Mechanism and Application Research on Removal of Pb and Cd from Coal Fly Ash by Chlorinating Calcination

-

摘要:

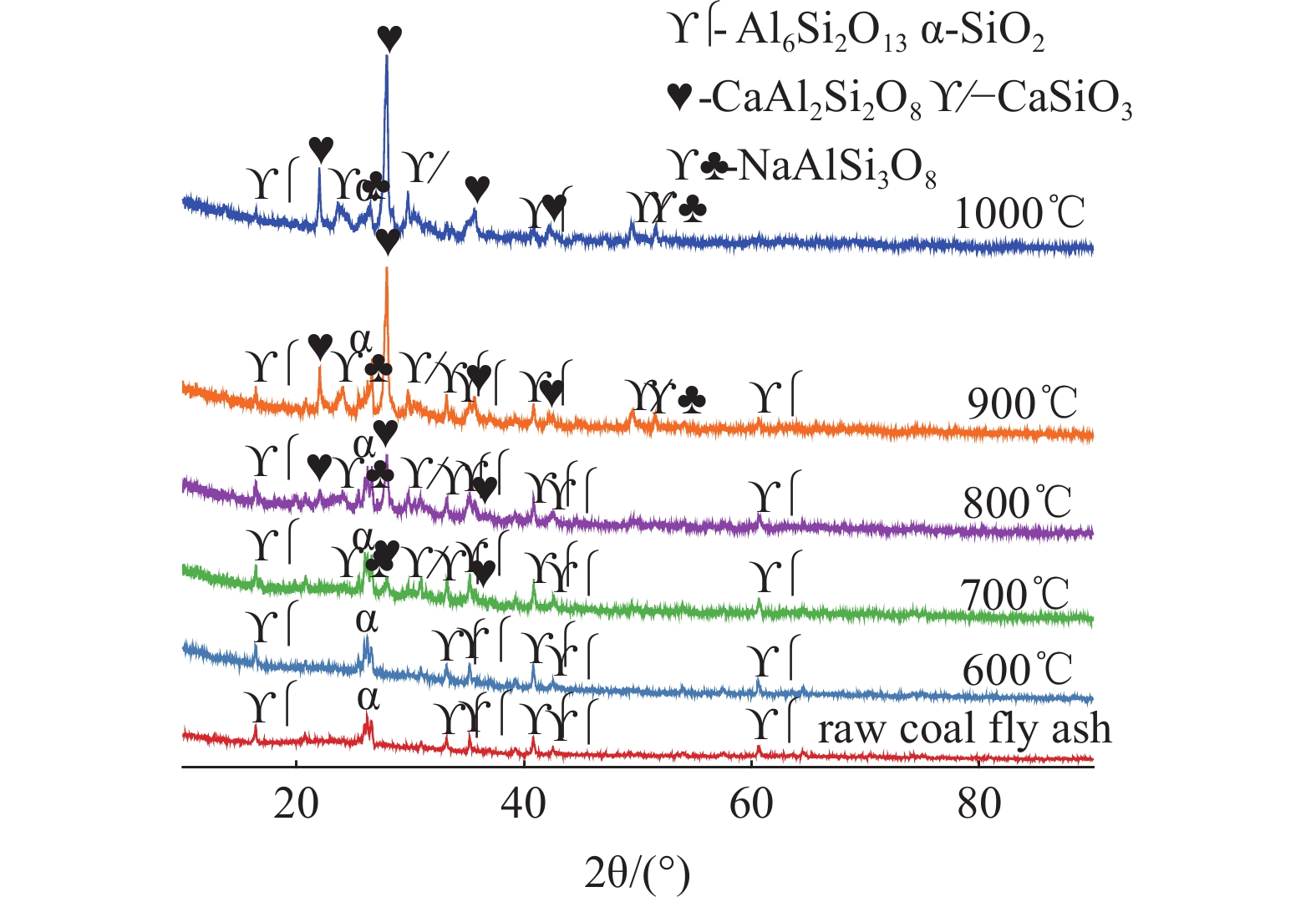

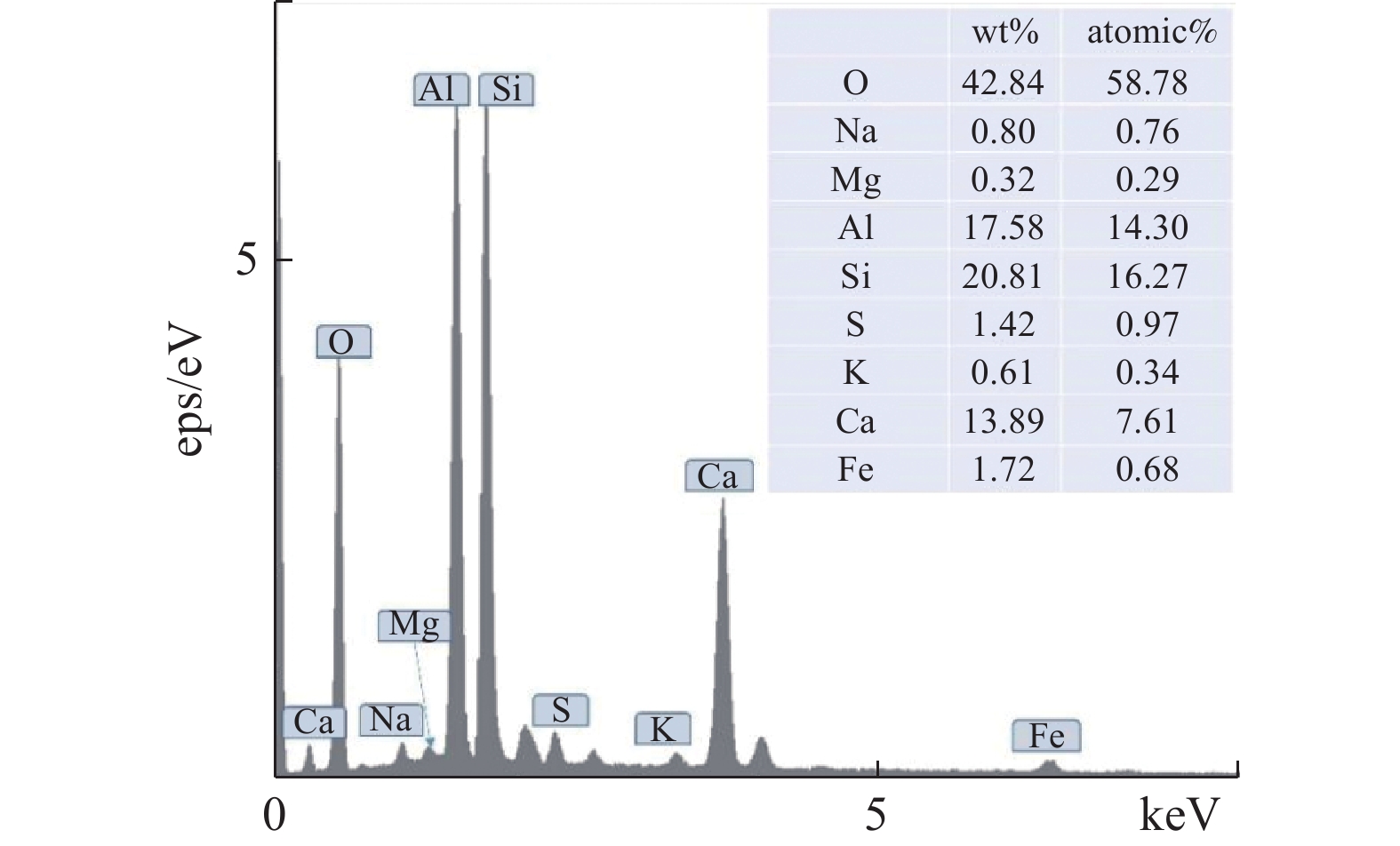

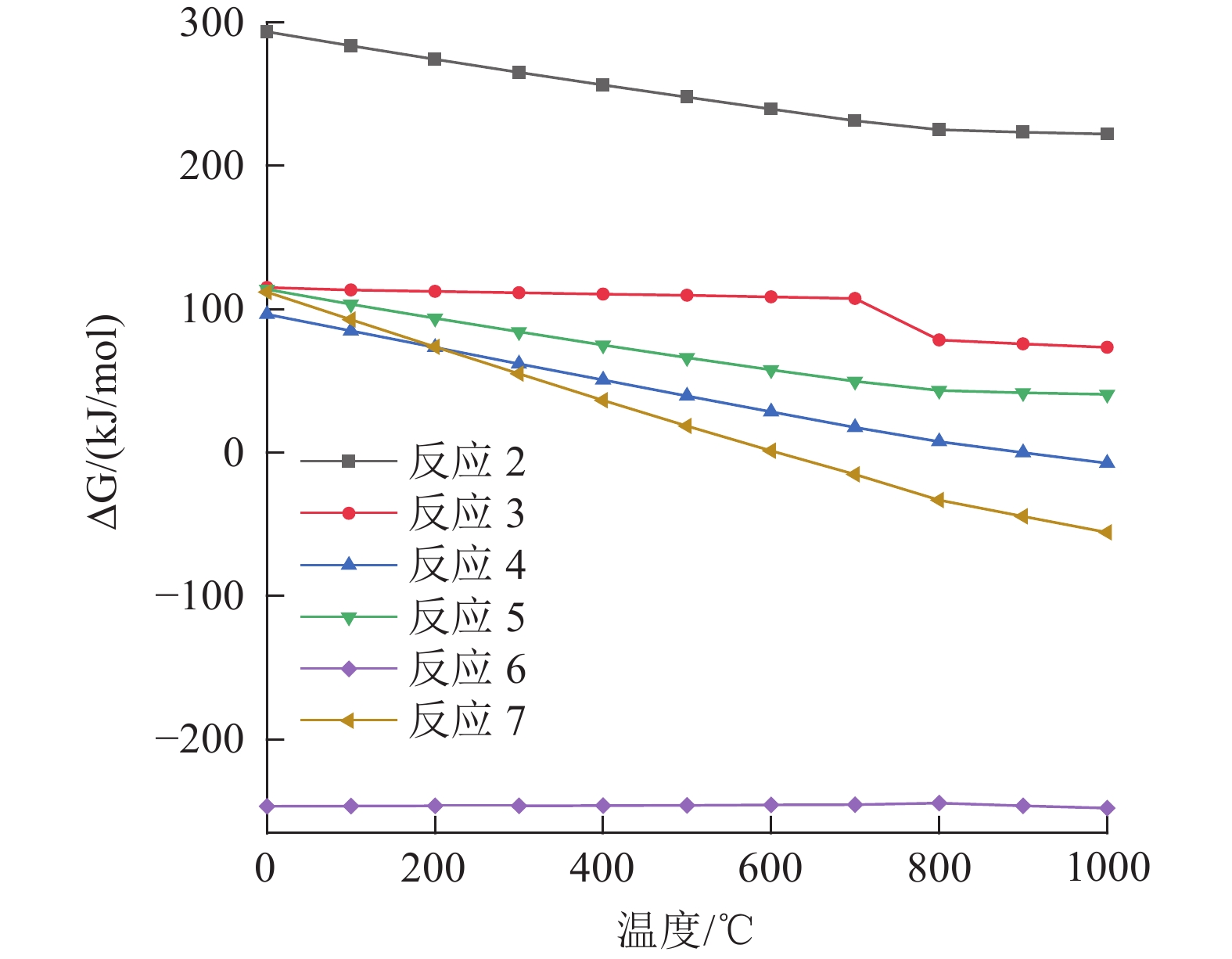

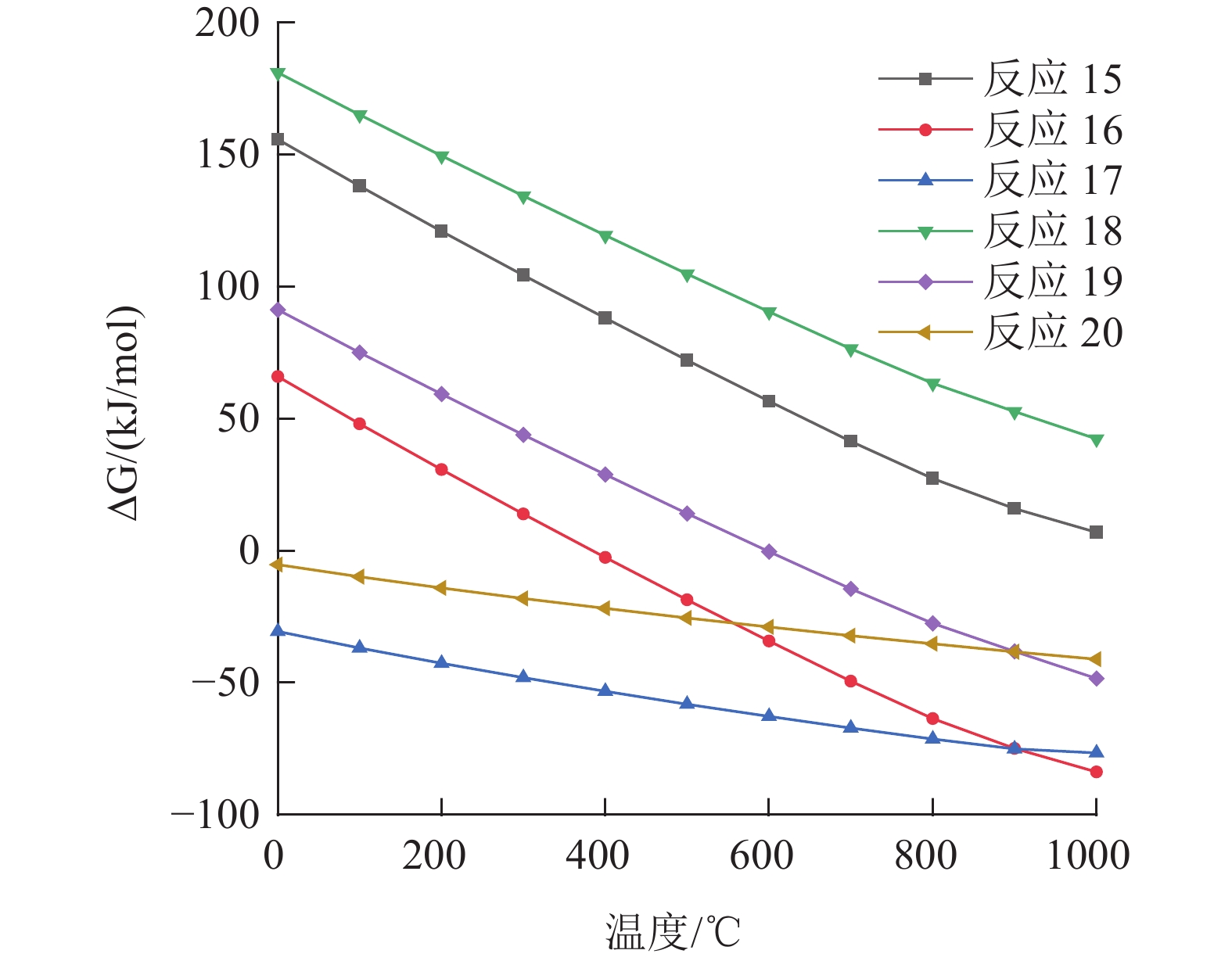

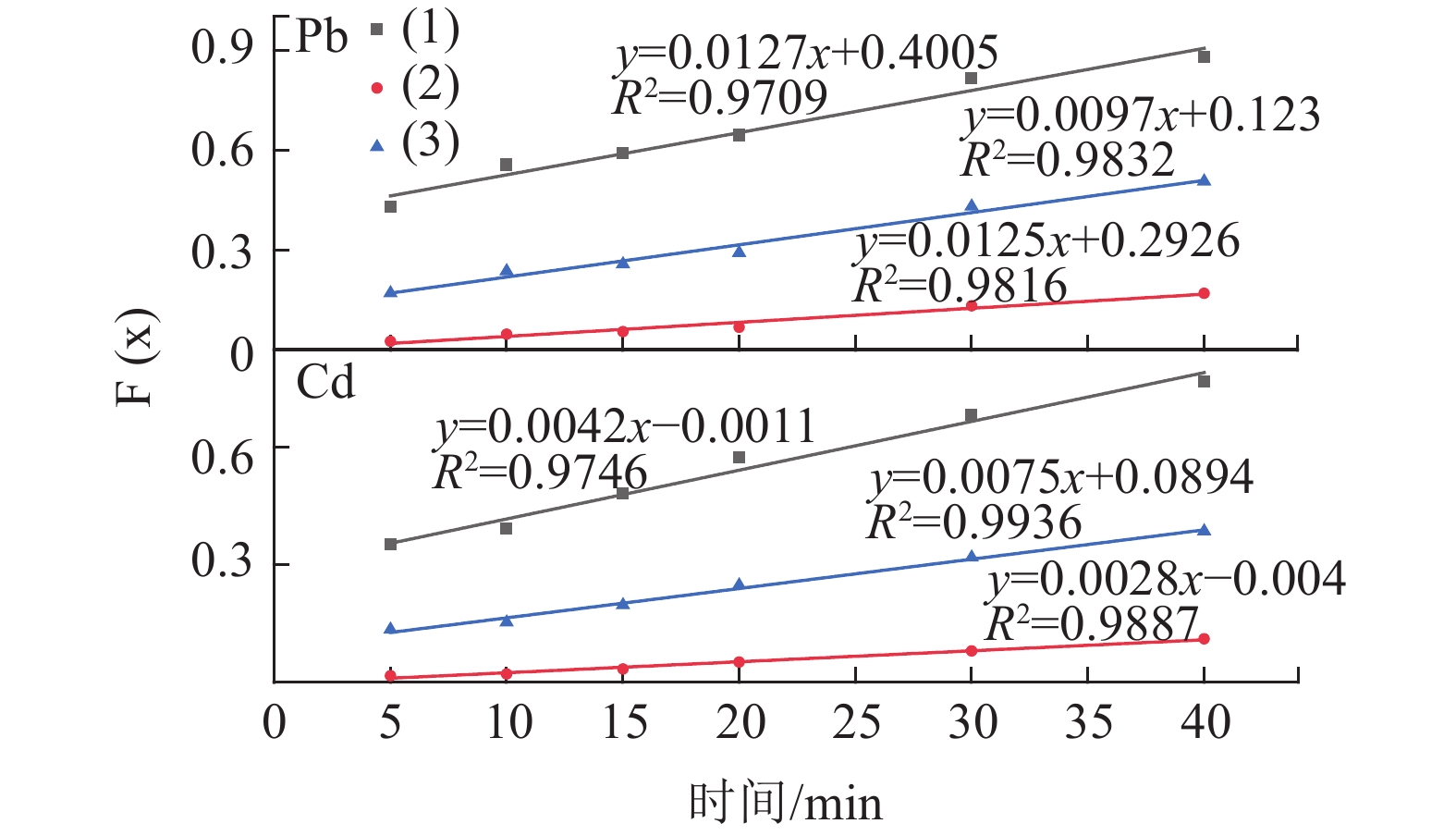

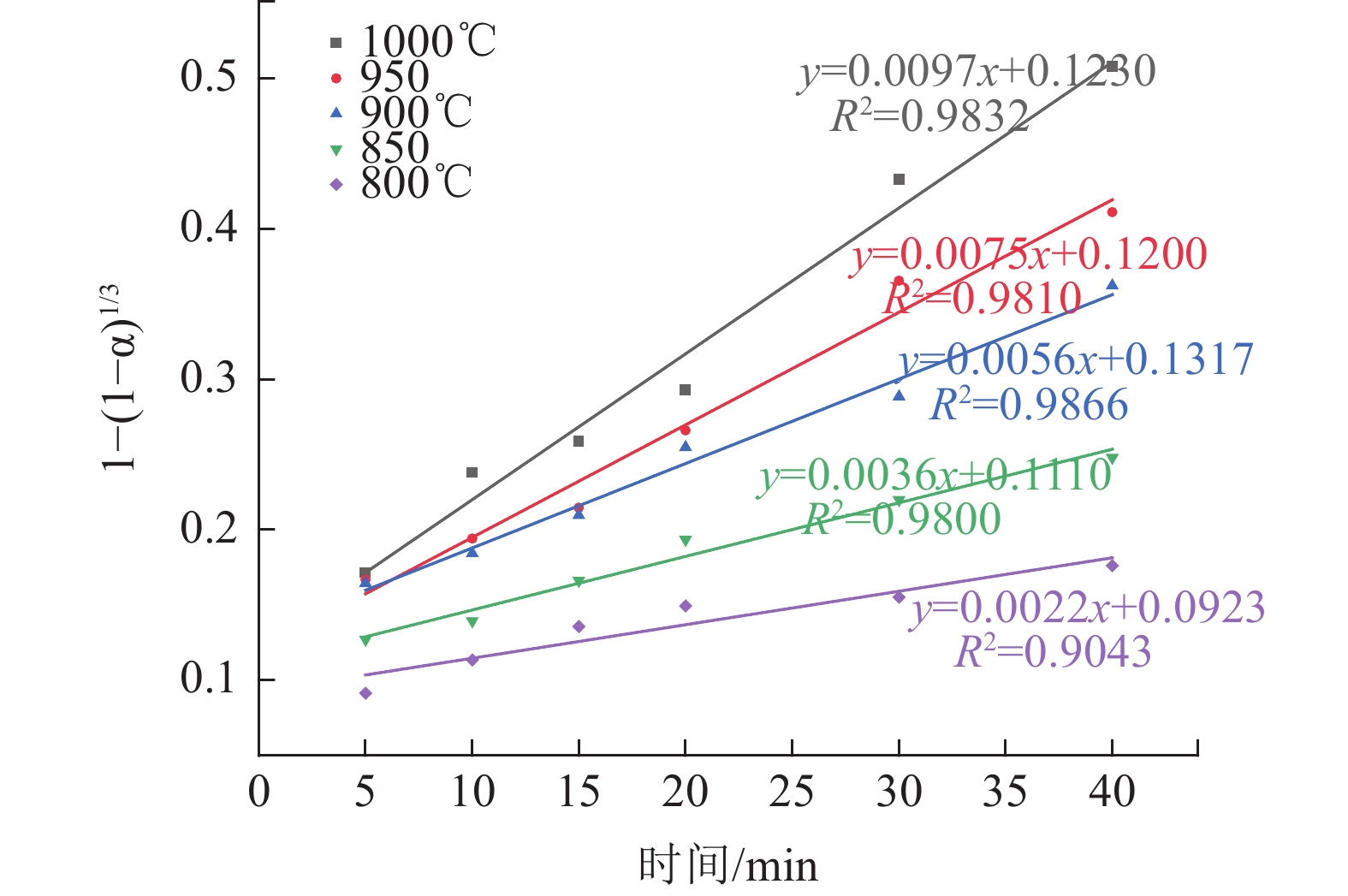

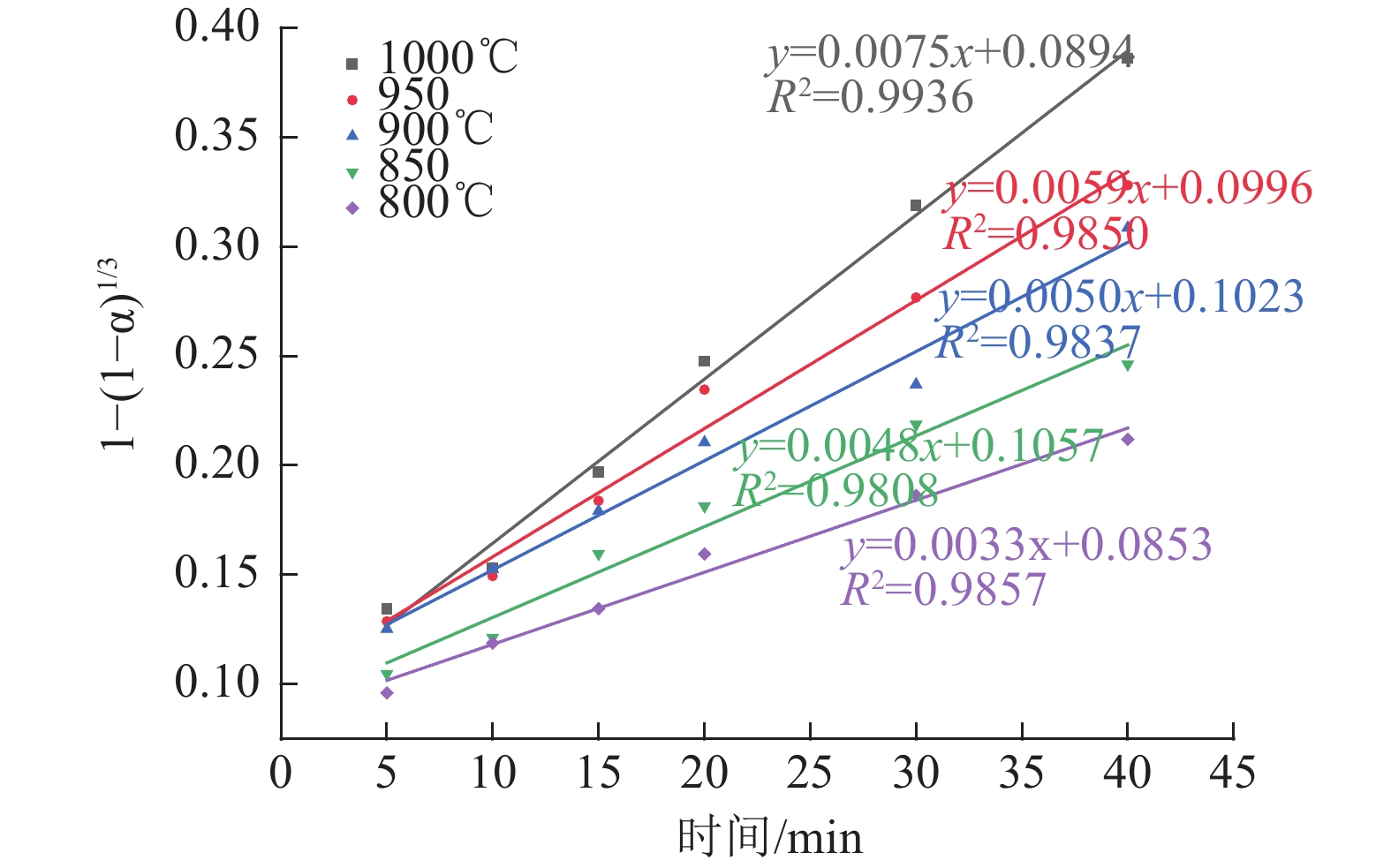

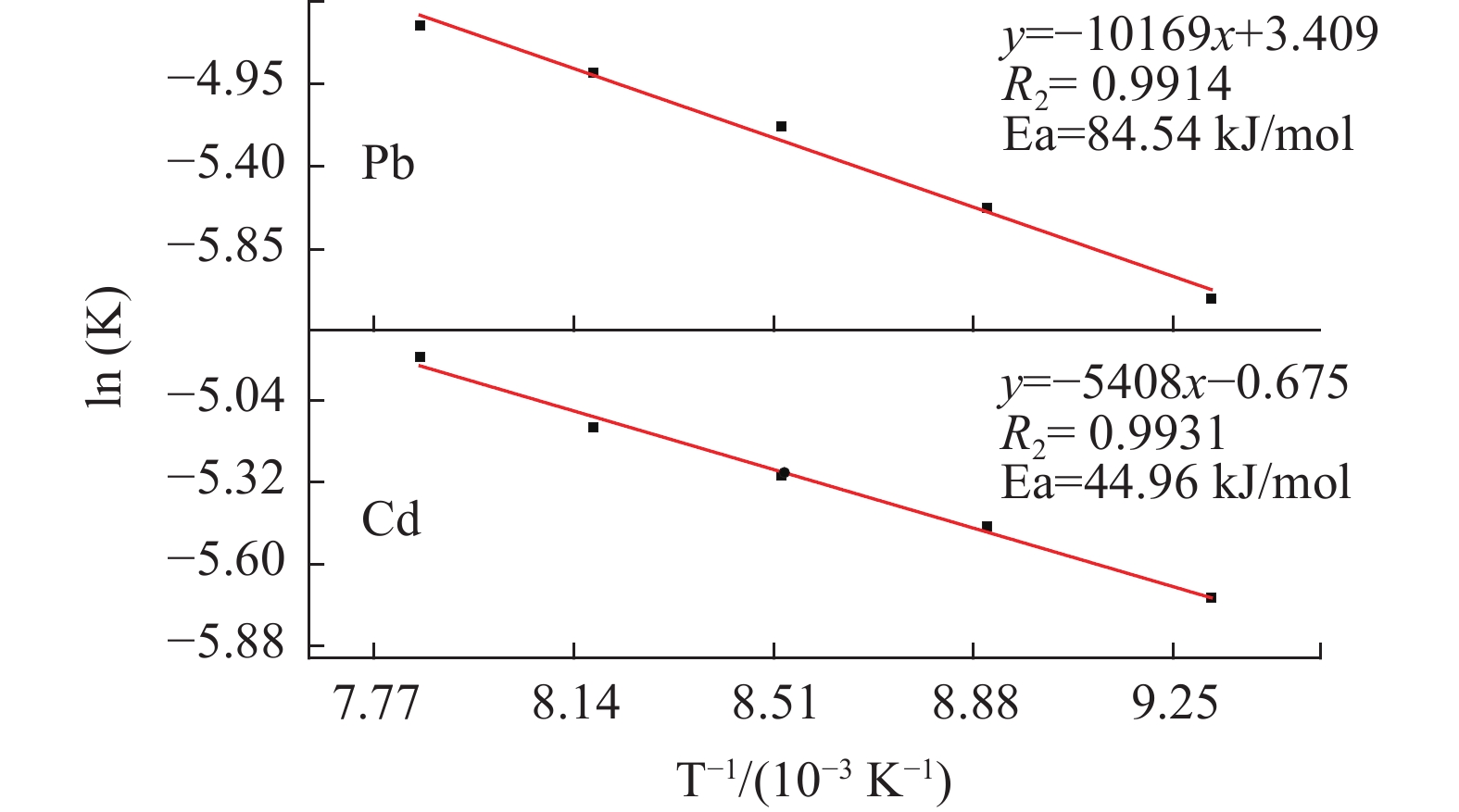

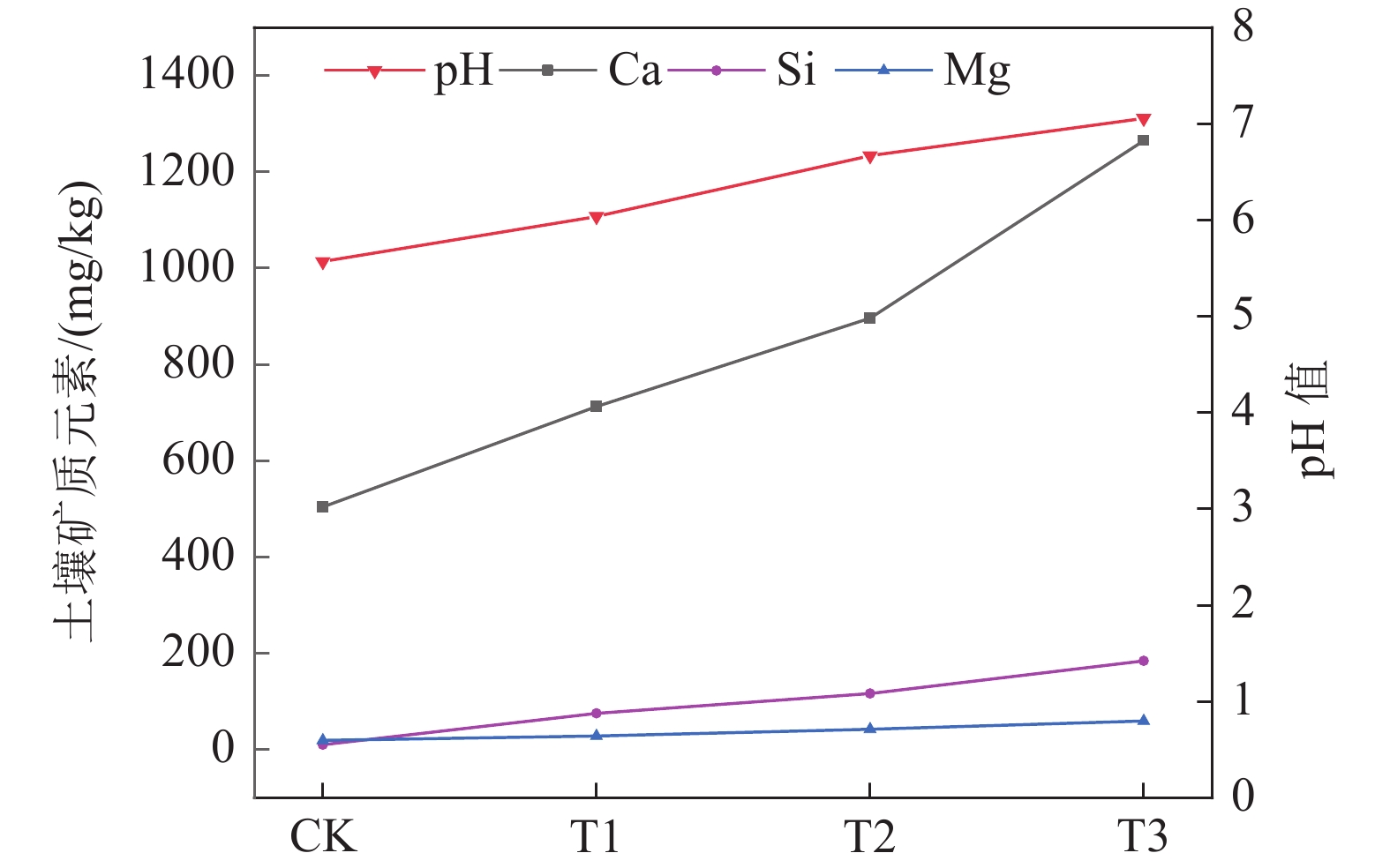

这是一篇冶金工程领域的论文。采用氯化钙作为氯化剂,对粉煤灰中重金属进行了脱除实验。考查了焙烧温度、焙烧时间和CaCl2添加量对重金属去除率的影响。将实验结果与热力学计算结果相结合,阐明了粉煤灰氯化焙烧脱除重金属的机理,并对焙烧过程的动力学模型进行了讨论。此外,以粉煤灰为原料制备土壤调理剂,通过盆栽实验研究其肥效。研究发现,添加16%氯化钙和高温锻烧40 min后,混合物中 Pb和 Cd的含量分别下降了89.26%和76.88%,而余量仅为10.22 g/t和0.54 g/t。粉煤灰中含有的石英、莫来石、氧化铝、氧化钠等组分促进CaCl2的分解。PbO和CdO不直接与CaCl2反应,而是主要与CaCl2分解生成的HCl反应生成挥发性氯化物。动力学结果表明,Pb和Cd的氯化挥分行为受界面化学反应控制,Pb氯化挥发的表观活化能为84.54 kJ/mol,Cd氯化挥发的表观活化能为44.96 kJ/mol。盆栽实验表明,制备的土壤调理剂能改善土壤环境,促进香葱对营养物质的吸收,改善香葱品质,添加CaCl2能降低产品中的重金属含量,提高有效钙含量。研究提供了一种综合利用粉煤灰的方法。

Abstract:This is an essay in the field of metallurgical engineering. Calcium chloride was used as chlorination agent to conduct the heavy metals removal experiments for coal fly ash, investigating the effects of calcination temperature, calcination time and amount of CaCl2 on the removal rate of heavy metals. The results of calcination experiments and thermodynamic calculation demonstrate the mechanism of heavy metals removal in fly ash by using chlorinating volatilization method; further, the kinetic model of chlorinating process was discussed. Moreover, the coal fly ash, as raw material, was used to produce soil conditioner which was studied to discover its fertilizing effect by pot experiments. Studies found that the remaining contents of Pb and Cd in mixture were 10.22 g/t and 0.54 g/t, respectively, which meant 89.26% of Pb and 76.88% of Cd were decreased after addition of CaCl2 at high calcination temperature for 40 min. The mineral of mullite, quartz, alumina and disodium oxide in fly ash contributed to the decomposition of CaCl2. PbO and CdO mainly reacted with HCl formed by the decomposition of CaCl2 to form volatile chloride, meaning the oxides do not directly react with CaCl2. thermodynamic models fitting implied that the chlorination of Pb and Cd were controlled by the chemical reaction, and the apparent activation energy of reactions was 84.54 and 44.96 kJ/mol, respectively. Further, the pot experiments showed that the synthesized soil conditioner can improve the condition of the soil, promote nutrient absorption of chives, and improve the quality of chives. The effective calcium content of soil conditional product was increased after the reduction of heavy metals by adding CaCl2. This research provides a method for comprehensive utilization of fly ash.

-

-

表 1 粉煤灰样品的主要成分/%

Table 1. Chemical components of the CFA sample

SiO2 Al2O3 Fe2O3 CaO MgO K2O TiO2 Na2O SO3 As* Cd* Cr* Hg* Pb* 51.17 31.12 6.17 4.81 1.76 1.38 1.29 1.11 0.31 41.2 2.8 76.9 3.0 112.0 *单位为g/t 表 2 CaCl2对土壤调理剂有效硅、有效钙的影响

Table 2. Effect of CaCl2 on the content of the effective silicon content and the effective calcium in soil conditioner

CaCl2 加入量/ % 有效硅/% 有效钙 /% 0 18.78 28.07 4 19.02 29.25 8 19.26 29.49 12 19.34 30.86 16 19.42 31.48 20 18.99 31.80 表 3 土壤调理剂的主要成分/%

Table 3. Main components of the soil conditioners

SiO2 Al2O3 Fe2O3 CaO MgO K2O 29.77 9.98 2.03 33.65 7.78 4.52 表 4 CaCl2对土壤调理剂中重金属全量的影响

Table 4. Effect of the CaCl2 on the content of heavy metals in soil conditioners

CaCl2 加入量 /% Pb /

(g/t)Cd /

(g/t)As /

(g/t)Hg /

(g/t)Cr /

(g/t)0 41.20 0.85 13.05 0.91 23.03 4 12.72 0.55 10.65 0.90 19.15 8 11.45 0.48 9.16 0.89 18.87 12 11.06 0.41 9.02 0.88 18.56 16 9.85 0.30 8.58 0.87 18.25 20 10.17 0.32 8.82 0.86 18.22 水平(GB/T 23349-2009) 200 10 50 5 500 表 5 土壤调理剂对香葱株高和产量的影响

Table 5. Effect of soil conditioners on plant height and yield of chives

植被高度 /cm 产量 /g 产率 /% CK 25.08 98.76 - T1 26.57 125.98 27.56 T2 28.15 144.34 46.15 T3 29.31 159.54 61.54 -

[1] Yao Z T, Xia M S, Sarker P K, et al. A review of the alumina recovery from coal fly ash, with a focus in China[J]. Fuel. 2014, 120: 74-85.

[2] 于成龙, 熊楠, 宋杰, 等. 近20 年来中国利用粉煤灰合成分子筛研究进展[J]. 矿产综合利用, 2020(4):26-35. YU C L, XIONG N, SONG J, et al. Development of molecular sieves composition from fly ash in China in the last two decades[J]. Multipurpose Utilization of Mineral Resources, 2020(4):26-35. doi: 10.3969/j.issn.1000-6532.2020.04.005

YU C L, XIONG N, SONG J, et al. Development of molecular sieves composition from fly ash in China in the last two decades [J]. Multipurpose Utilization of Mineral Resources, 2020(4): 26-35. doi: 10.3969/j.issn.1000-6532.2020.04.005

[3] 王建新, 李晶, 赵仕宝, 等. 中国粉煤灰的资源化利用研究进展与前景[J]. 硅酸盐通报, 2018, 37(12):3833-3841. WANG J X, LI J, ZHAO S B, et al. Research progress and prospects of resource utilization of fly ash in China[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(12):3833-3841. doi: 10.16552/j.cnki.issn1001-1625.2018.12.020

WANG J X, LI J, ZHAO S B, et al. Research progress and prospects of resource utilization of fly ash in China[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(12): 3833-3841. doi: 10.16552/j.cnki.issn1001-1625.2018.12.020

[4] Luo Y, Wu Y, Ma S, et al. Utilization of coal fly ash in China: a mini-review on challenges and future directions[J]. Environmental Science and Pollution Research. 2020.

[5] Gollakota A R K, Volli V, Shu C. Progressive utilisation prospects of coal fly ash: A review[J]. Science of The Total Environment, 2019, 672:951-989. doi: 10.1016/j.scitotenv.2019.03.337

[6] 王丽萍, 李超. 粉煤灰资源化技术开发与利用研究进展[J]. 矿产保护与利用, 2019, 39(4):38-45. WANG L P, LI C. Research progress in the development and utilization of fly ash resource technology[J]. Conservation and Utilization of Mineral Resources, 2019, 39(4):38-45. doi: 10.13779/j.cnki.issn1001-0076.2019.04.007

WANG L P, LI C. Research progress in the development and utilization of fly ash resource technology[J]. Conservation and Utilization of Mineral Resources, 2019, 39(4): 38-45. doi: 10.13779/j.cnki.issn1001-0076.2019.04.007

[7] Lima A T, Ribeiro A B, Rodríguez-Maroto J M, et al. Experimental and modeling of the electrodialytic and dialytic treatment of a fly ash containing Cd, Cu and Pb[J]. Journal of Applied Electrochemistry, 2010, 40(9):1689-1697. doi: 10.1007/s10800-010-0166-y

[8] Pangayao D, Gallardo S. Leaching of chromium from coal ash using citric acid, oxalic acid and gluconic acid by batch leaching procedure[C]. IEEE, 2014.

[9] Kurashima K, Matsuda K, Kumagai S, et al. A combined kinetic and thermodynamic approach for interpreting the complex interactions during chloride volatilization of heavy metals in municipal solid waste fly ash[J]. Waste Management, 2019, 87:204-217. doi: 10.1016/j.wasman.2019.02.007

[10] 韦琳, 吕晓蕾, 刘阳生, 等. CaCl2高温热处理垃圾焚烧飞灰中重金属的挥发特性[J]. 环境工程学报, 2013, 7(11):4533-4539. WEI L, LYU X L, LIU Y S, et al. Volatilization characteristics of heavy metals in fly ash from waste incineration with high temperature heat treatment of CaCl2[J]. Chinese Journal of Environmental Engineering, 2013, 7(11):4533-4539.

WEI L, LV X L, LIU Y S, et al. Volatilization characteristics of heavy metals in fly ash from waste incineration with high temperature heat treatment of CaCl2[J]. Chinese Journal of Environmental Engineering, 2013, 7(11): 4533-4539.

[11] Xing Z, Cheng G, Yang H, et al. Mechanism and application of the ore with chlorination treatment: A review[J]. Minerals Engineering, 2020, 154:106404. doi: 10.1016/j.mineng.2020.106404

[12] Fraissler G, Jöller M, Mattenberger H, et al. Thermodynamic equilibrium calculations concerning the removal of heavy metals from sewage sludge ash by chlorination[J]. Chemical Engineering and Processing:Process Intensification, 2009, 48(1):152-164. doi: 10.1016/j.cep.2008.03.009

[13] 刘洋, 张春霞. 水淬高炉渣制备硅肥的研究[J]. 矿产综合利用, 2019(5):116-120. LIU Y, ZHANG C X. Study on preparation of silicon fertilizer from water -quenched blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(5):116-120. doi: 10.3969/j.issn.1000-6532.2019.05.025

LIU Y, ZHANG C X. Study on preparation of silicon fertilizer from water -quenched blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(5): 116-120. doi: 10.3969/j.issn.1000-6532.2019.05.025

[14] 石林, 张华夏. 一种利用粉煤灰生产中微量元素酸性土壤调理剂的方法与产品, 201811083790.9[P]. 2019.02. 22.

SHI L, ZHANG H X. A method and product for producing acidic soil conditioner with trace elements in fly ash, 201811083790.9[P]. 2019.02. 22.

[15] 梁振凯, 雷雪飞, 孙应龙, 等. 氯化钙焙烧法提取粉煤灰中的氧化铝[J]. 中国环境科学, 2013, 33(9):1601-1606. LIANG Z K, LEI X F, SUN Y L, et al. Extraction of alumina from fly ash by calcium chloride roasting method[J]. China Environmental Science, 2013, 33(9):1601-1606.

LIANG Z K, LEI X F, SUN Y L, et al. Extraction of alumina from fly ash by calcium chloride roasting method[J]. China Environmental Science, 2013, 33(9): 1601-1606.

[16] 叶标, 郁青春, 邓攀, 等. 粉煤灰与氯化钙焙烧提取氧化铝的动力学[J]. 有色金属工程, 2019, 9(6):36-42. YE B, YU Q C, DENG P, et al. Kinetics of extraction of alumina by roasting fly ash and calcium chloride[J]. Nonferrous Metal Engineering, 2019, 9(6):36-42. doi: 10.3969/j.issn.2095-1744.2019.06.007

YE B, YU Q C, DENG P, et al. Kinetics of extraction of alumina by roasting fly ash and calcium chloride[J]. Nonferrous Metal Engineering, 2019, 9(6): 36-42. doi: 10.3969/j.issn.2095-1744.2019.06.007

[17] Nowak B, Frías Rocha S, Aschenbrenner P, et al. Heavy metal removal from MSW fly ash by means of chlorination and thermal treatment: influence of the chloride type[J]. Chemical Engineering Journal, 2012, 179:178-185. doi: 10.1016/j.cej.2011.10.077

[18] 曾萍, 唐朝波, 唐雷, 等. Na2CO3-NaCl-C-PbSO4-CuO体系热力学分析及应用研究[J]. 有色金属(冶炼部分), 2016(12):1-4. ZENG P, TANG C B, TANG L, et al. Thermodynamic analysis and application research of Na2CO3-NaCl-C-PbSO4-CuO system[J]. Nonferrous Metals (Extractive Metallurgy), 2016(12):1-4.

ZENG P, TANG C B, TANG L, et al. Thermodynamic analysis and application research of Na2CO3-NaCl-C-PbSO4-CuO system[J]. Nonferrous Metals (Extractive Metallurgy), 2016(12): 1-4. .

[19] 朱潇, 石林, 何柳青. 粉煤灰提铝渣对土壤养分及芹菜生长与品质的影响[J]. 西北师范大学学报(自然科学版), 2019, 55(3):98-104. ZHU X, SHI L, HE L Q. Effect of fly ash aluminum slag on soil nutrients and celery growth and quality[J]. Journal of Northwest Normal University (Natural Science Edition), 2019, 55(3):98-104. doi: 10.16783/j.cnki.nwnuz.2019.03.017

ZHU X, SHI L, HE L Q. Effect of fly ash aluminum slag on soil nutrients and celery growth and quality[J]. Journal of Northwest Normal University (Natural Science Edition), 2019, 55(3): 98-104. doi: 10.16783/j.cnki.nwnuz.2019.03.017

[20] 冀文文, 李静一, 尚中博, 等. 生物灰综合利用的研究进展[J]. 河南大学学报(自然科学版), 2017, 47(4):453-463. JI W W, LI J Y, SHANG Z B, et al. Research progress on comprehensive utilization of biological ash[J]. Journal of Henan University (Natural Science Edition), 2017, 47(4):453-463. doi: 10.15991/j.cnki.411100.2017.04.007

JI W W, LI J Y, SHANG Z B, et al. Research progress on comprehensive utilization of biological ash[J]. Journal of Henan University (Natural Science Edition), 2017, 47(4): 453-463. doi: 10.15991/j.cnki.411100.2017.04.007

-

下载:

下载: