Experimental Study on DMS-flotation Technology of a Spodumene Mine from Xinjiang

-

摘要:

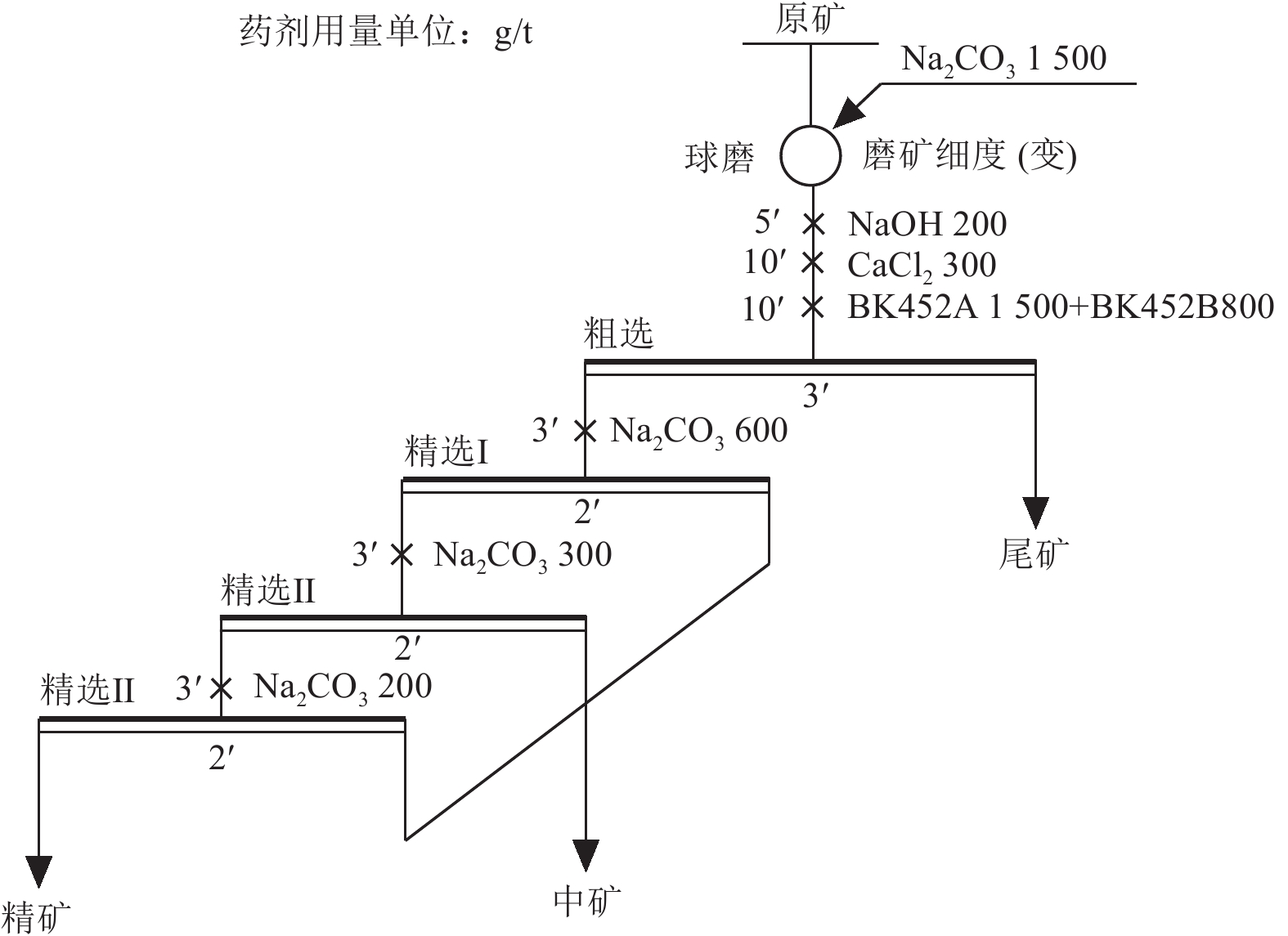

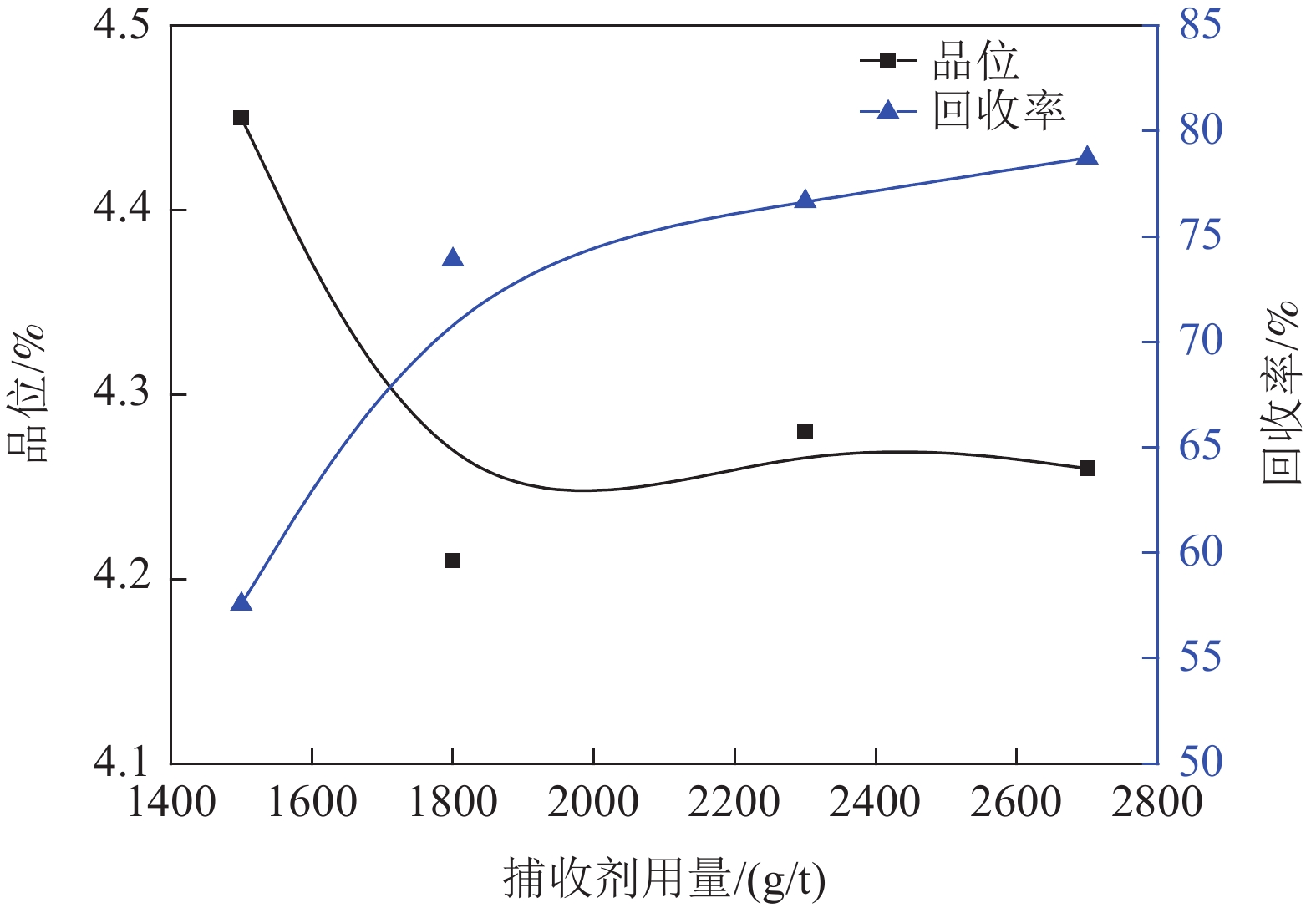

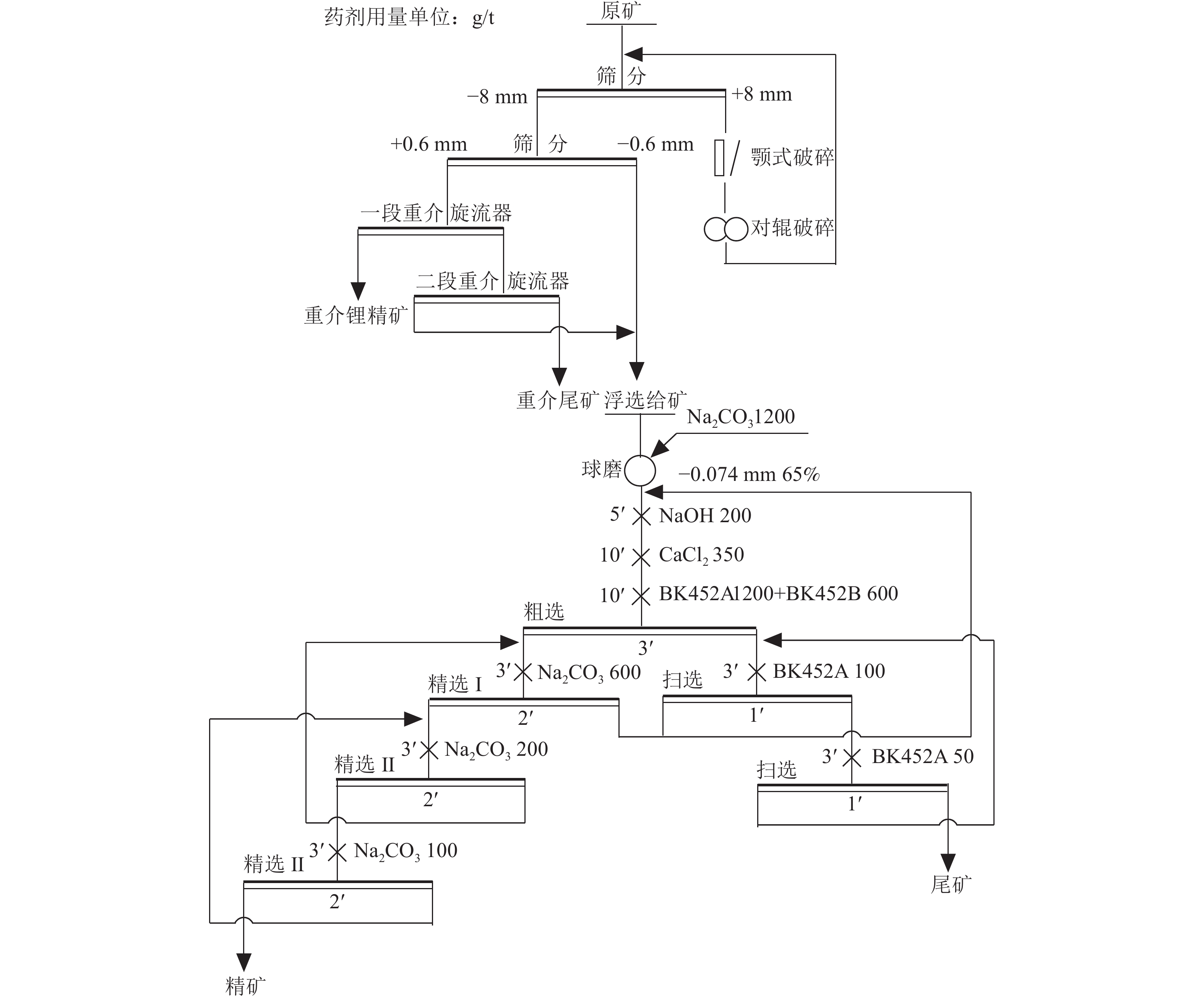

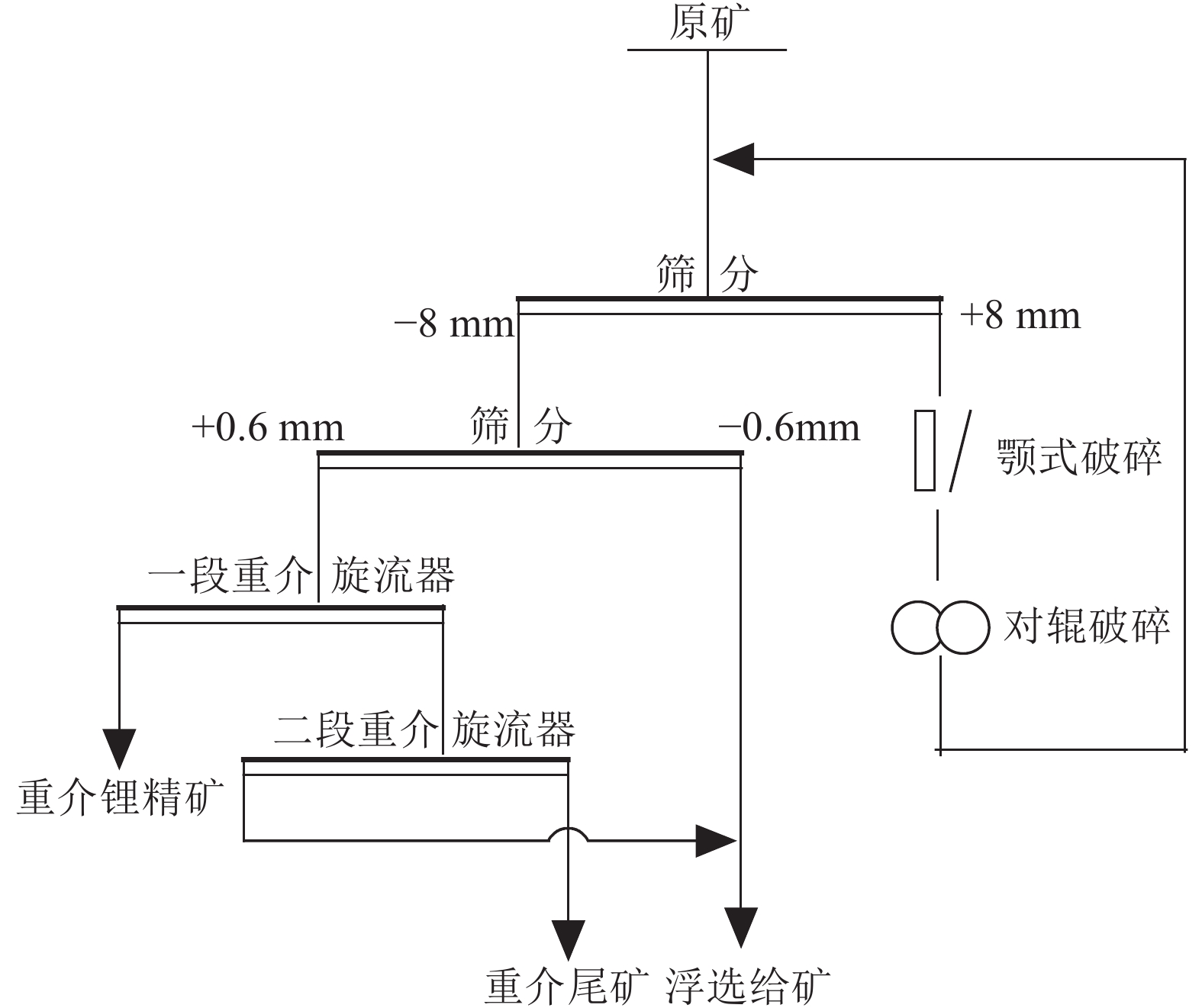

这是一篇矿物加工工程领域的论文。新疆某伟晶岩型锂辉石矿中主要目的矿物为锂辉石,伴生有少量的铌钽铁矿,脉石矿物主要为长石、石英和云母等。本文针对该锂辉石矿首先进行了重介质旋流器实验,将重介质选矿的中矿及-0.6 mm的细粒级合并作为浮选给矿,将浮选给矿磨细后进行了系统的浮选实验。采用“重介质选矿-浮选”工艺,针对含Li2O 1.68%的原矿,最终全流程实验可获得重介质精矿含Li2O 6.5%,回收率51.58%;浮选精矿含Li2O 5.37%,回收率31.94%,两个精矿合并后总精矿含Li2O 6.02%,回收率83.52%。重介质旋流器可以直接产出回收率约50%的高品位精矿,可以抛掉产率约43%的尾矿,可大大节省破碎成本和磨矿成本。

Abstract:This is an article in the field of mineral processing engineering. A pegmatitic lithium polymetallic mine in Xinjiang Province, in which the main target mineral is spodumene, accompanied by a small amount of niobium-tantalite, and the gangue minerals are mainly feldspar, quartz and mica. In this article, the DMS test is carried out for the spodumene ore firstly. The middling of DMS and the fine sample of -0.6 mm are combined as feed for flotation test. After grinding the feed, the systematic flotation tests were carried out. Finally, as to the raw ore containing Li2O 1.68%, by adopting the combined technology of DMS-Flotation, the dense medium concentrate obtained contains Li2O 6.5% and 51.58% of recovery, the flotation concentrate obtained contains Li2O 5.37%, and 31.94% of recovery. The total concentrate contains Li2O 6.02%, and the recovery is 83.52%. DMS for this spodumene ore can directly produce high-grade concentrate with a recovery of 50%, and discard tailings with a yield of 43%, which can greatly save the cost of crushing grinding.

-

Key words:

- Mineral processing engineering /

- Spodumene /

- DMS /

- Flotation /

- Combined technology

-

-

表 1 原矿的主要化学成分分析结果/%

Table 1. Analysis results of main chemical elements

Li2O Nb2O5 Ta2O5 BeO P2O5 SiO2 Al2O3 K2O Na2O CaO MnO MgO TFe S 1.68 0.007 0 0.011 6 0.045 0.22 74.39 15.83 2.49 3.49 0.28 0.091 0.04 0.94 0.082 表 2 重介选矿实验结果

Table 2. Results of DMS test

产品名称 产率/% 品位/% 回收率/% Li2O Ta2O5 Nb2O5 Li2O Ta2O5 Nb2O5 重介锂精矿 13.30 6.50 0.011 0 0.020 1 51.60 12.65 38.28 重介尾矿 42.78 0.13 0.015 2 0.007 2 3.32 56.22 44.11 浮选给矿 43.92 1.72 0.008 2 0.002 8 45.09 31.14 17.61 原矿 100.00 1.68 0.011 6 0.007 0 100.00 100.00 100.00 表 3 闭路实验结果

Table 3. Results of closed-circuit test

产品名称 产率/% Li2O品位/% Li2O作业回收率/% 精矿 22.70 5.37 70.81 尾矿 77.30 0.65 29.19 原矿 100.00 1.72 100.00 表 4 全流程实验结果

Table 4. Results of full test

产品名称 产率/% Li2O品位/% Li2O回收率/% 重介精矿 13.30 6.50 51.58 浮选精矿 9.97 5.37 31.94 合并精矿 23.27 6.02 83.52 浮选尾矿 33.95 0.65 13.17 重介尾矿 42.78 0.13 3.31 原矿 100.00 1.68 100.00 -

[1] 程仁举, 李成秀, 刘星, 等. 川西某伟晶岩型锂辉石矿浮选试验研究[J]. 矿产综合利用, 2020(6):153-157.CHEN R J, LI C X, LIU X, et al. Experimental research on the flotation of a pegmatite type spodumene ore in western Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2020(6):153-157. doi: 10.3969/j.issn.1000-6532.2020.06.026

CHEN R J, LI C X, LIU X, et al. Experimental research on the flotation of a pegmatite type spodumene ore in western Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2020(6):153-157. doi: 10.3969/j.issn.1000-6532.2020.06.026

[2] 于福顺, 蒋曼, 王建磊, 等. 澳大利亚某锂辉石矿预先脱泥-浮选试验研究[J]. 有色金属(选矿部分), 2019(6):69-72.YU F S, JIANG M, WANG J L, et al. Study on pre-desliming- flotation tests of spodumene ore in Australia[J]. Nonferrous Metal (Mineral Processing Section), 2019(6):69-72.

YU F S, JIANG M, WANG J L, et al. Study on pre-desliming- flotation tests of spodumene ore in Australia[J]. Nonferrous Metal (Mineral Processing Section), 2019(6):69-72.

[3] 曾宪勤. 澳大利亚锂矿资源现状浅析[J]. 世界有色金属, 2018(11): 87-88.ZENG X Q. Current situation of lithium ore resources in Australia[J]. World Nonferrous Metals. 2018 (11): 87-88.

ZENG X Q. Current situation of lithium ore resources in Australia[J]. World Nonferrous Metals. 2018 (11): 87-88.

[4] BOGALE T, FIDELE M, BORIS A. The beneficiation of lithium minerals from hard rock ores: Areview[J]. Minerals Engineering, 2019(3):170-184.

[5] 陈家灵, 谢海云, 柳彥昊, 等. 锂辉石的选矿研究进展[J]. 矿冶, 2022(3):1-7.CHEN J L, XIE H Y, LIU Y H, et al. The summary of the research status of spodumene beneficiation[J]. Mining and Metallurgy, 2022(3):1-7. doi: 10.3969/j.issn.1005-7854.2022.03.001

CHEN J L, XIE H Y, LIU Y H, et al. The summary of the research status of spodumene beneficiation[J]. Mining and Metallurgy, 2022(3):1-7. doi: 10.3969/j.issn.1005-7854.2022.03.001

[6] 陈超, 张裕书, 张少翔, 等. 川西九龙地区低品位锂辉石浮选试验研究[J]. 矿产综合利用, 2019(4):55-58.CHEN C, ZHANG Y S, ZHANG S X, et al. Flotation test of low-grade spodumene in the Jiulong area of west Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2019(4):55-58. doi: 10.3969/j.issn.1000-6532.2019.04.011

CHEN C, ZHANG Y S, ZHANG S X, et al. Flotation test of low-grade spodumene in the Jiulong area of west Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2019(4):55-58. doi: 10.3969/j.issn.1000-6532.2019.04.011

[7] 徐龙华, 田佳, 巫侯琴, 等. 川西伟晶岩型锂辉石矿选择性磨矿-强化浮选试验研究[J]. 有色金属(选矿部分), 2017(4):52-57.XU L H, TIAN J, WU H Q, et al. Experimental study on the selective grinding-strengthening flotation of the western Sichuan pegmatite spodumene ore[J]. Nonferrous metal (Mineral Processing Section), 2017(4):52-57.

XU L H, TIAN J, WU H Q, et al. Experimental study on the selective grinding-strengthening flotation of the western Sichuan pegmatite spodumene ore[J]. Nonferrous metal (Mineral Processing Section), 2017(4):52-57.

[8] 温胜来, 王玲珑, 范林青. 江西某低品位锂辉石矿选矿试验[J]. 金属矿山, 2017(6):109-112.WEN S L, WANG L L, FAN L Q, et al. Beneficiation experiment on a a low grade spodumene ore from Jiangxi[J]. Metal Mine, 2017(6):109-112. doi: 10.3969/j.issn.1001-1250.2017.06.022

WEN S L, WANG L L, FAN L Q, et al. Beneficiation experiment on a a low grade spodumene ore from Jiangxi[J]. Metal Mine, 2017(6):109-112. doi: 10.3969/j.issn.1001-1250.2017.06.022

-

下载:

下载: