Test of Comprehensive Recovery of Cyanide Residue

-

摘要:

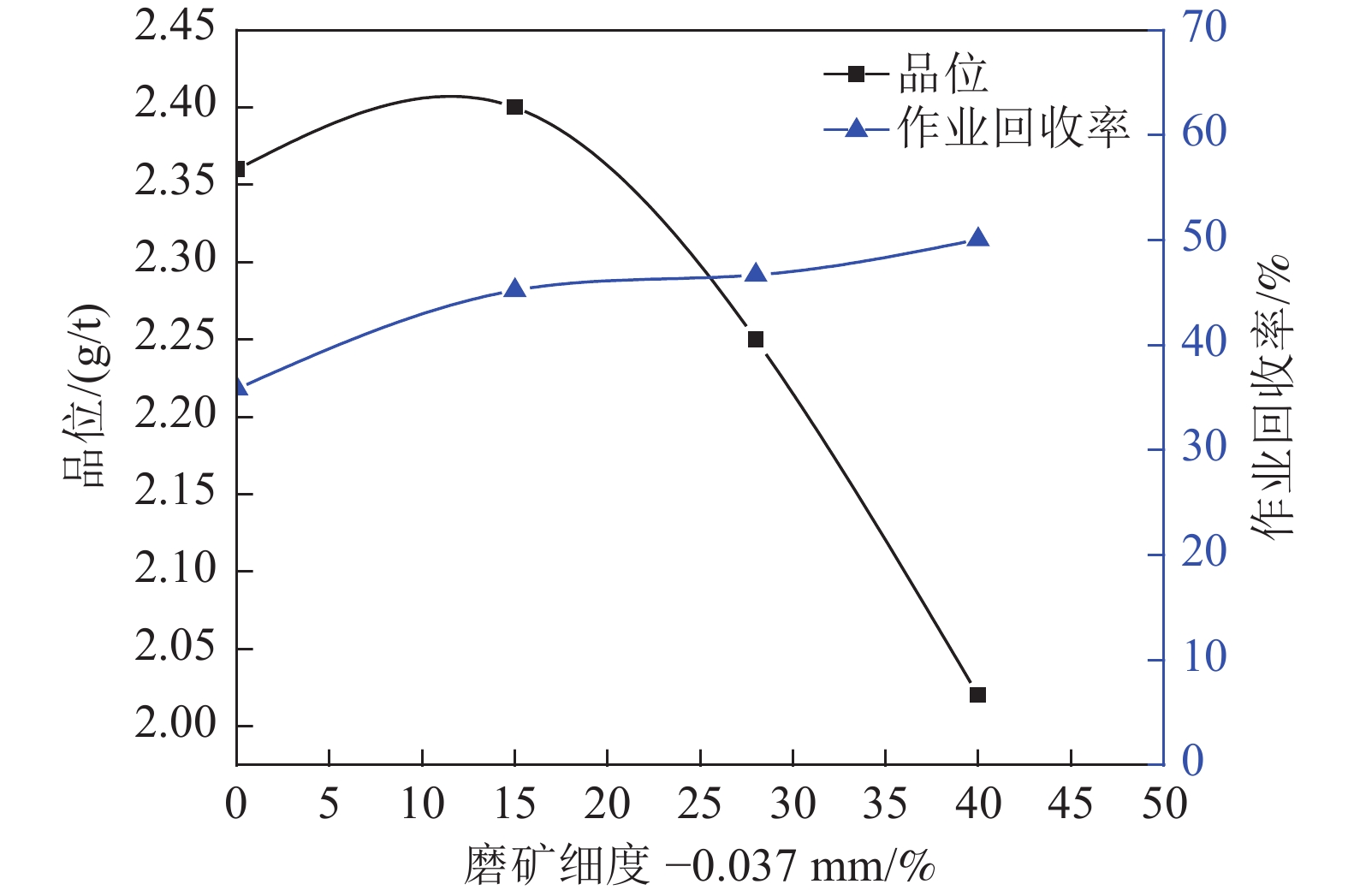

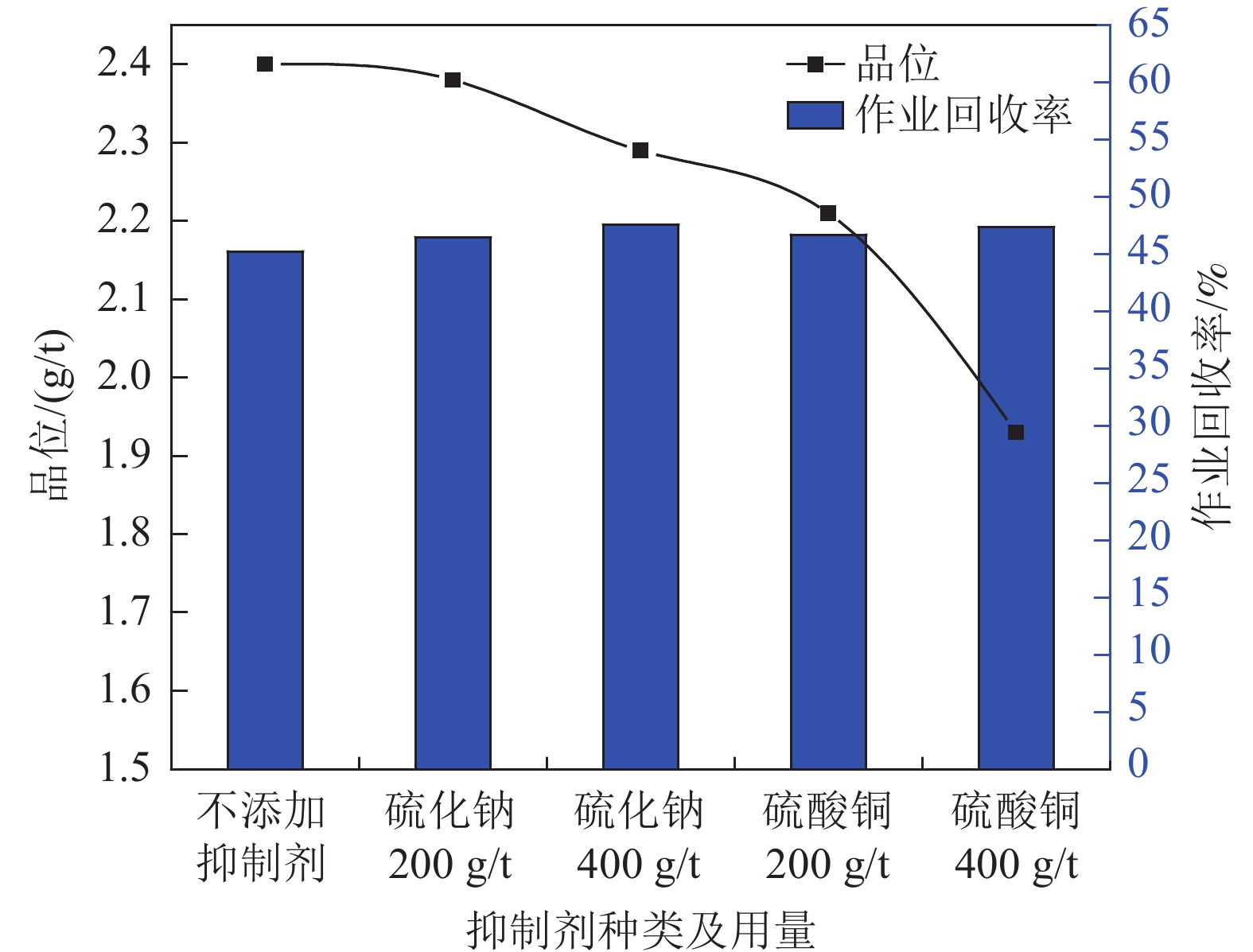

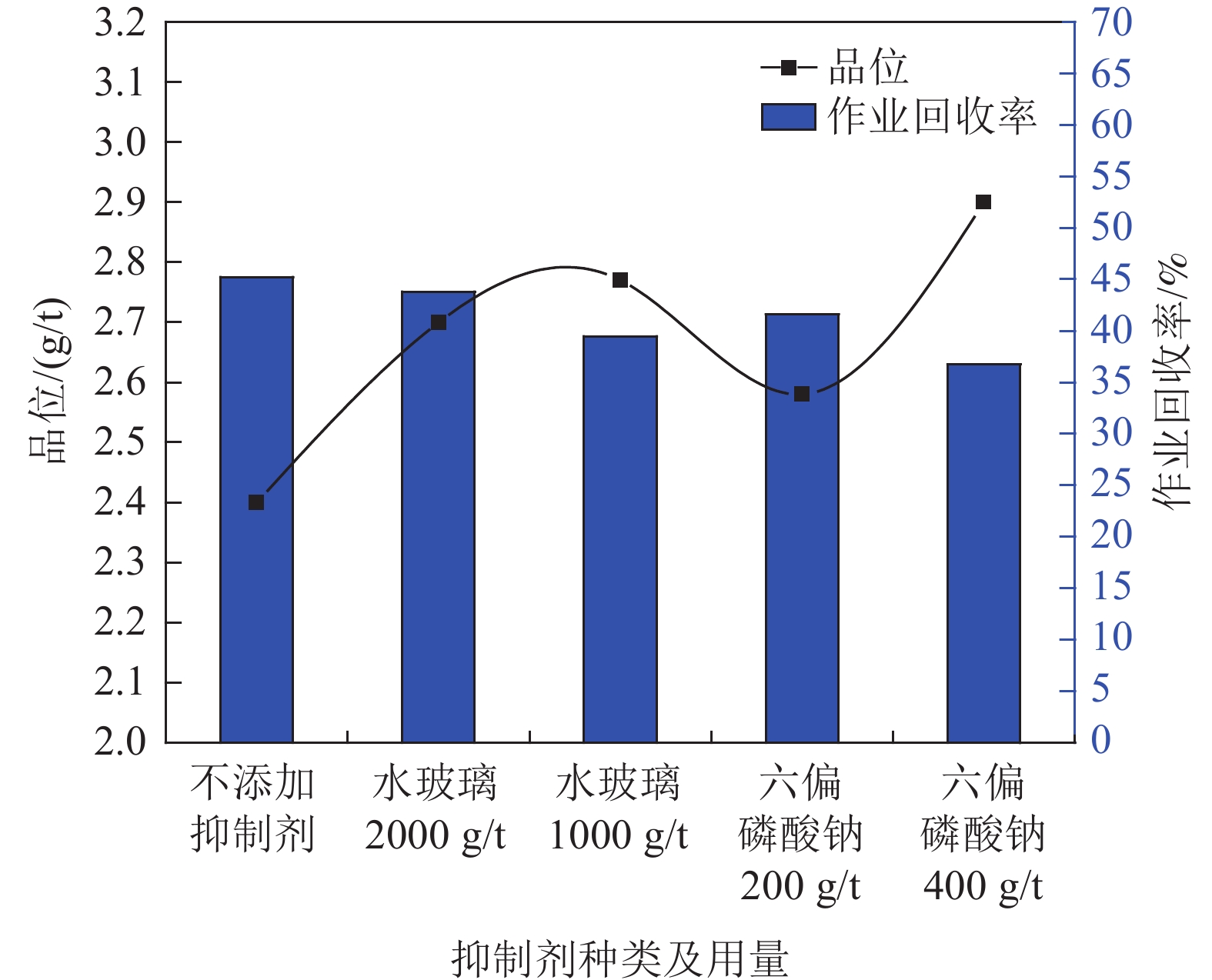

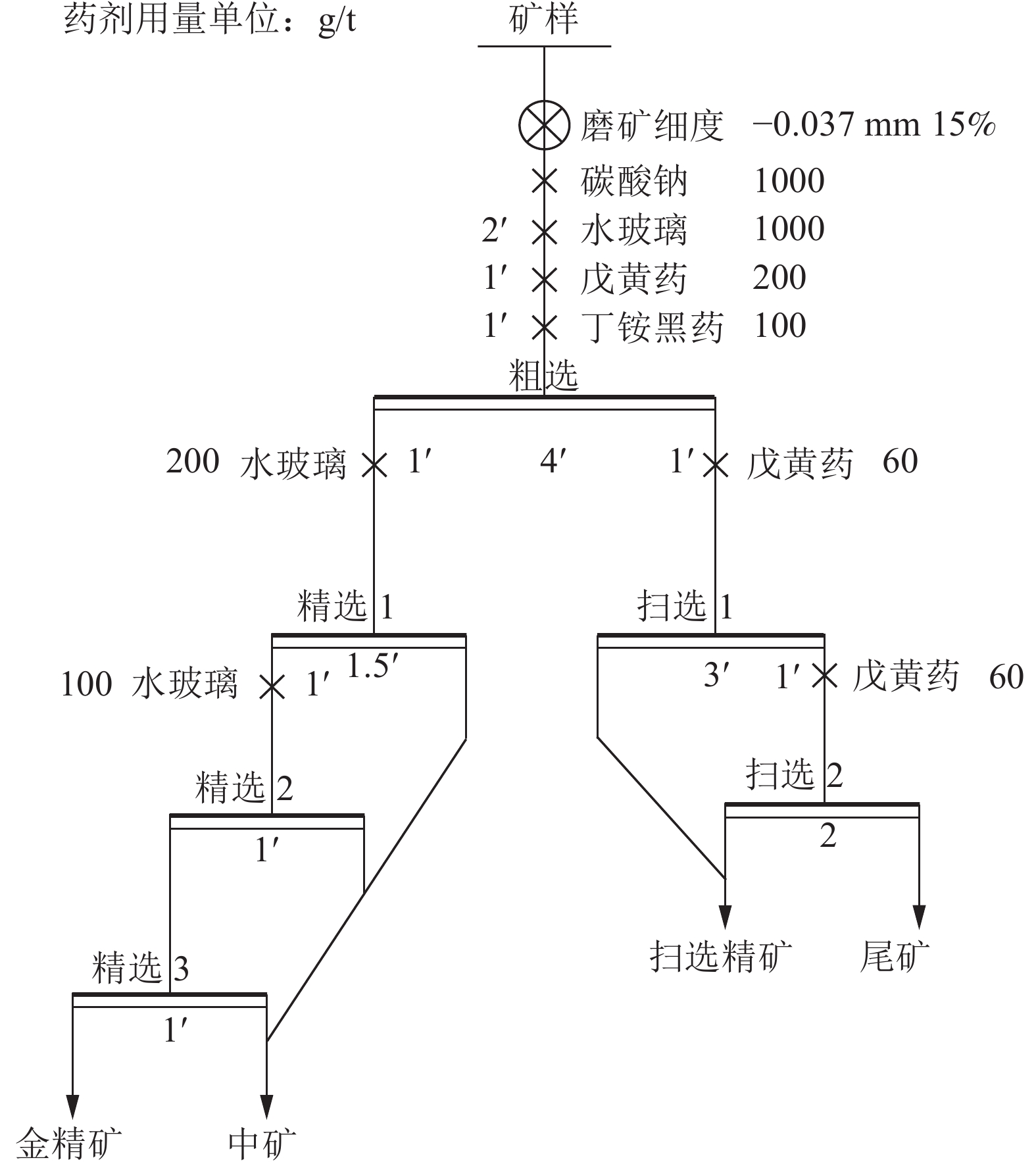

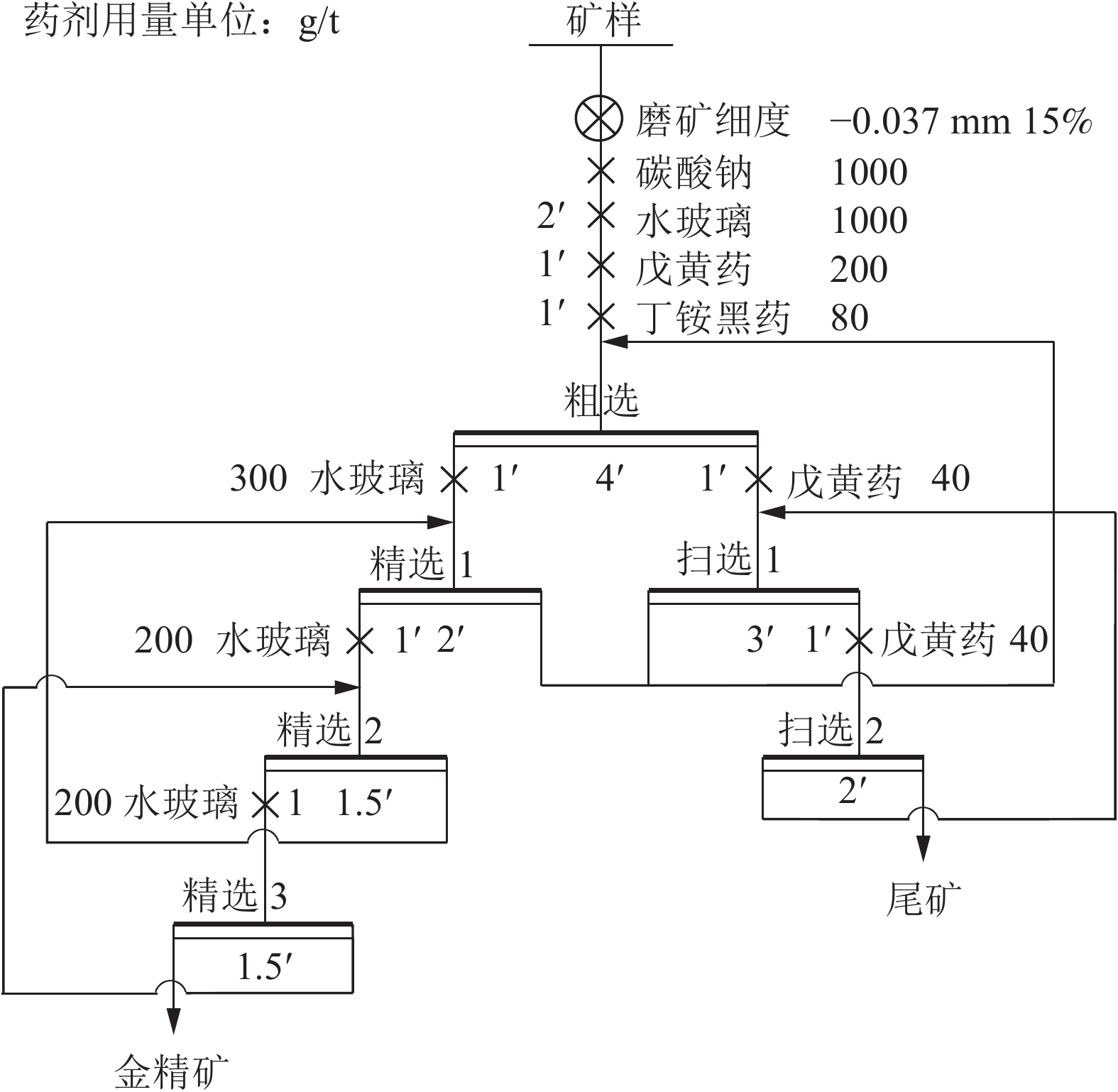

这是一篇矿物加工工程领域的论文。某金矿的全泥氰化尾渣含金0.45 g/t,金主要以硫化物包裹金形式存在,且主要分布于+0.037 mm粒级中。经过分级预处理后,对+0.037 mm矿样,在磨矿细度-0.037 mm 15%条件下,采用一次粗选两次扫选三次精选闭路实验流程,获得含金21.25 g/t,作业回收率72.27%的金精矿产品。

Abstract:This is an essay in the field of mineral processing engineering. Cyanide tailings of a gold mine contain gold 0.45 g/t, and the gold mainly exists in the form of vulcanized gold and is mainly distributed in coarse particles. After the classification treatment, for the +0.037 mm ore sample, under the condition of grinding fineness -0.037 mm content of 15%, by using floatation flowsheet “one roughing-two scavenging-three cleaning”, the gold concentrate with the grade of 21.25 g/t, and the operation recovery 72.27%. The Result shows that the cyanide tailings can be comprehensively recovered.

-

-

表 1 实验矿样化学成分分析结果/%

Table 1. Results of chemical composition analysis of the test ore samples

Au* Ag* Ni Ti REO Cu Pb Zn S As 0.45 6.80 0.20 0.11 0.12 0.031 0.0050 0.015 3.42 0.27 Fe Mn Co Sb Ta Nb CaO Al2O3 SiO2 C 7.25 0.081 0.0040 0.035 0.002 0.001 2.56 8.54 71.56 1.68 *单位为:g/t。 表 2 实验矿样中金的化学物相分析结果

Table 2. Results of chemical phase analysis of gold in the test ore samples

金相态 Au含量/(g/t) Au分布率/% 单体金+连生金 0.040 8.70 硫化物包裹金 0.270 58.70 铁等氧化物包裹金 0.100 21.74 硅酸盐中金 0.050 10.86 总金 0.460 100.00 表 3 实验矿样粒度分析结果

Table 3. Results of particle size analysis of the test ore samples

粒级/mm 产率/% 品位/% 分布率/% 正累计分布率/% Au* S Au S Au S +0.048 9.26 1.42 1.54 29.08 4.12 29.08 4.12 -0.048+0.037 25.51 0.86 2.25 48.52 16.59 77.61 20.72 -0.037+0.023 38.28 0.18 3.89 15.24 43.05 92.85 63.77 -0.023 26.95 0.12 4.65 7.15 36.23 100.00 100.00 合计 100.00 0.45 3.46 100.00 100.00 — — *单位为:g/t。 表 4 磨矿产品-0.037 mm 15%粒度分布结果

Table 4. Grinding products 15% particle size distribution results of -0.037 mm content

粒级/mm 产率/% 品位/% 分布率/% 正累计分布率/% Au* S Au S Au S +0.074 5.27 1.02 1.82 5.43 4.70 5.43 4.70 -0.074+0.048 50.28 1.21 2.33 61.49 57.36 66.92 62.05 -0.048+0.038 29.33 0.92 2.05 27.27 29.44 94.19 91.49 -0.038 15.12 0.38 1.15 5.81 8.51 100.00 100.00 合计 100.00 0.99 2.04 100.00 100.00 — — *单位为g/t 表 5 +0.037 mm矿样浮选捕收剂实验结果

Table 5. +0.037 mm flotation collector test results

产品名称 产率/% 品位/(g/t) 作业回收率/% 捕收剂种类

及用量/(g/t)粗精矿 16.33 2.72 44.96 戊黄药 100

丁铵黑药 100尾矿 83.67 0.65 55.04 合计 100.00 0.99 100.00 粗精矿 23.45 2.59 60.87 戊黄药 200

丁铵黑药 100尾矿 76.55 0.51 39.13 合计 100.00 1.00 100.00 粗精矿 25.41 2.52 65.61 戊黄药 300

丁铵黑药 100尾矿 74.59 0.45 34.39 合计 100.00 0.98 100.00 粗精矿 26.84 2.23 61.60 戊黄药 160

苯甲羟肟酸 40

丁铵黑药 100尾矿 73.16 0.51 38.40 合计 100.00 0.97 100.00 粗精矿 29.50 2.08 62.15 戊黄药 120

苯甲羟肟酸 80

丁铵黑药 100尾矿 70.50 0.53 37.85 合计 100.00 0.99 100.00 粗精矿 33.24 1.93 67.63 戊黄药 160

氧化石蜡皂 40

丁铵黑药 100尾矿 66.76 0.46 32.37 合计 100.00 0.95 100.00 表 6 +0.037 mm矿样浮选开路实验结果

Table 6. +0.037 mm ore flotation open circuit test results

产品名称 产率/%

品位/(g/t)作业回收率/% 金精矿 1.24 28.51 36.91 中矿 5.74 4.54 27.21 扫选精矿 4.43 2.76 12.76 尾矿 88.59 0.25 23.12 合计 100.00 0.96 100.00 表 7 +0.037 mm矿样浮选闭路实验结果

Table 7. +0.037 mm ore flotation closed circuit test results

产品名称 产率/%

品位/(g/t)作业回收率/% 金精矿 3.32 21.25 72.27 尾矿 96.68 0.28 27.73 合计 100.00 0.98 100.00 -

[1] 翁占平, 杨俊彦, 李雪林. 氰化尾渣资源综合回收利用研究进展[J]. 世界有色金属, 2017(4):40-42. WENG Z P, YANG J Y, LI X L. Research progress on comprehensive recovery and utilization of cyanide tailings[J]. World Non-Ferrous Metals, 2017(4):40-42.

WENG Z P, YANG J Y, LI X L. Research progress on comprehensive recovery and utilization of cyanide tailings[J]. World Non-Ferrous Metals, 2017, (4) : 40-42.

[2] 孙留根, 常耀超, 徐晓辉, 等. 氰化尾渣无害化、资源化利用的主要技术现状及发展趋势[J]. 中国资源综合利用, 2017, 35(10):59-62. SUN L G, CHANG Y C, XU X H, et al. The main technology status and development trend of harmless and resourceful utilization of cyanide tailings[J]. China Resources Comprehensive Utilization, 2017, 35(10):59-62. doi: 10.3969/j.issn.1008-9500.2017.10.023

SUN L G, CHANG Y C, XU X H, et al. The main technology status and development trend of harmless and resourceful utilization of cyanide tailings[J]. China Resources Comprehensive Utilization, 2017, 35(10): 59-62. doi: 10.3969/j.issn.1008-9500.2017.10.023

[3] 李大江, 郭持皓, 袁朝新, 等. 氰化尾渣浮选精矿焙砂提金工艺研究[J]. 矿产综合利用, 2019(5):107-110. LI D J, GUO C H, YUAN C X, et al. Study on gold recover from cyanide tailings floatation sulfur concentrate roasting residue[J]. Multipurpose Utilization of Mineral Resources, 2019(5):107-110. doi: 10.3969/j.issn.1000-6532.2019.05.023

LI D J, GUO C H, YUAN C X, et al. Study on gold recover from cyanide tailings floatation sulfur concentrate roasting residue [J]. Multipurpose Utilization of Mineral Resources, 2019(5): 107-110. doi: 10.3969/j.issn.1000-6532.2019.05.023

[4] 张亚莉, 于先进, 张丽鹏, 等. 高铁氰化渣湿法处理的研究进展及工艺开发[J]. 山东冶金, 2010, 32(5):3-5. ZHANG Y L, YU X J, ZHANG L P, et al. Research progress on hydrometallurgical treatment of cyanide tailings with highiron content and process development[J]. Shandong Metallurgy, 2010, 32(5):3-5. doi: 10.3969/j.issn.1004-4620.2010.05.002

ZHANG Y L, YU X J, ZHANG L P, et al. Research progress on hydrometallurgical treatment of cyanide tailings with highiron content and process development [J]. Shandong Metallurgy, 2010, 32(5): 3-5. doi: 10.3969/j.issn.1004-4620.2010.05.002

[5] 邓元良, 明平田, 王广伟, 等. 某金精矿焙烧氧化- 氰化尾矿工艺矿物学研究[J]. 矿产综合利用, 2020(4):121-125. DENG Y L, MING P T, WANG G W, et al. Research on process mineralogy of roasting oxidation - cyanide tailings of a gold concentrate[J]. Multipurpose Utilization of Mineral Resources, 2020(4):121-125. doi: 10.3969/j.issn.1000-6532.2020.04.020

DENG Y L, MING P T, WANG G W, et al. Research on process mineralogy of roasting oxidation - cyanide tailings of a gold concentrate[J]. Multipurpose Utilization of Mineral Resources, 2020(4): 121-125. doi: 10.3969/j.issn.1000-6532.2020.04.020

[6] 喻明军, 焦芬. 从某氰化尾渣中回收金的研究[J]. 矿冶工程, 2018, 38(2):66-69. YU M J, JIAO F. Experimental research on recycling gold from cyanide residue[J]. Mining and metallurgical engineering, 2018, 38(2):66-69. doi: 10.3969/j.issn.0253-6099.2018.02.016

YU M J, JIAO F. Experimental research on recycling gold from cyanide residue[J]. Mining and metallurgical engineering, 2018, 38(2): 66-69. doi: 10.3969/j.issn.0253-6099.2018.02.016

[7] 张博, 张雁生, 张家明, 等. 氰化尾渣提金选矿试验研究[J]. 矿冶工程, 2017, 37(6):60-62. ZHANG B, ZHANG Y S, ZHANG J M, et al. Flotation technology for gold reclaiming from cyanide tailings[J]. Mining and Metallurgical Engineering, 2017, 37(6):60-62. doi: 10.3969/j.issn.0253-6099.2017.06.015

ZHANG B, ZHANG Y S, ZHANG J M, et al. Flotation technology for gold reclaiming from cyanide tailings[J]. Mining and Metallurgical Engineering, 2017, 37(6): 60-62. doi: 10.3969/j.issn.0253-6099.2017.06.015

[8] 徐名特, 姜得男, 阎赞, 等. 某金矿氰化尾渣浮选试验研究[J]. 矿业研究与开发, 2015, 35:56-59. XU M T, JIANG D N, YAN Z, et al. Study on the flotation experiment of cyanide residues in a gold Mine[J]. Mining Research and Development, 2015, 35:56-59. doi: 10.13827/j.cnki.kyyk.2015.11.014

XU M T, JIANG D N, YAN Z, et al. Study on the flotation experiment of cyanide residues in a gold Mine[J]. Mining Research and Development, 2015, 35: 56-59. doi: 10.13827/j.cnki.kyyk.2015.11.014

[9] 张斌, 冯炎飞, 张勇. 陕西某金矿氰化尾渣的浮选活化试验[J]. 现代矿业, 2016, 32(10):48-50. ZHANG B, FENG Y F, ZHANG Y. Experiment on activate flotation of gold mine cyanide tailings from Shaanxi[J]. Modern Mining, 2016, 32(10):48-50. doi: 10.3969/j.issn.1674-6082.2016.10.018

ZHANG B, FENG Y F, ZHANG Y. Experiment on activate flotation of gold mine cyanide tailings from Shaanxi[J]. Modern Mining, 2016, 32(10): 48-50. doi: 10.3969/j.issn.1674-6082.2016.10.018

[10] 杨绍光. 极细难选金矿氰化尾渣资源综合回收利用试验研究 [D]: 青岛: 青岛理工大学, 2015.

YANG S G. Very fine to choose the gold cyanide tailings resources comprehensive recycling experimental study[D]. Qingdao : Qingdao University, 2015.

[11] 罗传胜. 从某氰化浸金尾渣中浮选回收金的研究 [J]. 材料研究与应用, 2012, 6(3): 181-184.

LUO C S . Test study of recovery gold from cyaniding slag by flotation[J]. Journal of Guangdong Non-Ferrous Metals. 2012, 6(3): 181-184.

-

下载:

下载: