Study on the Occurrence State of Valuable Metals in Waste Lithium Battery Electrode Material

-

摘要:

废弃锂离子电池中含有大量的钴、铜、铝、锂、锰、镍等金属,还含有大量的石墨等炭质粉末。传统的分析测试方法对该类型样品分析表征较为困难。本文主要采用MLA系统对某含石墨锂电池废料样品的物相组成、有价金属物相的嵌布关系进行研究,结果表明有价金属物相主要为镍钴锰酸锂(NCM)和氧化铝,少量镍钴铝酸锂(NCA)、钴酸锂(LCO)、锰酸锂(LMO)、磷酸铁锂(LFP),而且主要由氧化铝包覆,而铜由于主要以氧化铜或金属铜形式存在。有价金属物的赋存状态研究结果对该类型电极材料有价金属资源的综合利用提供了理论依据。

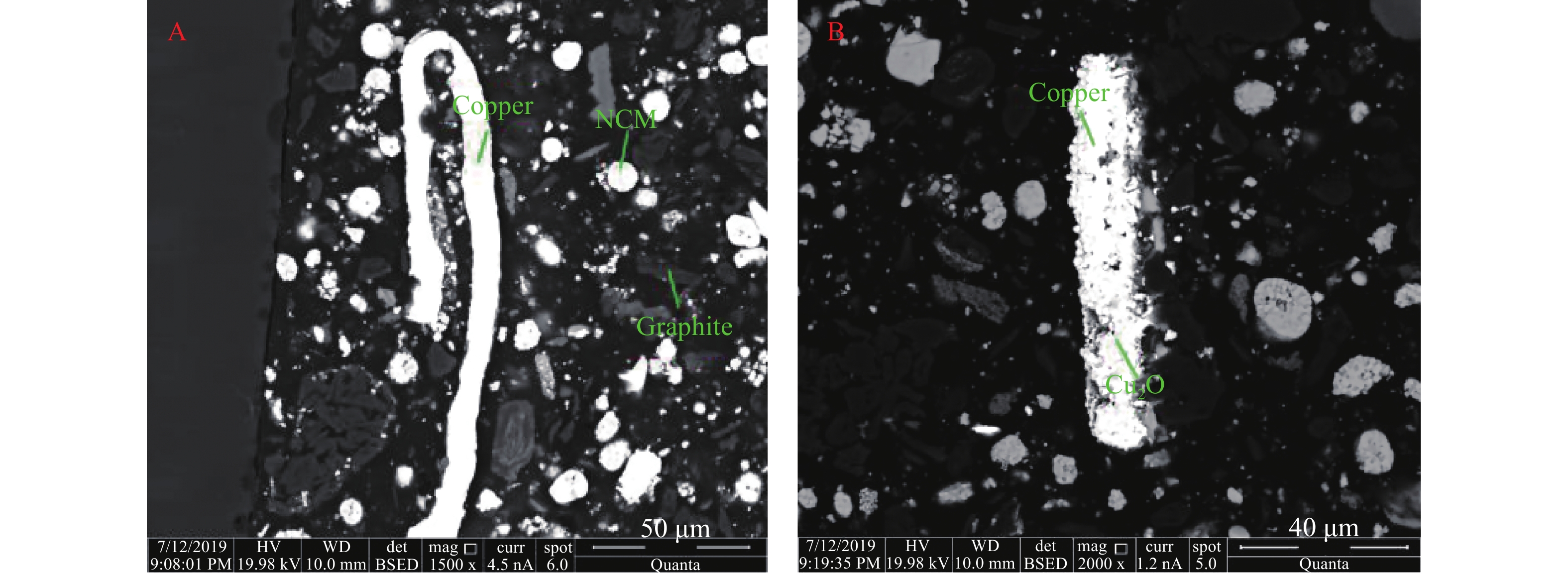

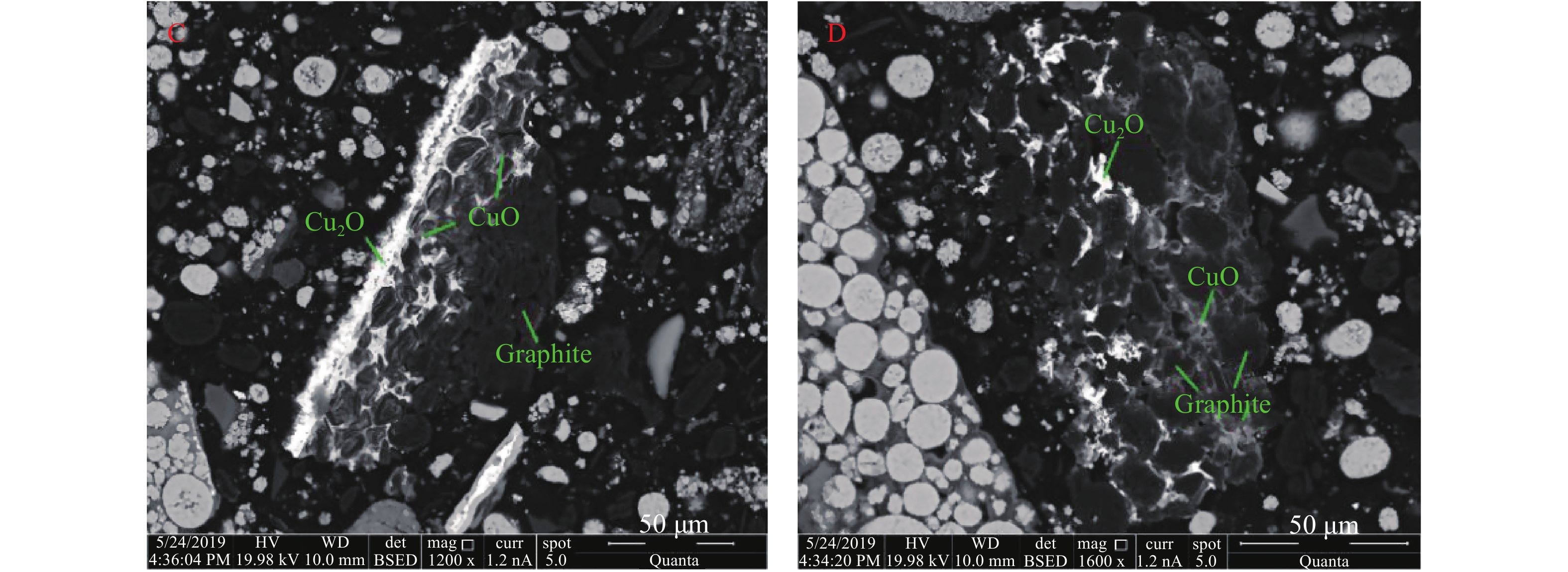

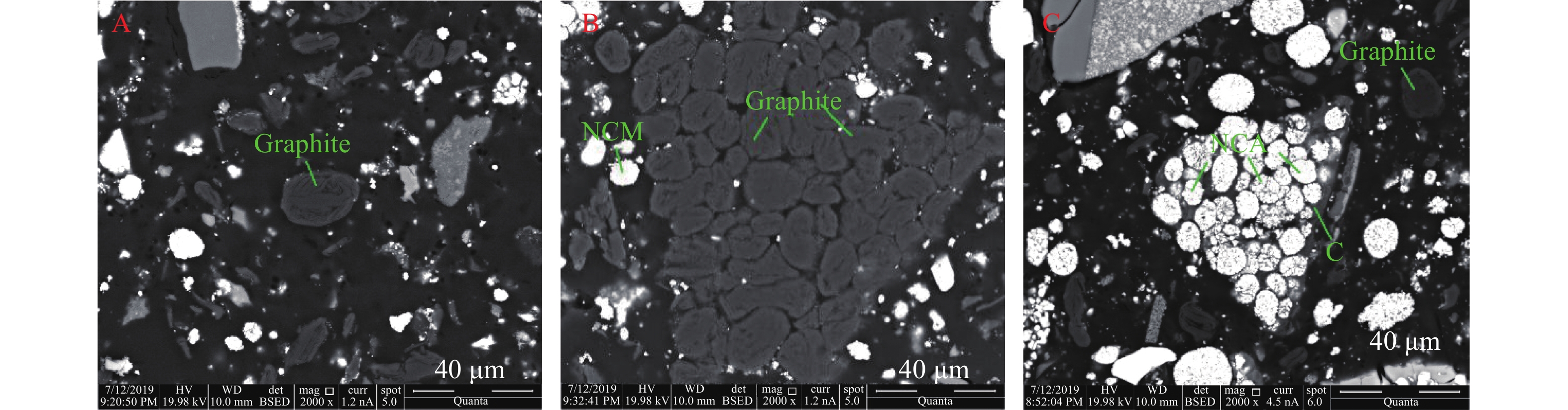

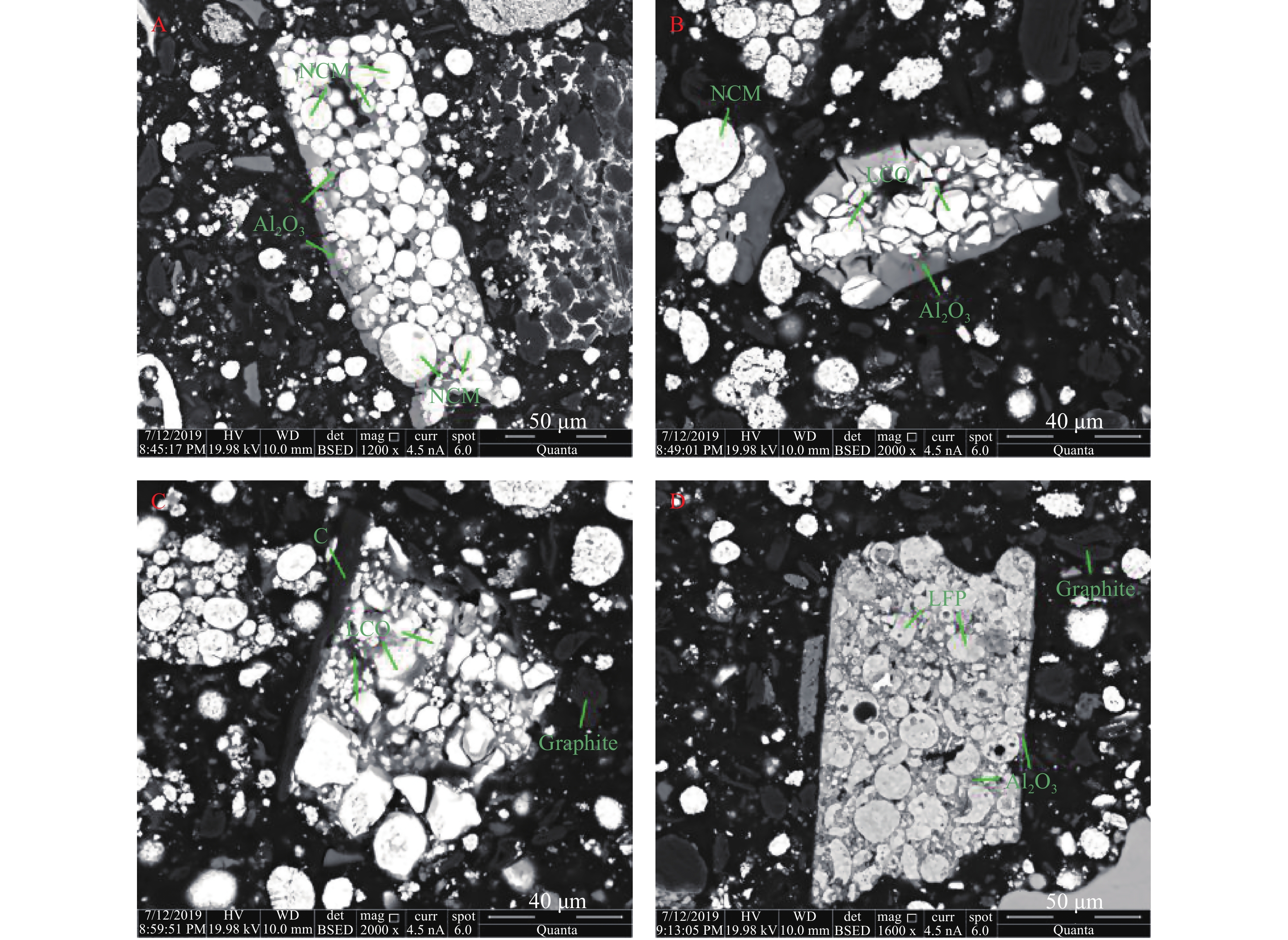

Abstract:The waste lithium ion battery contains a large number of cobalt, copper, aluminum, lithium, manganese, nickel and other metals, and also contains a large number of graphite and other carbonaceous powder. It is difficult to characterize this type of samples by traditional analytical methods. MLA system is mainly used to study the phase composition and valuable metal phases dissemination of a graphite lithium battery waste sample. The results show that the valuable metal phases are mainly lithium nickel-cobalt manganate (NCM) and alumina, and a small amount of lithium nickel-cobalt aluminate (NCA), lithium lithium cobalt oxides (LCO), lithium manganate (LMO) and lithium iron phosphate (LFP). The research results of valuable metal phases dissemination provide a theoretical basis for the comprehensive utilization of the valuable metal resources in this type of electrode material.

-

Key words:

- Lithium battery waste /

- Lithium nickel cobalt aluminate /

- Graphite /

- MLA

-

-

表 1 样品化学成分分析结果 /%

Table 1. Results of chemical composition analysis of samples

Ni Co Li2O Al2O3 Mn P2O5 Cu 12.72 8.41 8.89 9.37 6.05 2.62 2.20 表 2 样品MLA物相组成

Table 2. MLA phase composition of samples

物相名称 炭 钴酸锂 镍钴锰酸锂 镍钴铝酸锂 锰酸锂 铜箔 氧化铜 铝箔 氧化铝 磷酸铁锂 氟磷酸铝盐 其他 合计 含量/% 36.54 3.39 24.81 3.74 2.40 1.22 1.89 1.73 13.8 4.97 2.22 3.29 100.00 -

[1] 李金龙, 何亚群, 付元鹏, 等. 废弃锂离子电池正极材料酸浸出试验研究[J]. 矿产综合利用, 2020(2):128-134. doi: 10.3969/j.issn.1000-6532.2020.02.023

LI J L, HE Y Q, FU Y P, et al. Study on leaching cathode materials of spent lithium-ion batteries[J]. Multipurpose Utilization of Mineral Resources, 2020(2):128-134. doi: 10.3969/j.issn.1000-6532.2020.02.023

[2] ZENG X, LI J. Spent rechargeable lithium batteries in e-waste: composition and its implications[J]. Frontiers of Environmental Science & Engineering. 2014, 8(5): 792-796.

[3] R FANDRICH, GU Y, Debra Burrows, Kurt Moeller. Modern SEM-based mineral liberation analysis[J]. Minerals Engineering. 2007, 84(1-4): 310-320.

[4] 李波, 梁冬云, 张莉莉, 等. 自动矿物分析系统的统计误差分析[J]. 矿冶, 2018, 27(4):120-124. doi: 10.3969/j.issn.1005-7854.2018.04.025

LI B, LIANG D Y, ZHANG L L, et al. Statistical error analysis of automatic mineral analysis system[J]. Mining and Metallurgy, 2018, 27(4):120-124. doi: 10.3969/j.issn.1005-7854.2018.04.025

-

下载:

下载: