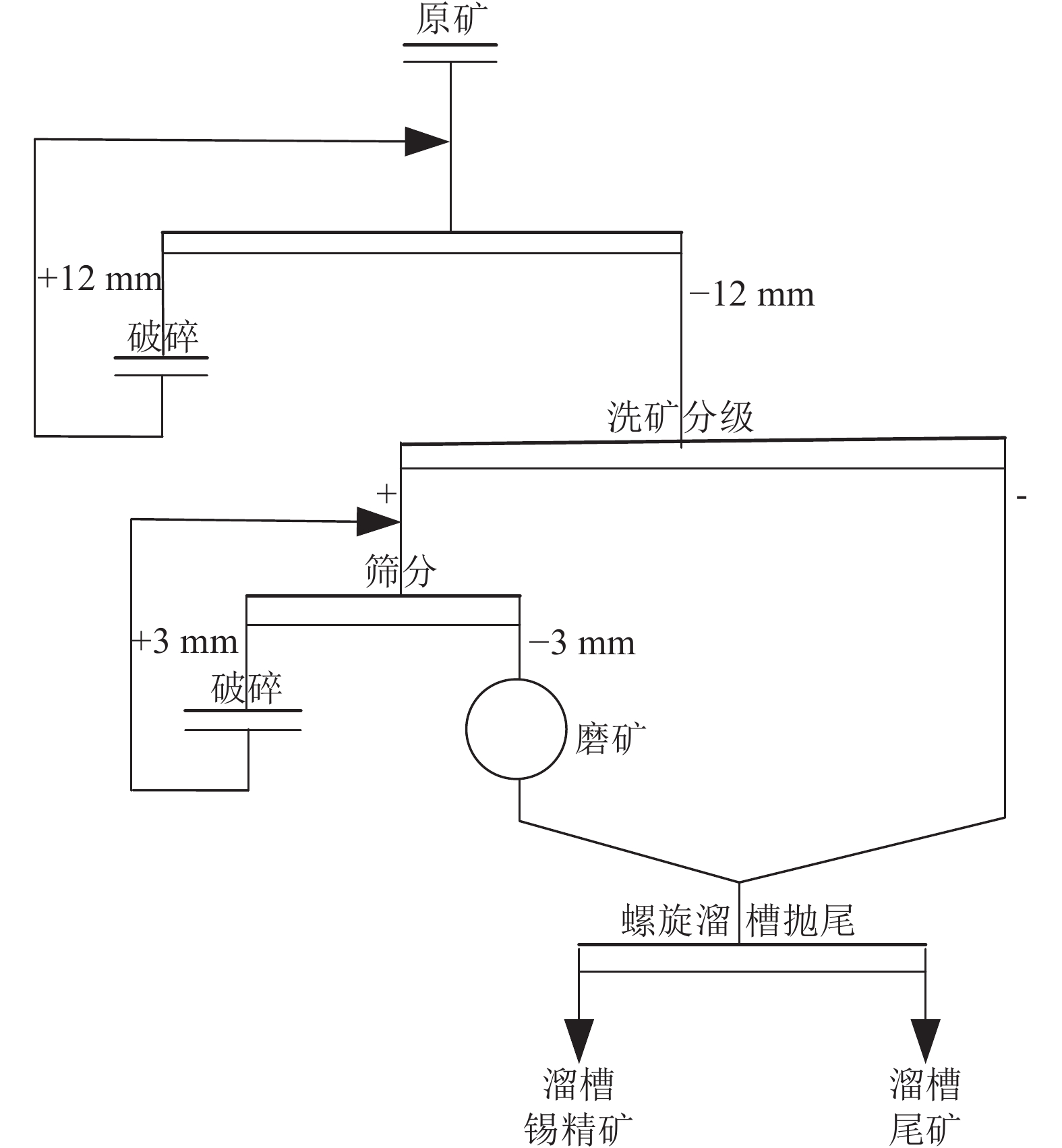

云南昌宁锡矿石主要有用金属矿物为锡石,其次为褐铁矿等,主要脉石矿物为石英,锡主要以锡石及酸溶锡形式存在。原矿Sn品位为0.166%,−0.074 mm矿泥含量为24.61%(其中−0.019 mm矿泥含量为14.27%),属低品位、高泥、含铁难选锡石矿。本文在对该矿石进行原矿性质研究的基础上,开展了该矿的重-磁选工艺研究。结果表明:原矿破碎至−12 mm按0.212 mm粒度洗矿分级,洗矿+0.212 mm粗粒破碎至−3 mm后磨矿至−0.074 mm 55.85%与洗矿细粒−0.212 mm合并,采用螺旋溜槽预先抛尾-溜槽精矿摇床分选-摇床精矿强磁选除铁的选矿工艺流程,可以获得产率为0.21%、Sn品位为41.32%、Sn回收率为52.27%的锡精矿,及产率为0.75%、Sn品位为4.750%、Sn回收率为21.46%的锡富中矿,锡精矿与锡富中矿Sn累计回收率为73.73%,锡精矿质量达到了YS/T339-2011标准中一类Ⅶ品级精矿质量要求,较好地实现了该锡矿的分选。

Abstract:The main useful metal mineral in the tin ore from Changning is cassiterite, followed by limonite, the main gangue mineral is quartz, and tin mainly exists in the form of cassiterite and acid soluble tin. The tin ore with tin grade of 0.166% and yield of −0.074 mm fine slime of 24.61% (−0.019 mm fine slime of 14.27%) belongs to an iron-containing, low grade, high slime and refractory tin ore. Based on the study of the properties of a refractory tin ore from Yunnan, the beneficiation process of the ore was studied. Test results showed that: the raw ore was crushed to −12 mm and classified by washing with 0.212 mm particle size. After the + 0.212 mm coarse grains were crushed to −3 mm and ground to −0.074 mm occupying 55.85% and then merged with −0.212 mm fine grains as raw ore, separation flowsheet of pre-discarding tailings by spiral chute - separation of chute concentrate by shaking table -iron removal from shaker concentrate by high intensity magnetic separator was adopted to separate the raw ore .Tin concentrate with yield of 0.21%, tin grade of 41.32%, tin recovery of 52.27%, tin rich middling with yield of 0.75%, tin grade of 4.750%, tin recovery of 21.46%, and cumulative recovery of tin concentrate and tin rich middling of 73.73% was obtained. The quality of tin concentrate, which realized separation of tin from the raw ore, meets the concentrate level of grade VII category I of YS/T 339-2011 standard.

-

-

表 4 试样粒度组成分析结果

Table 4. Particle size analysis of test samples

粒级/mm 部分

产率/%负累计

产率/%品位/Sn% 部分金属

分布率/%负累计

金属分

布率/%−12+3 31.06 100 0.245 45.84 100.00 −3+1 9.57 68.94 0.319 18.39 54.16 −1+0.5 10.15 59.37 0.137 8.38 35.77 −0.5+0.212 13.11 49.22 0.135 10.66 27.39 −0.212+0.15 4.68 36.11 0.142 4.00 16.73 −0.15+0.074 6.82 31.43 0.111 4.56 12.73 −0.074+0.044 3.65 24.61 0.119 2.62 8.17 −0.044+0.037 2.25 20.96 0.119 1.61 5.55 −0.037+0.019 4.44 18.71 0.058 1.55 3.94 −0.019+0.01 4.25 14.27 0.032 0.82 2.39 −0.01+0.005 5.03 10.02 0.035 1.06 1.57 −0.005 4.99 4.99 0.017 0.51 0.51 合 计 100.00 0.166 100.00 表 1 试样化学多元素分析结果/%

Table 1. Multi-element analysis results of test samples

Sn TFe Zn Pb WO3 Bi ZrO2 Cu Ni Sb TiO2 SiO2 Al2O3 K2O S As 0.166 4.74 0.34 0.02 0.002 0.0024 0.039 0.02 0.007 0.001 0.69 66.74 18.36 3.05 0.024 0.206 表 2 试样锡物相分析结果

Table 2. Analysis results of tin phases

项 目 锡石 酸溶锡 硅酸盐 合 计 Sn含量/% 0.133 0.032 0.001 0.166 Sn分布率/% 80.12 19.28 0.60 100.00 表 3 试样铁物相分析结果

Table 3. Analysis results of iron phases

项 目 褐铁矿 黄铁矿 硅酸铁及其他 合 计 Fe含量/% 4.06 0.50 0.18 4.74 Fe分布率/% 85.65 10.55 3.80 100.00 表 5 溜槽精矿摇床分选实验结果

Table 5. Test results of shaking table separation of chute concentrate

产品名称 作业

产率/%对原矿

产率/%Sn品位/% 作业Sn回

收率/%对原矿Sn

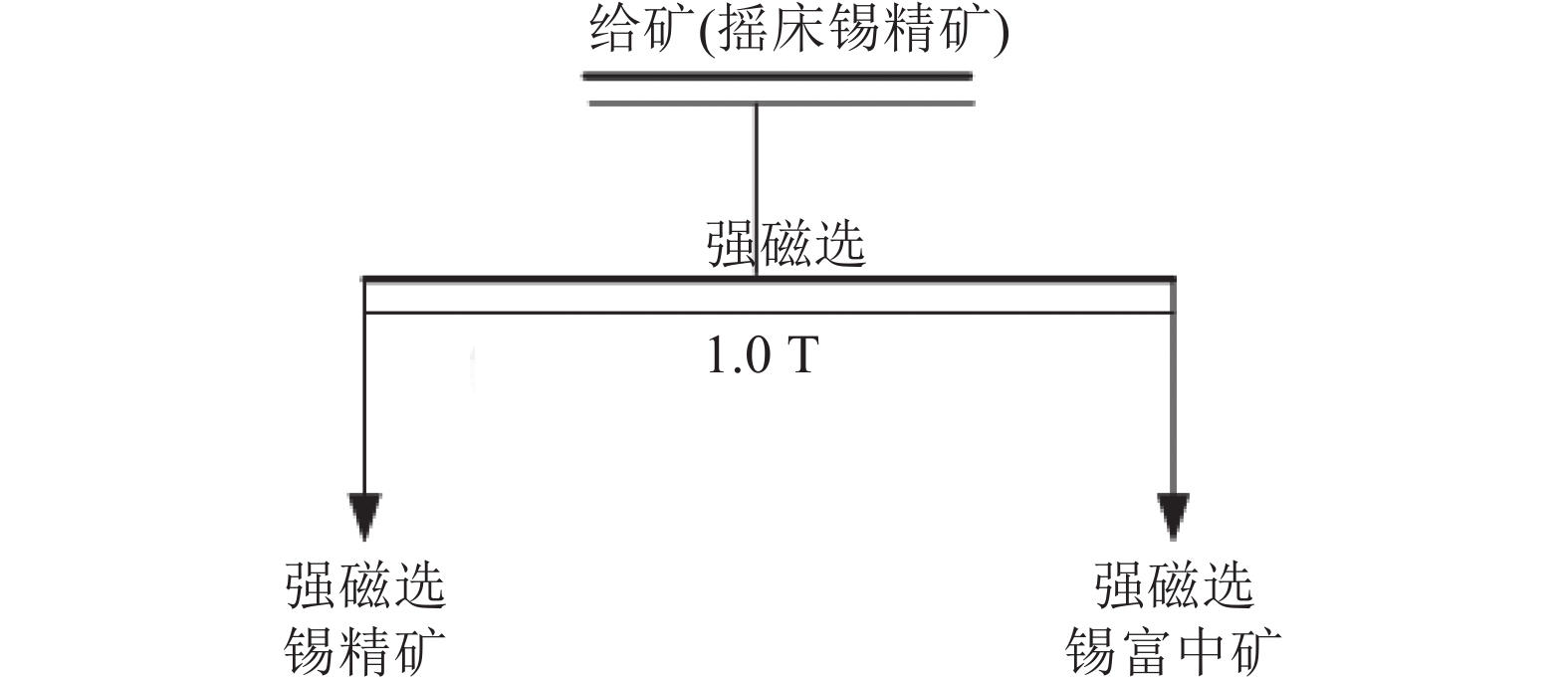

回收率/%摇床锡精矿 1.08 0.36 22.82 58.13 48.86 摇床中矿 24.86 8.18 0.580 34.01 28.59 尾矿 74.06 24.37 0.045 7.86 6.61 给矿 100.00 32.91 0.424 100.00 84.06 表 6 摇床精矿强磁选除铁实验结果

Table 6. Test results of iron removal from shaker concentrate by high-intensity magnetic separation

产品名称 作业

产率/%对原矿

产率/%Sn品位/% 作业Sn回

收率/%对原矿Sn

回收率/%强磁选锡精矿 37.93 0.14 51.96 86.44 42.23 强磁选锡富中矿 62.07 0.22 4.980 13.56 6.63 合 计 100.00 0.36 22.80 100.00 48.86 表 7 全流程扩大实验结果

Table 7. Expanded test results of the whole process

产品名称 产率/% Sn品位/% Sn回收率/% 锡精矿 0.21 41.32 52.27 锡富中矿 0.75 4.750 21.46 中矿 2.39 0.211 3.04 尾矿 96.65 0.040 23.23 原矿 100 0.166 100.00 表 8 选矿产品化学分析结果/%

Table 8. Chemical analysis results of mineral processing products

名称 Sn S As Bi Zn Sb TFe F Cu SiO2 Al2O3 Pb WO3 锡精矿 41.32 0.708 0.749 0.11 0.553 0.05 7.01 — 0.010 15.36 2.71 0.252 0.28 锡富中矿 4.75 0.085 0.519 0.07 0.066 0.003 35.49 — 0.015 26.41 5.62 0.078 0.046 -

[1] 卢致明, 韩彬. 微细粒锡石选别的研究进展及思考建议[J]. 世界有色金属, 2019(4):76-79.

LU Z M, HAN B. Research progress and thinking suggestions for the selection of sine-grained cassiterite[J]. World Nonferrous Metals, 2019(4):76-79.

[2] 汪泰, 胡真, 李汉文. 微细粒锡石浮选药剂筛选及选矿工艺研究[J]. 矿产综合利用, 2020(2): 96-101.

WANG T, HU Z, LI H W. Research on flotation agent screening and mineral processing technology for fine-grained cassiterite J]. Multipurpose Utilization of Mineral Resources, 2020(2): 96-101.

[3] 王灿霞. 新型盘式流膜选矿机分选广西凤凰山矿细泥锡尾矿试验研究[D]. 昆明: 昆明理工大学, 2009.

WANG C X. Experimental study on the separation of fine mudded tin tailings from Fenghuangshan Mine in Guangxi by a new type of disc flow film concentrator [D]. Kunming: Kunming University of Science and Technology, 2009.

[4] 黄位森. 锡[M]. 北京: 冶金工业出版社, 2000.

HUANG W S. Tin [M]. Beijing: Metallurgical Industry Press, 2000.

[5] 丛龙斐, 王霄鹏, 周长春, 等. 双涡耦合-导向平底旋流器在锡矿分选中的应用[J]. 矿产综合利用, 2020(2):177-181. doi: 10.3969/j.issn.1000-6532.2020.02.032

CONG L F, WANG X P, ZHOU C C, et al. Dual vortex coupling - guide flat-bottom cyclone application in tin ore separation[J]. Multipurpose Utilization of Mineral Resources, 2020(2):177-181. doi: 10.3969/j.issn.1000-6532.2020.02.032

[6] 吕超. 某锡石多金属硫化矿锌高效回收工艺研究[J]. 矿产综合利用, 2021(1):77-82. doi: 10.3969/j.issn.1000-6532.2021.01.012

LV C. Study on efficient recovery process of zinc from cassiterite polymetallic sulfide ore[J]. Multipurpose Utilization of Mineral Resources, 2021(1):77-82. doi: 10.3969/j.issn.1000-6532.2021.01.012

[7] 宋建文. 腾冲高镁微细粒级铁锡矿选矿试验研究[D]. 昆明: 昆明理工大学, 2018.

SONG J W. Experimental Study on the Beneficiation of Tengchong High Magnesium Fine Fe-tin Ore [D]. Kunming: Kunming University of Science and Technology, 2018.

-

下载:

下载: