Kinetics of Alkaline Leaching Process of Extractiing Silicon from the Residue of Titanium Extraction with Ammonium Sulfate Roasting

-

摘要:

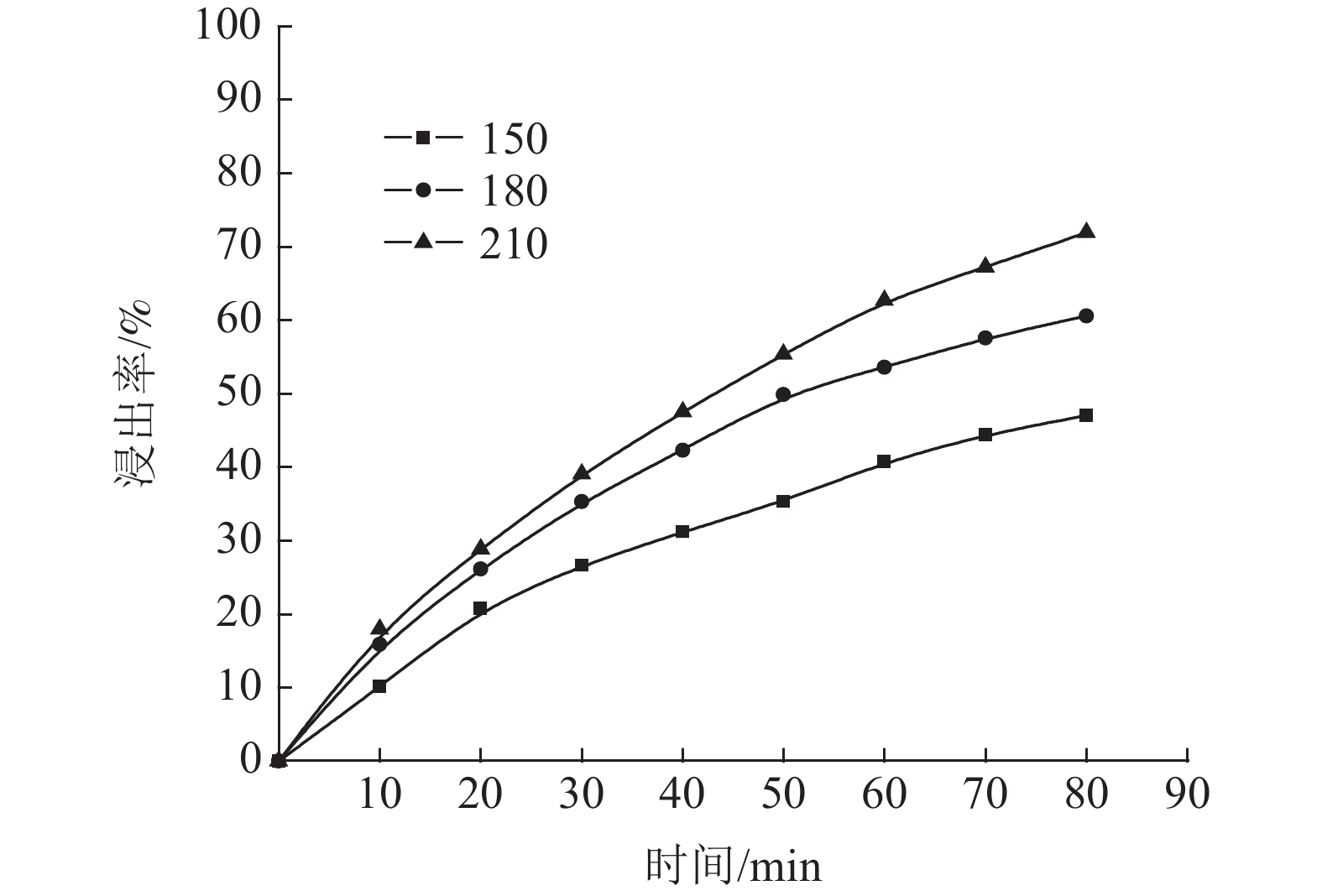

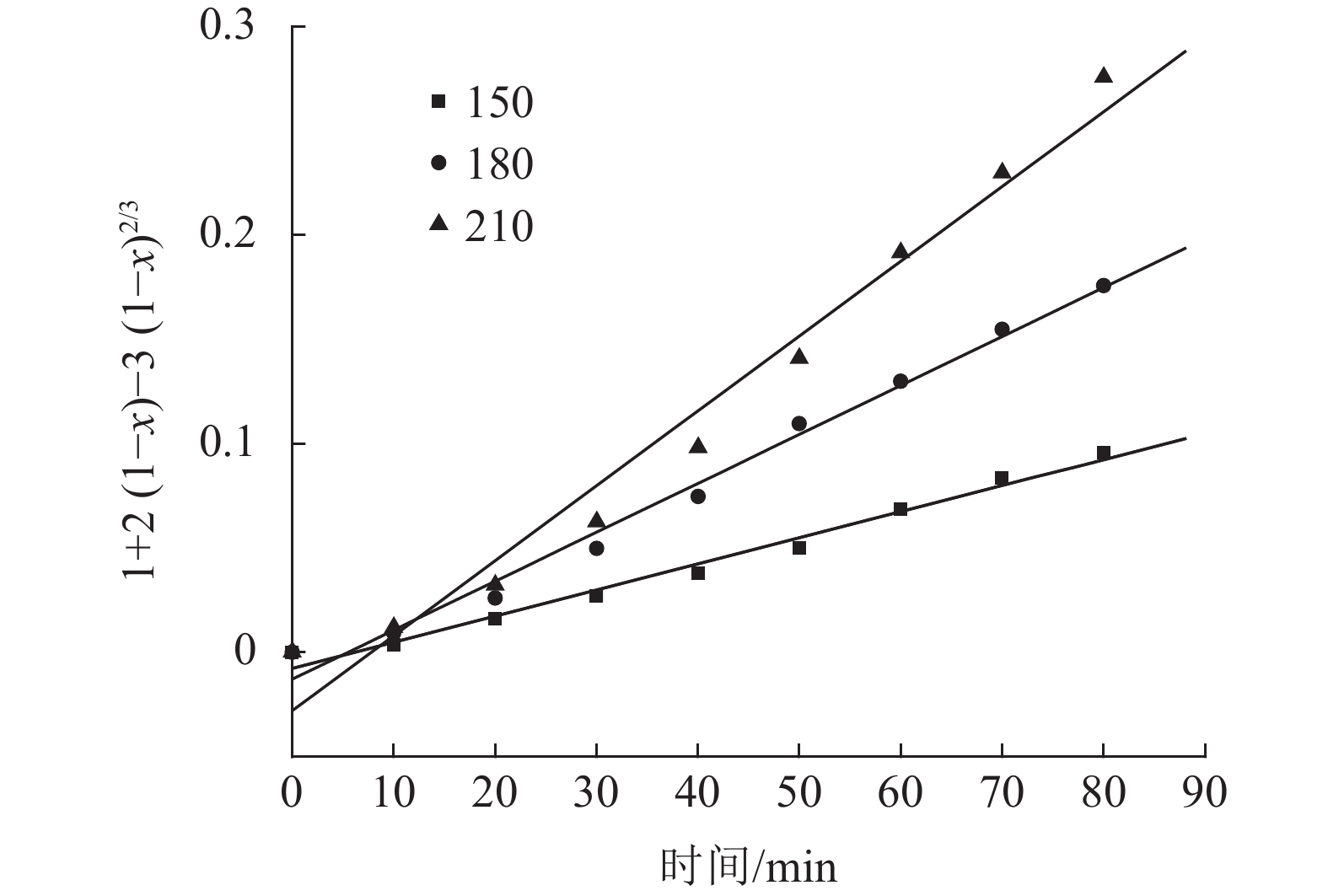

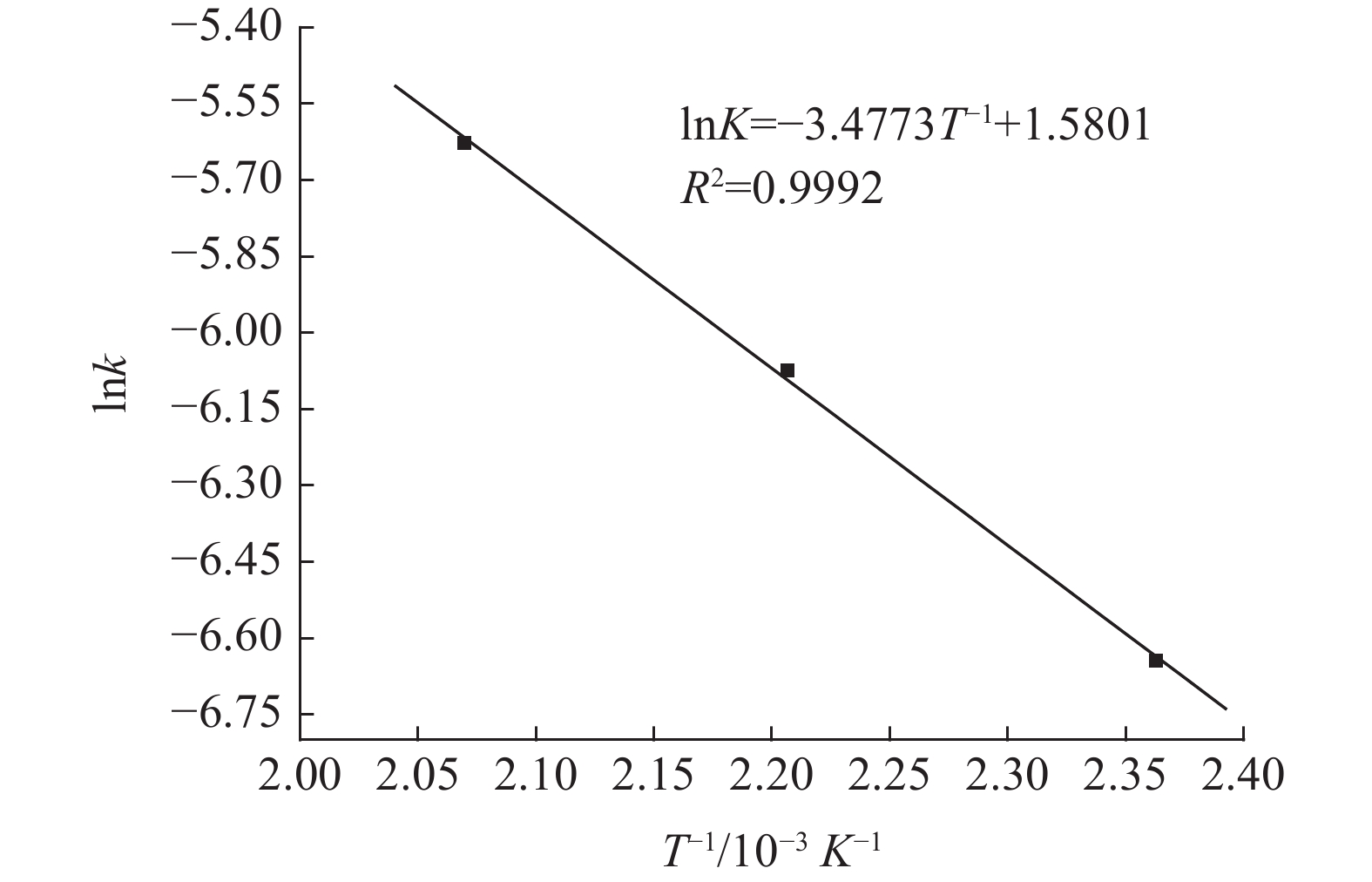

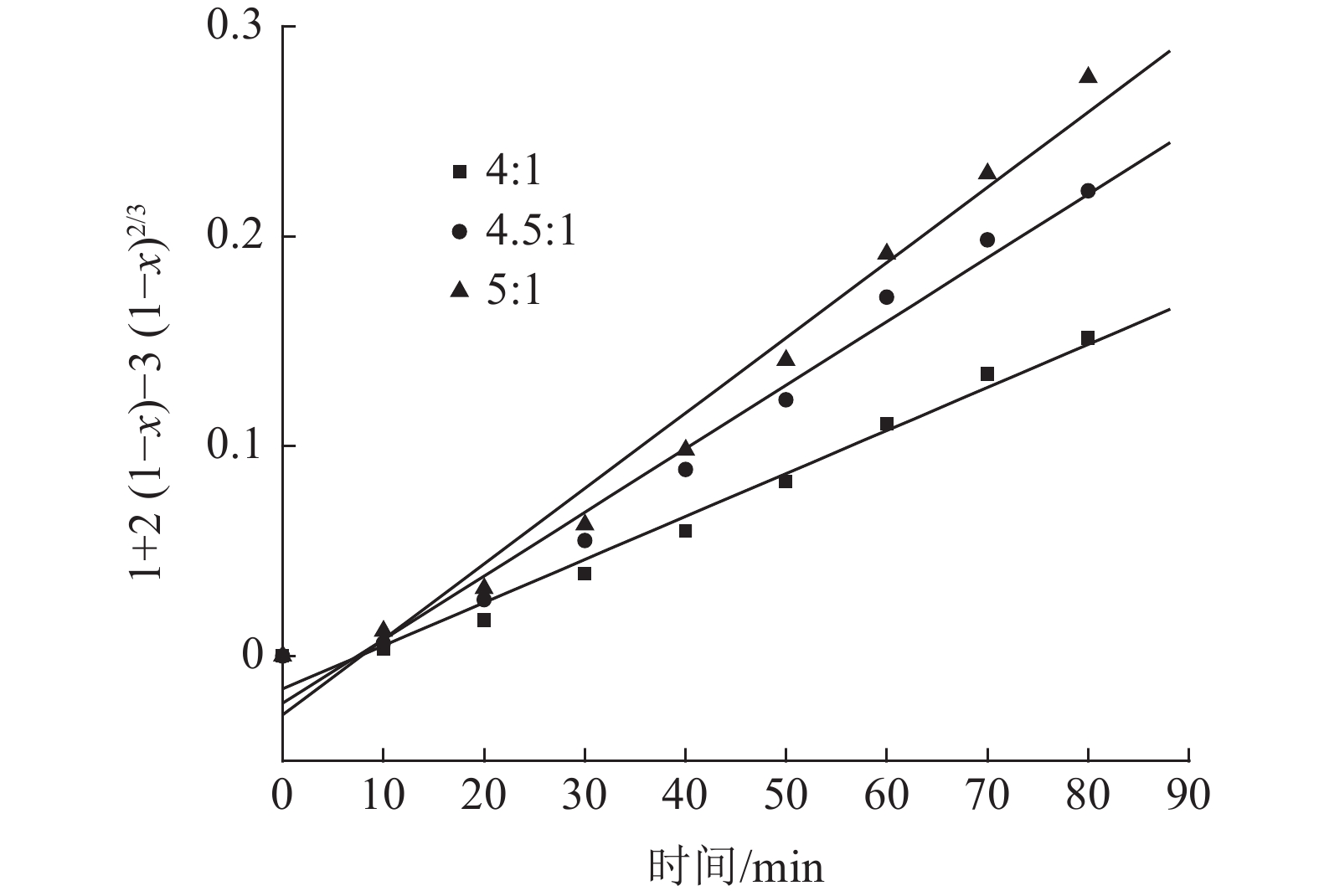

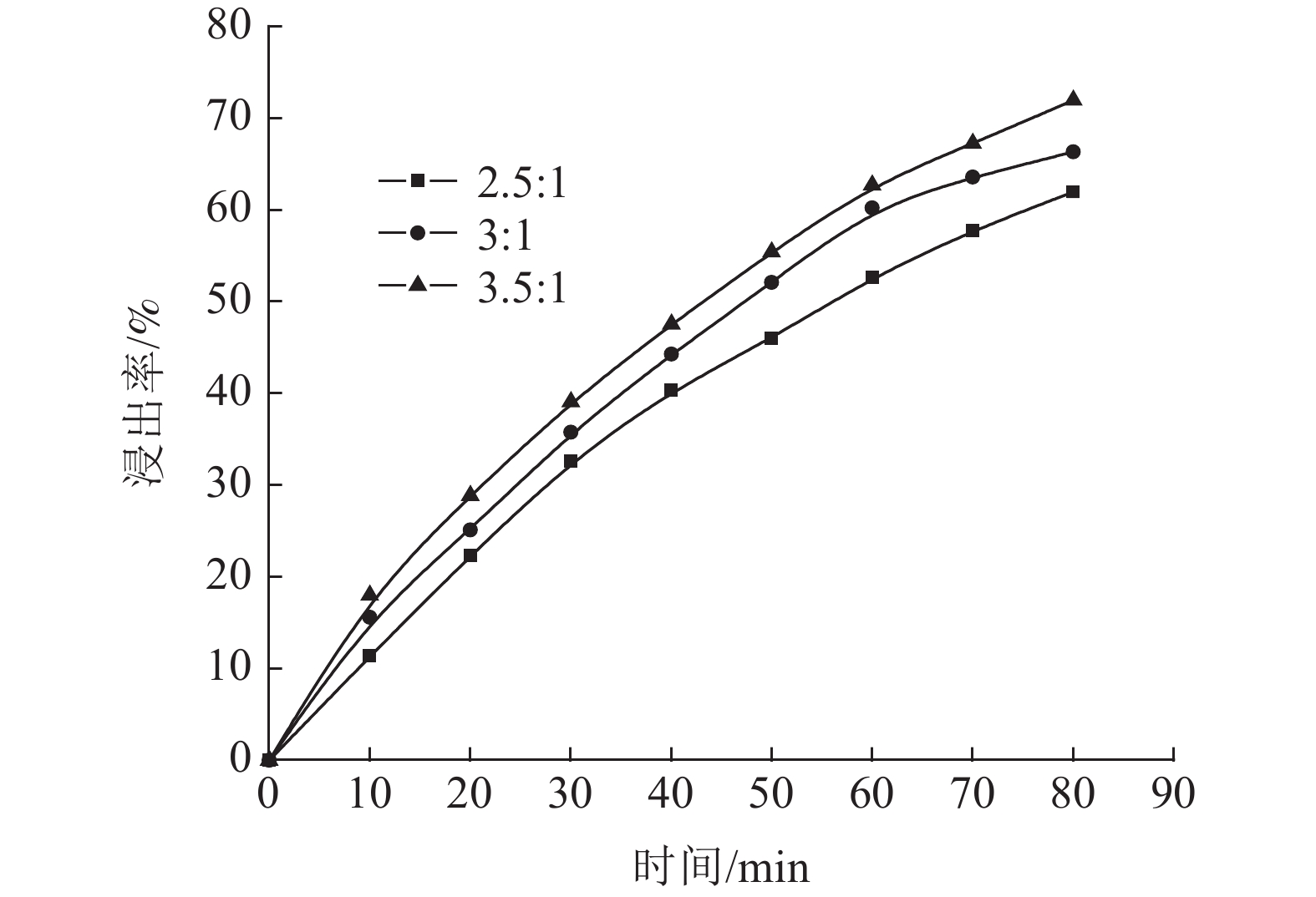

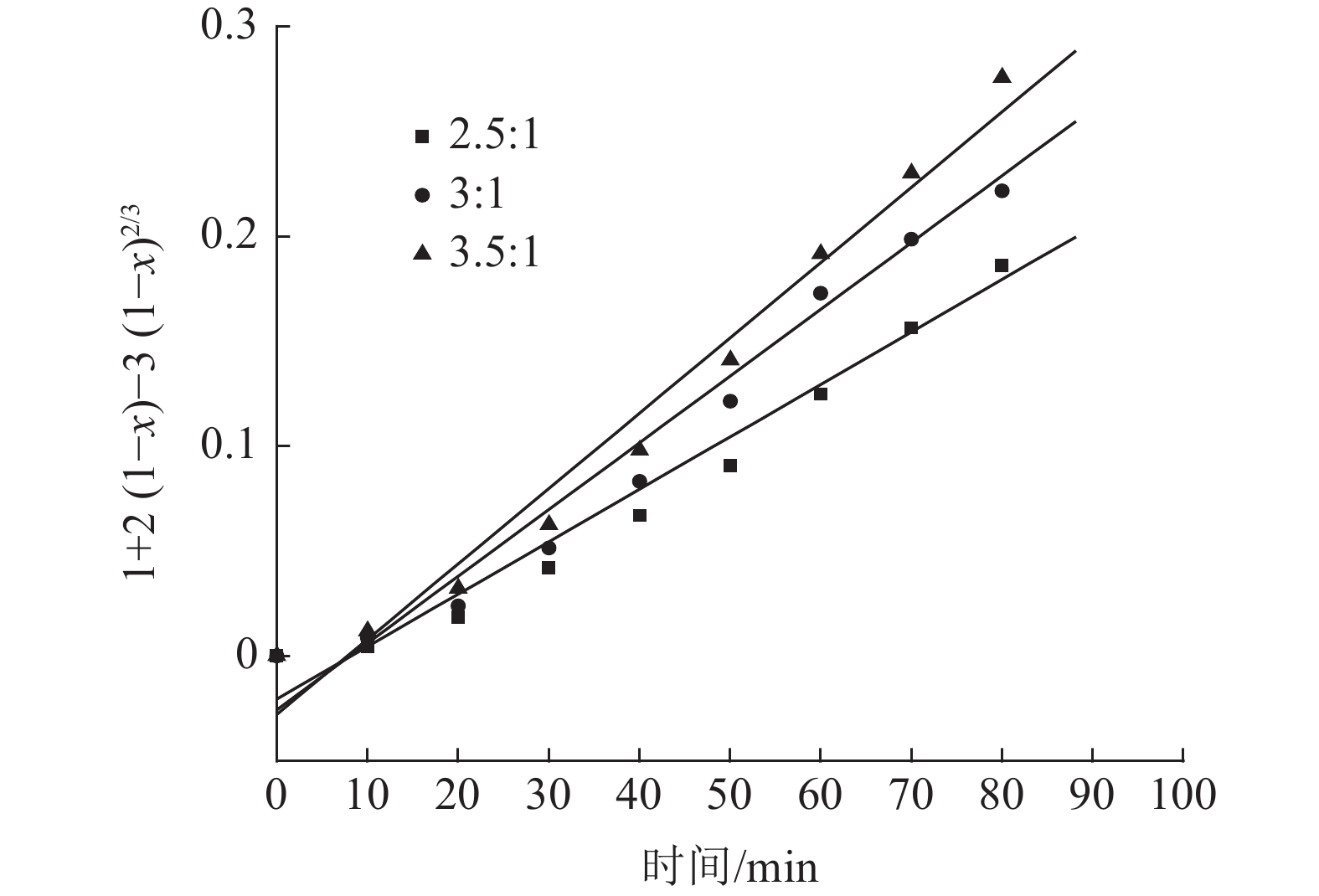

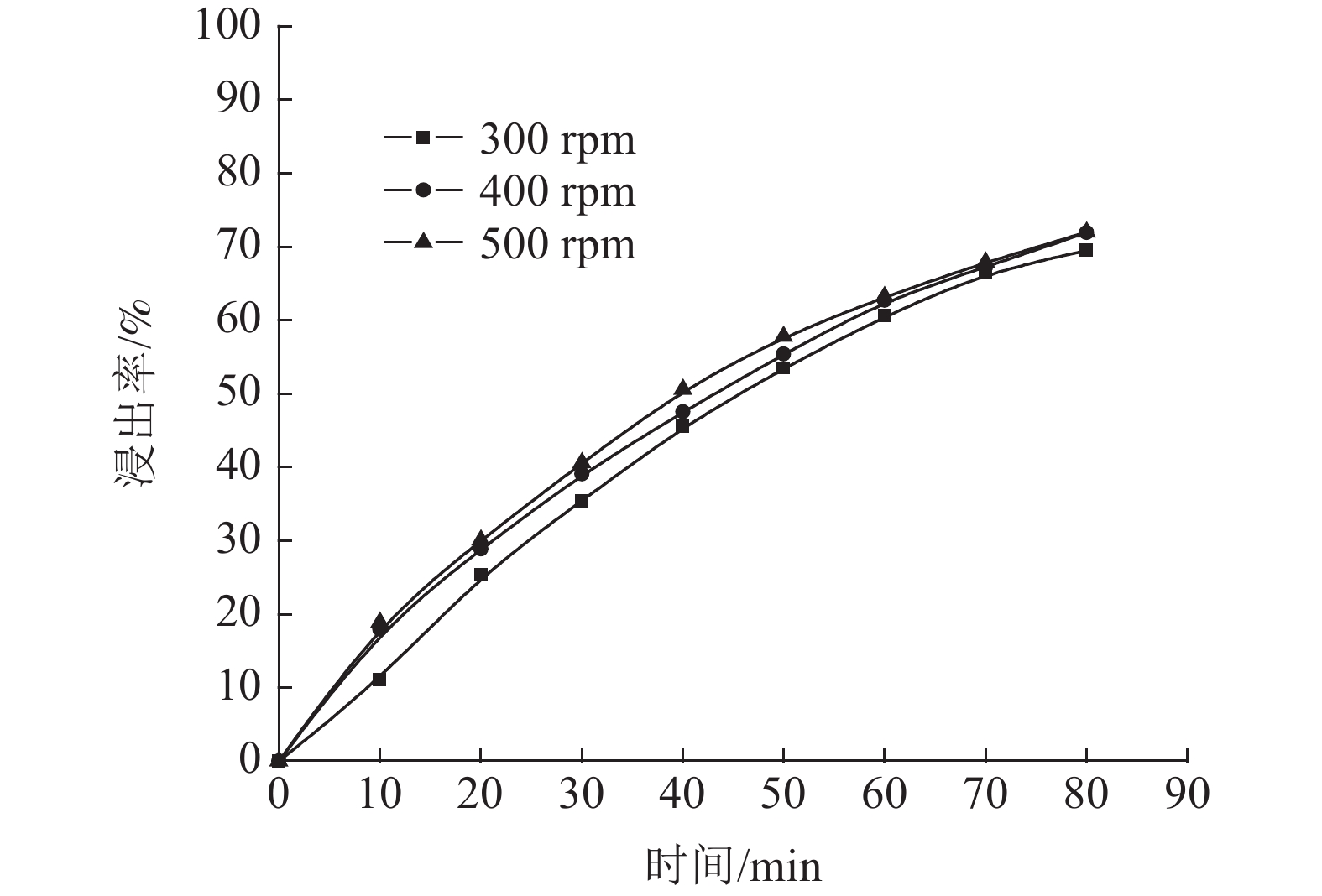

硫酸铵焙烧钛渣提钛后的滤渣中含有大量的硅,本文分析了碱浸提钛渣提硅的动力学反应过程,结果表明:该碱浸过程受克-金-布产物层固膜扩散控制,根据阿罗尼乌斯方程得到反应的表观活化能为28.91 kJ/mol,确定动力学方程式为:1+2(1-x)-3(1-x)2/3=4.8554exp[-28910/( RT)]•t。

Abstract:There is a large amount of silicon in the filter residue after extracting titanium from the titanium slag roasted with ammonium sulfate. Kinetics of alkaline leaching process of extracting silicon from the residue of titanium extraction were investigated. The results show that the internal diffusion on the solid product layer is the rate-controlling step in the leaching process. According to the Arrhenius expression, the apparent activation energy for the alkaline leaching process is 28.91 kJ/mol. The kinetics equation can be expressed as 1+2(1-x)-3(1-x)2/3=4.8554exp[-28910/(RT)]•t.

-

Key words:

- Ammonium sulfate /

- Titanium slag /

- Silicon dioxide /

- Alkaline leaching kinetics

-

-

表 1 滤渣的主要化学组成 /%

Table 1. Chemical compositions of the residue

TiO2 Al2O3 Fe2O3 SiO2 MgO CaO 11.24 10.15 1.76 54.60 3.76 12.47 表 2 不同温度下的浸出速率常数

Table 2. Rate constant values at different temperatures

T /K k /min-1 r 443 0.0013 0.9852 463 0.0023 0.9888 483 0.0036 0.975 -

[1] 郝百川, 李子越, 贾东方, 等. 含钛高炉渣的综合利用[J]. 矿产综合利用, 2020(6):1-6. doi: 10.3969/j.issn.1000-6532.2020.06.001

HAO B C, LI Z Y, JIA D F, et al. Comprehensive Utilization of Blast Furnace Slag Containing Titanium[J]. Multipurpose Utilization of Mineral Resources, 2020(6):1-6. doi: 10.3969/j.issn.1000-6532.2020.06.001

[2] 许莹, 李单单, 杨姗姗, 等. 含钛高炉渣综合利用研究进展[J]. 矿产综合利用, 2021(1):23-31. doi: 10.3969/j.issn.1000-6532.2021.01.004

XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):23-31. doi: 10.3969/j.issn.1000-6532.2021.01.004

[3] 高洋. 高钛高炉渣综合利用现状及展望[J]. 矿产综合利用, 2019(1):6-10. doi: 10.3969/j.issn.1000-6532.2019.01.002

GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1):6-10. doi: 10.3969/j.issn.1000-6532.2019.01.002

[4] Yu Yi, ZHANG Youxue, YANG Yuping. Kinetics of Quartz Dissolution in Natural Silicate Melts and Dependence of SiO2 Diffusivity on Melt Composition. ACS Earth Space Chem. 2019, 3, 599-616.

[5] 郝建璋, 曾冠武. 钒钛磁铁矿铁、钒、钛一步分离实验[J]. 矿产综合利用, 2020(6):73-78. doi: 10.3969/j.issn.1000-6532.2020.06.013

HAO J Z, ZENG G W. New technique for the separation of iron, vanadium and titanium in vanadium titanium magnetite[J]. Multipurpose Utilization of Mineral Resources, 2020(6):73-78. doi: 10.3969/j.issn.1000-6532.2020.06.013

[6] WANG Ruochao, ZHAI Yuchun, NING Zhiqiang, et al. Kinetics of SiO2 leaching from Al2O3 extracted slag of fly ash with sodium hydroxide solution[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6):1928-1936. doi: 10.1016/S1003-6326(14)63273-8

[7] 戚海平, 张印民, 张永锋, 等. 微硅粉碱溶脱硅及其反应动力学[J]. 环境工程学报, 2017, 11(4): 2 475-2 480.

QI H P, ZHANG Y M, ZHANG Y F, et al. Journal of Environmental Engineering, 2017, 11(4): 2, 475-2, 480

[8] 贺实月, 李会泉, 李少鹏, 等. 煤粉炉高铝粉煤灰碱溶脱硅反应动力学[J]. 中国有色金属学报, 2014, 24(7):1888-1894.

HE S Y, LI H Q, LI S P, et al. Kinetics of alkali dissolution and desilication of high alumina coal ash in pulverized coal furnace[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7):1888-1894.

[9] 张晗, 隋丽丽, 葛欣, 等. 钛渣硫酸铵焙烧法提钛渣提硅试验研究[J]. 矿产综合利用, 2018(1):111-114. doi: 10.3969/j.issn.1000-6532.2018.01.024

ZHANG H, SUI L L, GE X, et al. Experimental study on silicon extraction from titanium slag by roasting with ammonium sulfate from titanium slag[J]. Multipurpose Utilization of Mineral Resources, 2018(1):111-114. doi: 10.3969/j.issn.1000-6532.2018.01.024

[10] MU W N, LU X Y, CUI F H, et al. Transformation and leaching kinetics of silicon from low-grade nickel laterite ore by pre-roasting and alkaline leaching process[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(1):169-176. doi: 10.1016/S1003-6326(18)64650-3

[11] 罗玉长. 添加晶种低温脱硅及其动力学[J]. 轻金属, 1999(11): 27-29.

LUO Y C. Low temperature desilication kinetics of added crystal seed, Light Metals, 1999, 11: 27-29.

[12] 赵昌明, 翟玉春, 刘岩, 等. 红土镍矿在NaOH亚熔盐体系中的预脱硅[J]. 中国有色金属学报, 2009, 19(5):949-954. doi: 10.3321/j.issn:1004-0609.2009.05.026

ZHAO C M, ZHAI Y C, LIU Y, et al. Predesilication of laterite nickel ore in NaOH submolten salt system[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5):949-954. doi: 10.3321/j.issn:1004-0609.2009.05.026

-

下载:

下载: