Improvement and Practice of Grinding System in Section Ⅰ of a 6000 t/d Copper Polymetal Concentrator

-

摘要:

超低品铜多金属矿是国内铜矿石资源的重要组成部分,该类型矿石自身赋存品位较低、回收难度较大,同时选别工艺指标要求较高、生产成本较高。针对某超低品位铜多金属矿6000 t/d选矿厂Ⅰ段磨矿分级系统运转率不足的问题,通过系统性的工艺技术改造、设备技术改造、生产精准化管理等,Ⅰ段磨矿分级系统运转率由90.29%提高到97.27%、提高近7个百分点;选矿厂年处理量提高15万t以上,有效回收铜金属300 t/a、铁金属8500 t/a、钼金属15 t/a, 产生经济效益超过2500万元/a;达到了提高磨矿技术指标同时增加生产效益的目的。

Abstract:Ultra-low-grade copper polymetallic ore is an important component of domestic copper ore resources. This type of ore has a low storage grade and is difficult to recycle. Meanwhile, it requires higher processing index requirements and higher production costs. Aiming at the problem of insufficient operation rate of I-stage grinding classification system in 6000 t/d concentrator of an ultra-low grade copper polymetallic ore, the operation rate of I-stage grinding classification system was raised from 90.29% to 97.27% and increased by nearly 7 percentage points through systematic technological transformation, equipment technical transformation production precision management; The annual treatment capacity of the concentrator is increased by more than 150,000 tons, and the effective recovery of copper metal is 300 t/a, iron metal is 8500 t/a, molybdenum metal is 15 t/a, and the economic benefit is more than 25 million yuan/a. It achieves the aim of improving the technical index of grinding and increasing the efficiency of production.

-

-

表 1 选矿厂历年(2012~2018年度)运转情况统计

Table 1. Statistical table of the operation of the concentrator over the years (2012-2018)

磨矿机

运转情况单位 2012 2013 2014 2015 2016 2017 2018 算术

平均各类停车

时间比例/%备注 运转率 % 90.29 91.77 92.27 93.80 94.21 95.89 97.27 93.64 - 停车原因及时间 - - - - - - - - - - 无矿 h 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 客观

原因无水 h 4.15 0.00 4.35 6.35 3.40 34.45 0.00 7.53 0.55 无电 h 18.40 578.50 322.15 5.10 6.55 109.50 137.50 168.24 12.32 尾矿输送 h 0.00 0.00 28.05 116.02 0.00 0.00 0.00 20.58 1.51 主观

可改进检修 h 1955.10 1285.00 1053.10 931.30 949.55 912.25 807.45 1127.68 82.55 其他 h 45.50 43.10 16.35 34.55 54.30 37.05 63.30 42.02 3.08 客观

原因停产总时间 h 2023.15 1906.60 1424.00 1093.32 1013.80 1093.25 1008.25 1366.05 100.00 -

[1] 谢广元. 选矿学[M] . 徐州: 中国矿业大学出版社, 2016: 81-101.

XIE G Y. Beneficiation[M]. Xuzhou: China University of Mining and Technology Press, 2016.4: 81-101.

[2] 周乐光. 工艺矿物学[M]. 北京: 冶金工业出版社, 2007, 1: 223-241

ZHOU L G. Process mineralogy[M]. Beijing: Metallurgical Industry Press, 2007(1): 223-241.

[3] 周强. 会理县马鞍坪矿山废石综合利用有限责任公司矿山废石综合利用工程可行性研究报告[R]. 昆明: 昆明有色设计研究院. 2006.10: 21-24. .

ZHOU Q. Feasibility study report of mine waste rock comprehensive utilization project of Huili Maanping Mine waste rock comprehensive utilization Co. , Ltd. Kunming: Kunming Nonferrous Design Institute. ; 2006, 10: 21-24.

[4] 蔡爽, 蔡威, 滕桂平, 等. 矿浆浓度及粒度组成对某锌浸出渣分离粒度及磨矿参数的影响[J]. 矿产综合利用, 2018(4):46-49+36. doi: 10.3969/j.issn.1000-6532.2018.04.010

CAI S, CAI W, TENG G P, et al. Effect of slurry concentration and grain size composition on separation size and grinding parameters of a zinc leaching slag[J]. Multipurpose Utilization of Mineral Resources, 2018(4):46-49+36. doi: 10.3969/j.issn.1000-6532.2018.04.010

[5] 李炼, 戴思行, 王飞洋, 等. 改善赤铁矿磨矿效果的试验研究[J]. 矿产综合利用, 2019(1):61-65. doi: 10.3969/j.issn.1000-6532.2019.01.013

LI L, DAI S X, WANG F Y, et al. Experimental study on improving hematite grinding efficiency[J]. Multipurpose Utilization of Mineral Resources, 2019(1):61-65. doi: 10.3969/j.issn.1000-6532.2019.01.013

[6] 郭运鑫, 肖庆飞, 黄胤淇, 等. 提高永平铜矿一段球磨磨矿效率的研究[J]. 矿产综合利用, 2019(4):135-138. doi: 10.3969/j.issn.1000-6532.2019.04.029

GUO Y X, XIAO Q F, HUANG Y Q, et al. Study on improving the efficiency of ball grinding in the first section of Yongping copper mine[J]. Multipurpose Utilization of Mineral Resources, 2019(4):135-138. doi: 10.3969/j.issn.1000-6532.2019.04.029

[7] 王晨晨, 黄朝德, 付金涛, 等. 青海某铅锌矿磨矿动力学试验研究[J]. 矿产综合利用, 2020(1):59-61. doi: 10.3969/j.issn.1000-6532.2020.01.012

WANG C C, HUANG C D, FU J T, et al. Experimental study on grinding dynamics of a lead-zinc ore in Qinghai Province[J]. Multipurpose Utilization of Mineral Resources, 2020(1):59-61. doi: 10.3969/j.issn.1000-6532.2020.01.012

[8] 王肖江, 肖庆飞, 沈传刚, 等. 武山铜矿磨矿介质与矿石力学性质匹配性研究[J]. 矿产综合利用, 2016(4):56-60. doi: 10.3969/j.issn.1000-6532.2016.04.013

WANG X J, XIAO Q F, SHEN C G, et al. Study on the matching between grinding medium and mechanical properties of ore in Wushan copper mine[J]. Multipurpose Utilization of Mineral Resources, 2016(4):56-60. doi: 10.3969/j.issn.1000-6532.2016.04.013

[9] 邓禾淼, 肖庆飞, 黄胤淇, 等. 优化介质制度提高中矿再磨作业质量的试验研究[J]. 矿产综合利用, 2019(6):37-40+32. doi: 10.3969/j.issn.1000-6532.2019.06.008

DENG H M, XIAO Q F, HUANG Y Q, et al. Experimental study on improving the quality of intermediate regrinding operation by optimizing medium system[J]. Multi-purpose Utilization of Mineral Resources, 2019(6):37-40+32. doi: 10.3969/j.issn.1000-6532.2019.06.008

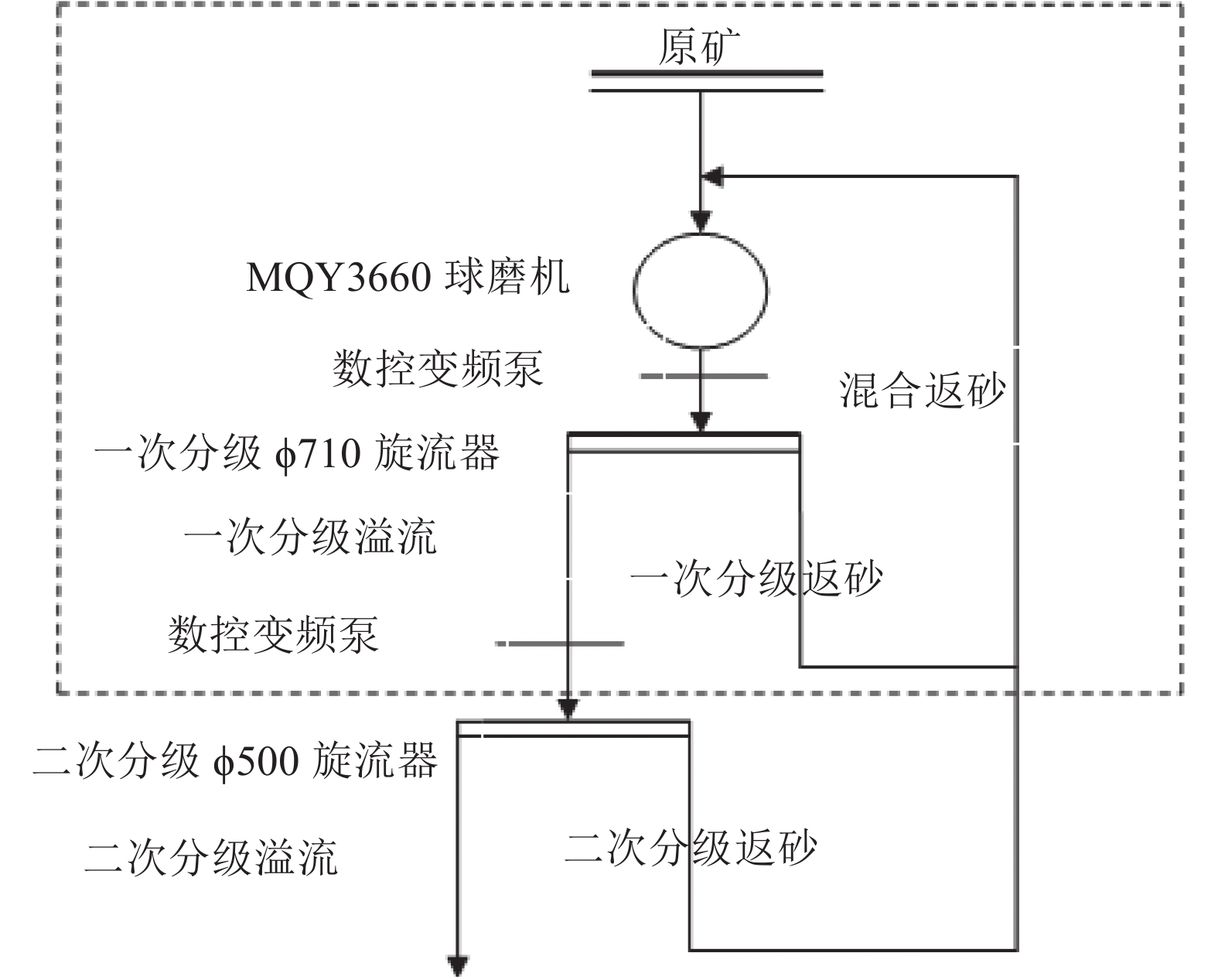

[10] 高天龙, 韩江峰. 某超低品位铜多金属矿磨矿分级工艺改进与实践[J]. 矿冶, 2018(S2): 102-107.

GAO T L, HAN J F. Improvement and practice of grinding and classification process for an ultra-low grade copper polymetallic ore [J]. Mining and Metallurgy, 2018(S2): 102-107.

[11] 吴莉娟, 艾立胜, 董大刚, 等. 一种磨矿二次分级系统: CN205146435U [P]. 2016: 4-13.

WU L J, AI L S, DONG D G, et al. A grinding secondary classification system: CN205146435U [P]. 2016: 4-13.

[12] 王继生, 卢建坤, 马伟, 等. 衬板形状对大型球磨机磨矿效率的影响[J]. 矿山机械, 2013, 41(8):68-72.

WANG J S, LU J K, MA W, et al. Influence of lining plate shape on grinding efficiency of large ball mill[J]. Mining & Processing Equipment, 2013, 41(8):68-72.

[13] 田秋娟, 郝万军, 邓立营, 等. 衬板的设计参数对球磨机磨矿效果的影响[J]. 矿山机械, 2010, 38(9):73-76.

TIAN Q J, HAO W J, DENG L Y, et al. Influence of design parameters of lining plate on grinding effect of ball mill[J]. Mining & Processing Equipment, 2010, 38(9):73-76.

[14] 艾立胜, 吴莉娟, 董大刚, 等. 一种尾矿管道连接处用耐磨设备: CN205155456U [P]. 2016-04-13.

AI L S, WU L J, DONG D G, et al. A Wear Resistant Equipment for Tailings Pipeline Connection: CN205155456U [P]. 2016-04-13.

[15] 许有国, 冯俊飞. 溢流型球磨机改造为格子型球磨机的应用实践[J]. 现代矿业, 2016, 32(10):202-203. doi: 10.3969/j.issn.1674-6082.2016.10.071

XU Y G, FENG J F. Application practice of transforming overflow type ball mill into lattice type ball mill[J]. Modern Mining, 2016, 32(10):202-203. doi: 10.3969/j.issn.1674-6082.2016.10.071

[16] 王东言, 刘涛. 溢流型球磨机改造为格子型球磨机的生产实践[J]. 现代矿业, 2013, 29(12):167. doi: 10.3969/j.issn.1674-6082.2013.12.061

WANG D Y, LIU T. Production practice of reforming overflow ball mill into grid ball mill[J]. ModernMining, 2013, 29(12):167. doi: 10.3969/j.issn.1674-6082.2013.12.061

[17] 鄢富坤, 肖庆飞, 罗春梅. 现阶段我国磨矿设备的研究进展及发展方向[J]. 矿产综合利用, 2013(2):12-16. doi: 10.3969/j.issn.1000-6532.2013.02.004

YAN F K, XIAO Q F, LUO C M. Research progress and development direction of grinding equipment in China at present stage[J]. Multipurpose Utilization of Mineral Resources, 2013(2):12-16. doi: 10.3969/j.issn.1000-6532.2013.02.004

[18] 高天龙, 韩江峰. 某超贫铜多金属矿山依托管理提高本质安全实践[J]. 有色金属科学与工程, 2019, 10(4):100-105.

GAO T L, HAN J F. Practice of improving intrinsic safety of an ultra-poor copper-polymetallic mine relying on management[J]. Nonferrous Metals Science and Engineering, 2019, 10(4):100-105.

-

下载:

下载: