Evolution of Viscosity and Structure Property during the Two-step Reduction of Vanadium Slags

-

摘要:

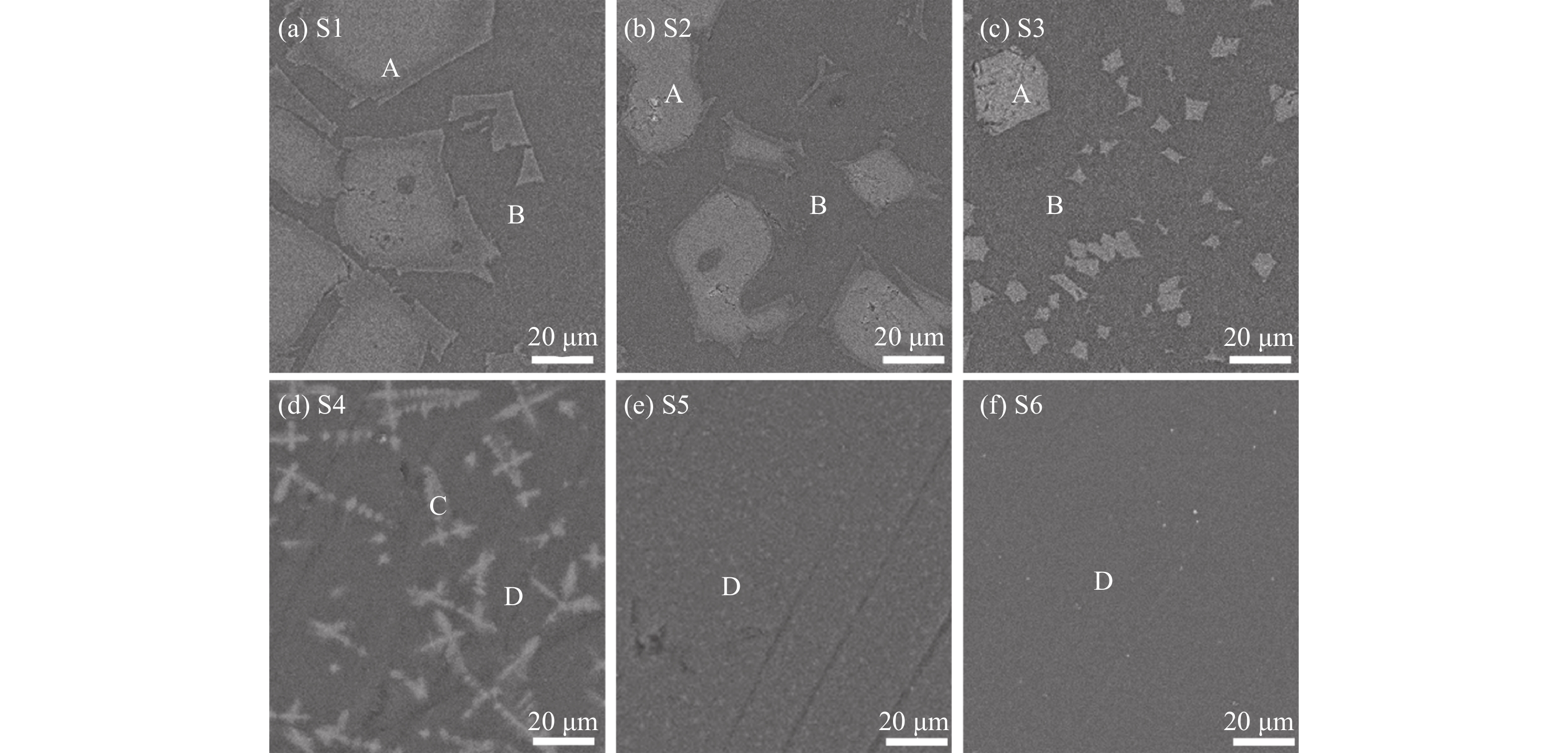

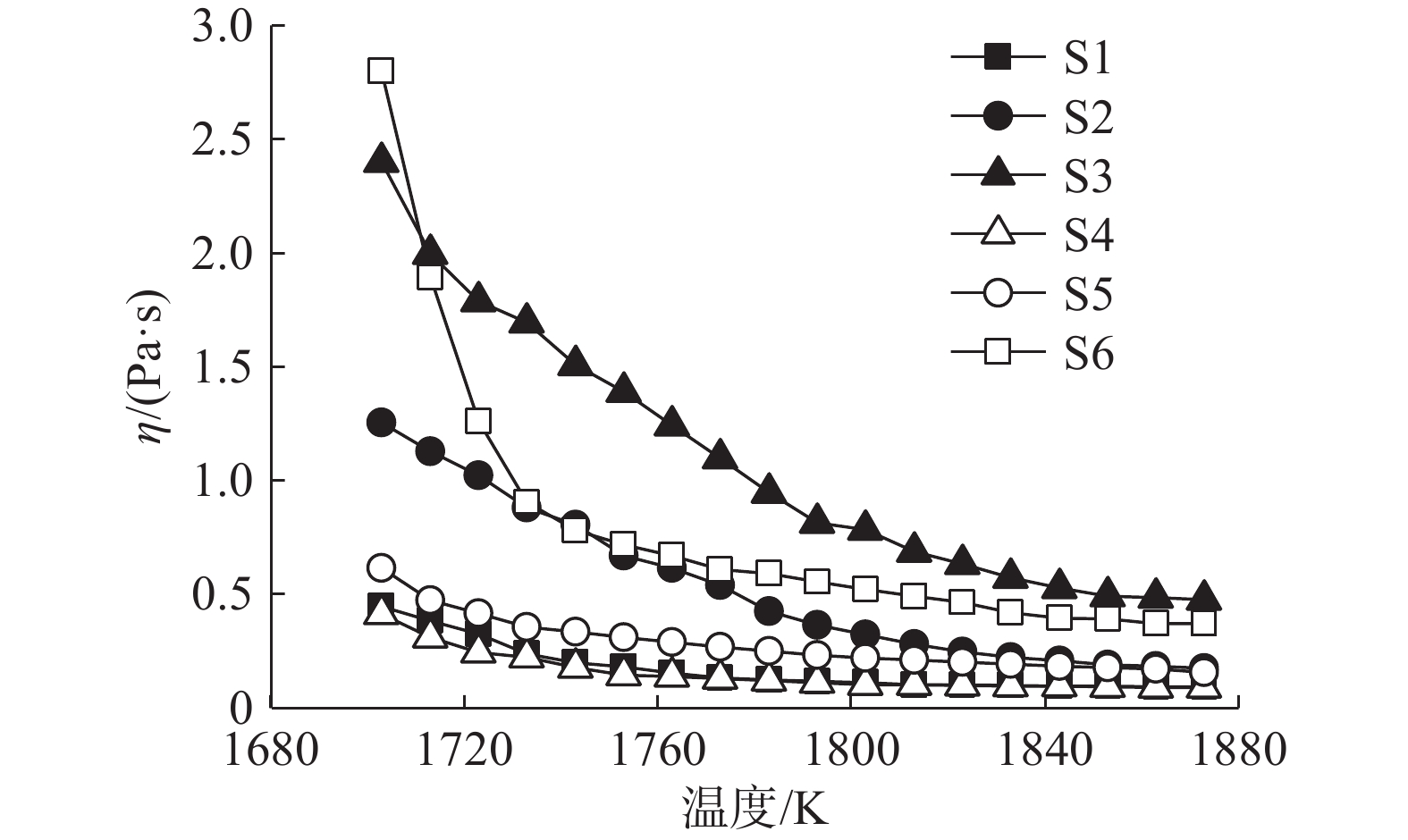

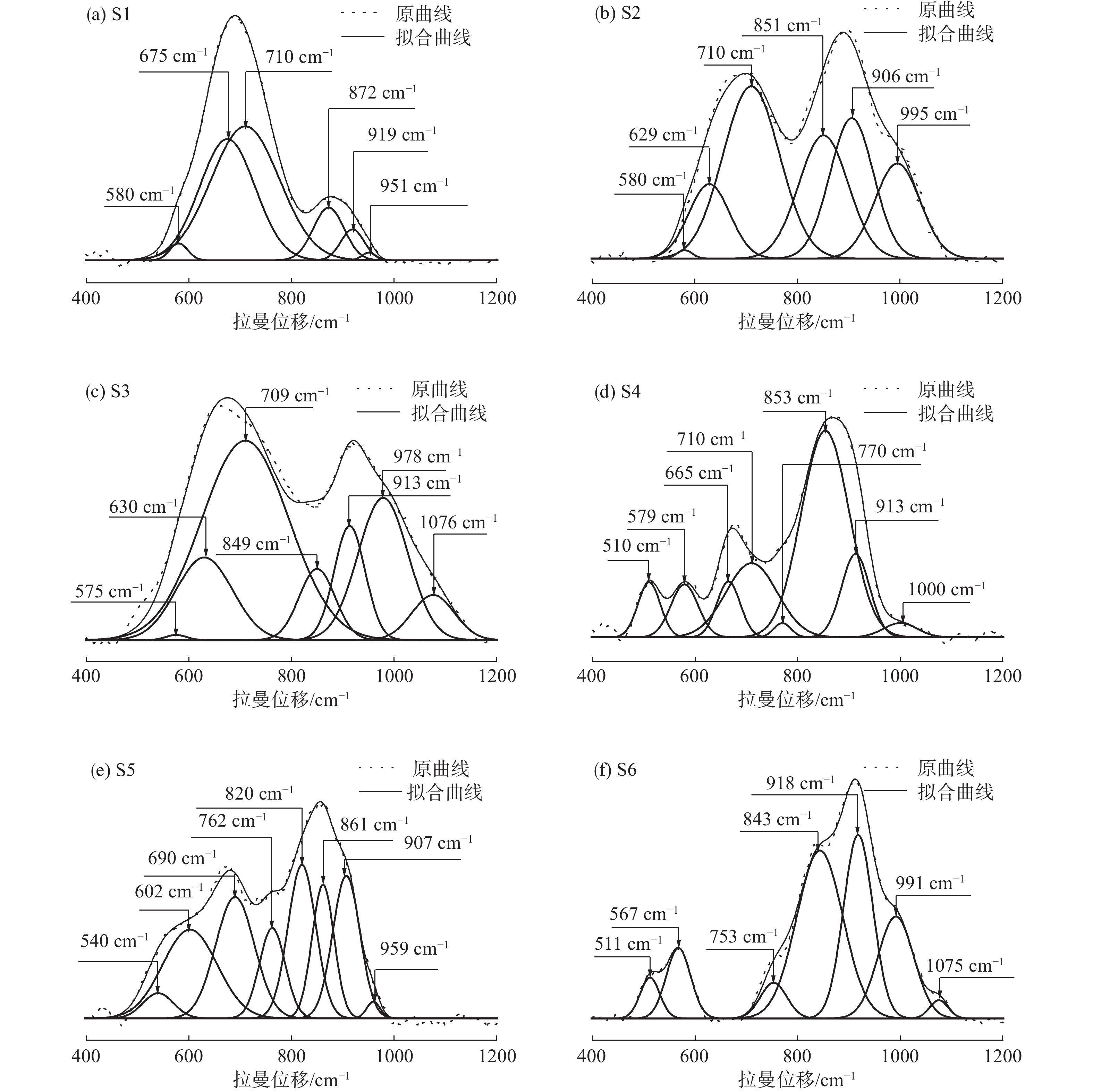

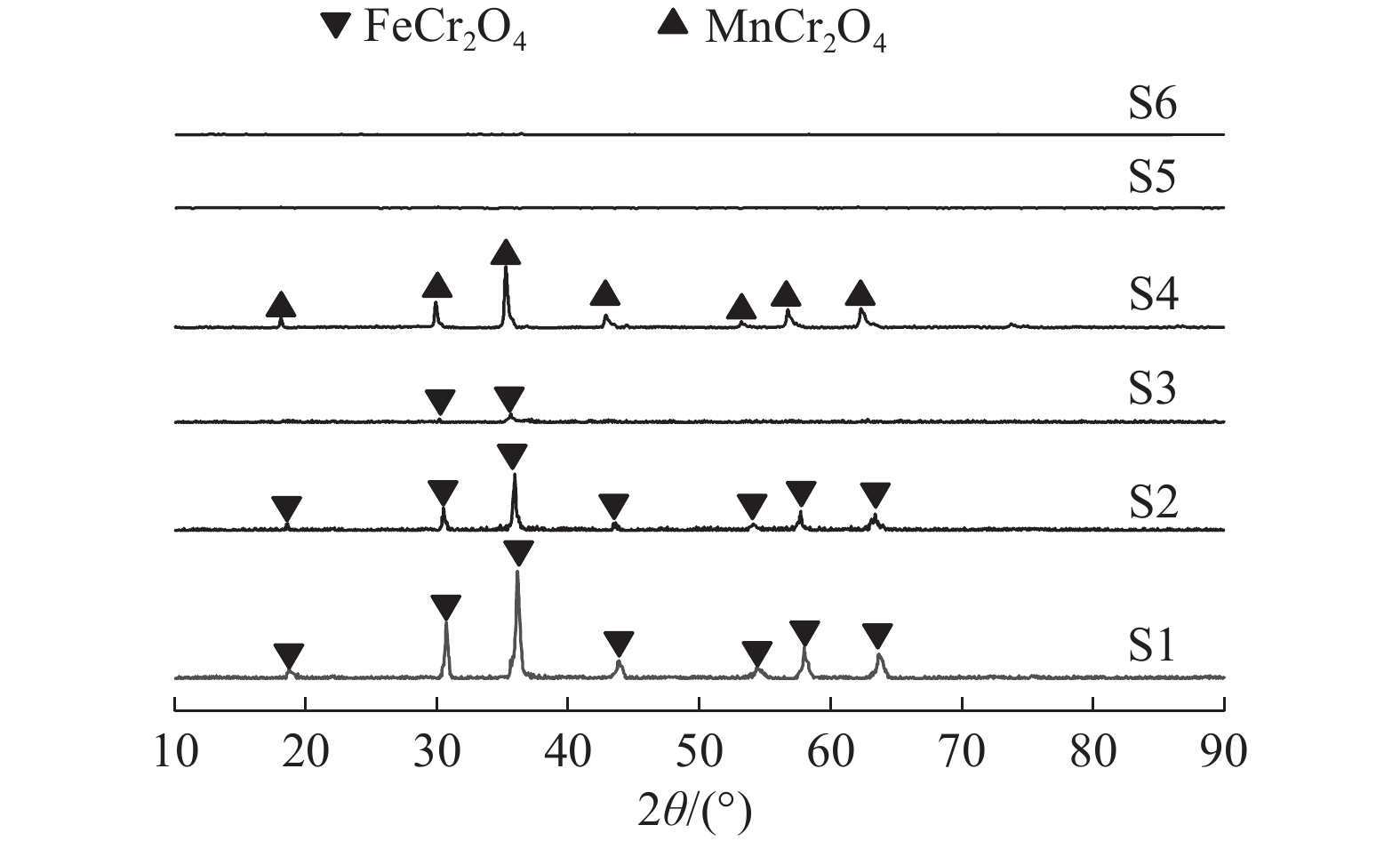

这是一篇冶金工程领域的论文。针对当前钒铁生产面临环境污染严重、流程冗长以及能耗较高等一系列问题,拟利用光伏硅片切割废料和铝灰分别作为预还原和终还原阶段的还原剂,对钒渣进行两步还原直接制备钒铁合金,研究了两步还原反应过程中对应渣系的黏度和熔体结构的演变规律。结果表明,1 873 K时,对应预还原过程的FeO-V2O3-Cr2O3-MnO-SiO2-TiO2-CaO渣系,随着渣中FeO组元含量的减少和SiO2组元含量的增加,铁铬尖晶石逐渐分解,影响熔体结构的主要因素由渣中FeO含量的变化转变为SiO2含量的变化,导致结构复杂度由0.176增至2.517,相应地,渣系黏度由0.092 Pa·s增至0.476 Pa·s;对应终还原过程的FeO-Cr2O3-MnO-V2O3-Al2O3-SiO2-TiO2-CaO渣系,随着渣中FeO、Cr2O3、MnO、V2O3组元含量的减少和Al2O3组元含量的增加,锰铬尖晶石逐渐分解,渣系由固液混合相转变为单一液相,影响熔体结构的主要因素为渣中Al2O3含量的变化,渣系由预还原阶段硅酸盐为主的熔体结构转变为终还原阶段铝硅酸盐为主的熔体结构,结构复杂度由0.252增至2.248,相应地,渣系黏度由0.091 Pa·s增至0.372 Pa·s。

Abstract:This is an article in the field of metallurgical engineering. At present, the cumbersome product routing of FeV alloy causes high energy consumption and hazardous leaching liquor waste. Therefore, a two-step direct reduction to produce FeV alloy from vanadium slags using photovoltaic silicon wafer cutting waste and aluminum ash as reductant, was investigated to solve the above problems. In the present work, the evolution of viscosity and the melt structure during the two-step reduction process of vanadium slags was investigated. The results showed that at 1 873 K, FeO-V2O3-Cr2O3-MnO-SiO2-TiO2-CaO slag system corresponding to the prereduction process, with the decrease of FeO content and the increase of SiO2 content in the slags, the size of FeCr2O4 spinel decreased gradually. The transition of the main influencing factor of the melt structure from FeO to SiO2 resulted in the increase of structure complexity, the structural complexity of the slag system increased from 0.176 to 2.517, the viscosity of the slag system increased from 0.092 Pa·s to 0.476 Pa·s. FeO-Cr2O3-MnO-V2O3-Al2O3-SiO2-TiO2-CaO slag system corresponding to the final reduction process, with the decrease of FeO, Cr2O3, MnO, V2O3 content and the increase of Al2O3 content in the slag, the size of MnCr2O4 spinel decreased gradually and the slag system comprised from a solid-liquid mixture to liquid, the transition of the main influencing factor from SiO2 to Al2O3 resulted in the transformation of the main structure of the slag system from silicate to aluminosilicate, the structural complexity of the slag system increased from 0.252 to 2.248, and the viscosity of the slag system increased from 0.091 Pa·s to 0.372 Pa·s.

-

Key words:

- Metallurgical engineering /

- Two-step reduction /

- Vanadium slags /

- Viscosity /

- Melt structure /

- Structural complexity

-

-

表 1 SCW、铝灰、钒渣的化学成分/%

Table 1. Chemical composition of SCW, aluminium ash and vanadium slags

名称 Al Al2O3 SiO2 SiC Si FeO Cr2O3 MnO V2O3 TiO2 SCW - - 14.9 25.8 59.3 - - - - - 铝灰 39.3 48.8 11.9 - - - - - - - 钒渣 - - 19.4 - - 41.2 4.9 11.1 14.2 9.2 表 2 实验渣样化学成分/%

Table 2. Chemical composition of test slags

名称 FeO Cr2O3 MnO V2O3 SiO2 TiO2 CaO Al2O3 S1 36 5 11 13 18 9 8 - S2 25 5 11 14 26 9 10 - S3 11 5 11 16 37 9 11 - S4 6 3 7 9 23 6 35 11 S5 - - 7 9 24 6 37 17 S6 - - - - 25 6 37 32 表 3 渣样各结构单元拉曼特征峰位置

Table 3. Raman characteristic peak position of each structural unit of test slags

名称 S1 S2 S3 S4 S5 S6 结构单元 拉曼位移(cm-1) - - - 510 540 511 Al-O-Al弯曲振动[12] 580 580 575 579 602 567 Si-O-Si弯曲振动[15] - 629 630 - - - FeCr2O4中F2g(3)振动[16] - - - 665 - - MnCr2O4中A1g振动[17] 675 - - - - - FeCr2O4中A1g振动[17] 710 710 709 710 690 - V-O3-V弯曲振动[18] - - - 770 762 753 Al-O-对称伸缩振动[19] - - - - 820 843 Al-O-Si伸缩振动[20] 872 851 849 853 861 - [SiO4]4-中Si-O-对称伸缩振动[19-20] 919 906 913 913 907 918 [Si2O7]6-中Si-O-对称伸缩振动[19-20] 951 995 978 1 000 959 991 [SiO3]2-中Si-O-对称伸缩振动[19-20] - - 1 076 - - 1 075 [Si2O5]2-中Si-O-对称伸缩振动[19-20] 表 4 渣中复杂结构和简单结构特征峰相对面积 /%

Table 4. Relative areas of characteristic peaks of complex structure and simple structure in test slag system

名称 Si-O-Si+Q2+Q3 Q0+Q1 Al-O-Si Al-O-Al Al-O- SC S1 14.94 85.06 - - - 0.176 S2 26.70 73.30 - - - 0.364 S3 71.57 28.43 - - - 2.517 S4 12.30 78.29 0 7.85 1.56 0.252 S5 26.33 35.42 22.21 4.01 12.03 1.108 S6 27.71 26.22 37.60 3.90 4.57 2.248 -

[1] 徐正震, 梁精龙, 李慧, 等. 含钒废弃物中钒的回收研究现状及展望[J]. 矿产综合利用, 2020(3): 8-13.XU Z Z, LIANG J L , LI H, et al. Research status and prospects of vanadium recovery in vanadium containing wastes[J]. Multipurpose Utilization of Mineral Resources, 2020(3): 8-13.

XU Z Z, LIANG J L , LI H, et al. Research status and prospects of vanadium recovery in vanadium containing wastes[J]. Multipurpose Utilization of Mineral Resources, 2020(3): 8-13.

[2] 吴诰, 潘鹏, 范鹤林, 等. 钒渣提钒研究现状及发展趋势[J]. 江西冶金, 2020, 40(4): 19-27.WU G, PAN P , FAN H L, et al. A review on the research status and development trend of vanadium extraction from vanadium slag[J]. Jiangxi Metallurgy, 2020, 40(4): 19-27.

WU G, PAN P , FAN H L, et al. A review on the research status and development trend of vanadium extraction from vanadium slag[J]. Jiangxi Metallurgy, 2020, 40(4): 19-27.

[3] 白凤仁, 刘福泉. 用钒渣直接冶炼钒铁的新工艺探讨[J]. 铁合金, 1995(1):30-33.BAI F R, LIU F Q. Discussion on new process of producing FeV using vanadium slag directly[J]. Ferro-Alloys, 1995(1):30-33.

BAI F R, LIU F Q. Discussion on new process of producing FeV using vanadium slag directly[J]. Ferro-Alloys, 1995(1):30-33.

[4] 赵昌明, 李博洋, 蔡永红, 等. 碳热还原含钒钢渣磷与钒的分离研究[J]. 矿产综合利用, 2018(6):106-110.ZHAO C M, LI B Y, CAI Y H, et al. Study on separation of vanadium slag, phosphorus and vanadium by carbon thermal reduction[J]. Multipurpose Utilization of Mineral Resources, 2018(6):106-110.

ZHAO C M, LI B Y, CAI Y H, et al. Study on separation of vanadium slag, phosphorus and vanadium by carbon thermal reduction[J]. Multipurpose Utilization of Mineral Resources, 2018(6):106-110.

[5] 周振宇, 唐萍, 侯自兵, 等. ω(SiO2)/ω(V2O3)对含钒炉渣熔化温度及黏度的影响[J]. 钢铁研究学报, 2019, 31(5):446-451.ZHOU Z Y, TANG P, HOU Z B, et al. Effect ofω(SiO2)/ω(V2O3) on melting and viscosity properties of vanadium slag[J]. Journal of Iron and Steel Research, 2019, 31(5):446-451.

ZHOU Z Y, TANG P, HOU Z B, et al. Effect ofω(SiO2)/ω(V2O3) on melting and viscosity properties of vanadium slag[J]. Journal of Iron and Steel Research, 2019, 31(5):446-451.

[6] Liu S, Wang L, Chou K C, et al. Viscosity measurement of FeO-SiO2-V2O3-TiO2 slags in the temperature range of 1644-1791 K and modelling by using ion-oxygen parameter[J]. Ironmaking& Steelmaking, 2017, 45(3):641-647.

[7] 曾晓兰. 钒渣物化性质与相图研究[D]. 重庆: 重庆大学, 2012.ZENG X L. Research on physicochemical properties and phase diagram of vanadium slag [D]. Chongqing: Chongqing University, 2012.

ZENG X L. Research on physicochemical properties and phase diagram of vanadium slag [D]. Chongqing: Chongqing University, 2012.

[8] 宋文臣. 熔融态钒渣直接氧化提钒新工艺的基础研究[D]. 北京: 北京科技大学, 2015.SONG W C. Basic research on the novel process of vanadium extraction from molten vanadium slag by direct oxidation method[D]. Beijing: University of Science and Technology Beijing, 2015.

SONG W C. Basic research on the novel process of vanadium extraction from molten vanadium slag by direct oxidation method[D]. Beijing: University of Science and Technology Beijing, 2015.

[9] 曾小平, 吴冰, 江山, 等. 碳酸钙在高温条件下的变化过程分析[J]. 广东化工, 2010, 37(5):70-72.ZENG X P, WU B, JIANG S, et al. The analysis for the calcium carbonate at high temperatures[J]. Guangdong Chemical Industry, 2010, 37(5):70-72.

ZENG X P, WU B, JIANG S, et al. The analysis for the calcium carbonate at high temperatures[J]. Guangdong Chemical Industry, 2010, 37(5):70-72.

[10] 叶明峰, 吴光亮. 铬铁矿固态还原研究进展[J]. 矿产综合利用, 2018(6):13-18.YE M F, WU G L. Research progress of solid-state reduction of chromite[J]. Multipurpose Utilization of Mineral Resources, 2018(6):13-18.

YE M F, WU G L. Research progress of solid-state reduction of chromite[J]. Multipurpose Utilization of Mineral Resources, 2018(6):13-18.

[11] 黄兵. CaO-SiO2-FeO-Cr2O3-MgO-MnO渣系粘度模型及熔渣结构的研究[D]. 重庆: 重庆大学, 2019.HUANG B. Study on viscosity model and structure of CaO-SiO2-FeO-Cr2O3-MgO-MnO slag[D]. Chongqing: Chongqing University, 2019.

HUANG B. Study on viscosity model and structure of CaO-SiO2-FeO-Cr2O3-MgO-MnO slag[D]. Chongqing: Chongqing University, 2019.

[12] Li Q H, Yang S, Zhang Y, et al. Effects of MgO, Na2O, and B2O3 on the viscosity and structure of Cr2O3-bearing CaO-SiO2-Al2O3 slags[J]. ISIJ International, 2017, 57(4):689-696. doi: 10.2355/isijinternational.ISIJINT-2016-569

[13] 刘小杰, 兰臣臣, 朱二涛, 等. 几种添加剂对煤灰渣流动性影响研究[J]. 矿产综合利用, 2018(5):33-37.LIU X J, LAN C C, ZHU E T, et al. Investigation on effect of several additives on the fluidity of slag[J]. Multipurpose Utilization of Mineral Resources, 2018(5):33-37.

LIU X J, LAN C C, ZHU E T, et al. Investigation on effect of several additives on the fluidity of slag[J]. Multipurpose Utilization of Mineral Resources, 2018(5):33-37.

[14] Xu J F, S u L J, Chen D, et al. Experimental investigation on viscosity of CaO-MgO(-Al2O3)-SiO2slags and solid-liquid mixtures[J]. Journal of Iron and Steel Research(International), 2015, 22(12):1091-1097. doi: 10.1016/S1006-706X(15)30117-5

[15] Mcmillan P F, Poe B T, Gillet P H, et al. A study of SiO2 glass and supercooled liquid to 1950 K via high-temperature Raman spectroscopy[J]. Geochimicaet Cosmochimica Acta, 1994, 58(17):3653-3664. doi: 10.1016/0016-7037(94)90156-2

[16] Ippolito V, Andreozzi G B, Bersani D, et al. Raman fingerprint of chromate, aluminate and ferrite spinels[J]. Journal of Raman Spectroscopy, 2015, 46(12):1255-1264. doi: 10.1002/jrs.4764

[17] Dutta B, Pal D. Absorption and Raman spectroscopy: ferrimagnet spinel MnCr2O4[C]//DAE SolidState Physics Symposium 2018.2019.

[18] Whittaker L, Velazquze J M, Banerjee S. A VO-seeded approach for the growth of star-shaped VO2 and V2O5 nanocrystals: facile synthesis, structural characterization, and elucidation of electronic structure[J]. CrystEngComm, 2011, 13(17):5328-5336. doi: 10.1039/c0ce00832j

[19] 严照照, 张淑会, 董晓旭, 等. 高炉渣的化学成分对其微观结构影响的研究现状[J]. 矿产综合利用, 2019(1):22-27.YAN Z Z, ZHANG S H, DONG X X, et al. Research status of the influence of blast furnace slag chemical composition on its microstructure[J]. Multipurpose Utilization of Mineral Resources, 2019(1):22-27.

YAN Z Z, ZHANG S H, DONG X X, et al. Research status of the influence of blast furnace slag chemical composition on its microstructure[J]. Multipurpose Utilization of Mineral Resources, 2019(1):22-27.

[20] 严志明. 铝硅酸盐基高炉渣结构和性能基础研究[D]. 重庆: 重庆大学, 2019.YAN Z M. Fundamental research on the structure and physicochemical properties of aluminosilicatebased blast furnace slag[D]. Chongqing : Chongqing University, 2019.

YAN Z M. Fundamental research on the structure and physicochemical properties of aluminosilicatebased blast furnace slag[D]. Chongqing : Chongqing University, 2019.

-

下载:

下载: