Removal and Recycling of Antimony in a Gold Concentrate

-

摘要:

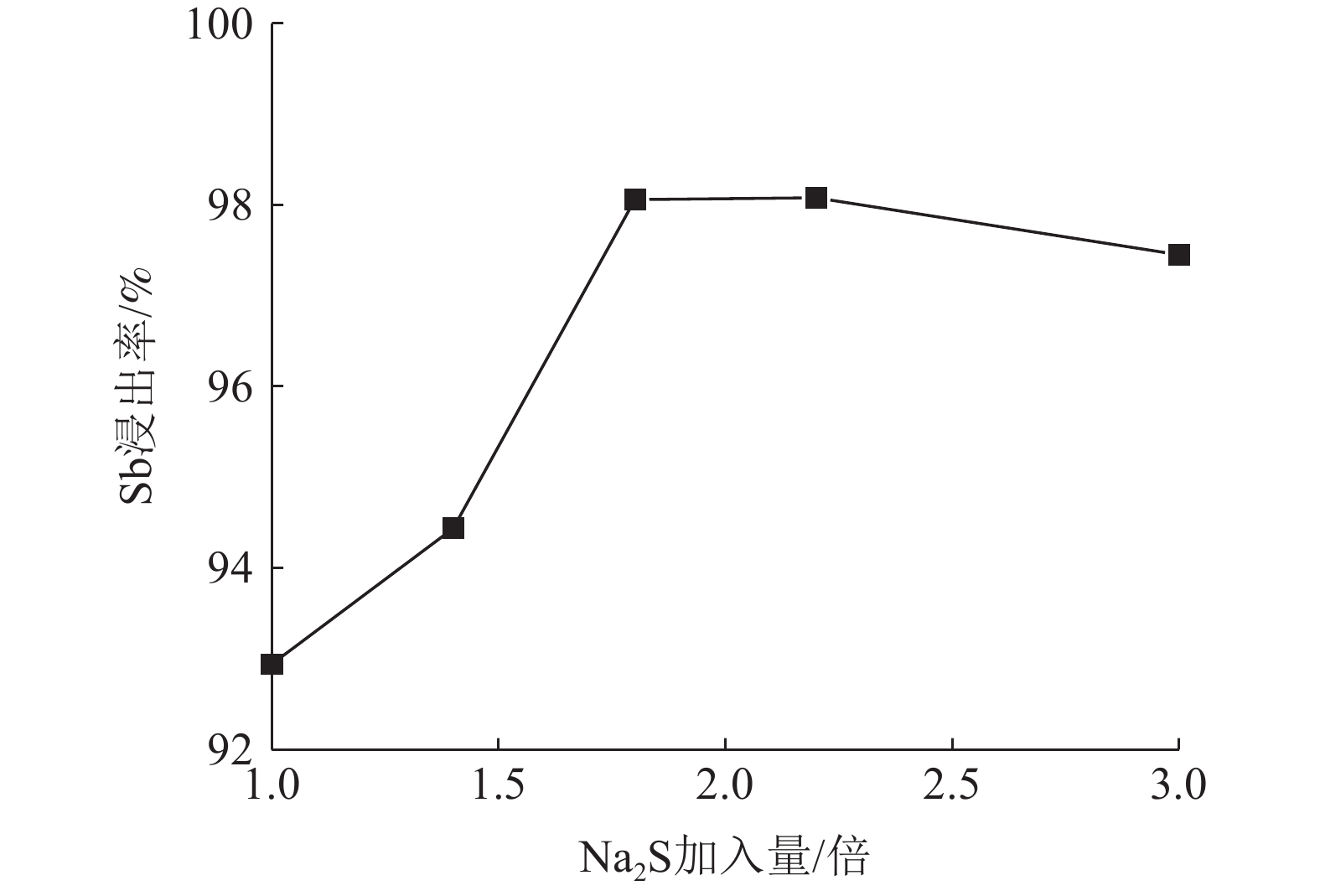

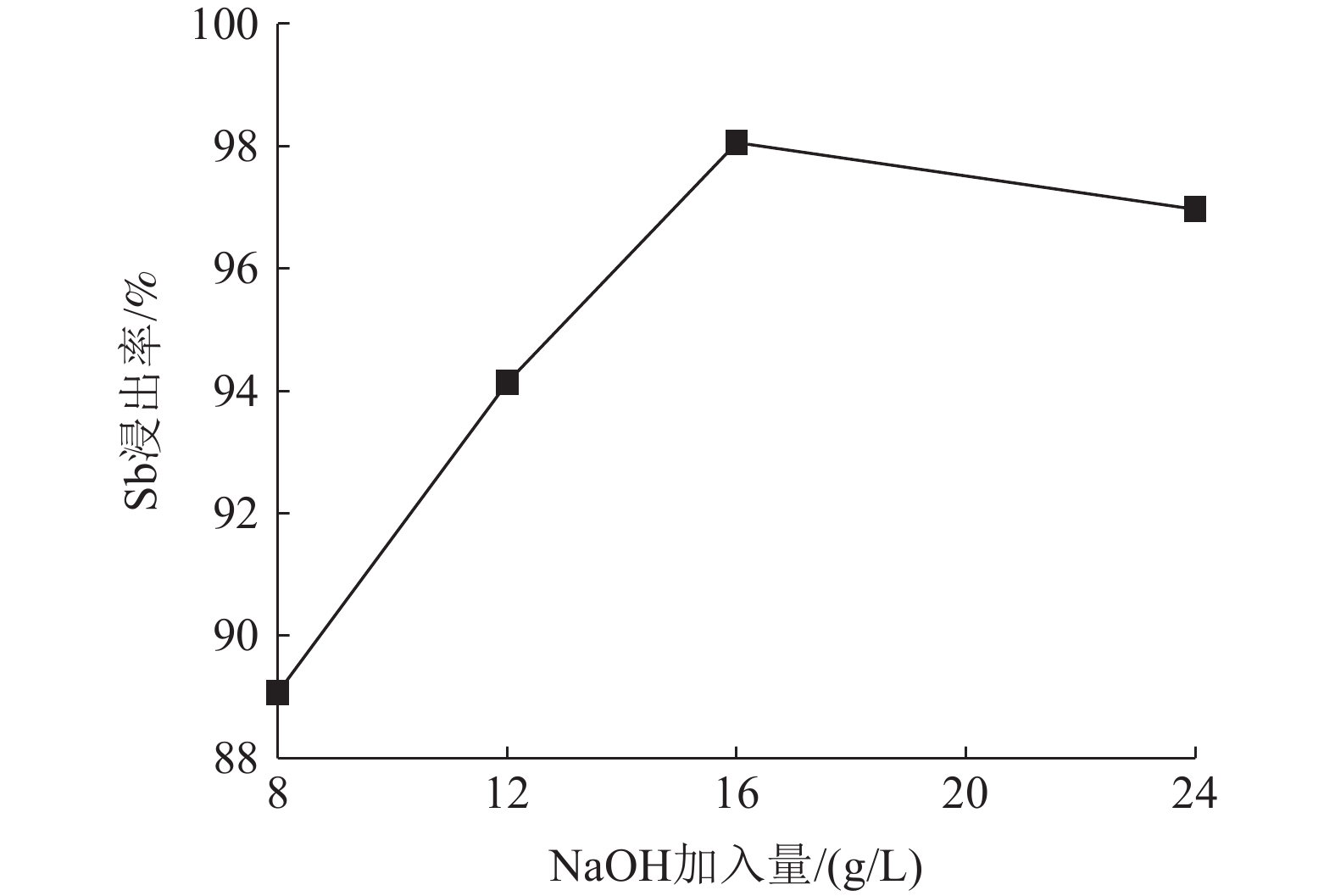

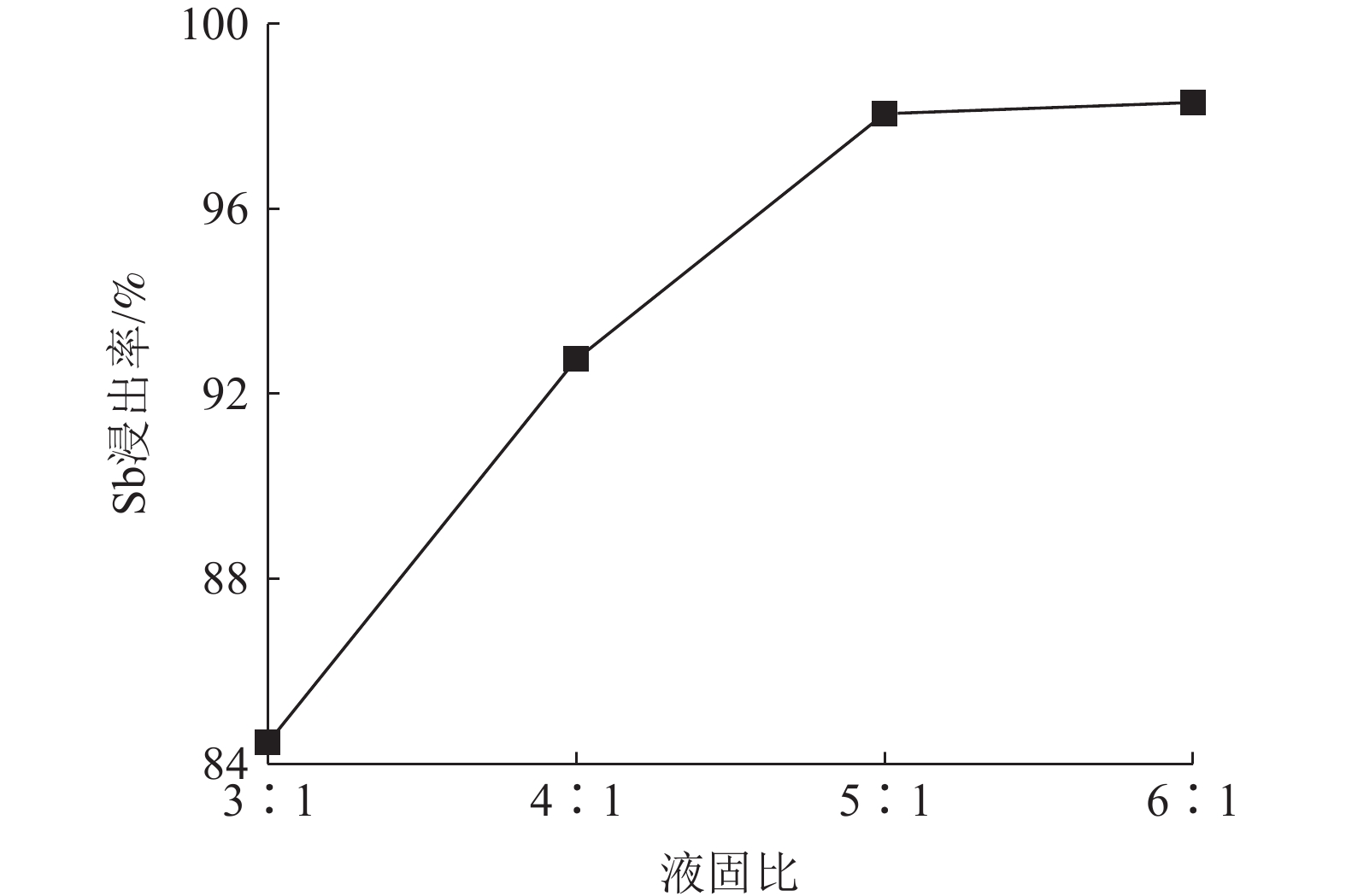

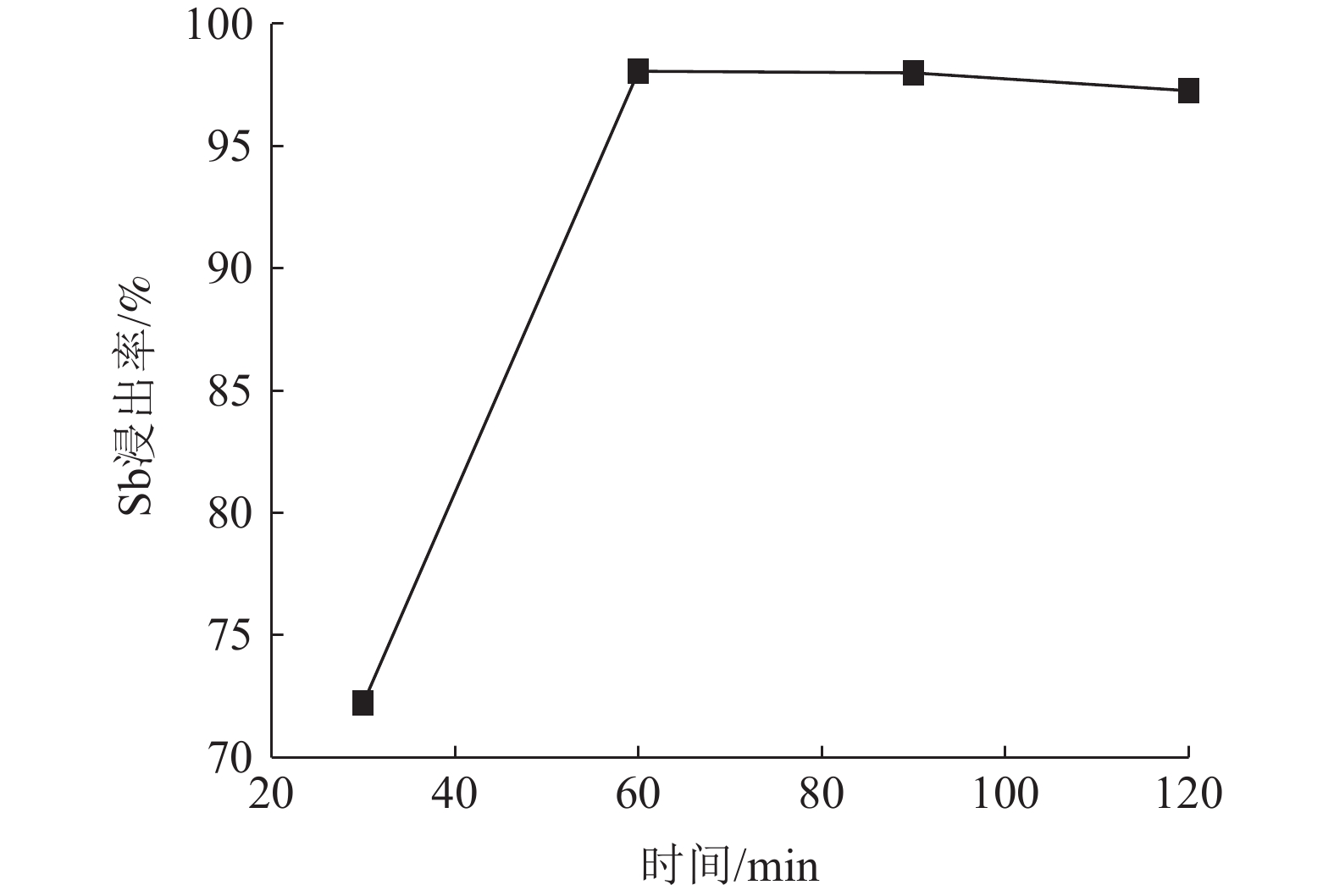

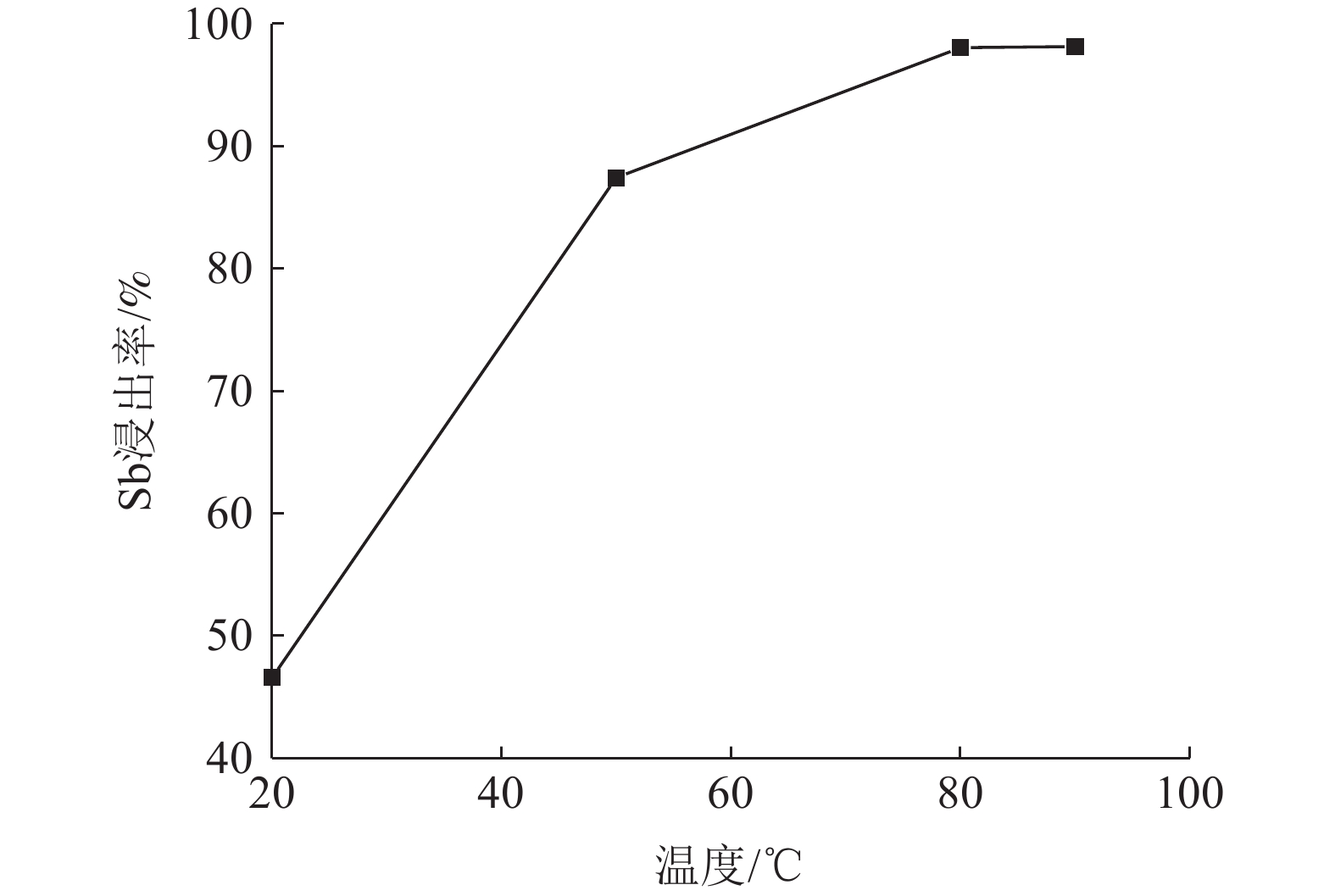

本文对金精矿进行了碱浸预处理脱锑,并对脱锑液的回收利用进行了实验研究。实验确定了运用NaOH-Na2S工艺对金精矿中的锑进行了脱除,达到了降低金精矿中杂质元素锑的目的,确定了脱锑较佳工艺参数,即Na2S加入量为理论量的1.8倍、温度80 ℃、NaOH浓度16 g/L、液固比5∶1、时间60 min,在较佳工艺条件下锑脱除率可达98%。可运用中和沉淀法回收利用锑,也可运用氧化法从浸锑液中回收得到合格的锑盐产品,含锑可达49%。

Abstract:In this article, antimony was removed from the gold concentratebythe alkali leaching method, and then the recovery of antimony solution was also studied. The test used NaOH-Na2S process to remove in gold concentrate, which achieved the purpose of reducing antimony in the gold concentrate, and determined the best process parameters for the antimony removal.The addition amount of Na2S is more than 1.8 times the theoretical amount, the temperature is 80 ℃, the NaOH concentration is 16 g/L, the liquid to solid ratio is 5∶1, the time is 60 min, and the removal rate can reach more than 98% at the optimal process conditions. Antimony can be recovered by neutralizing precipitation method, oxygen method can also be used from the antimony solution to obtain qualified antimony salt products, and the antimony content can reach more than 49%.

-

Key words:

- Gold concentrate /

- NaOH-Na2S /

- Antimony removal /

- Recycled antimony

-

-

表 1 金精矿原料化学成分

Table 1. Chemical composition of the gold concentrate

部分金属及SiO2含量/% 贵金属含量/(g/t) Ni Cu Fe As Bi Sb SiO2 Au Pd Pt Ag 0.013 0.048 17.83 6.34 0.009 8 4.32 30.85 52.3 0.05 0.05 17.0 表 2 金精矿中各矿物相对含量统计结果/%

Table 2. Statistical results of the relative content of each mineral in gold concentrate

矿物分类 矿物名称 相对含量 小计 金属硫化矿物 方铅矿 0.01 54.17 黄铁矿 25.83 辉锑矿 10.48 毒砂 17.78 闪锌矿 0.07 金属氧化物 磁铁矿(含少量As、Sb) 0.94 0.94 硅酸盐矿物(脉石) 钾长石 19.95 44.40 白云石 5.00 石英 19.44 副矿物 锆石 0.01 0.49 其他 0.48 合计 100.00 100.00 表 3 工艺条件验证实验结果

Table 3. Results of the optimal process condition validation test

编号 渣量/g 含量 脱除率/% Sb/% Au/(g/t) Sb Au 原料1# 200.0 4.32 52.3 1# 184.8 0.074 56.4 98.41 0.36 2# 188.4 0.079 55.2 98.27 0.58 表 4 较佳工艺条件下脱锑金属平衡

Table 4. Antimony removal metal balance sheet at the recommended process conditions

类别 名称 物料量 Sb Au 品位 含量/g 分配率/% 品位/(g/t) 含量/g 分配率/% 投入 原料 600 g 4.32% 25.92 100.00 52.3 0.031 38 100.00 合计 25.92 100.00 0.031 38 100.00 产出 渣 530.4 g 0.07% 0.371 1.43 61.77 0.032 76 100.00 液 2 900 mL 8.70 g/L 25.23 97.56 未检出 0 0 洗水 950 mL 0.27 g/L 0.257 0.99 未检出 0 0 合计 25.86 100.00 0.032 76 100.00 误差率 +0.23% +4.14% 表 5 中和法沉淀锑实验结果

Table 5. Results of the neutralization method for the precipitation antimony test

名称 液/渣量 Sb含量 浸锑液 2 000 mL 7.77 g/L 中和液 1 881 mL 0.002 7 g/L 中和渣 34.2 g 45.12% 沉淀率 99.29% 表 6 氧化实验产出锑盐成分/%

Table 6. Antimony salt composition obtained from the concentrated oxidation test

实验编号 Sb Mn 1# 49.63 0.006 5 2# 49.09 0.005 1 -

[1] 李勇, 徐忠敏, 吕翠翠, 等. 碱浸预处理提高某含砷锑难处理金精矿回收率的试验研究[J]. 黄金, 2013, 34(3):61-64.LI Y, XU Z M, LYU C C, et al. Experimental research on the improvement of gold recovery rate applying alkaline leaching pretreatment of a refractory arsenic and antimony contained gold concentrate[J]. Gold, 2013, 34(3):61-64.

LI Y, XU Z M, LYU C C, et al. Experimental research on the improvement of gold recovery rate applying alkaline leaching pretreatment of a refractory arsenic and antimony contained gold concentrate[J]. Gold, 2013, 34(3):61-64.

[2] 王梅君, 谢洪珍. Solomon某金矿浸出工艺探索研究[J]. 矿产综合利用, 2020(2):71-74.WANG M J, XIE H Z. Study on leaching technology of a gold ore in Solomon[J]. Multipurpose Utilization of Mineral Resources, 2020(2):71-74. doi: 10.3969/j.issn.1000-6532.2020.02.012

WANG M J, XIE H Z. Study on leaching technology of a gold ore in Solomon[J]. Multipurpose Utilization of Mineral Resources, 2020(2):71-74. doi: 10.3969/j.issn.1000-6532.2020.02.012

[3] 贺秀珍, 钟清慎, 马玉天, 等. 复杂金精矿矿物特性及焙烧预处理工艺研究[J]. 有色金属(冶炼部分), 2014(8):38-41.HE X Z, ZHONG Q S, MA Y T, et al. Study of mineral characteristics and roasting pretreatment technology of complex gold concentrate[J]. Nonferrous Metals(Extractive Mentallurgy), 2014(8):38-41.

HE X Z, ZHONG Q S, MA Y T, et al. Study of mineral characteristics and roasting pretreatment technology of complex gold concentrate[J]. Nonferrous Metals(Extractive Mentallurgy), 2014(8):38-41.

[4] 温建康, 阮仁满. 高硫含砷金精矿加碱焙烧—氰化浸出工艺的研究[J]. 黄金, 1996, 17(9):34-37.WEN J K, RUAN R M. Study on alkalinebaking-cyanide leaching of high-sulfur, arsenic-containing gold concentrate[J]. Gold, 1996, 17(9):34-37.

WEN J K, RUAN R M. Study on alkalinebaking-cyanide leaching of high-sulfur, arsenic-containing gold concentrate[J]. Gold, 1996, 17(9):34-37.

[5] 靳冉公, 王云, 李云, 等. 碱性硫化钠浸出含锑金精矿过程中金锑行为[J]. 有色金属(冶炼部分), 2014(7): 38-41.JIN R G, WANG Y, LI Y, et al. Behavior of gold and antimony during leaching of Sb-bearing gold concentrate sodium sulfide. Nonferrous Metals(Extractive Mentallurgy), 2014(7): 38-41.

JIN R G, WANG Y, LI Y, et al. Behavior of gold and antimony during leaching of Sb-bearing gold concentrate sodium sulfide. Nonferrous Metals(Extractive Mentallurgy), 2014(7): 38-41.

[6] 张水龙, 刘金艳, 杨林恒, 等. 吉林铜钴镍多金属硫化矿的生物浸出实验研究[J]. 矿产综合利用, 2020(1):50-53.ZHANG S L, LIU J Y, YANG L H, et al. Bioleaching of copper-cobalt-nickel polymetallic sulfide ores in Jilin[J]. Multipurpose Utilization of Mineral Resources, 2020(1):50-53. doi: 10.3969/j.issn.1000-6532.2020.01.010

ZHANG S L, LIU J Y, YANG L H, et al. Bioleaching of copper-cobalt-nickel polymetallic sulfide ores in Jilin[J]. Multipurpose Utilization of Mineral Resources, 2020(1):50-53. doi: 10.3969/j.issn.1000-6532.2020.01.010

[7] 李双双, 戴友芝, 罗春香, 等. 锑在水中的形态变化及除锑技术现状[J]. 化工环保, 2009, 29(2):131-134.LI S S, DAI Y Z, LUO C X, et al. Morphological changes of antimony in water and status quo of antimony-removal technologies[J]. Enviromental protection of chemical industry, 2009, 29(2):131-134. doi: 10.3969/j.issn.1006-1878.2009.02.008

LI S S, DAI Y Z, LUO C X, et al. Morphological changes of antimony in water and status quo of antimony-removal technologies[J]. Enviromental protection of chemical industry, 2009, 29(2):131-134. doi: 10.3969/j.issn.1006-1878.2009.02.008

-

下载:

下载: