Effect of B2O3 on High Aluminum Low Magnesium Slag Stability

-

摘要:

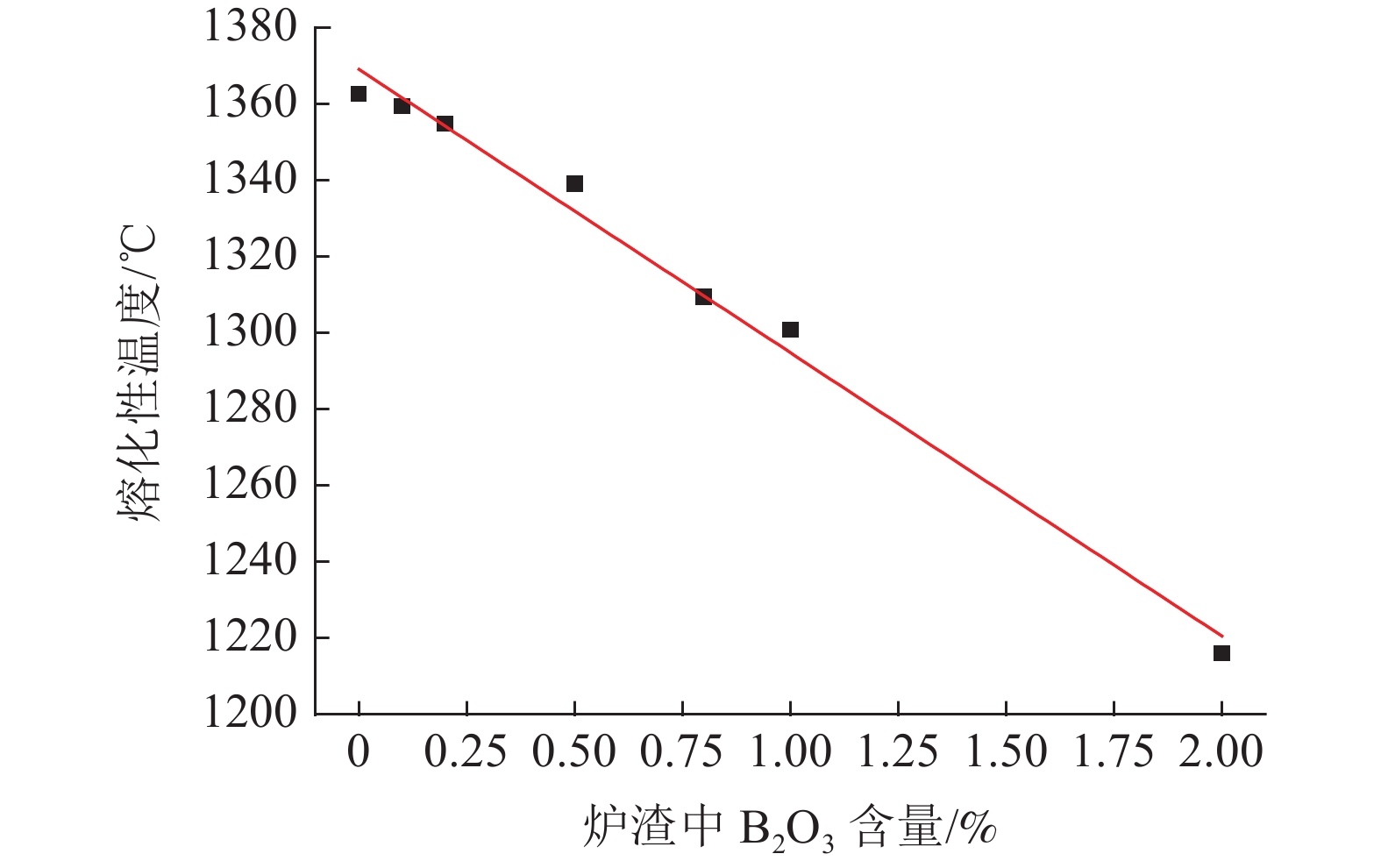

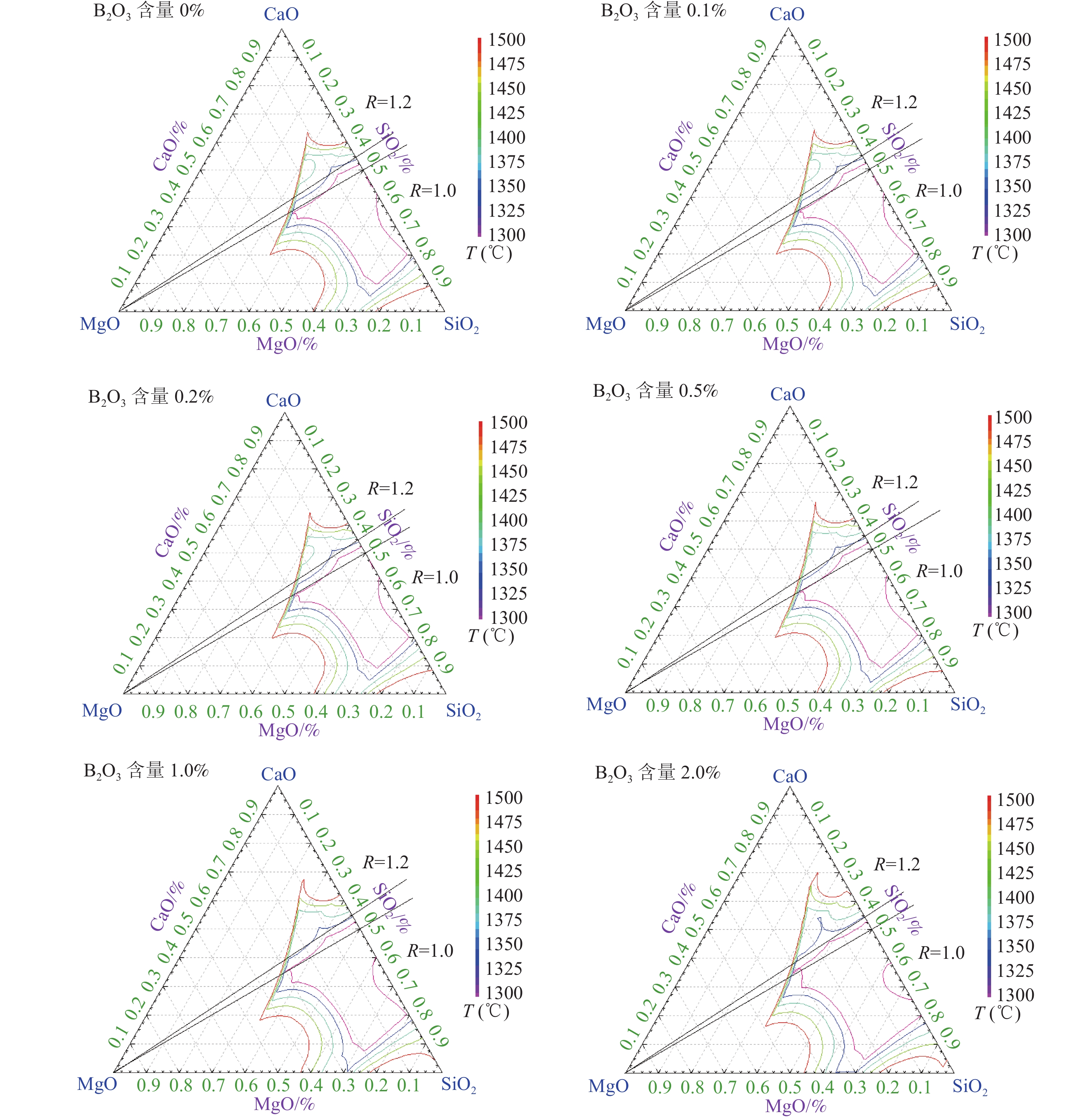

为了明确B2O3对高铝低镁渣稳定性的影响,基于现场高炉渣的实际成分,通过熔体物性测定仪、Factsage软件、XPS光谱分析了B2O3对炉渣粘度和炉渣微观结构的影响。结果表明:随着B2O3含量的增加,炉渣粘度降低;当炉渣温度低于1360℃时,炉渣随着B2O3的增加稳定性增强;炉渣温度为1216℃, B2O3质量分数2.0%时,炉渣的稳定性最好。随着B2O3含量的增加,炉渣的液相区逐渐向MgO的区域扩大, B2O3的加入不仅改善了MgO含量过高引起的炉渣难熔现象,同时提高了炉渣在二元碱度波动时的稳定性。

Abstract:In order to clarify the impact mechanisms of B2O3 on the stability of high aluminum and low magnesium slag, based on the actual composition of blast furnace slag in the field, the viscosity and microstructure of slag were investigated by the high-temperature melt properties tester, Factsage software and XPS spectroscopy. The results showed that slag viscosity decreases with the increase of B2O3 content and the stability of slag increases with the increase of B2O3 when the slag temperature is lower than 1360℃.The slag stability is the best when the slag temperature is 1216℃ and the content of B2O3 is 2.0%. The liquid region of slag gradually expands to the MgO region with the increase of B2O3 content, The addition of B2O3 not only improves the refractory phenomenon of slag caused by excessive MgO content, but also improves the stability of slag when the binary alkalinity fluctuates.

-

Key words:

- B2O3 /

- High aluminum low magnesium slag /

- Stability /

- Effect

-

-

表 1 高炉现场渣成分/%

Table 1. Actual composition of blast furnace slag in the field

Al2O3 MgO CaO SiO2 TiO2 S 16.1 7.5 38.8 33.2 0.9 0.8 表 2 实验渣样组成

Table 2. Chemical constituents of test slags

式样编号 0 1 2 3 4 5 6 B2O3含量/% 0 0.1 0.2 0.5 0.8 1.0 2.0 现场渣含量/% 100 99.9 99.8 99.5 99.2 99.0 98.0 -

[1] 梁子怡, 宁晓钧. 高铝渣黏度和热力学性质分析[J].金属世界, 2019(1): 16-19.

LIANG Z Y, NING X J. Analysis of viscosity and thermodynamic properties of high aluminium slag [J]. Metal World, 2019(1): 16-19.

[2] 姜喆, 车玉满, 郭天永. Al2O3、MgO和二元碱度对高炉渣稳定性影响研究[J], 鞍钢技术, 2019(1): 22-25

JIANG Z, CHE Y M, GUO T Y. Effect of Al2O3, MgO and Bi alkalinity on the stability of blast furnace slag [J]. Angang Technology, 2019(1): 22-25

[3] 高艳宏. 含硼高炉钛渣粘性特征与结构的研究[D]. 重庆: 重庆大学: 2012.

GAO Y H. Study on viscosity characteristics and structure of titanium slag of blast furnace containing boron [D]. Chongqing: Chongqing University: 2012.

[4] GAO Y H, BIAN L T, LIANG Z Y. Influence of B2O3 and TiO2 on viscosity of Titanium-bearing blast furnace slag[J]. Steel Research International, 2014, 86(4): 386-390.

[5] LIN Y H, WEN Y C, FU W G, et al. Effect and mechanism of B2O3 on apparent viscosity of slag during smelting of vanadium-titanium magnetite in the blast furnace[J]. Metallurgical Research & Technology, 2016, 113(5): 506-514.

[6] SUN Y Q, ZHANG Z T. Structural roles of boron and silicon in the CaO-SiO2-B2O3 glasses using FTIR, Raman and NMR spectroscopy[J]. Metallurgical and Materials Transactions B, 2015, 46(4): 1549-1554. doi: 10.1007/s11663-015-0374-2

[7] 范筱玥, 张建良, 许仁泽, 等. B2O3对含钛低镁渣系流动性的影响及其机理研究[J]. 中南大学学报(自然科学版), 2018, 49(8):1863-1868.

FAN X Y, ZHANG J L, XU R Z, et al. The effect of B2O3 on the fluidity of titanium-containing low-magnesium slag and its mechanism[J]. Journal of Central South University (Natural Science Edition), 2018, 49(8):1863-1868.

[8] LIN Y H, WENY C, FU W G, et al. Effect and mechanism of B2O3 on apparent viscosity of slag during smelting of vanadiumtitanium magnetite in the blast furnace[J]. Metallurgical Research and Technology, 2016, 113: 506. doi: 10.1051/metal/2016038

[9] Lingtao Bian, Yanhong Gao. Influence of B2O3 and basicity on viscosity and structure of medium titanium bearing blast furnace slag[J]. 2016: 1-8.

[10] 孙正汉, 黄晓丽, 丁跃华, 等. B2O3对含钛高炉渣中钙钛矿相及渣铁分离的影响[J]. 钢铁, 2018, 53(2): 73-77.

SUN Z H, HUANG X L, DING Y H, et al. Effect of B2O3 on perovskite phase and slag iron separation in titanium bearing blast furnace slag[J]. Iron and Steel, 2018, 53(2): 73-77.

[11] 林银河, 符娅玲, 罗林根, 等. 高钛型高炉渣中B2O3替代CaF2的作用机理[J], 钢铁, 2019, 54(2): 26-30

LIN Y H, FU Y L, LUO L G, et al. Mechanism of replacing CaF2 with B2O3 in high titanium blast slag [J]. Iron and Steel, 2019, 54(2) : 26 - 30.

[12] 严照照, 张淑会, 董晓旭, 等. 高炉渣的化学成分对其微观结构影响的研究现状[J], 矿产综合利用, 2019(1): 22-27.

YAN Z Z, ZHANG S H, DONG X X, et al. Research status of the effect of chemical composition of blast furnace slag on its microstructure [J]. Multipurpose Utilization of Mineral Resources, 2019(1): 22-27.

[13] 张杰, 高铝高炉渣流动性及结构研究[D]. 重庆: 重庆大学, 2016.

ZHANG J. Study on fluidity and structure of high-alumina blaster slag [D]. Chongqing: Chongqing University, 2016.

-

下载:

下载: