Effect of Iron Tailings with Different Content on the Properties of 3D Printing Concrete Cementitious Materials

-

摘要:

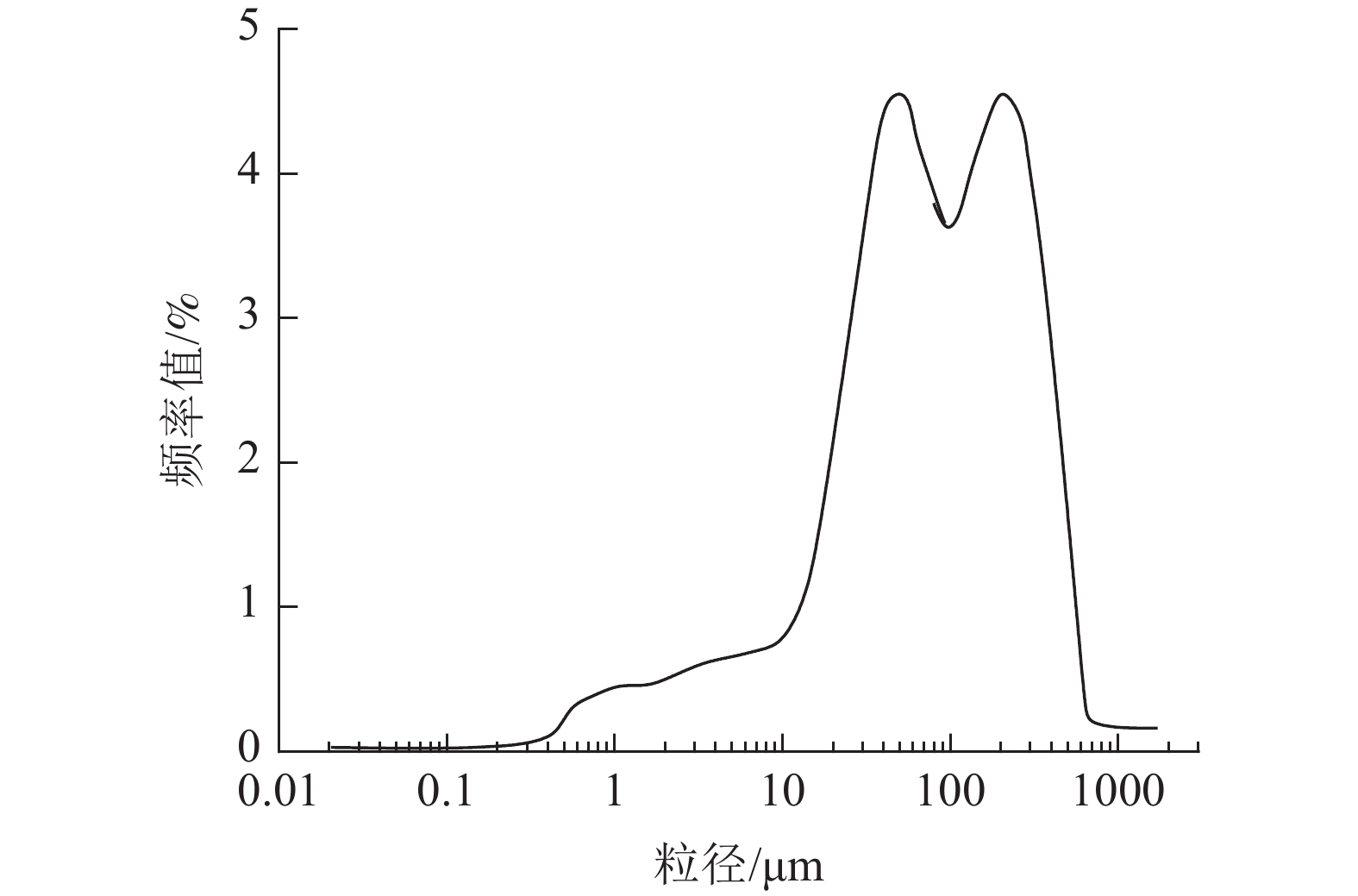

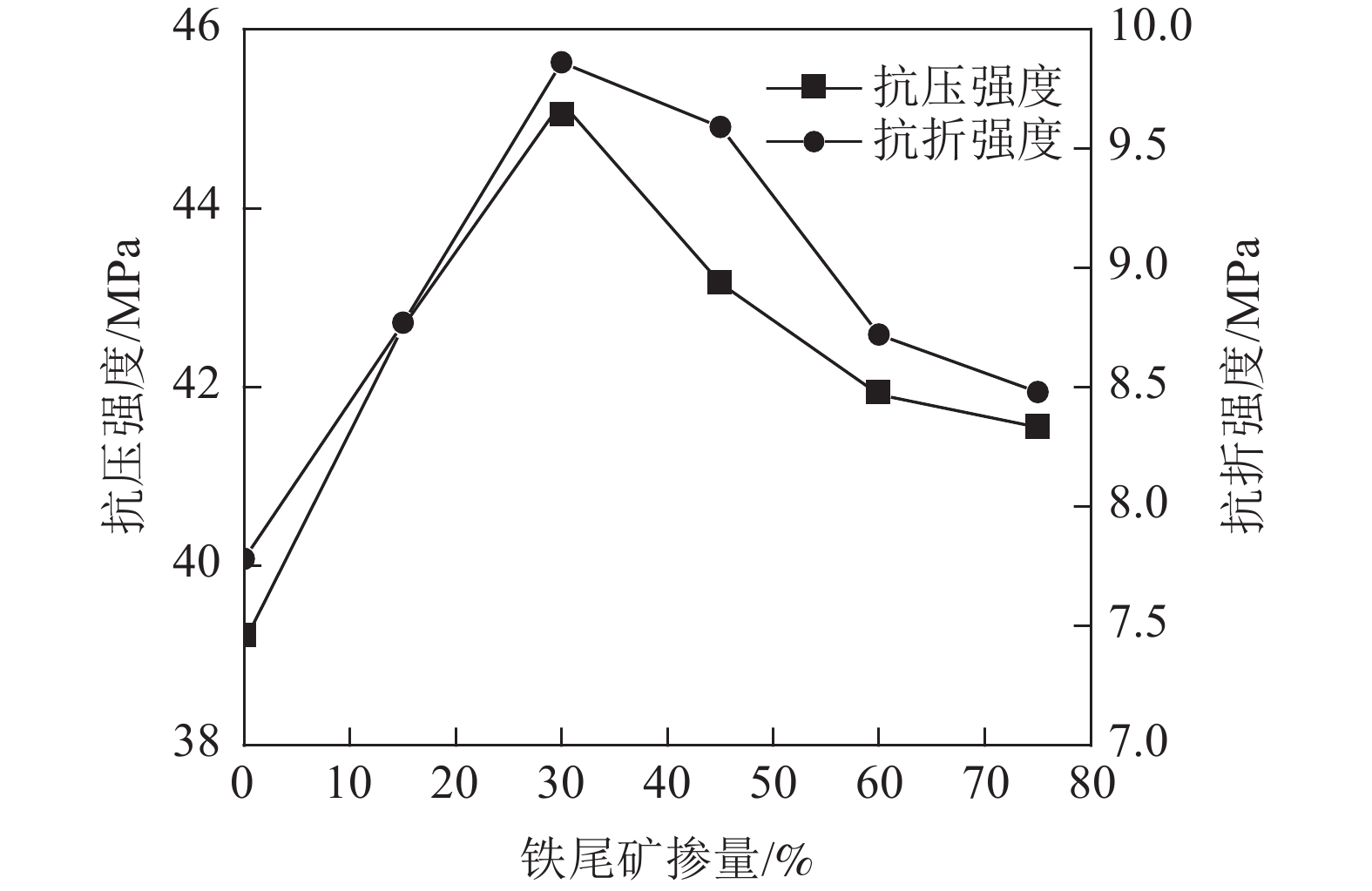

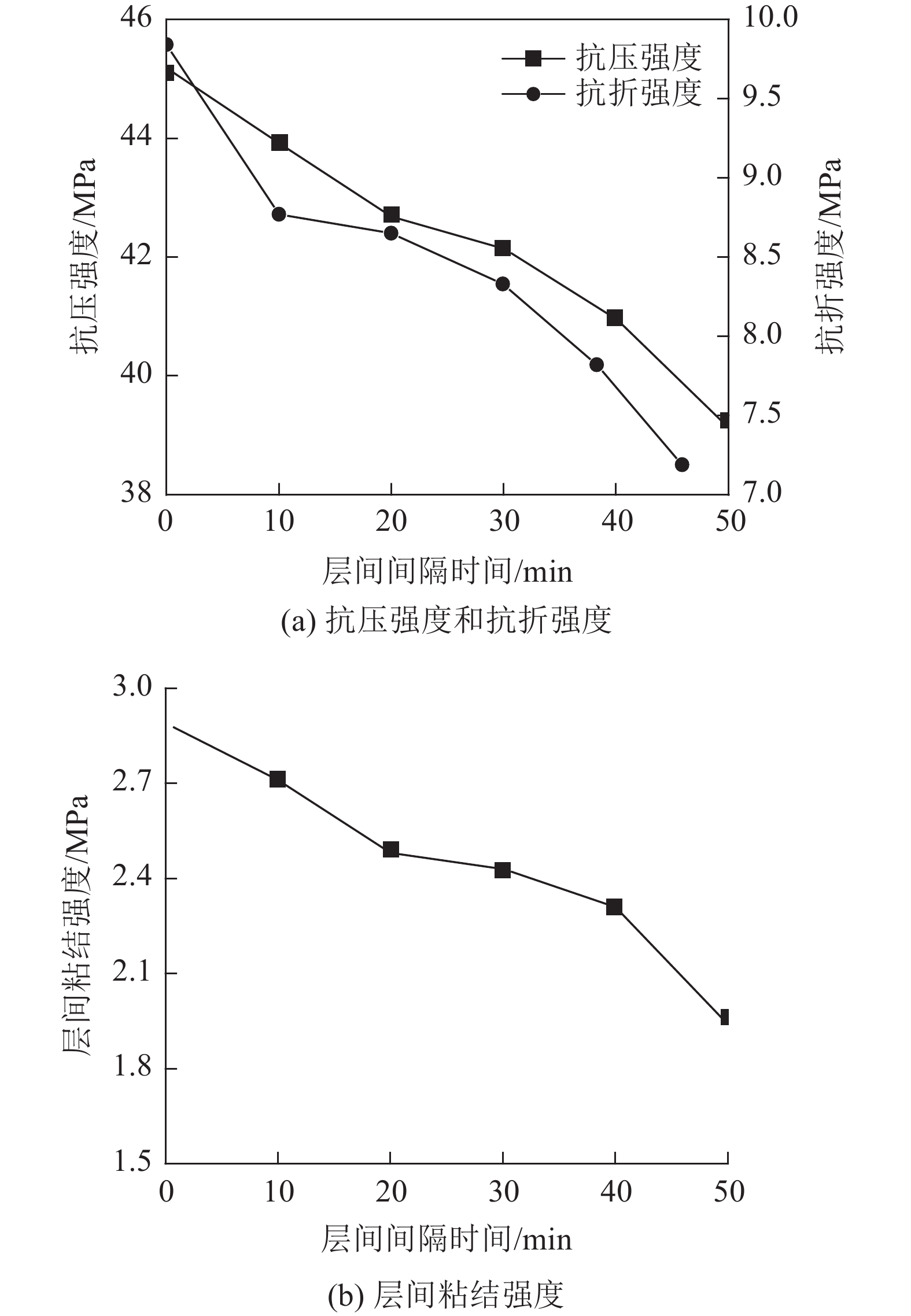

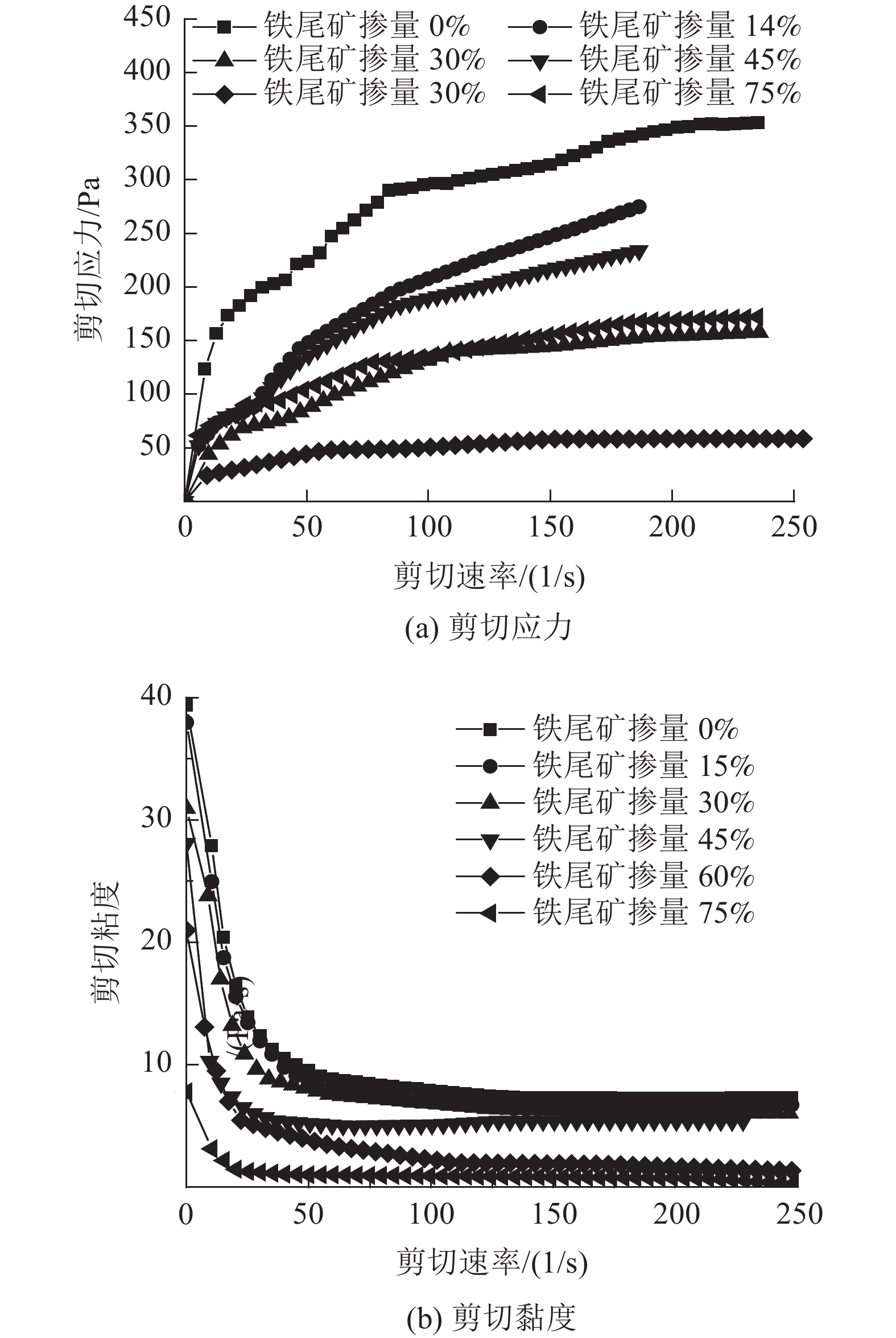

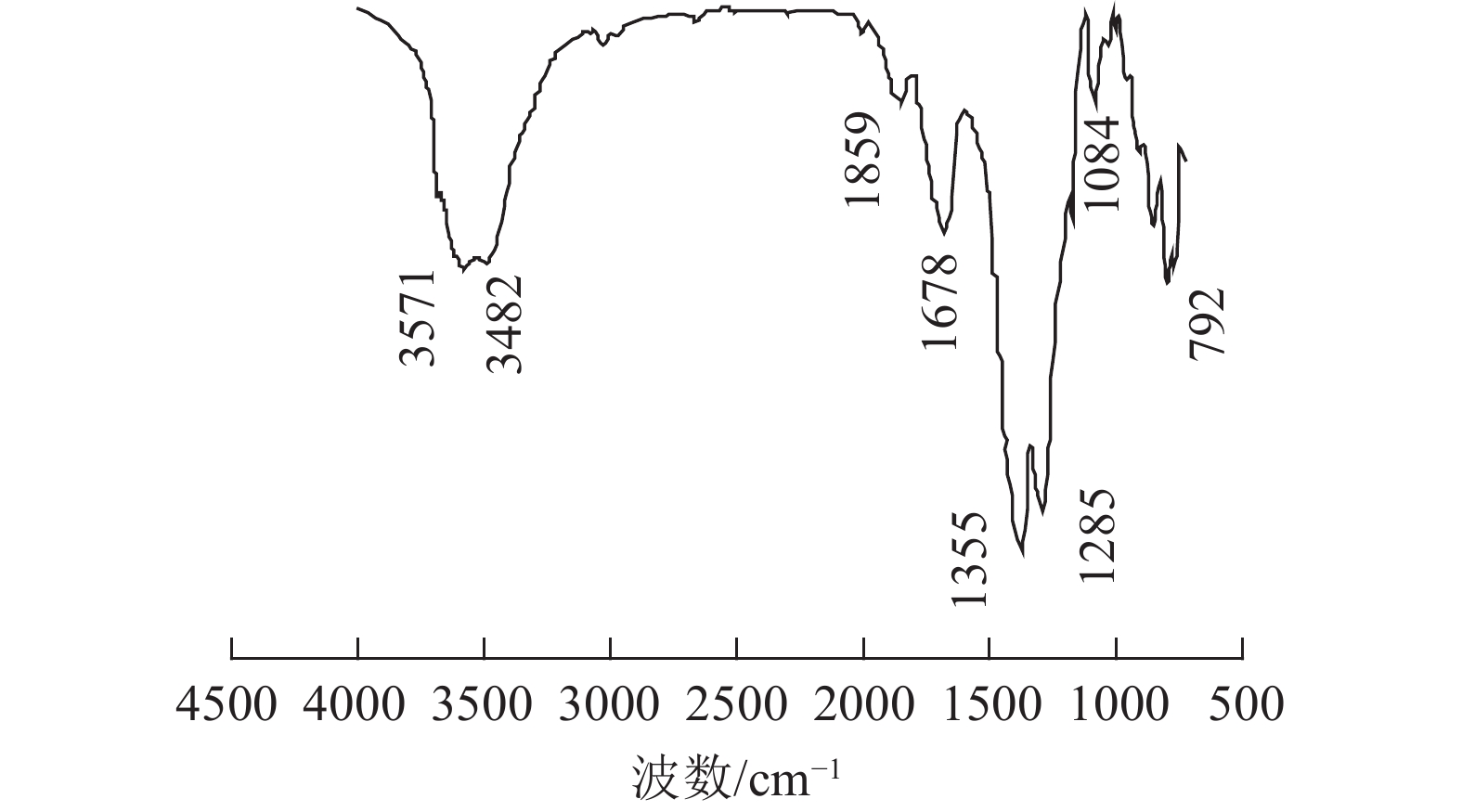

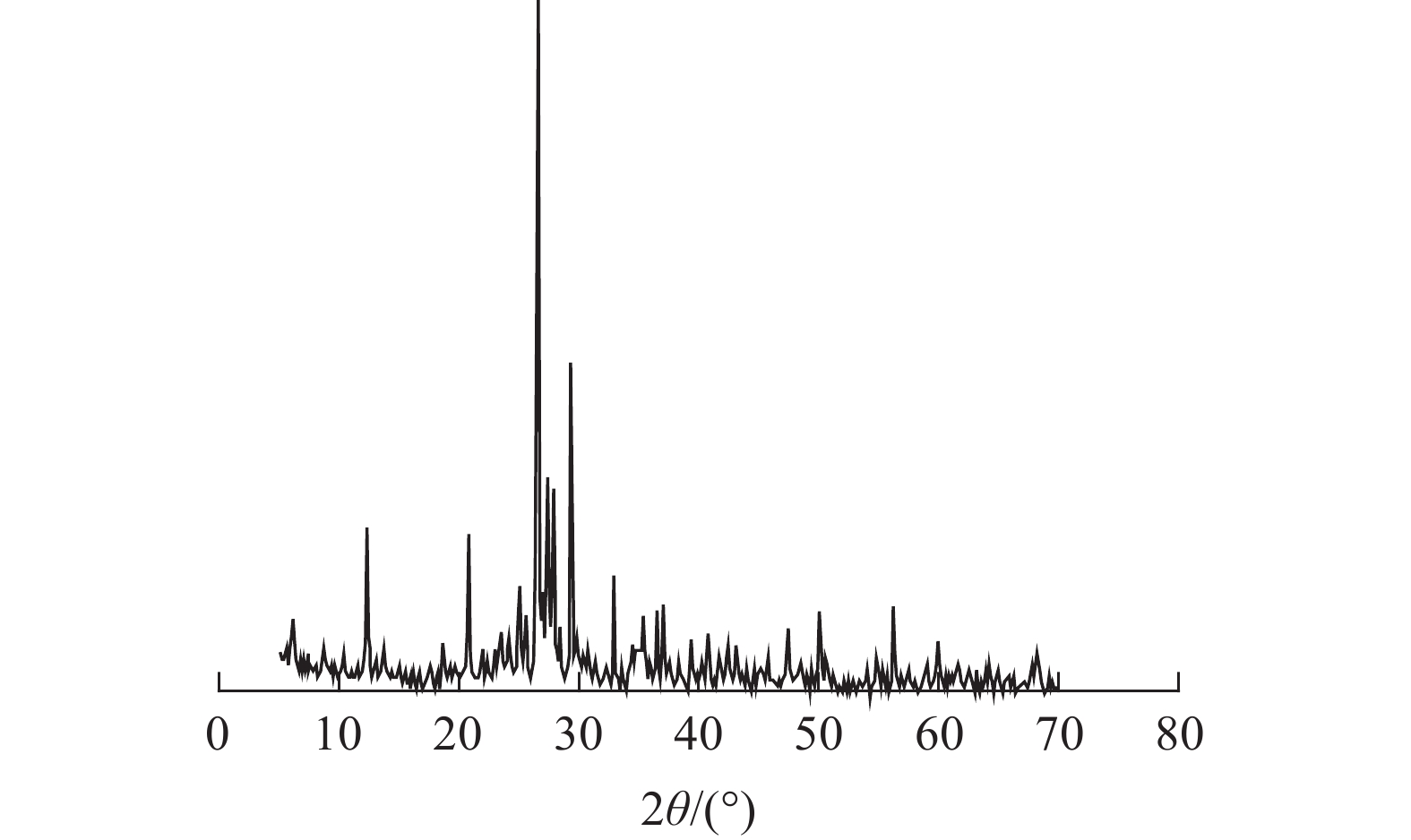

这是一篇陶瓷及复合材料领域的论文。本文研究了掺铁尾矿3D打印胶凝材料的力学性能、流变性和微观结构性能,结果表明:尾矿的粒径较小,可以作为3D打印材料的骨料,在3D打印过程中可以顺利通过输送胶凝材料的管道。随着铁尾矿掺量的不断增大,3D打印胶凝材料的剪切黏度的变化规律呈现出先减小后稳定的趋势,剪切应力的变化规律却呈现出不断增大的趋势,随着层间间隔时间不断增大,3D打印胶凝材料的抗压强度和抗折强度均呈现下降的变化趋势,但是在层间间隔时间在20~30 min之间时,抗压强度和抗折强度下降幅度较为平缓;随着层间间隔时间不断增大,3D打印胶凝材料的层间粘结强度均呈现下降的变化趋势。铁尾矿掺量为30%的3D打印胶凝材料在水化90 d后,经过XRD衍射实验得到胶凝材料的物质成分主要有石英、钙矾石、方解石、钠长石、钙钛矿、Ca2SiO4和水化硅酸钙等七种物质。

Abstract:This is an article in the field of ceramics and composites. Rheology and microstructure properties of iron-doped tailings 3D printing cementitious materials were studied in this paper. The results show that the particle size of tailings is small and can be used as aggregates for 3D printing materials. In the 3D printing process, it can smoothly pass through the pipeline for conveying the cementitious material. As the content of iron tailings continues to increase, the shear viscosity of 3D printing cementitious materials shows a trend that first decreases and then stabilizes in the region. However, the changing law of shear stress shows an increasing trend as the interval between layers increases. The compressive strength and flexural strength of 3D printing cementitious materials both show a decreasing trend. When the interval between layers is in between 20~30 min, the compressive strength and flexural strength decrease more slowly. As the interval between layers continues to increase, the interlayer bonding strength of 3D printing cementitious materials shows a decreasing trend. The 3D printing cementitious material with 30% iron tailings content is hydrated for 90 days after XRD diffraction test. The main material components of the cementitious material are quartz, ettringite, calcite, albite, perovskite, Ca2SiO4 and seven substances such as calcium silicate hydrate.

-

-

表 1 铁尾矿的化学成分/%

Table 1. Chemical composition of iron tailings

SiO2 Al2O3 CaO Fe2O3 MgO K2O TiO2 Na2O 其他氧化物 51.25 15.23 12.36 10.58 4.98 2.74 0.71 0.68 1.47 -

[1] 曾兴华, 黄高明, 吴炎平, 等. 铜尾矿硅质原料在蒸压加气混凝土砌块中应用技术研究[J]. 新型建筑材料, 2021, 48(5):146-148.ZENG X H, HUANG G M, WU Y P, et al. Research on application technology of copper tailings siliceous materials in autoclaved aerated concrete blocks[J]. New Building Materials, 2021, 48(5):146-148.

ZENG X H, HUANG G M, WU Y P, et al. Research on application technology of copper tailings siliceous materials in autoclaved aerated concrete blocks[J]. New Building Materials, 2021, 48(5):146-148.

[2] 刘竞怡, 孙志华, 温久然, 等. 金尾矿砂作为混凝土集料的物化性质及其改性实验[J]. 金属矿山, 2021(5):211-220.LIU J Y, SUN Z H, WEN J R, et al. The physical and chemical properties of gold tailings as concrete aggregate and its modification test[J]. Metal Mine, 2021(5):211-220.

LIU J Y, SUN Z H, WEN J R, et al. The physical and chemical properties of gold tailings as concrete aggregate and its modification test[J]. Metal Mine, 2021(5):211-220.

[3] 宁波, 闫艳, 左夏伟, 等. 铁尾矿砂混凝土力学特性实验研究[J]. 矿产综合利用, 2021(4):159-164.NING B, YAN Y, ZUO X W, et al. Experimental study on mechanical properties of iron tailings concrete[J]. Multipurpose Utilization of Mineral Resources, 2021(4):159-164.

NING B, YAN Y, ZUO X W, et al. Experimental study on mechanical properties of iron tailings concrete[J]. Multipurpose Utilization of Mineral Resources, 2021(4):159-164.

[4] 孙强强, 李兆, 韩茜, 等. 低硅铁尾矿微晶泡沫玻璃的耐酸碱性研究[J]. 矿产综合利用, 2021(6):40-46.SUN Q Q, LI Z, HAN Q, et al. Research on acid and alkali resistance of foam glass-ceramics from low-silicon iron ore tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(6):40-46.

SUN Q Q, LI Z, HAN Q, et al. Research on acid and alkali resistance of foam glass-ceramics from low-silicon iron ore tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(6):40-46.

[5] 冯卡, 王馨语. 硫铁矿尾矿矿渣改良混凝土力学性质与耐久性[J]. 矿产综合利用, 2022(3):6-11.FENG K, WANG X Y. Research on mechanical properties and durability of concrete improved by pyrite tailings and slag[J]. Multipurpose Utilization of Mineral Resources, 2022(3):6-11.

FENG K, WANG X Y. Research on mechanical properties and durability of concrete improved by pyrite tailings and slag[J]. Multipurpose Utilization of Mineral Resources, 2022(3):6-11.

[6] 尤帆, 耿向. 筛分法和激光粒度法联合测定陆源碎屑岩粒度[J]. 计量学报, 2021, 42(3):380-387.YOU F, GENG X. Combination of sieving method and laser particle size method to determine the grain size of terrigenous clastic rocks[J]. Acta Metrology, 2021, 42(3):380-387.

YOU F, GENG X. Combination of sieving method and laser particle size method to determine the grain size of terrigenous clastic rocks[J]. Acta Metrology, 2021, 42(3):380-387.

[7] 杨钱荣, 赵宗志, 肖建庄, 等. 矿物掺合料与化学外加剂对3D打印砂浆性能的影响[J]. 建筑材料学报, 2021, 24(2):412-418.YANG Q R, ZAO Z Z, XIAO J Z, et al. The influence of mineral admixtures and chemical admixtures on the properties of 3D printing mortar[J]. Journal of Building Materials, 2021, 24(2):412-418.

YANG Q R, ZAO Z Z, XIAO J Z, et al. The influence of mineral admixtures and chemical admixtures on the properties of 3D printing mortar[J]. Journal of Building Materials, 2021, 24(2):412-418.

[8] 施佳楠, 雷文. 打印温度对3D打印用黄芪药渣/聚乳酸材料性能的影响[J]. 塑料工业, 2021, 49(3):69-73.SHI J N, LEI W. The effect of printing temperature on the properties of Astragalus medicinal residue/polylactic acid material for 3D printing[J]. Plastic Industry, 2021, 49(3):69-73.

SHI J N, LEI W. The effect of printing temperature on the properties of Astragalus medicinal residue/polylactic acid material for 3D printing[J]. Plastic Industry, 2021, 49(3):69-73.

[9] 田小永, 闫万权, 黄兰, 等. 石墨烯/柔性聚乳酸自传感复合材料结构3D打印与性能研究[J]. 机械工程学报, 2021, 57(7):215-223.TIAN X Y, YAN W Q, HUANG L, et al. 3D printing and properties of graphene/flexible polylactic acid self-sensing composite structure[J]. Chinese Journal of Mechanical Engineering, 2021, 57(7):215-223. doi: 10.3901/JME.2021.07.215

TIAN X Y, YAN W Q, HUANG L, et al. 3D printing and properties of graphene/flexible polylactic acid self-sensing composite structure[J]. Chinese Journal of Mechanical Engineering, 2021, 57(7):215-223. doi: 10.3901/JME.2021.07.215

[10] 武雷, 孙远, 杨威, 等. 3D打印混凝土层间黏结强度增强技术及实验研究[J]. 混凝土与水泥制品, 2020(7):1-6.WU L, SUN Y, YANG W, et al. 3D printing concrete interlayer bonding strength enhancement technology and experimental research[J]. Concrete and Cement Products, 2020(7):1-6.

WU L, SUN Y, YANG W, et al. 3D printing concrete interlayer bonding strength enhancement technology and experimental research[J]. Concrete and Cement Products, 2020(7):1-6.

[11] 吴昊一, 蒋亚清, 潘亭宏, 等. 3D打印水泥基材料层间结合性能研究[J]. 新型建筑材料, 2019, 46(12):5-8.WU H Y, JIANG Y Q, PAN T H, et al. Research on the interlayer bonding performance of 3D printing cement-based materials[J]. New Building Materials, 2019, 46(12):5-8.

WU H Y, JIANG Y Q, PAN T H, et al. Research on the interlayer bonding performance of 3D printing cement-based materials[J]. New Building Materials, 2019, 46(12):5-8.

[12] 陆文君, 孙君, 石世宏. 聚乳酸基木塑3D打印材料性能研究[J]. 合成技术及应用, 2018, 33(3):10-12.LU W J, SUN J, SHI S H. Study on properties of polylactic acid-based wood-plastic 3D printing materials[J]. Synthesis Technology and Application, 2018, 33(3):10-12.

LU W J, SUN J, SHI S H. Study on properties of polylactic acid-based wood-plastic 3D printing materials[J]. Synthesis Technology and Application, 2018, 33(3):10-12.

-

下载:

下载: