Effect of Furnace Slag Fiber on Strength and Deformation Characteristics of Cemental Sand

-

摘要:

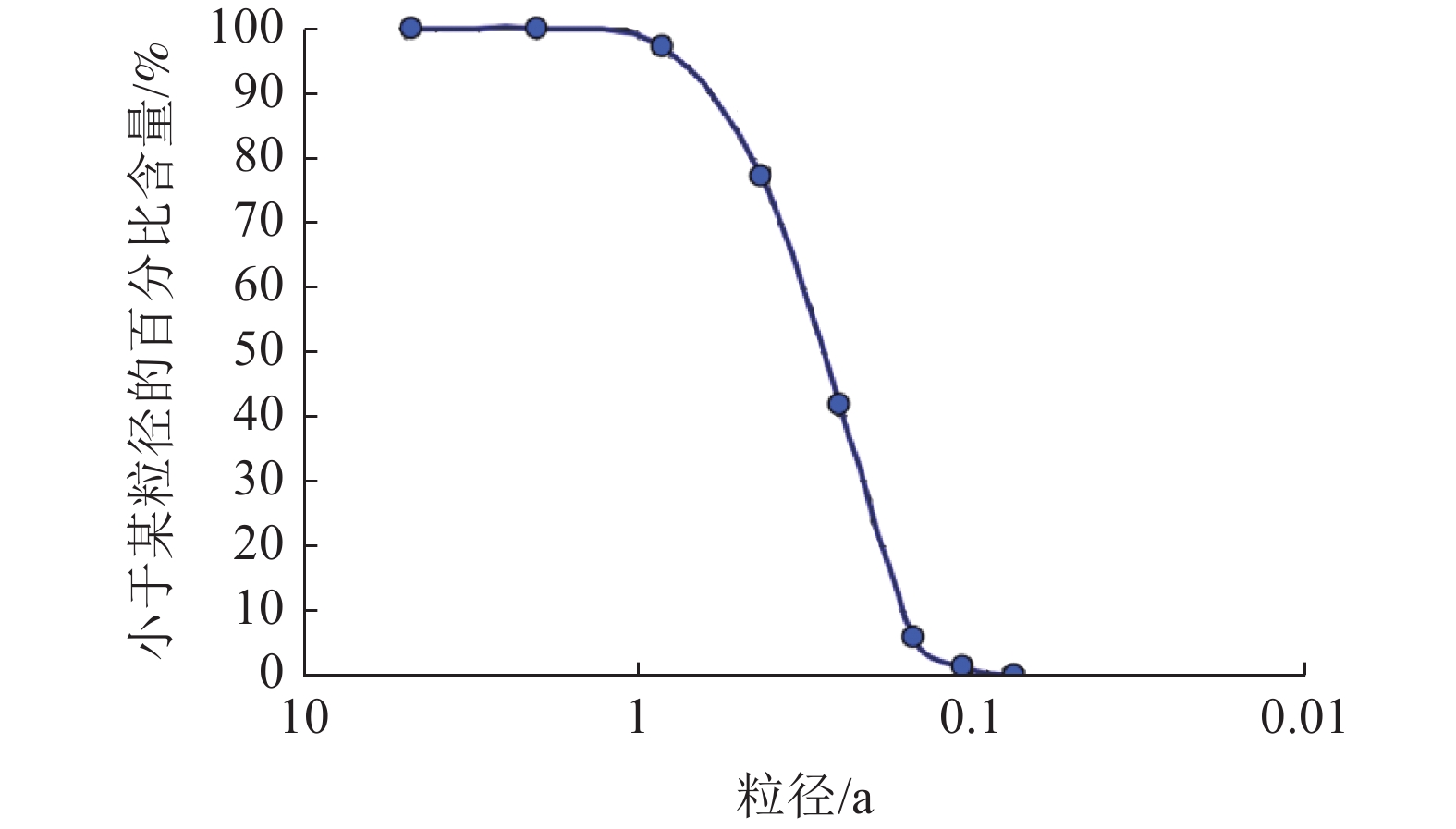

这是一篇矿物陶瓷材料领域的论文。为了增强胶结砂材料的力学性能,同时提高矿产资源利用率,将高炉矿渣纤维与河砂、水泥和水混合后压制成加筋胶结砂试样。通过开展无侧限压缩实验研究了高炉矿渣纤维的掺量和长度对加筋试样强度于变形特性的影响规律。结果表明:随着纤维掺量的增加,胶结砂试样的无侧限强度呈增长趋势,但增长幅度在掺量超过0.3%后明显降低;采用5 mm和10 mm的两种长度纤维进行实验,在相同掺量条件下,长纤维对胶结砂强度的增强效果是短纤维的1.25~1.55倍左右;经过微观形态观察,发现高炉矿渣纤维掺入胶结砂后,提高了颗粒间的黏结程度和团聚效果,进而增强了胶结砂的强度和韧性。

Abstract:This is a paper in the field of mineral ceramic materials. In order to enhance the mechanical properties of cemental sand materials and improve the utilization rate of mineral resources, the reinforced samples were made by mixing blast furnace slag fiber with river sand, cement and water. The effects of the content and length of furnace slag fibers on the strength characteristics of reinforced specimens were studied by unconfined compression tests. The results show that the unconfined strength of cemental sand samples increases with the increase of the content of furnace slag fiber, but the increase rate decreases obviously when the content of fiber reaches 0.3%. Using 5 mm and 10 mm fiber length to modify the cemented sand, the strengthening effect of the long fiber on the strength of the cemented sand is 1.25~1.55 times that of the short fiber under the condition of the same dosage. Through the microscopic morphology observation, it is found that the addition of furnace slag fibers to the cemental sand can improve the degree of adhesion between particles and agglomeration effect, and then enhance the strength and toughness of the cemented sand.

-

Key words:

- Slag fiber /

- Ceramics and composite /

- Cemental sand /

- Unconfined compression experiment /

- Strength /

- Microstructure

-

-

表 1 高炉矿渣纤维的化学成分/%

Table 1. Chemical composition of slag fiber

CaO SiO2 Al2O3 MgO K2O Fe2O3 Fe3O4 其他 32.5 40.7 12.2 7.5 1.2 2.0 1.8 2.1 表 2 高炉矿渣纤维的基本技术指标

Table 2. Basic technical index of slag fiber

密度/(g·cm-3) 平均直径/μm 抗拉强度/MPa 断裂拉伸率/% 0.65 5.5 55 6.2 表 3 加筋前后的力学参数及增幅度

Table 3. Mechanical parameters and amplitude increase before and after reinforcement

名称 无侧限抗压强度/kPa 增幅/% 破坏应变/% 增幅/% 加筋试样 1052.8 66.1 2.85 29.1 普通试样 634.2 3.68 -

[1] 高洋. 高钛高炉渣综合利用现状及展望[J]. 矿产综合利用, 2019(1):6-10. GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1):6-10. doi: 10.3969/j.issn.1000-6532.2019.01.002

GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1): 6-10. doi: 10.3969/j.issn.1000-6532.2019.01.002

[2] 严照照, 张淑会, 董晓旭, 等. 高炉渣的化学成分对其微观结构影响的研究现状[J]. 矿产综合利用, 2019(1):22-27. YAN Z Z, ZHANG S H, DONG X X, et al. Research status of the influence of blast furnace slag chemical composition on its microstructure[J]. Multipurpose Utilization of Mineral Resources, 2019(1):22-27. doi: 10.3969/j.issn.1000-6532.2019.01.005

YAN Z Z, ZHANG S H, DONG X X, et al. Research status of the influence of blast furnace slag chemical composition on its microstructure[J]. Multipurpose Utilization of Mineral Resources, 2019(1): 22-27. doi: 10.3969/j.issn.1000-6532.2019.01.005

[3] 易耀林, 卿学文, 庄焱, 等. 粒化高炉矿渣微粉在软土固化中的应用及其加固机理[J]. 岩土工程学报, 2013, 35(S2):829-833. YI Y L, QING X W, ZHUANG Y, et al. Application of granulated blast furnace slag powder in soft soil solidification and its reinforcement mechanism[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(S2):829-833.

YI Y L, QING X W, ZHUANG Y, et al. Application of granulated blast furnace slag powder in soft soil solidification and its reinforcement mechanism[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(S2): 829-833.

[4] 孙晓刚, 赵英良, 邢军, 等. 碱激发高炉矿渣-粉煤灰制备充填胶凝材料[J]. 金属矿山, 2016(11):189-192. SUN X G, ZHAO Y L, XING J, et al. Alkali-activated blast furnace slag-fly ash to prepare filling cementitious materials[J]. Metal Mine, 2016(11):189-192. doi: 10.3969/j.issn.1001-1250.2016.11.040

SUN X G, ZHAO Y L, XING J, et al. Alkali-activated blast furnace slag-fly ash to prepare filling cementitious materials[J]. Metal Mine, 2016(11): 189-192. doi: 10.3969/j.issn.1001-1250.2016.11.040

[5] 张遵乾, 邢宏伟, 张玉柱. 熔渣离心成纤及纤维拉伸变形研究[J]. 矿产综合利用, 2018(5):138-142+146. ZHANG Z Q, XING H W, ZHANG Y Z. Study on the centrifugal fiber formation of molten slag and fiber tensile deformation[J]. Multipurpose Utilization of Mineral Resources, 2018(5):138-142+146. doi: 10.3969/j.issn.1000-6532.2018.05.031

ZHANG Z Q, XING H W, ZHANG Y Z. Study on the centrifugal fiber formation of molten slag and fiber tensile deformation[J]. Multipurpose Utilization of Mineral Resources, 2018(5): 138-142+146. doi: 10.3969/j.issn.1000-6532.2018.05.031

[6] 唐续龙, 邢修君. 高炉渣和粉煤灰制备矿渣纤维实验研究[J]. 环境工程, 2020, 38(11):180-186. TANG X L, XING X J. Experimental research on preparation of slag fiber from blast furnace slag and fly ash[J]. Environmental Engineering, 2020, 38(11):180-186.

TANG X L, XING X J. Experimental Research on Preparation of Slag Fiber from Blast Furnace Slag and Fly Ash[J]. Environmental Engineering, 2020, 38(11): 180-186.

[7] 范剑明, 李娜, 冯鑫国. 粉煤灰/矿渣复合基沙土固化剂的制备及固化性能研究[J]. 矿产综合利用, 2019(6):105-109. FAN J M, LI N, FENG X G. Study on preparation and curing performance of fly ash/slag-based soil stabilizer[J]. Multipurpose Utilization of Mineral Resources, 2019(6):105-109. doi: 10.3969/j.issn.1000-6532.2019.06.023

FAN J M, LI N, FENG X G. Study on preparation and curing performance of fly ash/slag-based soil stabilizer[J]. Multipurpose Utilization of Mineral Resources, 2019(6): 105-109. doi: 10.3969/j.issn.1000-6532.2019.06.023

[8] Erhan G, Yahya R. Atewi, Mustafa F. Hasan. Fresh and rheological properties of glass fiber reinforced self-compacting concrete with nanosilica and fly ash blended[J]. Construction and Building Materials, 2019, 211:349-362.

[9] 宁波, 闫艳, 左夏伟, 等. 铁尾矿砂混凝土力学特性实验研究[J]. 矿产综合利用, 2021(4):159-164. NING B, YAN Y, ZUO X W, et al. Experimental study on mechanical properties of iron tailings concrete[J]. Multipurpose Utilization of Mineral Resources, 2021(4):159-164.

NING B, YAN Y, ZUO X W, et al. Experimental study on mechanical properties of iron tailings concrete [J]. Multipurpose Utilization of Mineral Resources, 2021(4): 159-164.

[10] 梁仕华, 曾伟华, 肖雪莉, 等. 纤维长度对微生物胶结砂力学性能的影响[J]. 工业建筑, 2019, 49(10):136-140. LIANG S H, ZENG W H, XIAO X L, et al. The effect of fiber length on the mechanical properties of microbial cemented sand[J]. Industrial Construction, 2019, 49(10):136-140.

LIANG S H, ZENG W H , XIAO X L, et al. The effect of fiber length on the mechanical properties of microbial cemented sand[J]. Industrial Construction, 2019, 49(10): 136-140.

[11] 李博, 陈宇龙. 颗粒破碎条件下的胶结砂力学行为[J]. 西南交通大学学报, 2016, 51(4):729-735. LI B, CHEN Y L. Mechanical behavior of cemented sand under the condition of particle crushing[J]. Journal of Southwest Jiaotong University, 2016, 51(4):729-735. doi: 10.3969/j.issn.0258-2724.2016.04.018

LI B, CHEN Y L. Mechanical behavior of cemented sand under the condition of particle crushing[J]. Journal of Southwest Jiaotong University, 2016, 51(4): 729-735. doi: 10.3969/j.issn.0258-2724.2016.04.018

[12] Hadi Abioghli, Amir Hamidi. A constitutive model for evaluation of mechanical behavior of fiber-reinforced cemented sand[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2019, 11(2):200-209.

[13] 姜屏, 杨建冬, 李娜, 等. 纤维改性水泥稳定铁尾矿砂的无侧限抗压性能研究[J]. 复合材料科学与工程, 2021(8):73-79. JIANG P, YANG J D, LI N, et al. Study on unconfined compressive performance of fiber-modified cement stabilized iron tailings[J]. Composite Materials Science and Engineering, 2021(8):73-79.

JIANG P, YANG J D, LI N, et al. Study on unconfined compressive performance of fiber-modified cement stabilized iron tailings[J]. Composite Materials Science and Engineering, 2021(8): 73-79.

[14] 张广泰, 耿天娇, 鲁海波, 等. 冻融循环下沙漠砂纤维混凝土损伤模型研究[J]. 硅酸盐通报, 2021, 40(7):2225-2231. ZHANG G T, GENG T J, LU H B, et al. Research on damage model of desert sand fiber concrete under freeze-thaw cycles[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(7):2225-2231.

ZHANG G T, GENG T J, LU H B, et al. Research on damage model of desert sand fiber concrete under freeze-thaw cycles[J]. Bulletin of the Chinese Ceramic Society, 2021, 40(7): 2225-2231.

-

下载:

下载: