Flotation and Humic Acid Extraction Test of Zhaotong Lignite

-

摘要:

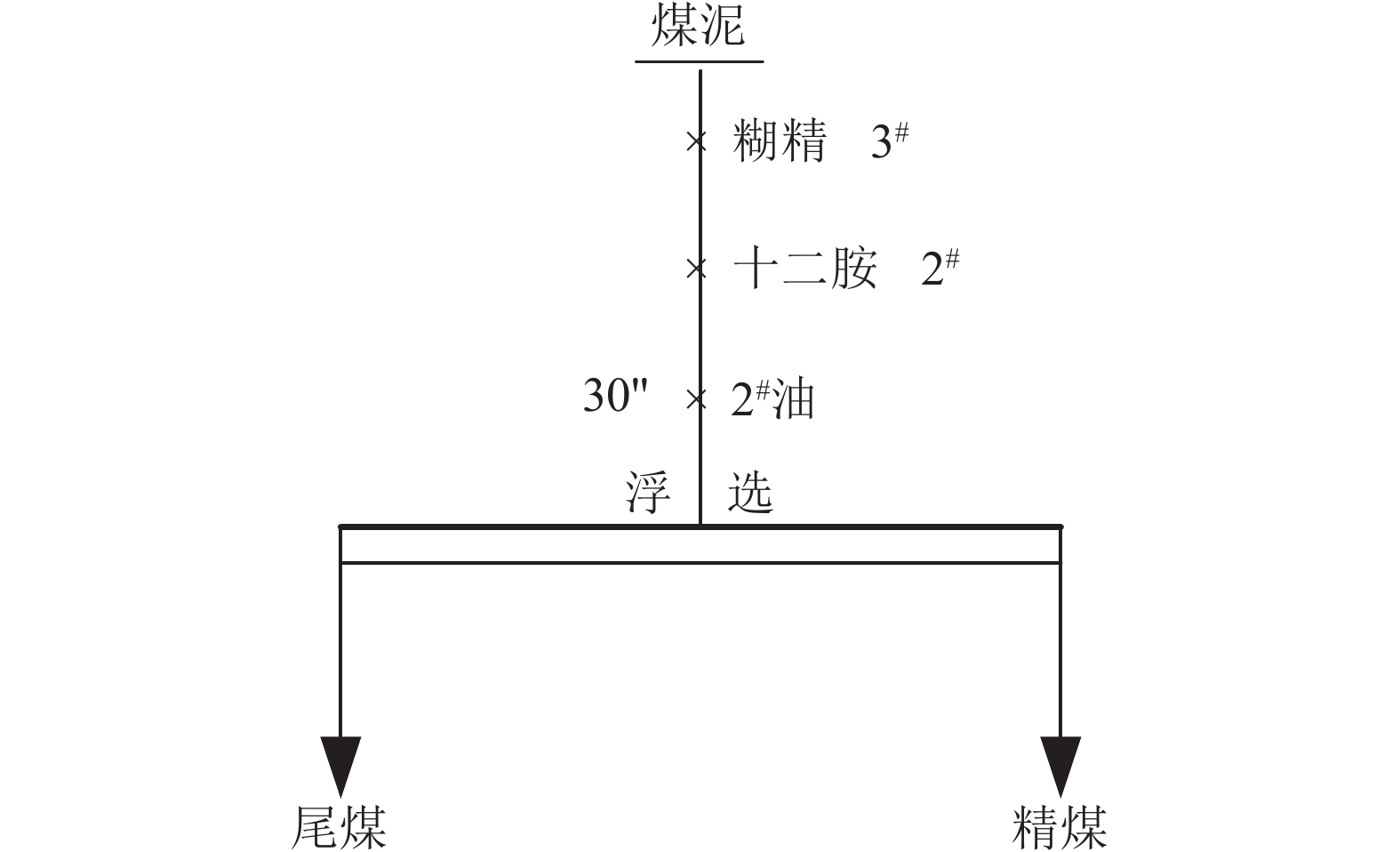

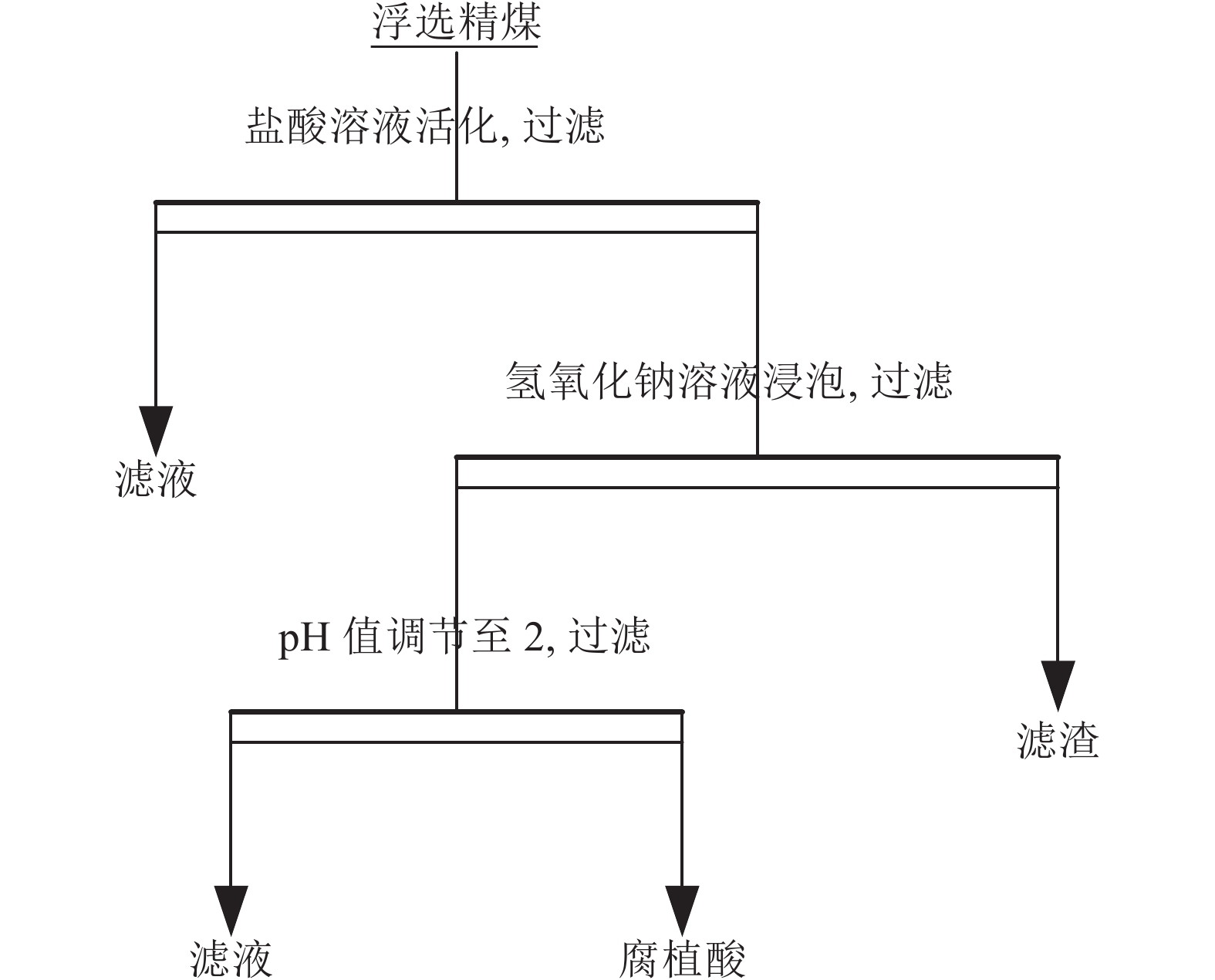

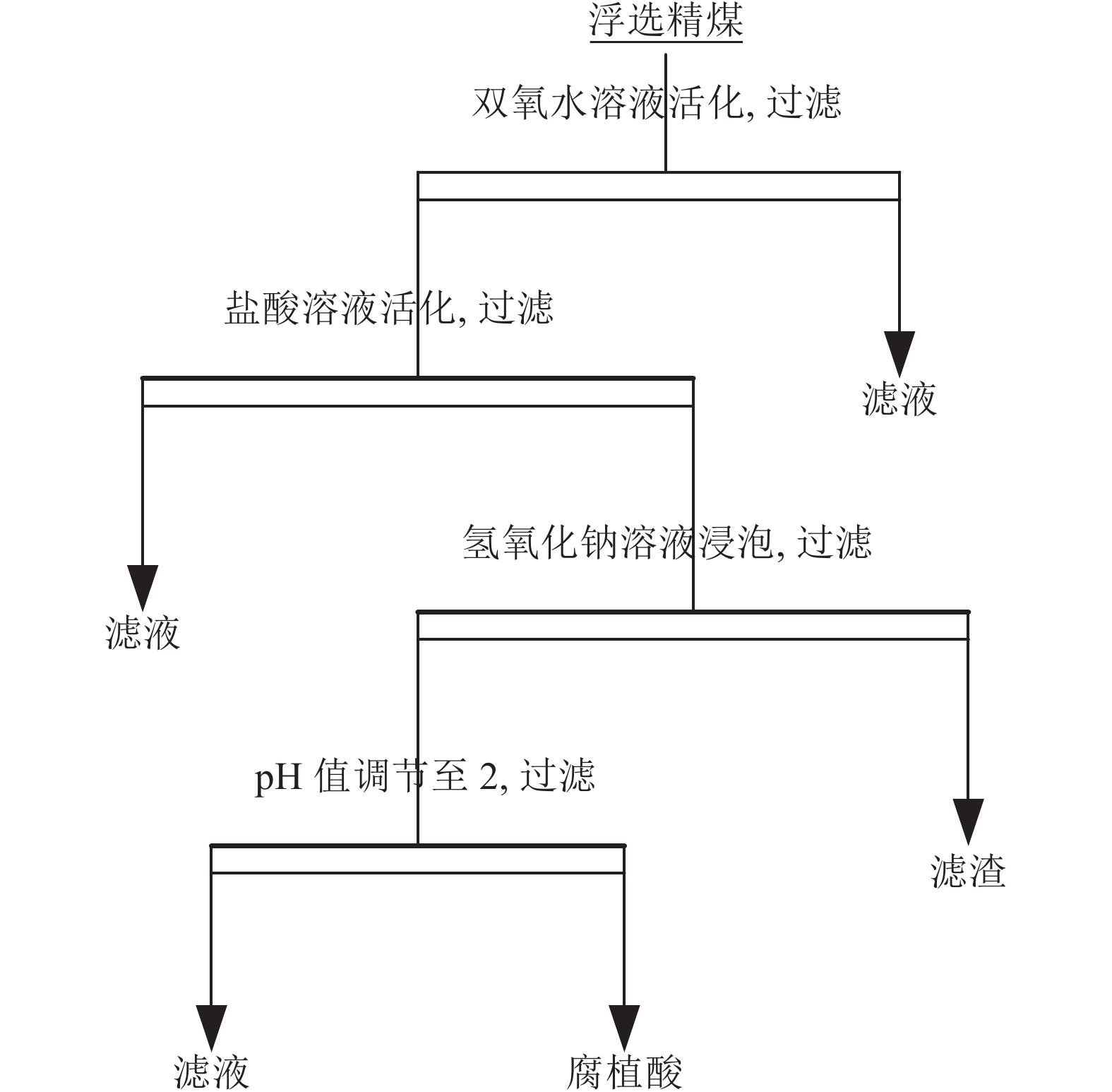

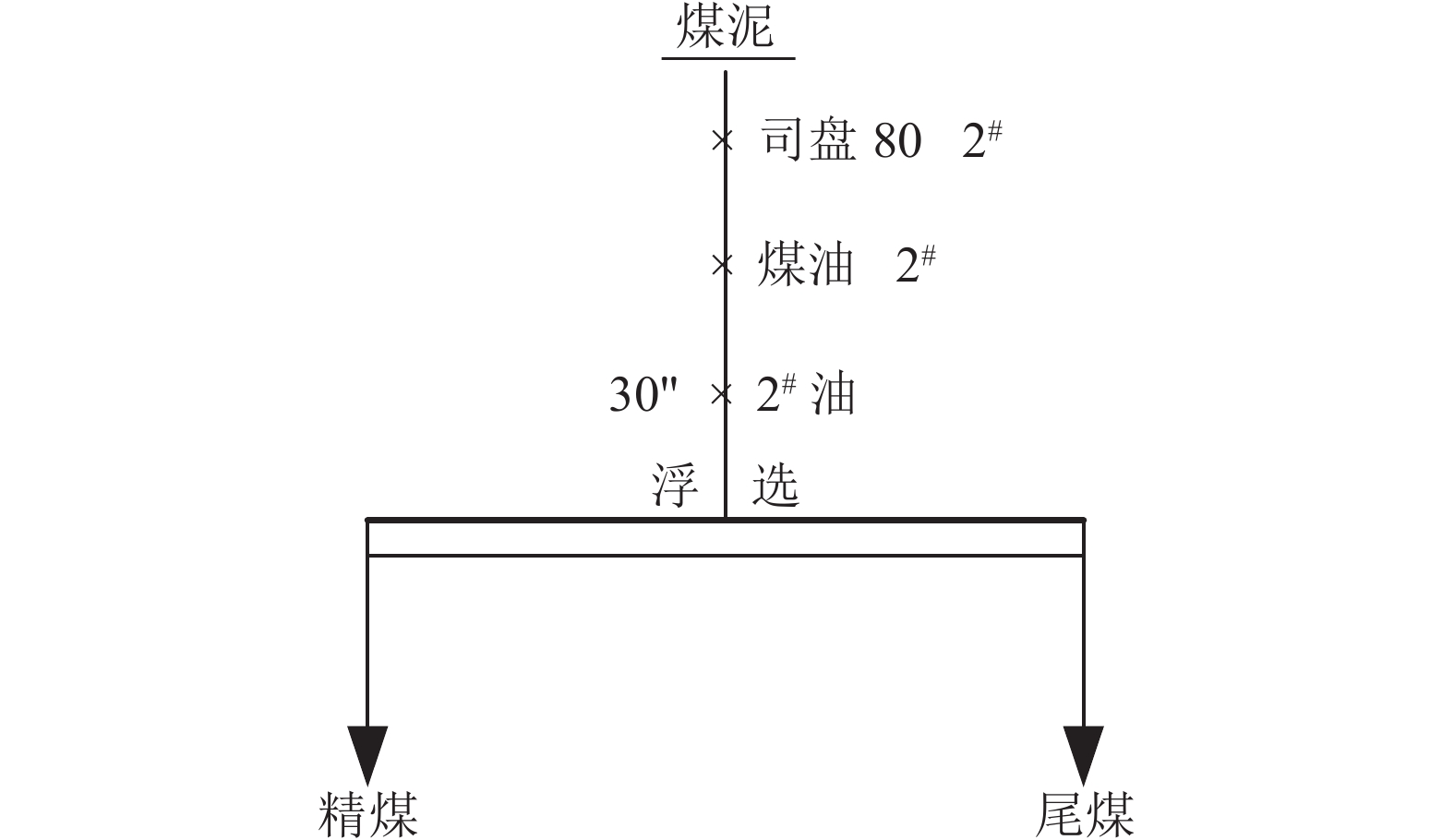

这是一篇矿物加工工程领域的论文。腐植酸是昭通褐煤的重要组成部分,为了高效地提取腐植酸,采用正浮选、反浮选工艺探索了昭通褐煤的较优浮选条件,并分别利用氧解法、碱溶酸析法设计正交实验,对浮选精煤进行腐植酸提取,探索了腐植酸提取的较优条件。实验结果表明:正浮选捕收剂消耗量大,在司盘80进行表面改性的条件下,浮选精煤产率较高为26.64%,灰分较低为20.08%;反浮选较佳条件为十二胺5 kg/t、糊精3 kg/t、起泡剂260 g/t,较佳浮选指标为浮选精煤产率84.35%、灰分20.52%,浮选尾煤产率15.65%、灰分36.75%,浮选完善指标12.08;氧解法较佳的提取条件为H2O2浓度0.7 mol/L、H2O2活化时间35 min、NaOH浓度0.3 mol/L、NaOH浸泡时间30 min,腐植酸提取率37.14%;碱溶酸析法较佳的提取条件为HCl浓度10%、HCl活化时间30 min、NaOH浓度0.7 mol/L、NaOH浸泡时间30 min,提取率43.80%。反浮选相对正浮选可以获得更高产率的高灰浮选精煤,碱溶酸析法提取昭通褐煤的腐植酸时,提取率更高。

Abstract:This is an essay in the field of mineral processing engineering. Humic acid is an important part of Zhaotong lignite. In order to extract humic acid efficiently, the optimum flotation conditions of Zhaotong lignite were explored by using the process of direct flotation and reverse flotation. Orthogonal experiments were designed by using the method of oxygen decomposition and alkali solution-acid separation to extract humic acid from flotation cleaned coal, and the optimal conditions of humic acid extraction were explored. The results show that the positive flotation collector consumption is large, and under the condition of surface modification of Span 80, the flotation cleaned coal yield is the highest of 26.64% and ash content is the lowest of 20.08%; the optimum conditions of reverse flotation are laurylamine 5 kg/t, dextrin 3 kg/t and foaming agent 260 g/t, and the optimum flotation indexes are as follows: flotation cleaned coal yield 84.35% and ash 20.52%, flotation tailcoal yield 15.65% and ash 36.75%, and flotation perfection index 12.08; the optimum extraction conditions of oxygen decomposition are as follows: H2O2 concentration 0.7 mol/L, H2O2 activation time 35 min, NaOH concentration 0.3 mol/L, NaOH soaking time 30 min, and the extraction rate of humic acid 37.14%; the optimal extraction conditions of alkali-soluble acid chromatography are as follows: concentration of hydrochloric acid 10%, activation time of hydrochloric acid 30 min, NaOH concentration 0.7 moL/L, NaOH soaking time 30 min, and the extraction yield 43.80%. Reverse flotation can obtain higher yield of high ash flotation clean coal than normal flotation, and the extraction rate is higher when the humic acid of Zhaotong lignite is extracted by alkali solution-acid separation method.

-

-

表 1 昭通褐煤煤泥粒度组成

Table 1. Particle size composition of Zhaotong lignite slime

粒级/mm 产率/% 灰分/% 筛上累计 筛下累计 产率/% 灰分/% 产率/% 灰分/% -0.50+0.25 35.21 22.59 35.21 22.59 100.00 23.29 -0.25+0.125 19.42 22.41 54.63 22.53 64.79 23.67 -0.125+0.075 18.31 22.76 72.94 22.58 45.37 24.21 -0.075+0.045 13.32 22.64 86.26 22.59 27.06 25.20 -0.045 13.74 27.68 100.00 23.29 13.74 27.68 合计 100.00 23.29 表 2 昭通褐煤煤泥密度组成

Table 2. Density composition of Zhaotong lignite slime

密度级/(g/cm3) 产率/% 灰分/% 浮物累计 沉物累计 产率/% 灰分/% 产率/% 灰分/% <1.30 29.25 19.53 29.25 19.53 100.00 23.58 1.30~1.40 55.63 21.11 84.88 20.57 70.75 25.26 1.40~1.50 6.58 28.46 91.46 21.13 15.12 40.53 1.50~1.60 2.91 36.47 94.37 21.61 8.54 49.84 1.60~1.80 2.13 46.08 96.50 22.15 5.63 56.75 >1.80 3.50 63.24 100.00 23.58 3.5 63.24 小计 100.00 23.58 表 3 昭通褐煤煤泥正浮选实验结果

Table 3. Positive flotation test results of Zhaotong lignite slime

司盘80

/(kg/t)捕收剂

/(kg/t)起泡剂

/(g/t)浮选精煤/% 浮选尾煤/% 计算煤泥

灰分/%γ Ad γ Ad 20 20 260 8.67 22.43 91.33 23.64 23.54 30 10.02 22.35 89.98 23.31 23.21 40 11.86 21.93 88.14 23.42 23.24 40 20 260 11.24 22.02 88.76 23.81 23.61 40 12.96 20.08 87.04 23.87 23.38 60 26.64 21.15 73.36 23.98 23.23 表 4 昭通褐煤煤泥反浮选多因素逐项实验结果

Table 4. Multi - factor test results of reverse flotation of Zhaotong lignite slime

十二胺/(kg/t) 糊精/(kg/t) 起泡剂/(g/t) 精煤/% 尾煤/% 计算煤泥灰分/% 浮选完善指标 γ Ad γ Ad 5 3 260 82.62 21.01 17.38 33.07 23.11 9.75 7 66.83 20.65 33.17 27.88 23.05 9.04 9 71.59 20.63 28.41 29.89 23.26 10.55 9 1 260 63.48 21.11 36.52 26.75 23.17 7.35 3 72.98 20.63 27.02 30.75 23.36 11.15 5 71.59 20.62 28.41 29.62 23.18 10.28 9 3 130 81.02 20.53 18.98 34.6 23.20 12.14 260 71.59 20.63 28.41 29.05 23.02 9.66 390 75.93 20.77 24.07 31.24 23.29 10.71 表 5 昭通褐煤煤泥反浮选正交实验结果

Table 5. Orthogonal test results of reverse flotation of Zhaotong lignite slime

实验序号 十二胺/(kg/t) 糊精/(kg/t) 起泡剂/(g/t) 精煤/% 尾煤/% 计算煤泥灰分/% 浮选完善指标 γ Ad γ Ad 1 5 1 130 82.29 21.04 17.71 32.52 23.07 9.43 2 5 3 260 84.35 20.52 15.65 36.75 23.06 12.08 3 5 5 390 85.78 20.97 14.22 36.03 23.11 10.34 4 7 1 390 83.05 21.15 16.95 32.79 23.12 9.22 5 7 3 130 81.52 21.02 18.48 33.04 23.24 10.15 6 7 5 260 86.49 21.15 13.51 34.72 22.98 8.96 7 9 1 260 66.86 20.98 33.14 27.97 23.30 8.67 8 9 3 390 82.34 20.91 17.66 33.03 23.05 9.94 9 9 5 130 84.97 21.26 15.03 32.92 23.01 8.41 K1 31.84 27.31 27.98 K2 28.33 32.16 29.70 K3 27.01 27.70 29.49 极差 4.83 4.85 1.72 主次顺序 糊精>十二胺>起泡剂 各因素较佳水平 5 3 260 较佳水平搭配 5 3 260 表 6 碱溶酸析法腐植酸提取正交实验结果

Table 6. Orthogonal test results of humic acid extraction by alkali-soluble acid separation

实验序号 HCl浓度

/%HCl活化

时间/minNaOH浓度

/(mol/L)NaOH浸泡

时间/min提取率/% 1 5 20 0.7 40 22.73 2 5 25 0.1 20 3.52 3 5 30 0.5 50 27.91 4 5 35 0.3 30 18.5 5 10 20 0.5 30 21.54 6 10 25 0.3 50 14.06 7 10 30 0.7 20 30.03 8 10 35 0.1 40 21.49 9 15 20 0.1 50 5.68 10 15 25 0.7 30 32.69 11 15 30 0.3 40 21.56 12 15 35 0.5 20 21.89 13 20 20 0.3 20 23.27 14 20 25 0.5 40 17.58 15 20 30 0.1 30 29.9 16 20 35 0.7 50 4.12 K1 72.66 73.22 60.59 78.71 K2 87.12 67.85 77.39 102.63 K3 81.82 109.40 88.92 83.36 K4 74.87 66.00 89.57 51.77 极差 14.46 43.40 28.98 50.86 主次顺序 NaOH浸泡时间>HCl活化时间>NaOH浓度>HCl浓度 较佳水平 10 30 0.7 30 较佳水平搭配 10 30 0.7 30 注:较佳水平搭配经验证而来。 表 7 氧解法腐植酸提取正交实验结果

Table 7. Orthogonal test results of humic acid extraction by oxylysis

实验序号 H2O2浓度

/(mol/L)H2O2活化

时间/minNaOH浓度

/(mol/L)NaOH浸泡

时间/min提取率/% 1 0.1 20 0.7 40 18.81 2 0.1 25 0.1 20 5.10 3 0.1 30 0.5 50 24.80 4 0.1 35 0.3 30 25.29 5 0.3 20 0.5 30 20.89 6 0.3 25 0.3 50 26.80 7 0.3 30 0.7 20 4.29 8 0.3 35 0.1 40 27.52 9 0.5 20 0.1 50 5.55 10 0.5 25 0.7 30 28.36 11 0.5 30 0.3 40 21.99 12 0.5 35 0.5 20 26.44 13 0.7 20 0.3 20 27.23 14 0.7 25 0.5 40 16.62 15 0.7 30 0.1 30 16.30 16 0.7 35 0.7 50 27.77 K1 74.00 72.48 54.47 63.06 K2 79.50 76.88 101.31 90.84 K3 82.34 67.38 88.75 84.94 K4 87.92 107.02 79.23 84.92 极差 13.92 39.64 46.84 27.78 主次顺序 NaOH浓度>H2O2活化时间>NaOH浸泡时间>H2O2浓度 较佳水平 0.7 35 0.3 30 较佳水平搭配 0.7 35 0.3 30 注:较佳水平搭配经验证而来。 -

[1] 周云龙, 姚灏, 王迪, 等. 褐煤预干燥发电机组特性仿真对比及投资经济性分析[J]. 热能动力工程, 2021, 36(1):100-107. ZHOU Y L, YAO H, WANG D, et al. Simulation comparison and investment economy analysis of generation units with lignite pre-drying system[J]. Journal of Engineering for Thermal Energy and Power, 2021, 36(1):100-107.

ZHOU Y L, YAO H, WANG D, et al. Simulation comparison and investment economy analysis of generation units with lignite pre-drying system[J]. Journal of Engineering for Thermal Energy and Power, 2021, 36(1): 100-107.

[2] 杨芊, 杨晓龙, 刘佳金, 等. 褐煤作为气化原料在煤化工企业中的应用[J]. 煤炭加工与综合利用, 2020(6):51-54+58+5. YANG Q, YANG X L, LIU J J, et al. Application of lignite as gasification raw material in coal chemical enterprises[J]. Coal Processing & Comprehensive Utilization, 2020(6):51-54+58+5.

YANG Q, YANG X L, LIU J J, et al. Application of lignite as gasification raw material in coal chemical enterprises[J]. Coal Processing & Comprehensive Utilization, 2020(6): 51-54+58+5.

[3] 李建涛, 刘向荣, 杨杰, 等. 真菌筛选及降解光-氧氧化褐煤工艺条件优化研究[J]. 矿产综合利用, 2020(5):82-86+157. LI J T, LIU X R, YANG J, et al. Screening of fungi and condition optimization for biodegradation of photooxidized lignite[J]. Multipurpose Utilization of Mineral Resources, 2020(5):82-86+157.

LI J T, LIU X R, YANG J, et al. Screening of fungi and condition optimization for biodegradation of photooxidized lignite [J]. Multipurpose Utilization of Mineral Resources, 2020(5): 82-86+157.

[4] 张传祥, 张效铭, 程敢. 褐煤腐植酸提取技术及应用研究进展[J]. 洁净煤技术, 2018, 24(1):6-12. ZHANG C X, ZHANG X M, CHENG G. Research progress on extraction technology and application of lignite humic acid[J]. Clean Coal Technology, 2018, 24(1):6-12.

ZHANG C X, ZHANG X M, CHENG G. Research progress on extraction technology and application of lignite humic acid [J]. Clean Coal Technology, 2018, 24(1): 6-12.

[5] 张远琴, 李艳红, 常丽萍, 等. 昭通褐煤制备农业腐植酸的提取工艺条件优化[J]. 化学世界, 2021, 62(3):176-182. ZHANG Y Q, LI Y H, CHANG L P, et al. Optimization of extraction process conditions for preparing agricultural humic acid from Zhaotong lignite[J]. Chemical World, 2021, 62(3):176-182.

ZHANG Y Q, LI Y H, CHANG L P, et al. Optimization of extraction process conditions for preparing agricultural humic acid from Zhaotong lignite[J]. Chemical World, 2021, 62(3): 176-182.

[6] 桂夏辉, 邢耀文, 连露露, 等. 煤泥浮选过程强化之三——低阶/氧化煤浮选界面强化篇[J]. 选煤技术, 2017(3):87-91+96. GUI X H, XING Y W, LIAN L L, et al. Fine coal flotation process intensification-part III: interface intensification of low-rank and oxidized coal[J]. Coal Preparation Techenology, 2017(3):87-91+96.

GUI X H, XING Y W, LIAN L L, et al. Fine coal flotation process intensification-part III: interface intensification of low-rank and oxidized coal [J]. Coal Preparation Techenology, 2017(3): 87-91+96.

[7] Cheng Gan, Li Ziyou, Cao Yijun, et al. Research progress in lignite flotation intensification[J]. International Journal of Coal Preparation and Utilization, 2020, 40(1):59-76. doi: 10.1080/19392699.2018.1541894

[8] Kurniati E, Muljani S, Virgani D G, et al. Humic acid isolations from lignite by ion exchange method[J]. Journal of Physics Conference, 2018, 953:012234. doi: 10.1088/1742-6596/953/1/012234

[9] 谢才秀, 张永菊, 龙涛, 等. 不同实验设计方法在高灰分煤泥浮选优化实验中的应用[J]. 矿产综合利用, 2021(1):72-76+56. XIE C X, ZHANG Y J, LONG T, et al. The application of different experimental design method in the flotation optimization experiments of high ash coal slime[J]. Multipurpose Utilization of Mineral Resources, 2021(1):72-76+56.

XIE C X, ZHANG Y J, LONG T, et al. The application of different experimental design method in the flotation optimization experiments of high ash coal slime [J]. Multipurpose Utilization of Mineral Resources, 2021(1): 72-76+56.

[10] 宁可佳, 崔家画, 徐宏祥, 等. 褐煤反浮选试验工艺研究[J]. 矿业科学学报, 2021, 6(2):207-215. NING K J, CUI J H, XU H X, et al. Lignite reverse flotation test process and mechanism[J]. Journal of Mining Science and Technology, 2021, 6(2):207-215. doi: 10.19606/j.cnki.jmst.2021.02.011

NING K J, CUI J H, XU H X, et al. Lignite reverse flotation test process and mechanism [J]. Journal of Mining Science and Technology, 2021, 6(2): 207-215. doi: 10.19606/j.cnki.jmst.2021.02.011

[11] Temel H A. Removal of gangue minerals containing major elements from karl A+/-ova-Der double dagger ay (bingol) lignite using a reverse flotation method[J]. JOM:the journal of the Minerals, Metals & Materials Society, 2015, 67(12):3002-3009.

[12] Zhang H, Liu J, Cao Y, et al. Effects of particle size on lignite reverse flotation kinetics in the presence of sodium chloride[J]. Powder Technology, 2013, 246:658-663. doi: 10.1016/j.powtec.2013.06.033

[13] 郭雅妮, 马畅柠, 惠璠, 等. 风化煤中腐殖酸的提取及其性能表征[J]. 环境工程学报, 2017, 11(5):3153-3160. GUO Y N, MA C N, HUI P, et al. Humic acid extraction from weathered coal and its properties characterization[J]. Chinese Journal of Environmental Engineering, 2017, 11(5):3153-3160. doi: 10.12030/j.cjee.201601216

GUO Y N, MA C N, HUI P, et al. Humic acid extraction from weathered coal and its properties characterization [J]. Chinese Journal of Environmental Engineering, 2017, 11(5): 3153-3160. doi: 10.12030/j.cjee.201601216

-

下载:

下载: