Experimental Research on Recovery Copper and Iron from Copper Smelting Slags by Direct Reduction Roasting-magnetic Separation

-

摘要:

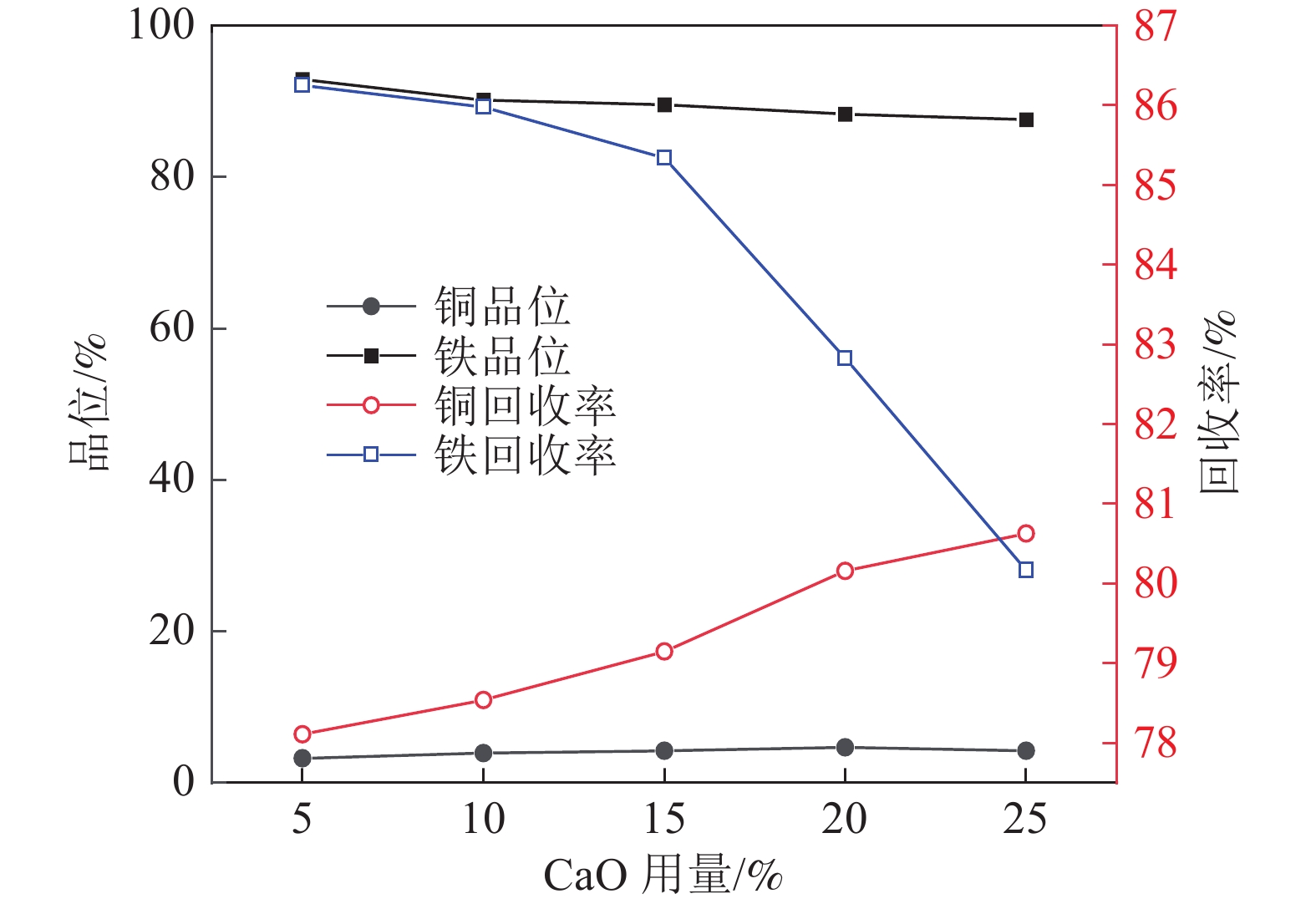

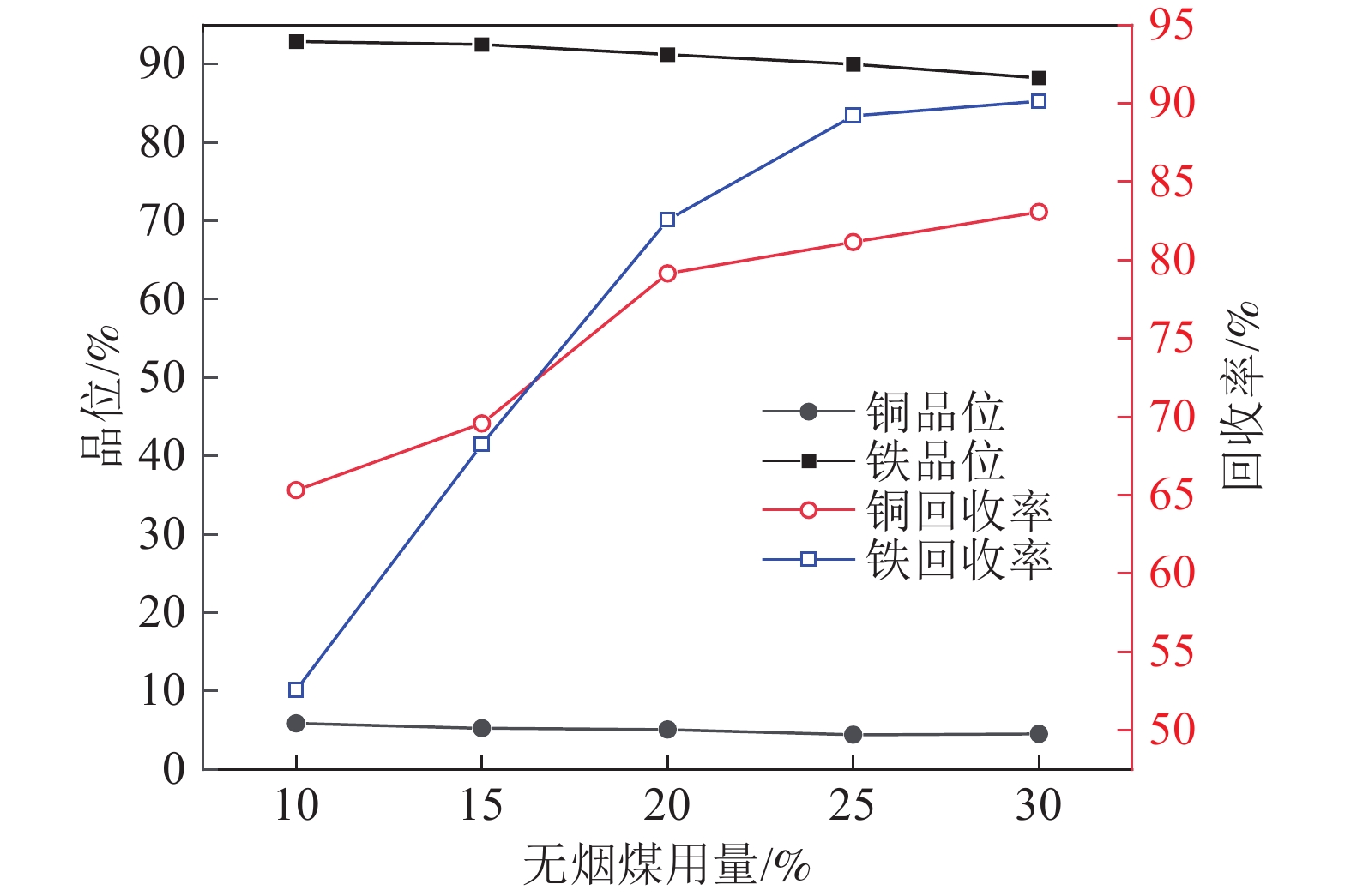

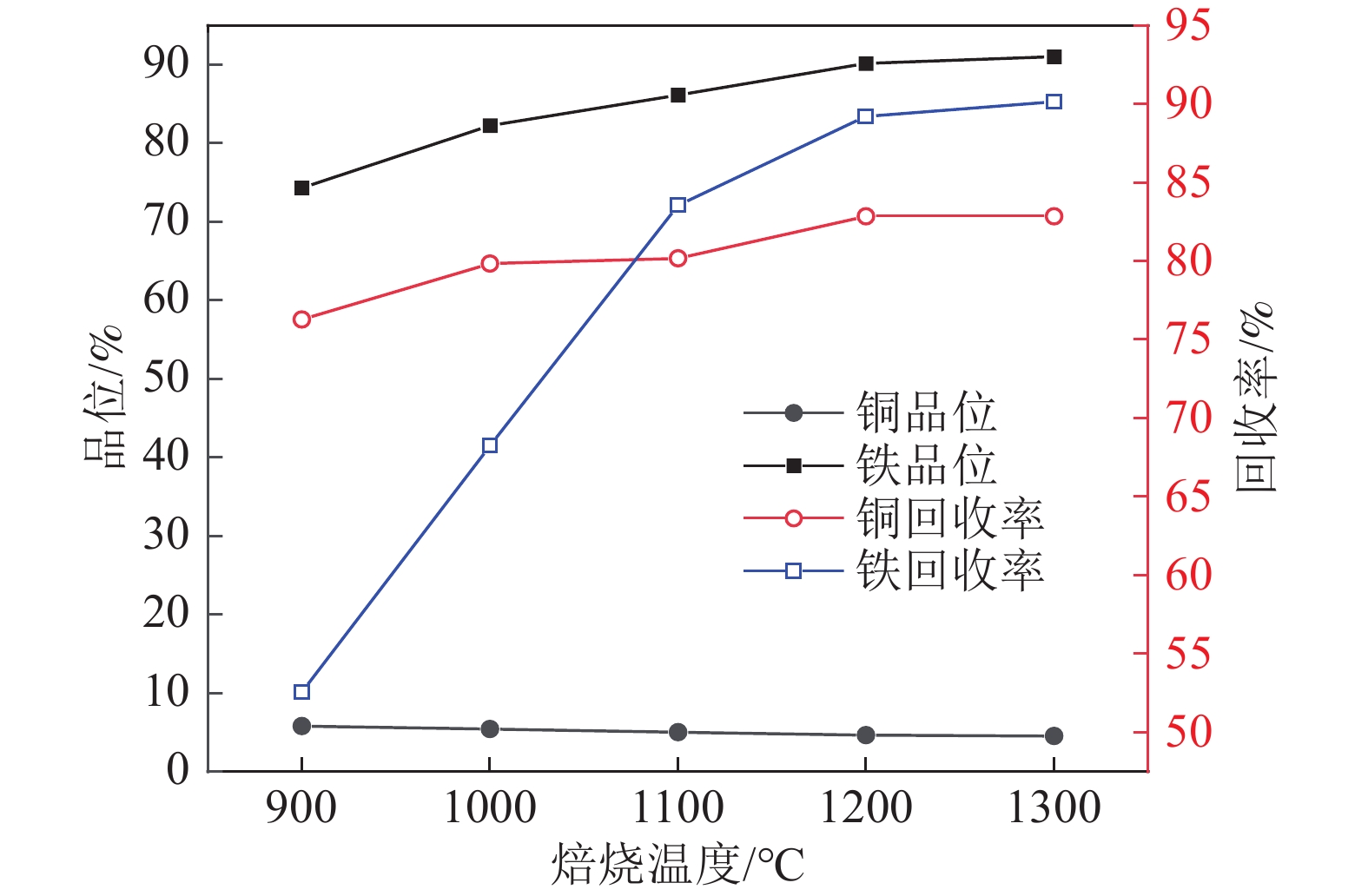

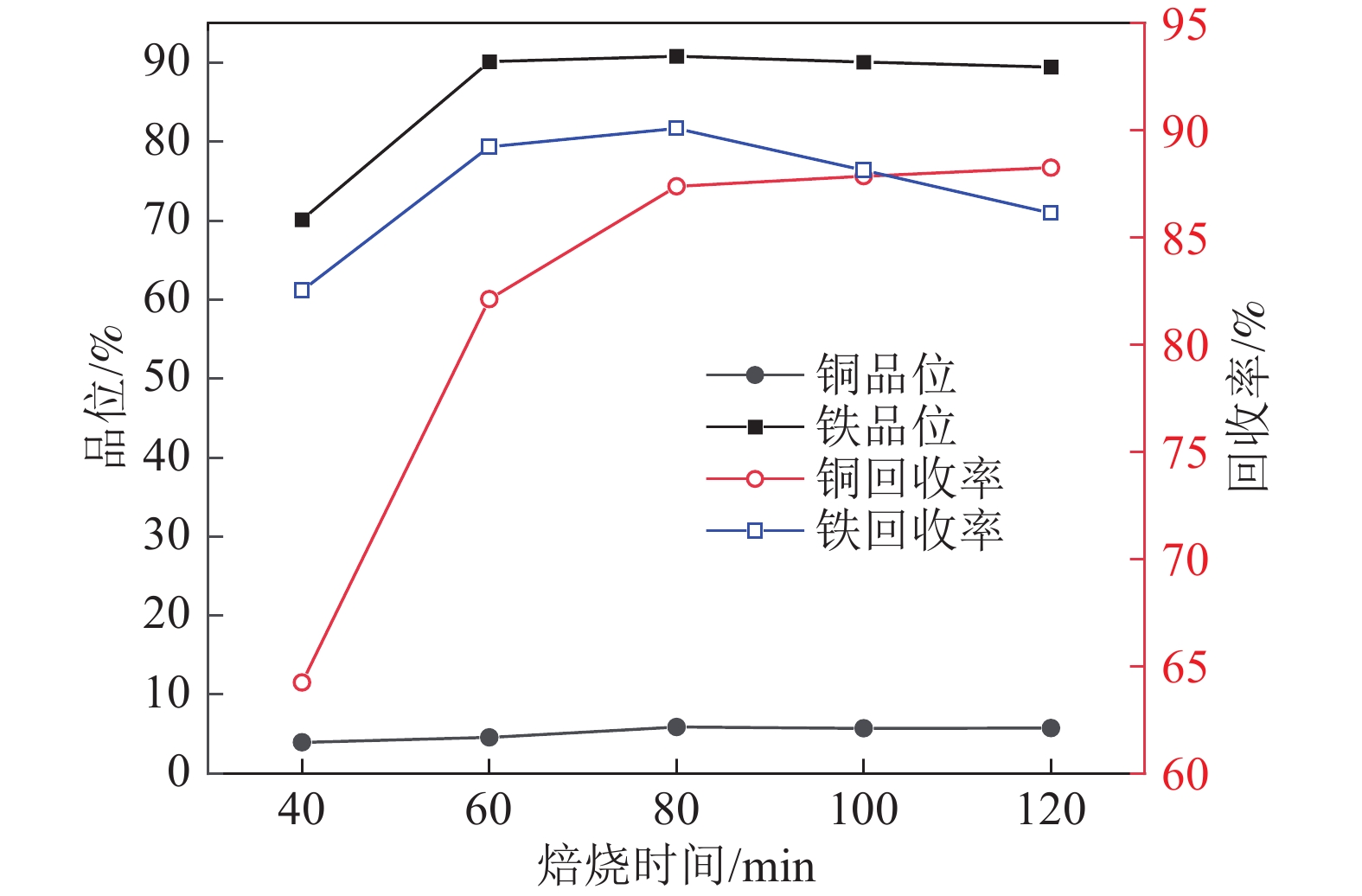

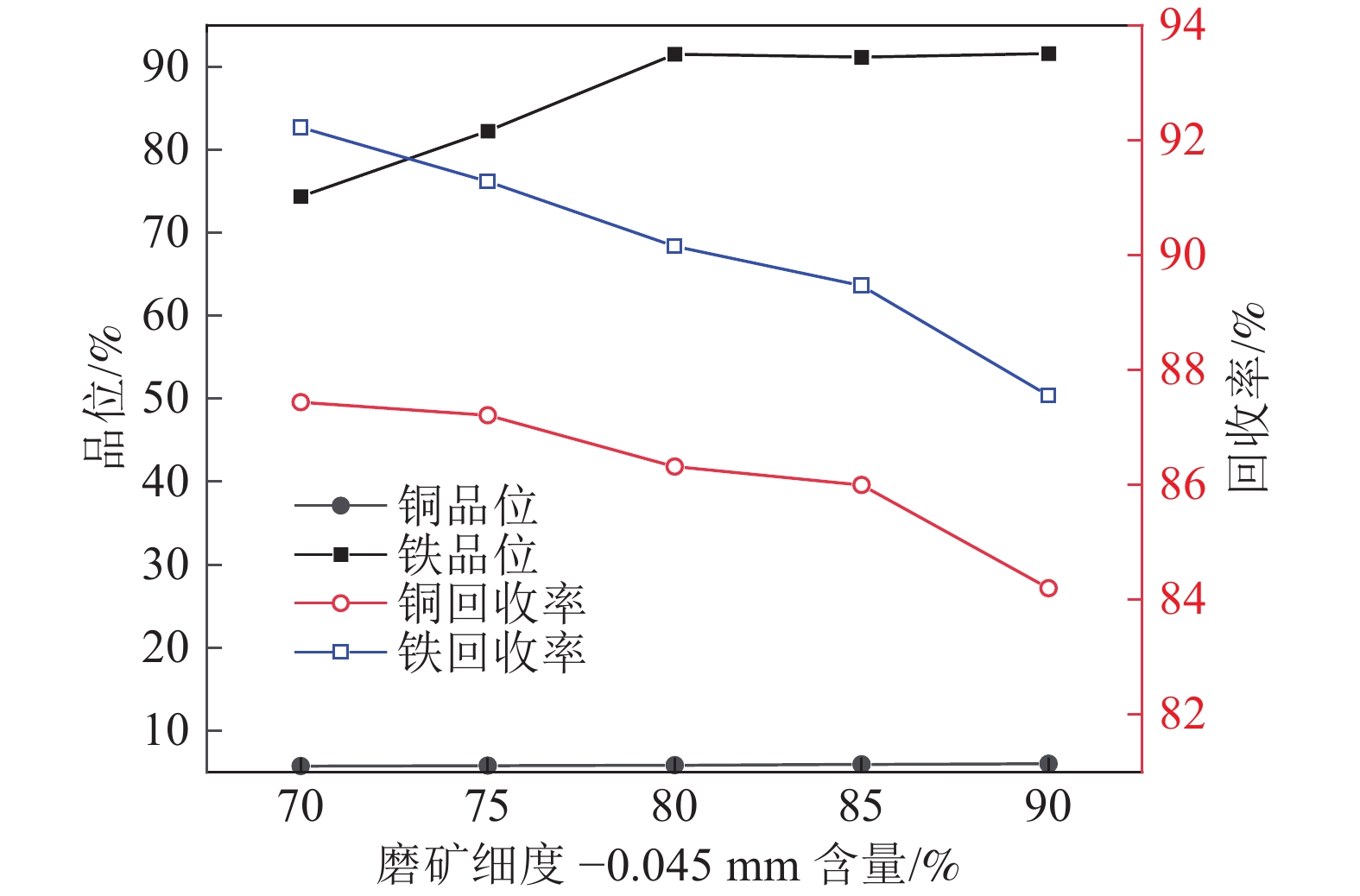

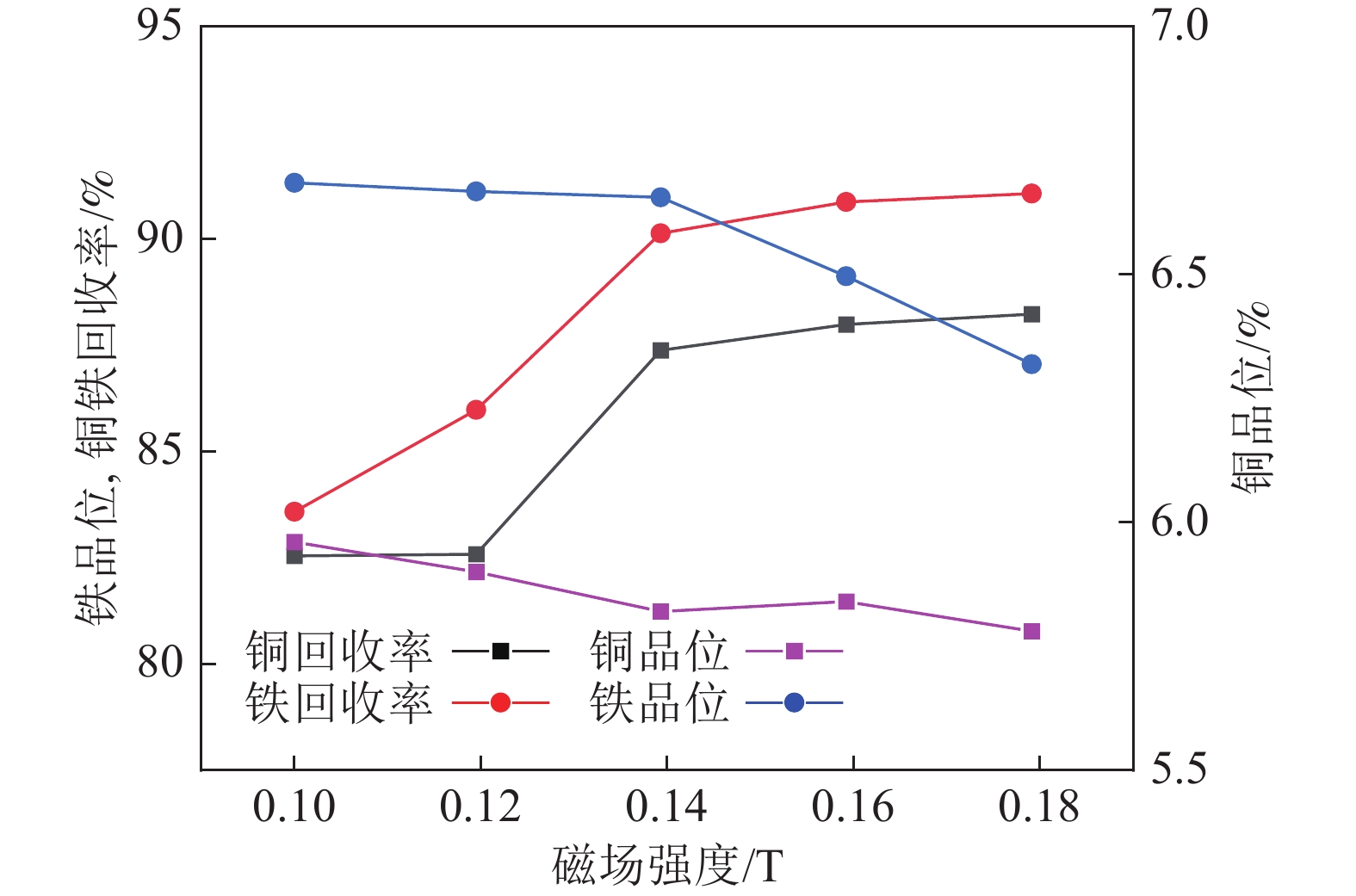

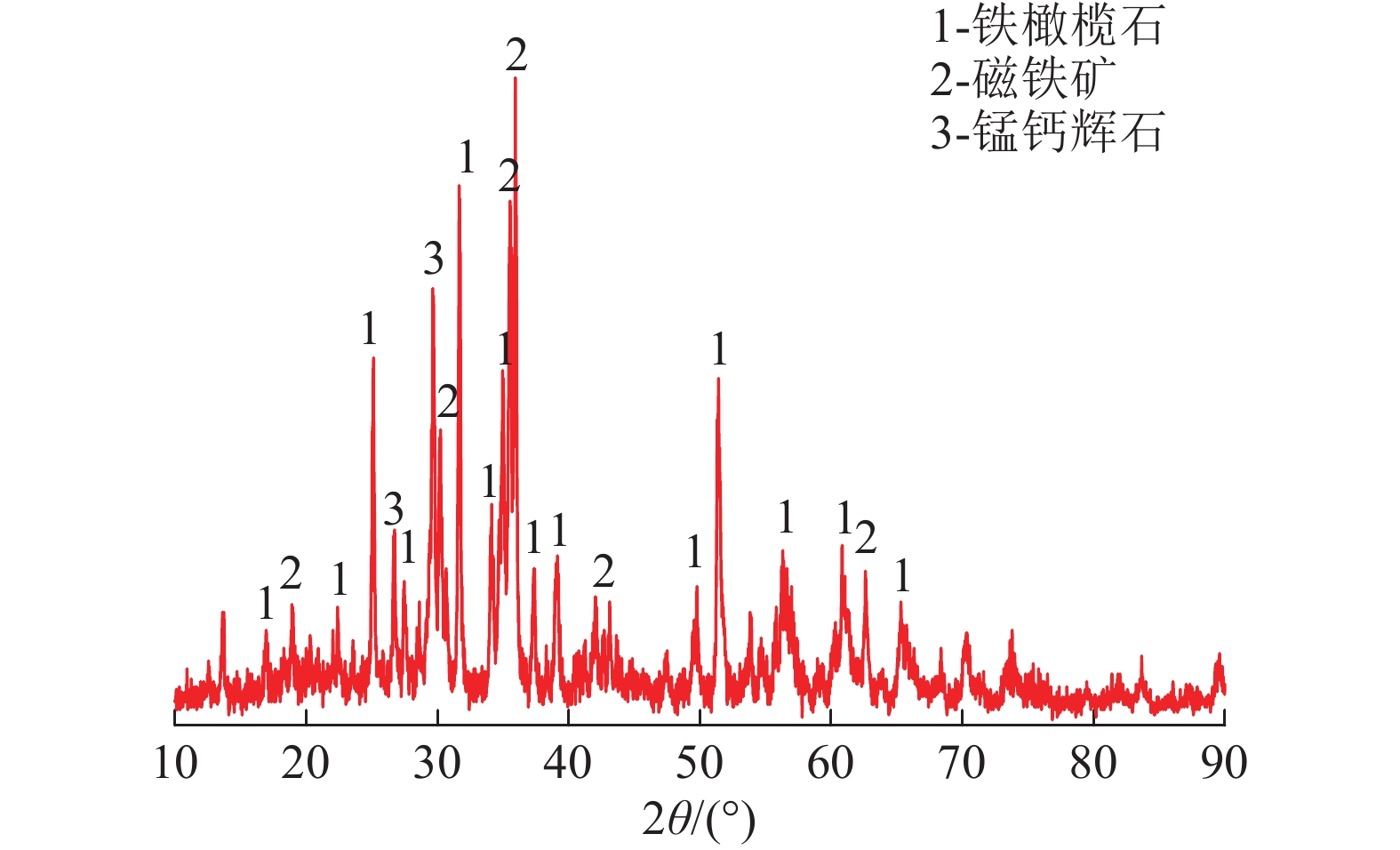

这是一篇冶金工程领域的论文。某铜冶炼渣浮选尾渣中铁品位为37.42%,铜品位为1.86%,根据其矿石性质特点,采用烟煤作为还原剂,应用直接还原焙烧-磁选工艺回收铜尾渣中铜铁,实验结果表明:将铜冶炼渣、烟煤和生石灰(作为助还原剂)按 100∶25∶20的质量比混合,在焙烧温度定

1200 ℃,时间为80 min,磨矿细度为-0.045 mm 80%,磁场强度为0.139 T条件下可获得铁品位为90.98%,铁回收率为90.13%,铜品位为5.82%、铜回收率为 87.38%的含铜铁精矿,实现了冶炼渣铜中铜铁的综合回收。Abstract:This is an article in the field of metallurgical engineering. Torecover copper and iron from a copper smelting slag flotation tailingwith iron grade of 37.42% and copper grade of 1.86%, according to the characteristics of its ore properties, the bituminous coal was used as a reductant, the process of direct reduction roasting - magnetic separation was applied.The experimental results show that copper smelting slag, bitumite and quicklime (as a co-reducing agent) are mixed in the mass ratio of 100∶25∶20, and at the conditions of roasting temperature of 1 200 ℃, time of 80 min, the roasted ores gringding fineness of -0.045 mm 80%, and magnetic strength of 0.139 T, the copper-bearing iron ore concentrate can be obtained with an iron grade of 90.98%, iron recovery of 90.13%, copper grade of 5.82% and copper recovery of 87.38%, thus realizing the comprehensive recovery of copper and iron from copper smelting slags.

-

-

表 1 铜尾渣主要元素分析结果/%

Table 1. Main-element analysis results of copper tailing slags

Cu Pb Zn S TFe As Al2O3 MnO MgO SiO2 P CaO Au* Ag* 1.86 0.60 2.12 0.66 37.42 0.02 3.47 0.58 2.55 34.35 0.03 3.94 0.33 15.70 *单位为g/t 表 2 铜尾渣铜物相分析结果

Table 2. Analysis results of copper phase of copper tailing slags

相别名称 原生铜 次生铜 氧化铜 金属铜 全铜 含量/% 1.28 0.42 0.06 0.10 1.86 占有率/% 68.82 22.58 3.23 5.37 100.00 表 3 铜尾渣铁物相分析结果

Table 3. Analysis results of iron phaseof copper tailing slags

相别

名称磁性

铁中铁赤、褐铁

矿中铁硅酸

铁中铁菱铁

矿中铁硫化

铁中铁全铁 含量/% 12.41 0.38 23.82 0.12 0.69 37.42 占有率/% 33.16 1.02 63.66 0.32 1.84 100.00 表 4 最终精矿产品多元素分析结果/%

Table 4. Multi-element analysis results of the final concentrate products

TFe Cu Pb Zn MnO S SiO2 MgO CaO Al2O3 As P 90.98 5.82 0.03 0.02 0.08 0.02 0.52 0.23 0.07 0.07 0.02 0.08 -

[1] 魏志芳, 赵凯, 张巧荣, 等. 铜渣碳热还原改性对 Cu、S 在铁中溶解行为影响[J]. 矿产综合利用, 2021(2):44-48.WEI Z F, ZHAO K, ZHANG Q R, et al. Effect of carbon thermal reduction modification on the dissolution behavior of Cu and S in iron[J]. Multipurpose Utilization of Mineral Resources, 2021(2):44-48. doi: 10.3969/j.issn.1000-6532.2021.02.009

WEI Z F, ZHAO K, ZHANG Q R, et al. Effect of carbon thermal reduction modification on the dissolution behavior of Cu and S in iron[J]. Multipurpose Utilization of Mineral Resources, 2021(2):44-48. doi: 10.3969/j.issn.1000-6532.2021.02.009

[2] 袁喜振, 尹明水, 单志强. 赞比亚某冶炼铜渣的综合利用[J]. 矿产综合利用, 2021(2):49-51.YUAN X Z, YIN M S, SHAN Z Q. Comprehensive utilization of copper slag from a smelting plant in Zambia[J]. Multipurpose Utilization of Mineral Resources, 2021(2):49-51. doi: 10.3969/j.issn.1000-6532.2021.02.010

YUAN X Z, YIN M S, SHAN Z Q. Comprehensive utilization of copper slag from a smelting plant in Zambia[J]. Multipurpose Utilization of Mineral Resources, 2021(2):49-51. doi: 10.3969/j.issn.1000-6532.2021.02.010

[3] 朱茂兰, 王俊娥, 陈杭, 等. 铜渣熔融还原回收铁试验研究[J]. 有色金属(冶炼部分), 2019(1):16-18.ZHU M L, WANG J E, CHEN H, et al. Experimental study on iron recovery from copper slag by smelting reduction[J]. Nonferrous Metals(Extractive Metallurgy), 2019(1):16-18.

ZHU M L, WANG J E, CHEN H, et al. Experimental study on iron recovery from copper slag by smelting reduction[J]. Nonferrous Metals(Extractive Metallurgy), 2019(1):16-18.

[4] 刘洋, 张春霞. 钢铁渣的综合利用现状及发展趋势[J]. 矿产综合利用, 2019(2):21-25.LIU Y, ZHANG C X. Comprehensive utilization situation and development trend of iron and steel slag in China and abroad[J]. Multipurpose Utilization of Mineral Resources, 2019(2):21-25. doi: 10.3969/j.issn.1000-6532.2019.02.004

LIU Y, ZHANG C X. Comprehensive utilization situation and development trend of iron and steel slag in China and abroad[J]. Multipurpose Utilization of Mineral Resources, 2019(2):21-25. doi: 10.3969/j.issn.1000-6532.2019.02.004

[5] 李国栋, 林海, 董颖博, 等. 湿法冶金法从铅银渣中异步回收锌、铅银的试验研究[J]. 稀有金属, 2017, 41(10):1143-1150.LI G D, LIN H, DONG Y B, et al. Hydrometallurgy asynchronous recovery of zinc, lead and silver from Pb-Ag residue[J]. Chinese Journal of Rare Metals, 2017, 41(10):1143-1150.

LI G D, LIN H, DONG Y B, et al. Hydrometallurgy asynchronous recovery of zinc, lead and silver from Pb-Ag residue[J]. Chinese Journal of Rare Metals, 2017, 41(10):1143-1150.

[6] 李国栋, 林海, 孙运礼, 等. 酸性焙烧-浮选联合工艺从铅银渣中回收铅银的影响因素和机制[J]. 稀有金属, 2017, 41(9):1042-1049.LI G D, LIN H, SUN Y L, et al. recovery of lead and silver from Pb-Ag residue by acid roasting-flotation combined process[J]. Chinese Journal of Rare Metals, 2017, 41(9):1042-1049.

LI G D, LIN H, SUN Y L, et al. recovery of lead and silver from Pb-Ag residue by acid roasting-flotation combined process[J]. Chinese Journal of Rare Metals, 2017, 41(9):1042-1049.

[7] 李晓波, 徐晓衣, 李国栋. 内蒙某难处理铁矿石选矿试验[J]. 金属矿山, 2016(1):60-63LI X B, XU X Y, LI G D. Experiment on beneficiation of a refractory iron ore in Inner Mongolia[J]. Metal Mine, 2016(1):60-63. doi: 10.3969/j.issn.1001-1250.2016.01.014

LI X B, XU X Y, LI G D. Experiment on beneficiation of a refractory iron ore in Inner Mongolia[J]. Metal Mine, 2016(1):60-63. doi: 10.3969/j.issn.1001-1250.2016.01.014

[8] 李涛, 刘晨, 佘世杰. 铜渣中铁铜回收的实验研究[J]. 矿产综合利用, 2020(2):145-150.LI T, LIU C, SHE S J. Research on recovery of iron and copper in copper slag[J]. Multipurpose Utilization of Mineral Resources, 2020(2):145-150. doi: 10.3969/j.issn.1000-6532.2020.02.026

LI T, LIU C, SHE S J. Research on recovery of iron and copper in copper slag[J]. Multipurpose Utilization of Mineral Resources, 2020(2):145-150. doi: 10.3969/j.issn.1000-6532.2020.02.026

[9] 邱廷省, 周丽萍, 李国栋. 铜冶炼渣直接还原焙烧—磁选回收铜、铁实验研究[J]. 金属矿山, 2020(9):202-207.QIU T S, ZHOU L P, LI G D. Experimental study on copper and iron recovery by direct reduction roasting-magnetic separation of copper smelting slag[J]. Metal Mining, 2020(9):202-207.

QIU T S, ZHOU L P, LI G D. Experimental study on copper and iron recovery by direct reduction roasting-magnetic separation of copper smelting slag[J]. Metal Mining, 2020(9):202-207.

[10] 田树国, 崔立凤, 王军荣, 等. 国外某铜铅锌多金属矿工艺矿物学特性及影响浮选的因素[J]. 矿产综合利用, 2019(1):78-82.TIAN S G, CUI L F, WANG J R, et al. Process mineralogy and factors affecting mineral processing for a foreign copper-lead-zinc polymetallic ore[J]. Multipurpose Utilization of Mineral Resources, 2019(1):78-82. doi: 10.3969/j.issn.1000-6532.2019.01.017

TIAN S G, CUI L F, WANG J R, et al. Process mineralogy and factors affecting mineral processing for a foreign copper-lead-zinc polymetallic ore[J]. Multipurpose Utilization of Mineral Resources, 2019(1):78-82. doi: 10.3969/j.issn.1000-6532.2019.01.017

-

下载:

下载: