Optimization and Practice of Flotation Process Flow in a Mineral Processing Plant in Xizang

-

摘要:

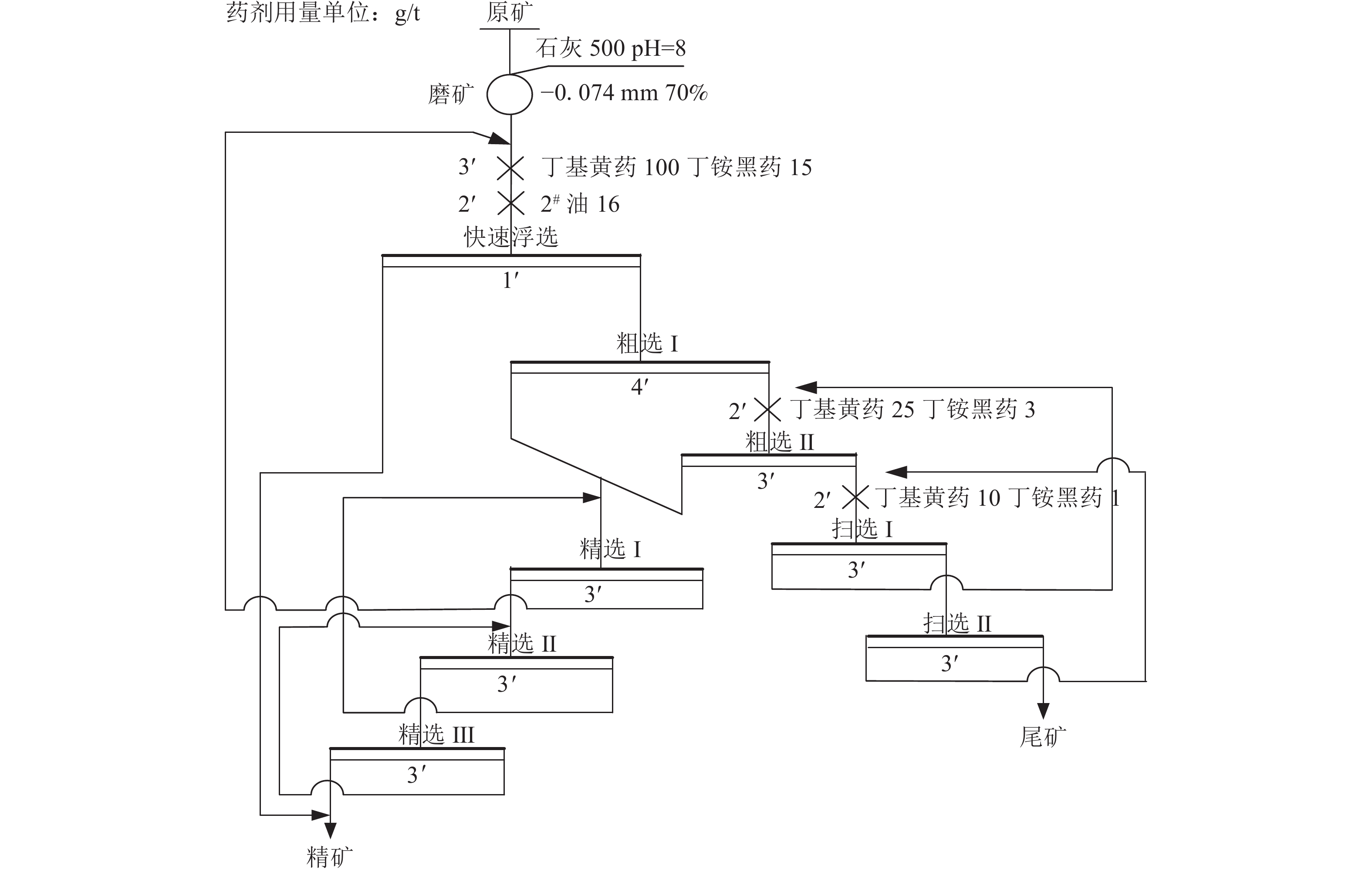

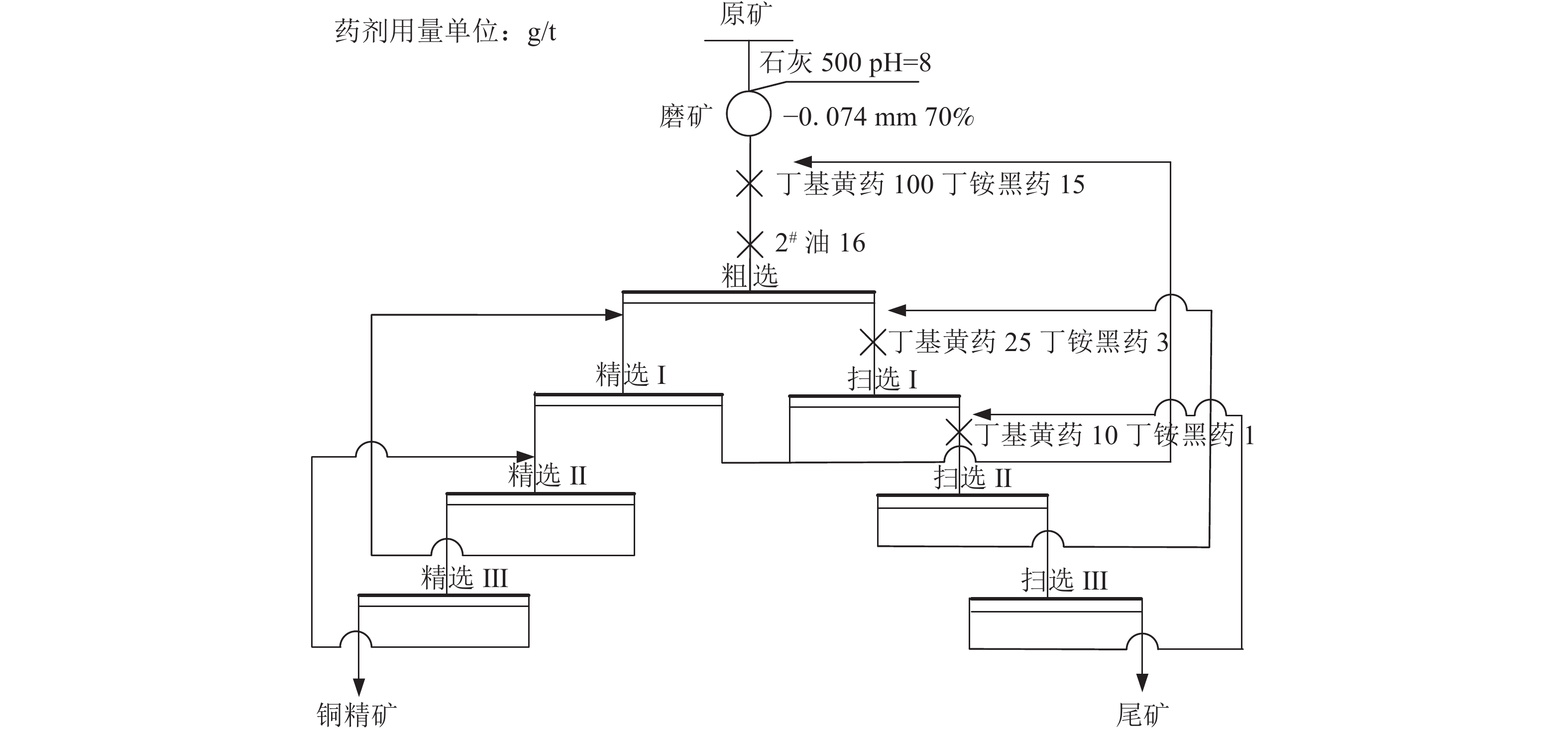

西藏某选矿厂,浮选流程为1粗3精3扫,处理原矿铜品位为0.85%,铜氧化率为6.14%的硫化铜矿石,最终得到铜回收率为88.79%,精矿铜品位为19.91%的选矿指标。为了进一步提升铜回收率指标,针对该选矿厂浮选流程结构,通过现场考查和小型实验进行优化,研究表明,相同的药剂制度,将浮选流程结构调整为“部分快速浮选+两次粗选”,在得到合格铜精矿的同时,铜回收率达到了92.18%,铜回收率提高了3.39个百分点。选矿厂根据实验结论进行浮选流程结构优化改造,铜回收率提高了2.93个百分点,达到了91.72%。结论对同类别选矿厂生产具有重要的参考和借鉴意义。

Abstract:In a concentrator in Xizang, the flotation flowsheet is one roughing three cleaning three scavenging, the copper grade of the raw ore is 0.85% and the copper oxidation rate is 6.14% . The copper recovery rate is about 88.79% , and the copper grade of the concentrate is 19.91% . In order to improve the recovery of copper, the flotation process structure of the concentrator was optimized by field investigation and small scale test, by adjusting the structure of flotation process to “partial rapid flotation + two roughing”, the recovery of copper was 92.18% and 3.39% higher than before. According to the test results, the flotation flowsheet was optimized and the recovery of copper was increased by 2.93 percentage points to 91.72%. The conclusion has important reference significance for the production of the same type of concentrators.

-

Key words:

- Flow structure /

- Rapid flotation /

- Two roughing /

- Early harvest and overharvest

-

-

表 1 矿石化学多元素分析结果/%

Table 1. Chemical multi-element analysis results of the ore

Au* Ag* Cu Mo Zn Fe S As Pb 0.35 23.27 0.85 0.018 0.031 6.66 0.99 0.078 0.030 Sb WO3 CaO MgO Al2O3 SiO2 Mn C / 0.008 9 0.052 26.52 1.39 4.41 35.42 0.25 2.06 / *单位为g/t。 表 2 选矿厂生产指标

Table 2. Production indicators of the concentrator

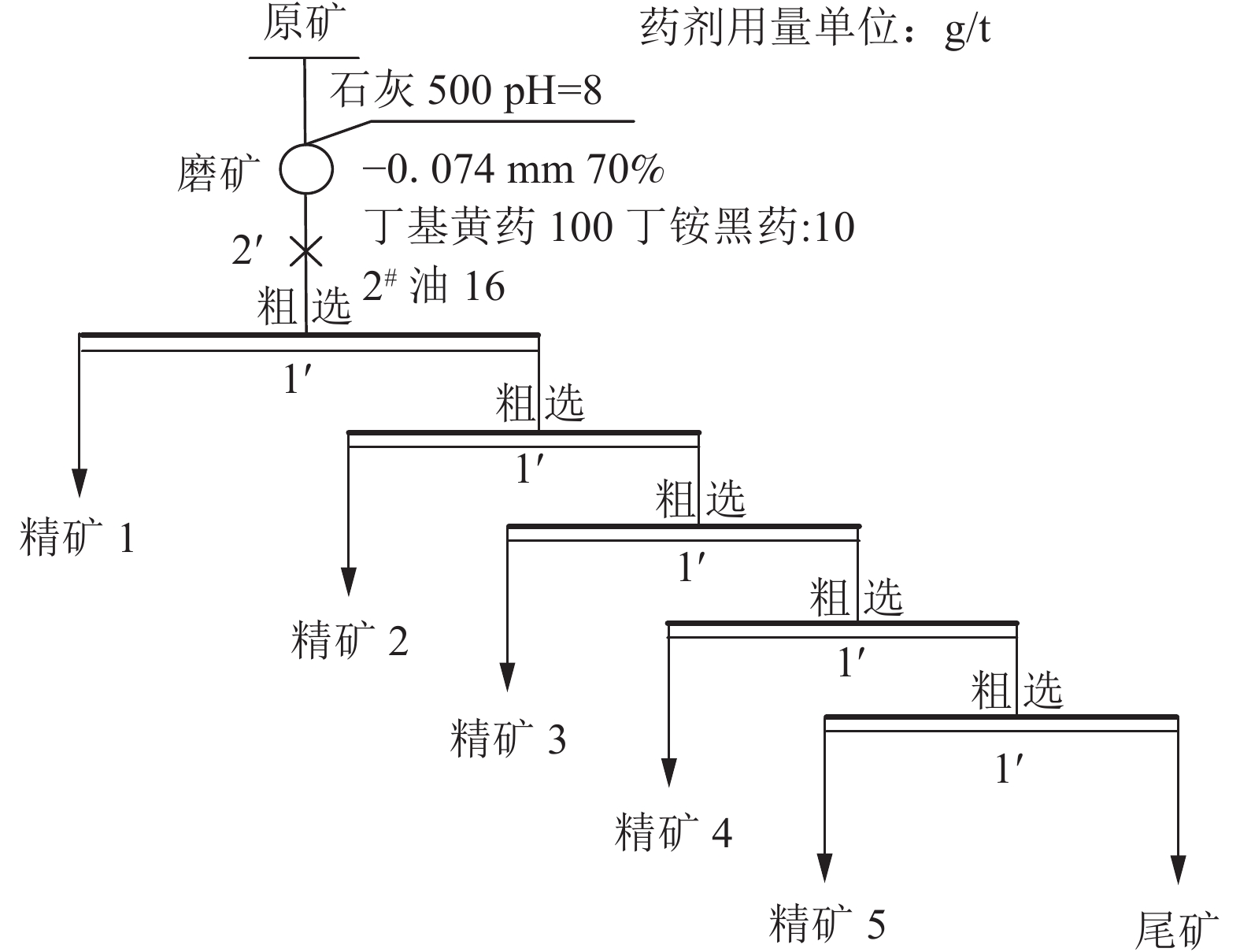

产品名称 产率/% Cu品位/% Cu回收率/% 铜精矿 3.79 19.91 88.79 尾矿 96.21 0.10 11.21 原矿 100.00 0.85 100.00 表 3 粗选浮选时间实验结果

Table 3. Test results of roughing flotation time

产品名称 产率/% Cu品位/% Cu回收率/% 精矿1 3.03 20.17 71.91 精矿2 1.05 8.53 10.54 精矿3 0.71 4.36 3.64 精矿4 0.60 2.23 1.58 精矿5 0.47 2.03 1.12 尾矿 94.14 0.10 11.21 粗精矿 5.86 12.88 88.79 原矿 100.00 0.85 100.00 表 4 常规流程与部分快速浮选流程对比实验结果

Table 4. Contrast test results of conventional and partial rapid flotation process

实验条件 产品名称 产率/% Cu品位/% Cu回收率/% 常规流程 精矿 3.79 19.91 88.79 尾矿 96.21 0.10 11.48 原矿 100.00 0.85 100.00 部分快速浮选 精矿 3.84 20.19 90.16 尾矿 96.16 0.088 9.84 原矿 100.00 0.86 100.00 表 5 常规浮选流程和两次粗选流程实验结果

Table 5. Test results of conventional flotation and two roughing processes

实验条件 产品名称 产率/% Cu品位/% Cu回收率/% 常规流程 精矿 6.80 10.97 88.79 尾矿 93.20 0.10 11.21 原矿 100.00 0.84 100.00 两次粗选 精矿 7.76 10.04 90.55 尾矿 92.24 0.088 9.45 原矿 100.00 0.86 100.00 表 6 闭路实验结果

Table 6. Results of the closed-circuit test

产品名称 产率/% Cu品位/% Cu回收率/% 精矿 4.02 19.72 92.18 尾矿 95.98 0.07 7.82 原矿 100.00 0.86 100.00 表 7 新型浮选工艺和常规流程工业指标

Table 7. Industrial indicators of new type flotation and conventional process

生产条件 产品名称 产率/% Cu品位/% Cu回收率/% 常规流程 铜精矿 3.79 19.91 88.79 尾矿 96.21 0.10 11.21 原矿 100.00 0.85 100.00 部分快速浮选+

两次粗选精矿 4.13 19.32 91.72 尾矿 95.87 0.075 8.28 原矿 100.00 0.87 100.00 -

[1] 周平, 唐金荣, 杨宗喜, 等. 铜矿资源战略分析 [M]. 北京: 地质出版社, 2012.ZHOU P, TANG J R, YANG Z X, et al. Strategic analysis of copper resources [M] . Beijing: Geology Press, 2012.

ZHOU P, TANG J R, YANG Z X, et al. Strategic analysis of copper resources [M] . Beijing: Geology Press, 2012.

[2] 王京, 石香江, 牛丽贤, 等. 基于情景分析法的我国铜资源需求预测[J]. 中国国土资源经济, 2015(5):53-57.WANG J, SHI X J, NIU L X, et al. Scenario analysis based demand forecast of copper resources in China[J]. China’s Land and Resources Economy, 2015(5):53-57. doi: 10.3969/j.issn.1672-6995.2015.05.017

WANG J, SHI X J, NIU L X, et al. Scenario analysis based demand forecast of copper resources in China[J]. China’s Land and Resources Economy, 2015(5):53-57. doi: 10.3969/j.issn.1672-6995.2015.05.017

[3] 唐菊兴, 王勤. 西藏铜矿资源优势及开发利用展望[J]. 中国工程科学, 2019, 21(1):140-147.TANG J X, WANG Q. Superiority and prospect of development and utilization of copper resources in Xizang[J]. Chinese Engineering Science, 2019, 21(1):140-147. doi: 10.15302/J-SSCAE-2019.01.020

TANG J X, WANG Q. Superiority and prospect of development and utilization of copper resources in Xizang[J]. Chinese Engineering Science, 2019, 21(1):140-147. doi: 10.15302/J-SSCAE-2019.01.020

[4] 沈继财. 部分快速浮选新工艺在某硫化铜矿中的应用研究[J]. 矿产综合利用, 2019(1):48-50+38.SHEN J C. Study on the application of partial rapid flotation in a copper sulfide ore[J]. Multipurpose Utilization of Mineral Resources, 2019(1):48-50+38. doi: 10.3969/j.issn.1000-6532.2019.01.010

SHEN J C. Study on the application of partial rapid flotation in a copper sulfide ore[J]. Multipurpose Utilization of Mineral Resources, 2019(1):48-50+38. doi: 10.3969/j.issn.1000-6532.2019.01.010

[5] 李宁. 一种胶磷矿浮选工艺改造实践[J]. 矿产综合利用, 2018(3):129-131.LI N. Reform practice of flotation process for collophanite[J]. Multipurpose Utilization of Mineral Resources, 2018(3):129-131. doi: 10.3969/j.issn.1000-6532.2018.03.027

LI N. Reform practice of flotation process for collophanite[J]. Multipurpose Utilization of Mineral Resources, 2018(3):129-131. doi: 10.3969/j.issn.1000-6532.2018.03.027

[6] 王伟之, 刘泽伟, 来有邦. 某磁赤混合铁矿的柱式阳离子反浮选实验研究[J]. 矿产综合利用, 2017(6):64-67.WANG W Z, LIU Z W, LAI Y B. Experimental study on column cation reverse flotation of a magnetic hematite mixed iron ore[J]. Multipurpose Utilization of Mineral Resources, 2017(6):64-67. doi: 10.3969/j.issn.1000-6532.2017.06.013

WANG W Z, LIU Z W, LAI Y B. Experimental study on column cation reverse flotation of a magnetic hematite mixed iron ore[J]. Multipurpose Utilization of Mineral Resources, 2017(6):64-67. doi: 10.3969/j.issn.1000-6532.2017.06.013

[7] 杨春刚, 戈保梁, 张晋禄, 等. 汤丹某难选氧化铜选矿实验研究[J]. 矿产综合利用, 2017(1):37-41+36.YANG C G, GE B L, ZHANG J L, et al. Experimental study on a refractory copper oxide ore in Tangdan[J]. Multipurpose Utilization of Mineral Resources, 2017(1):37-41+36. doi: 10.3969/j.issn.1000-6532.2017.01.008

YANG C G, GE B L, ZHANG J L, et al. Experimental study on a refractory copper oxide ore in Tangdan[J]. Multipurpose Utilization of Mineral Resources, 2017(1):37-41+36. doi: 10.3969/j.issn.1000-6532.2017.01.008

[8] 王显强, 戈保梁, 伏彦雄, 等. 某混合铜矿选矿实验研究[J]. 矿产综合利用, 2016(4):31-34+20.WANG X Q, GE B L, FU Y X, et al. Experimental study on beneficiation of a mixed copper ore[J]. Multipurpose Utilization of Mineral Resources, 2016(4):31-34+20. doi: 10.3969/j.issn.1000-6532.2016.04.007

WANG X Q, GE B L, FU Y X, et al. Experimental study on beneficiation of a mixed copper ore[J]. Multipurpose Utilization of Mineral Resources, 2016(4):31-34+20. doi: 10.3969/j.issn.1000-6532.2016.04.007

[9] 张艳娇, 常学勇, 郭珍旭, 等. 新疆某铁尾矿中伴生钴的回收实验研究[J]. 矿产保护与利用, 2019, 39(2):37-40.ZHANG Y J, CHANG X Y, GUO Z X, et al. Experimental study on recovery of associated cobalt from an iron tailings in Xinjiang[J]. Protection and Utilization of Mineral Resources, 2019, 39(2):37-40. doi: 10.13779/j.cnki.issn1001-0076.2018.06.040

ZHANG Y J, CHANG X Y, GUO Z X, et al. Experimental study on recovery of associated cobalt from an iron tailings in Xinjiang[J]. Protection and Utilization of Mineral Resources, 2019, 39(2):37-40. doi: 10.13779/j.cnki.issn1001-0076.2018.06.040

-

下载:

下载: