Study on Occurrence and Optionality of Vanadium in Bauxite-type Vanadium Deposits, Northern Sichuan.

-

摘要:

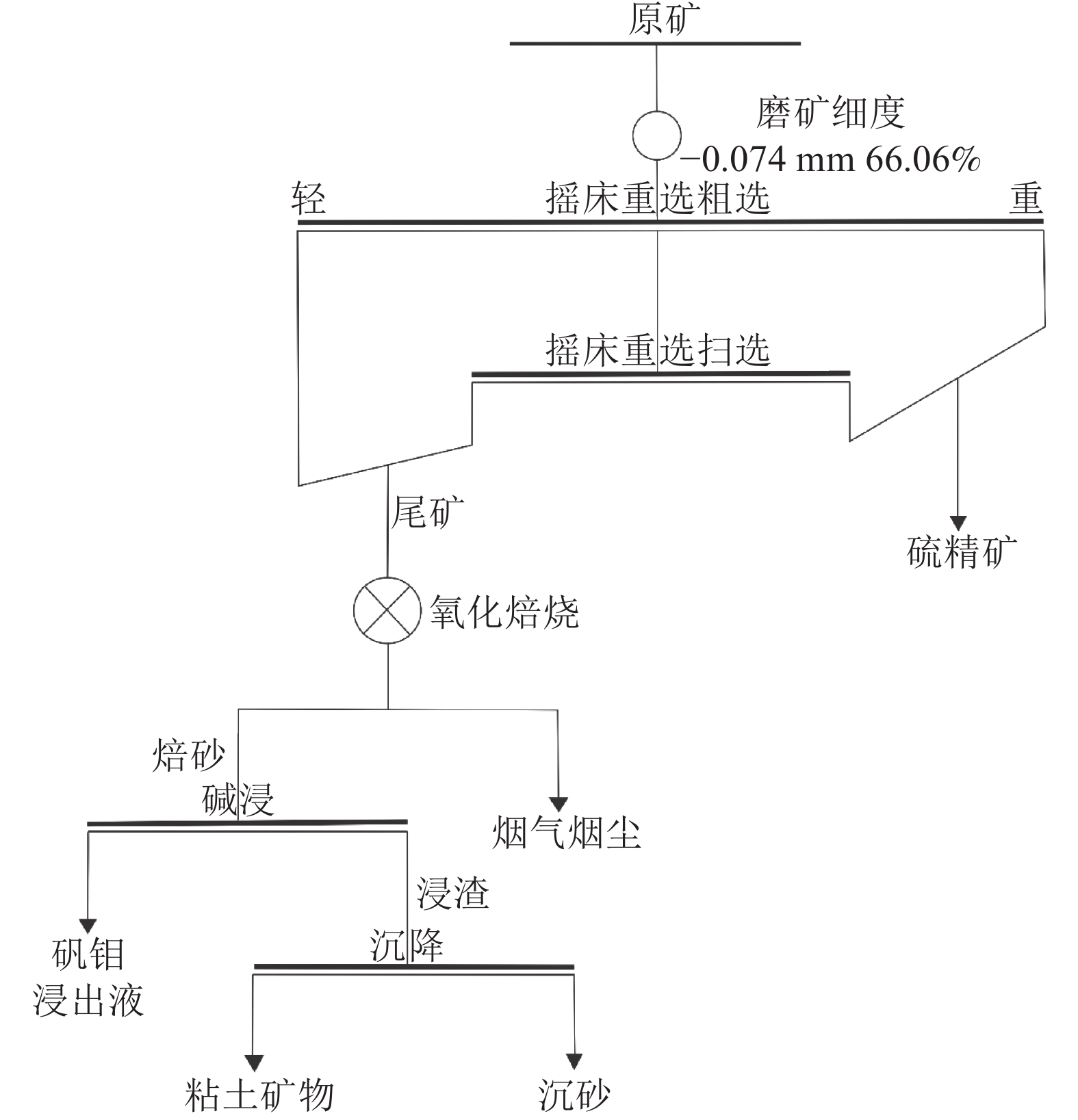

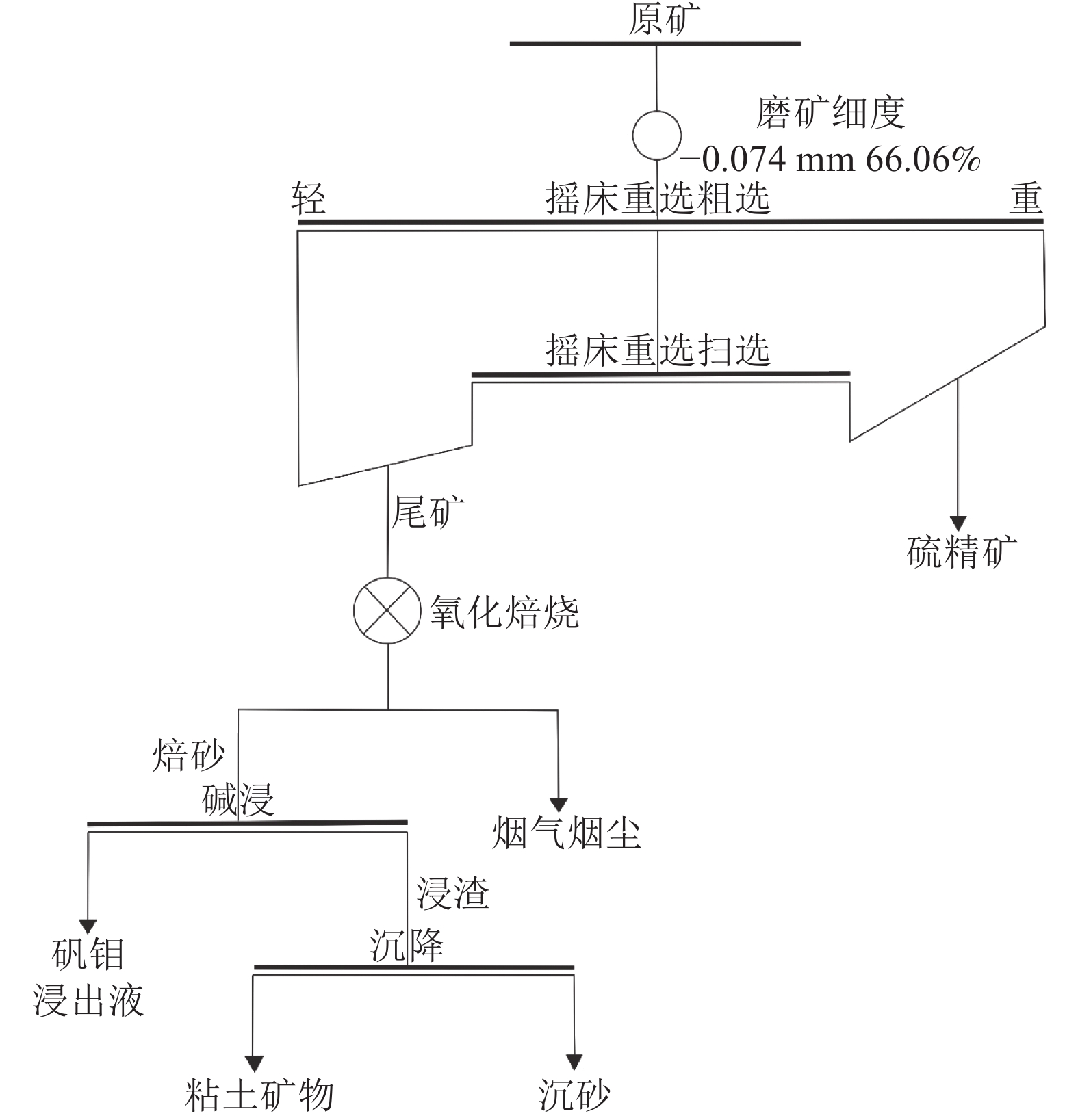

川北铝土岩型钒矿是一种新发现的钒矿床类型,通过开展钒的工艺矿物学及可选性研究,发现钒有两种赋存状态:主要呈钒云母的独立矿物形式存在,另一种则呈类质同象的形式存在于绢云母和伊利石中。钒的可选性实验研究表明该铝土岩型钒矿经济可选,采用“重选选硫-尾矿氧化焙烧碱浸钒钼-浸渣选粘土”的选冶联合工艺,可以有效回收矿石中有价元素钒、钼,并综合利用矿石中伴生的黄铁矿和粘土矿物。其中,钒的渣计浸出率74.42%、液计浸出率75.97%,钼的渣计浸出率88.77%、液计浸出率91.00%。

Abstract:Bauxite-type vanadium deposit in north sichuan is a newly discovered type of vanadium deposit. Through the study of process mineralogy and selectivity of vanadium, it is found that vanadium has two kinds of occurrence states: The main is an independent mineral in the form of vanadite, and the other is in the form of isomorphism in sericite and illite. The experimental study on the washability of vanadium ore shows that the bauxite type vanadium ore is economic. The valuable element vanadium and molybdenum in ore can be recovered effectively by the combined flowsheet of “ Recovery of sulfide by heavy separation- recovery of vanadium and molybdenum from tailings by roasting in air and alkaline leaching-Recovery of clay ore by leaching residue”. The associated pyrite and clay minerals in ore are utilized synthetically. After the test, the slag leaching rate of vanadium is 74.42%, the liquid leaching rate of vanadium is 75.97%, the slag leaching rate of molybdenum is 88.77%, the liquid leaching rate of molybdenum is 91.00%.

-

Key words:

- Bauxite /

- Vanadium ore /

- Occurrence of vanadium /

- Vanadium mica /

- roast /

- Alkali leaching

-

-

表 1 矿石的XRF测试结果/%

Table 1. XRF results of the ore

V2O5 MoO3 SiO2 Al2O3 Fe2O3 K2O TiO2 S Na2O MgO CaO Cr2O3 0.91 0.067 50.8 21.4 9.42 2.37 3.64 1.33 0.41 0.49 0.14 0.20 表 2 矿石化学多元素分析结果/%

Table 2. Chemical multi-element analysis results of the ore

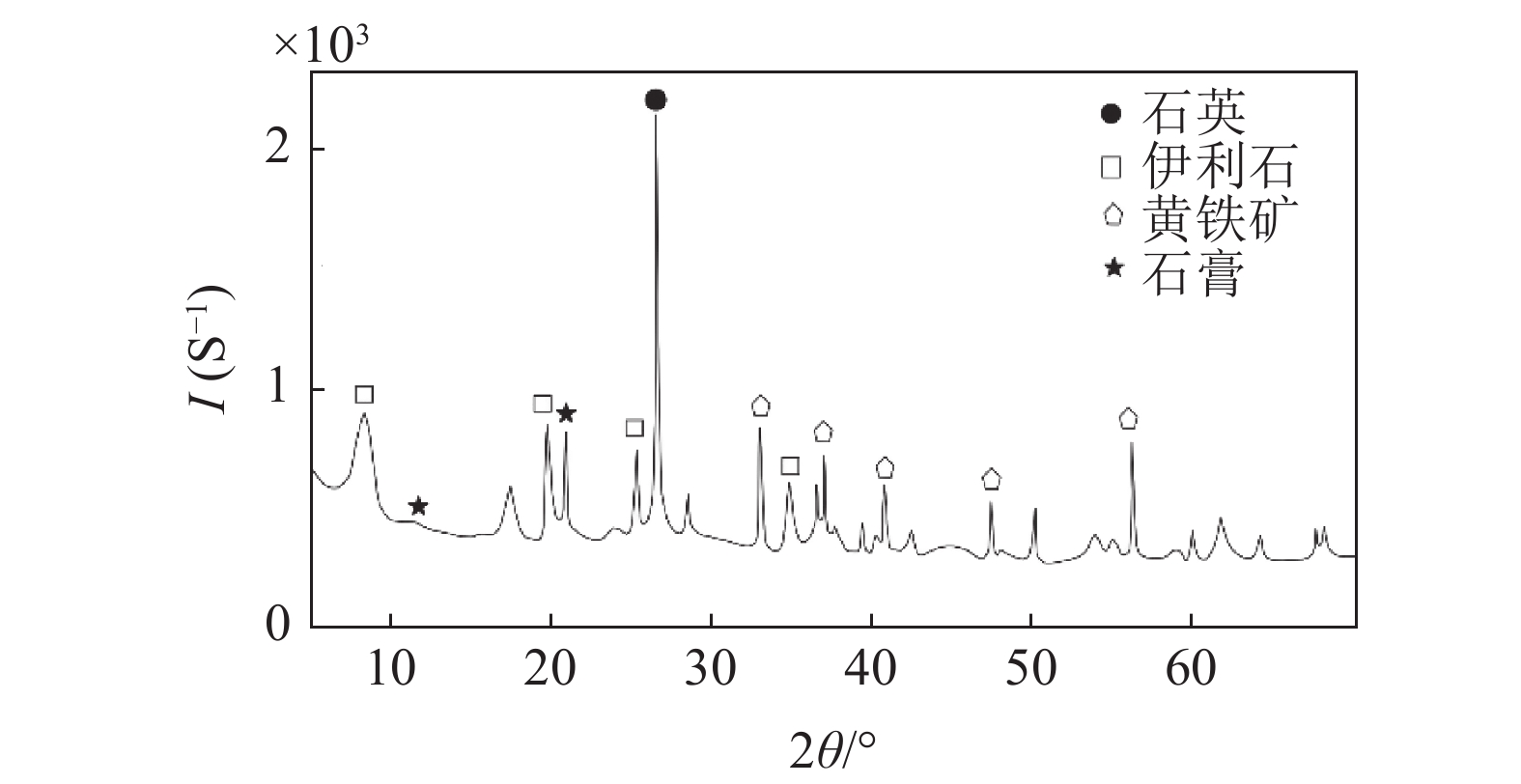

V2O5 Mo SiO2 Al2O3 S K2O Na2O CaO MgO TFe TiO2 总C 0.96 0.050 39.4 22.2 7.82 1.88 1.41 0.53 0.72 9.64 2.18 0.38 表 3 矿石的矿物组成

Table 3. Mineral composition of the ore

矿物 石墨 有机碳 粘土矿物(包括钒云母、

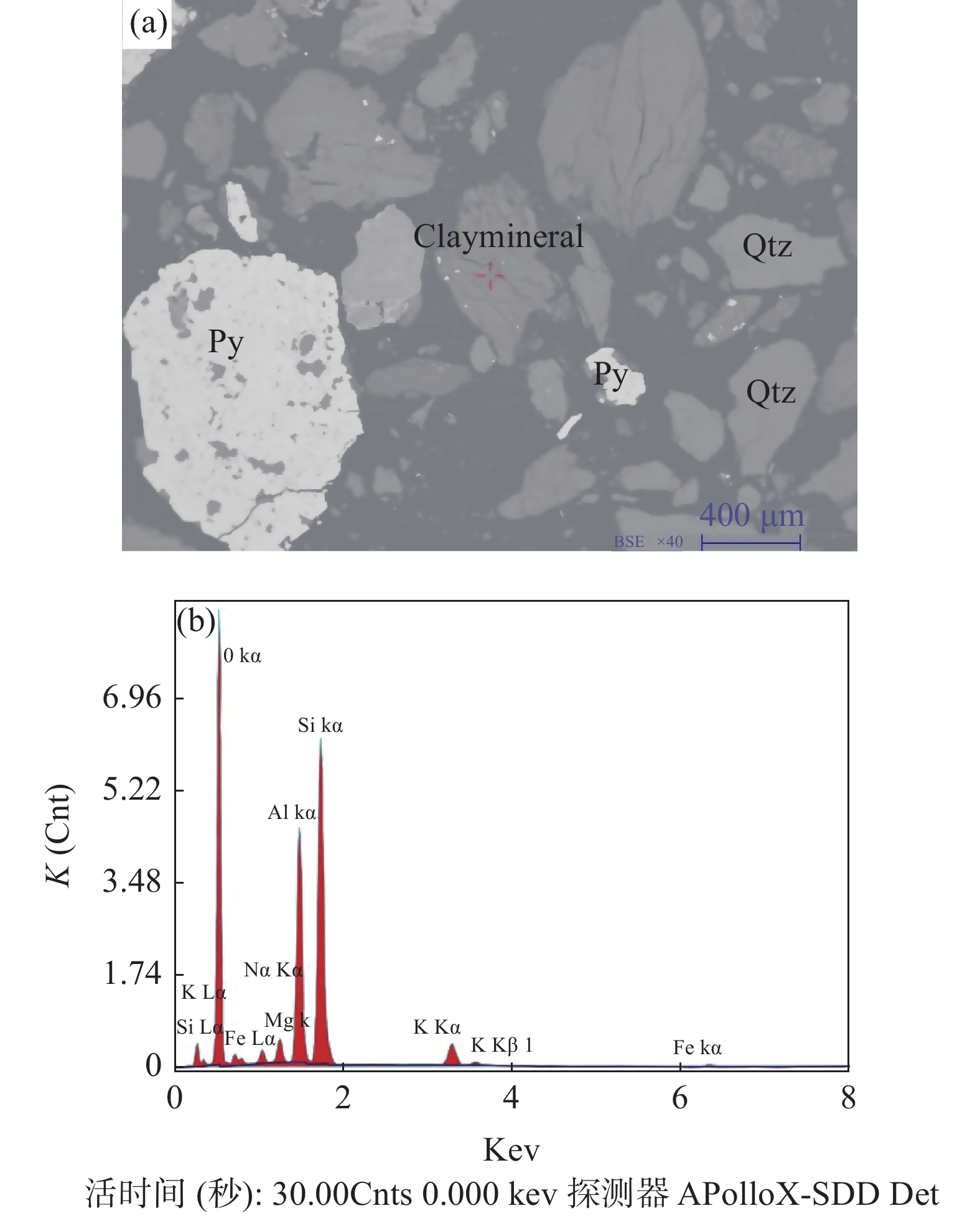

绢云母、伊利石、高岭石)含量/% 0 0.3 62.7 矿物 石英 黄铁矿 锐钛矿 褐铁矿 斜长石 方解石 石膏 含量/% 13.4 16.1 2.2 2.9 0.3 0.2 1.4 表 4 粘土矿物电子探针分析结果/%

Table 4. Electron microprobe analyses of clay minerals in the ore samples

样点 Na2O K2O V2O5 MgO CaO FeO Al2O3 SiO2 TiO2 合计 fm-9 0.64 2.22 1.40 1.03 0.00 0.51 31.50 53.21 1.48 91.99 fm-8 0.50 1.52 0.77 0.77 0.02 2.22 27.61 50.58 1.56 85.53 fm-7 0.47 2.88 0.33 1.34 0.00 2.09 29.12 50.89 1.07 88.20 fm-6 0.25 2.73 0.14 1.05 0.00 0.55 24.26 56.91 0.38 86.26 fm-5 0.74 2.66 2.14 1.22 0.00 0.59 31.05 51.87 1.77 92.06 fm-4 0.59 1.41 0.45 0.83 0.11 0.83 29.56 45.07 4.05 82.89 平均值 0.53 2.24 0.87 1.04 0.02 1.13 28.85 51.42 1.72 87.28 最大值 0.74 2.88 2.14 1.34 0.11 2.22 31.50 56.91 4.05 92.06 最小值 0.25 1.41 0.14 0.77 0.00 0.51 24.26 45.07 0.38 82.89 表 5 硫酸浸出工艺综合条件实验结果

Table 5. Synthetical condition test results of sulfuric acid leaching

H2SO4

/mL浸液

/mL渣率

/%浸渣品位/% 渣计浸出率/% 浸液品位/% 液计浸出率/% V2O5 Mo V2O5 Mo V2O5 Mo V2O5 Mo 50 497.3 92.25 0.35 0.022 70.65 60.21 1.97 0.073 74.42 59.32 60 494.0 87.42 0.22 0.021 82.52 64.00 2.24 0.078 83.83 62.96 表 6 焙烧-碱浸出工艺综合条件实验结果

Table 6. Synthetical condition test results of roasting-alkali leaching

浸液

/mL渣率

/%浸渣品位/% 渣计浸出率/% 浸液品位/% 液计浸出率/% V2O5 Mo V2O5 Mo V2O5 Mo V2O5 Mo 494 112.35 0.28 0.0057 74.42 88.77 2.27 0.126 75.97 91.00 表 7 碱浸渣、细泥粘土及沉砂产品化学分析结果/%

Table 7. Chemical analysis results of basic leached residue andfine clayand tailings settling

名称 Al2O3 SiO2 K2O Na2O CaO MgO TiO2 TFe2O3 S 碱浸渣 24.57 48.75 1.97 5.20 0.62 0.99 2.51 5.91 0.069 细泥粘土 24.77 49.99 1.97 4.92 0.73 1.04 2.46 4.54 0.052 沉砂 22.39 47.19 1.87 1.85 0.69 1.23 2.89 12.80 0.054 -

[1] 段威, 张飞, 冉强, 等. 旺苍县黄洋-五权地区钒矿地质特征与找矿前景[J]. 四川地质学报, 2019, 39(S1):50-54.

DUAN W, ZHANG F, RAN Q, et al. Geological characteristics and prospecting potential of Vanadium deposit in Huangyang and Wuquan of Wangcangxian area[J]. Acta Geologica Sichuan, 2019, 39(S1):50-54.

[2] 常福增, 赵备备, 李兰杰, 等. 钒钛磁铁矿提钒技术研究现状与展望[J]. 钢铁钒钛, 2018, 39(5):71-78.

CHANG F Z, ZHAO B B, LI L J, et al. Research status and prospect of vanadium extraction from vanadium titano-magnetite[J]. Iron Steel Vanadium Titanium, 2018, 39(5):71-78.

[3] 邓志敢, 魏昶, 李兴彬, 等. 钒钛磁铁矿提钒尾渣浸取钒[J]. 中国有色金属学报, 2012, 22(6):1770-1777.

DENG Z G, WEI C, LI X B, et al. Leaching Vanadium from extracted vanadium residue of vanadium titano-magnetite[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6):1770-1777.

[4] 丁满堂. 含钒钢渣提钒利用研究[J]. 矿产综合利用, 2020(6):69-72.

DING M T. Research on utilization of vanadium extraction from vanadium-bearing steel slag[J]. Multipurpose Utilization of Mineral Resources, 2020(6):69-72.

[5] 宾智勇. 石煤提钒研究进展与五氧化二钒的市场状况[J]. 湖南有色金属, 2006(1):16-20+74. doi: 10.3969/j.issn.1003-5540.2006.01.006

BIN Z Y. Progress of the research on extraction of vanadium pentoxide from stone coal and the market of the V2O5[J]. Hunan Nonferrous Metals, 2006(1):16-20+74. doi: 10.3969/j.issn.1003-5540.2006.01.006

[6] 张帅,李慧, 梁精龙,等. 石煤钒矿提取五氧化二钒的技术现状[J]. 矿产综合利用, 2021(2):119-124.

ZHANG S, LI H, LIANG J L, et al. Status of the preparation process of vanadium dioxide[J]. Multipurpose Utilization of Mineral Resources, 2021(2):119-124.

[7] 胡艺博,叶国华,左琪,等. 从石煤钒矿酸浸液中萃取提钒的研究进展与前景[J]. 矿产综合利用, 2020(1):10-15.

HU Y B,YE G H,ZUO Q,et al. The research progress and prospect of extractants for vanadium from acid leaching solution of stone coal vanadium ore[J]. Multipurpose Utilization of Mineral Resources, 2020(1):10-15.

[8] 宾智勇. 钒矿石无盐焙烧提取五氧化二钒试验[J]. 钢铁钒钛, 2006(1):21-26. doi: 10.3969/j.issn.1004-7638.2006.01.005

BIN Z Y. Study on extraction of V2O5 from vanadium ore by roasting and acid leaching process[J]. Iron Steel Vanadium Titanium, 2006(1):21-26. doi: 10.3969/j.issn.1004-7638.2006.01.005

[9] 史政良,严海军,周玉娟. 用酸法从石煤中提取五氧化二钒的实验研究与工业实践[J]. 矿产综合利用, 2020(3):158-163.

SHI Z L,YAN H J,ZHOU Y J. Study on comprehensive utilization technology of sulphate roasting ash and slag of vanadium ore from stone coal in Gansu Province[J]. Multipurpose Utilization of Mineral Resources, 2020(3):158-163.

[10] 漆明鉴. 酸浸法从石煤中提钒的中间试验研究[J]. 湿法冶金, 2000(2):7-17. doi: 10.3969/j.issn.1009-2617.2000.02.002

QI M J. Pilot-scale experiment for recovering V2O5 from stone coal by acid leaching[J]. Hydrometallurgy of China, 2000(2):7-17. doi: 10.3969/j.issn.1009-2617.2000.02.002

[11] 张成强, 孙传尧, 印万忠, 等. 以氟化钙为助浸剂的某伊利石型含钒石煤酸浸提钒工艺[J]. 矿产综合利用, 2019(5):42-47. doi: 10.3969/j.issn.1000-6532.2019.05.009

ZHANG C Q, SUN CY, YIU W Z, et al. Acid leaching of vanadium from an illite-typevanadium-containing stone using calcium fluoride as acid-leaching reagent[J]. Multipurpose Utilization of Mineral Resources, 2019(5):42-47. doi: 10.3969/j.issn.1000-6532.2019.05.009

[12] 庄树新. 硅质岩钒矿中无污染提取五氧化二钒的新工艺研究[D]. 长沙: 中南大学, 2007.

ZHUANG S X. New non-pollution technology of extracting V2O5 from the siliceous navajoite[D]. Changsha: Central South University, 2007.

[13] 马胜芳, 张光旭. 钙化焙烧粘土钒矿提钒过程的研究Ⅰ焙烧工艺的研究[J]. 稀有金属, 2007(6):813-817. doi: 10.3969/j.issn.0258-7076.2007.06.019

MA S F, ZHANG G X. Leaching Process of Vanadium from Argillaceous Vanadium Ore Using Calcified Roasting Ⅰ Study on Roasting Technology[J]. Chinese Journal of Rare Metals, 2007(6):813-817. doi: 10.3969/j.issn.0258-7076.2007.06.019

-

下载:

下载: