Beneficiation Process Test of a Refractory Iron Ore in Zimbabwe

-

摘要:

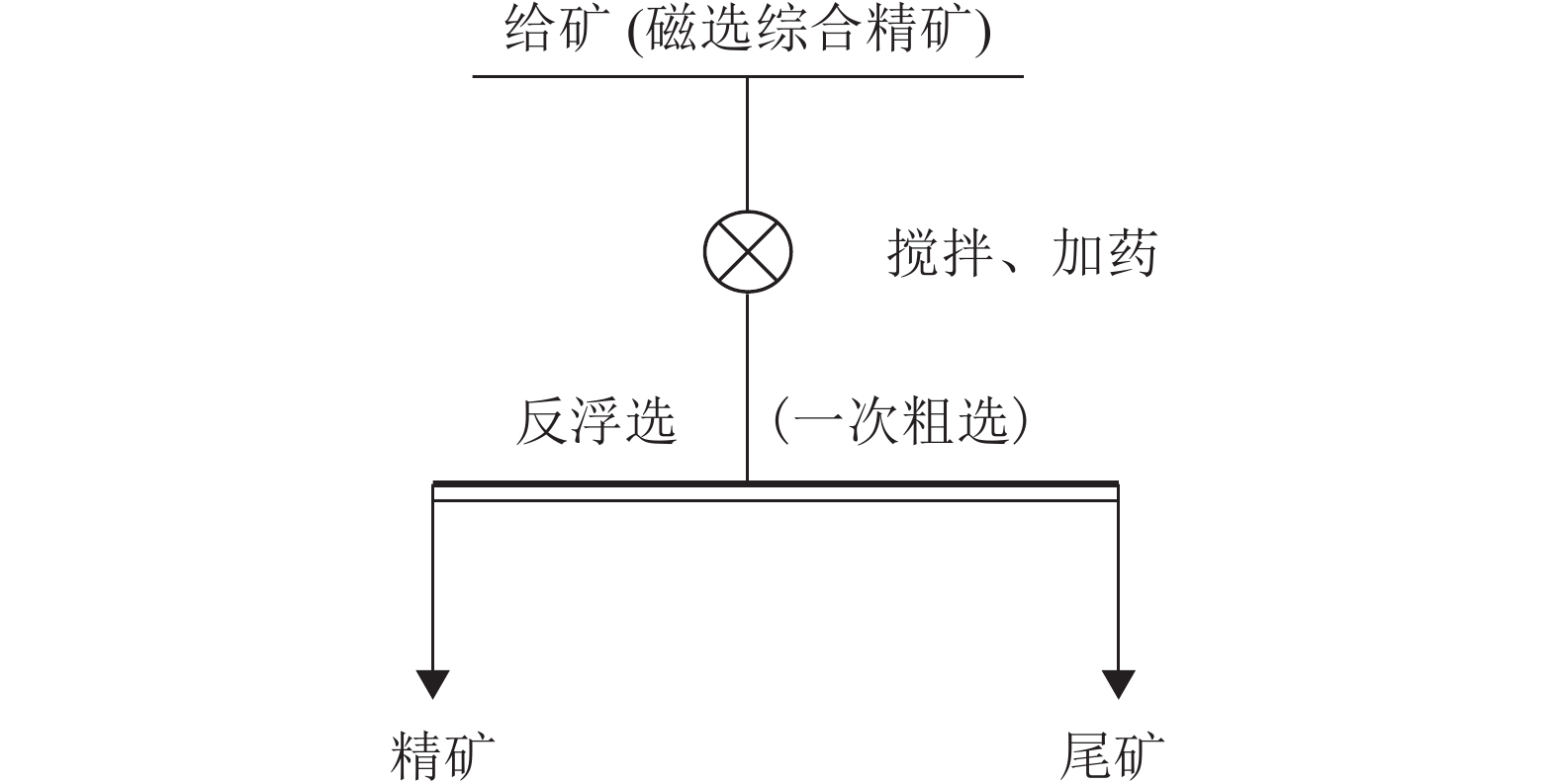

为了确定津巴布韦某难选铁矿石合理的选矿工艺流程和技术指标,更好地开发该矿山铁矿石资源,在原矿化学多元素分析、铁物相分析、矿物组成分析、主要矿物单体解离度分析等矿石性质研究的基础上,进行了大量的工艺条件实验,最终确定了阶段磨矿-弱磁选-脉动高梯度强磁选-磁选精矿阳离子反浮选的工艺流程。研究表明,矿石中有用铁矿物以磁铁矿、赤铁矿为主,且结晶粒度较细,主要分布在-0.05 mm,在一段磨矿粒度P80 63 μm条件下进行一段弱磁选和强磁选、二段磨矿粒度P80 45 μm条件下进行二段弱磁选、强磁选和阳离子反浮选,可以获得产率38.25%、铁品位66.75%、SiO2含量3.56%的合格铁精矿,达到精矿品位≥66.20%的目标要求。

Abstract:In order to determine the reasonable beneficiation process and technical indicators of the refractory iron ore in Zimbabwe and better develop its iron ore resources , a lot of process condition tests were carried out based on ore properties such as chemical element analysis of the raw ore, iron phase, mineral composition, and dissociation degree analysis of main mineral monomers. Finally, the process flow of stage grinding-low-intensity magnetic separation-pulsed high-gradient magnetic separation- cationic reverse flotation was determined. The results show that the useful iron minerals in the ore are mainly magnetite and hematite, and the crystal size is fine, mainly distributed below -0.05 mm. At the condition of primary grinding particle size P80 63 μm, the first stage low-intensity magnetic separation and high-intensity magnetic separation are carried out, and the second stage low- intensity magnetic separation, high-intensity magnetic separation and cationic reverse flotation are carried out at the condition of secondary grinding particle size P80 45 μm. The qualified iron concentrate with yield of 38.25%, iron grade of 66.75% and SiO2 content of 3.56% can be obtained, which meets the target requirement of concentrate grade ≥ 66.20%.

-

-

表 1 原矿化学多元素分析结果/%

Table 1. Multi-element analysis results of the raw ore

TFe SiO2 CaO MgO Al2O3 S P TiO2 PbO 39.03 39.50 0.25 0.98 0.35 0.05 0.027 0.017 0.037 K2O Na2O Cu Zn NiO CrO V MnO 烧损 0.052 0.007 未检出 未检出 0.011 0.076 0.002 5 0.16 1.34 表 2 原矿铁物相分析结果

Table 2. Phase analysis results of the iron raw ore

铁物相 磁铁矿 赤、褐铁矿 磁黄铁矿 黄铁矿 碳酸铁 硅酸铁 合计 含铁量/% 23.38 11.63 0.15 0.40 2.08 1.51 39.15 铁分布率/% 59.72 29.71 0.38 1.02 5.31 3.86 100.00 表 3 物理机械性能分析结果

Table 3. Physical and mechanical properties analysis results

产品名称 密度/(g/cm3) 松散密度/(g/cm3) 安息角/(°) 原矿 3.67 2.23 36 表 4 矿石矿物组成及含量分析结果/%

Table 4. Ore mineral composition and content analysis results

磁铁矿 赤铁矿 褐铁矿 黄铁矿

(磁黄铁)石英 碳酸盐 菱铁矿 方解石、白云石 32.34 15.64 1.22 1.17 36.98 6.50 闪石 绿泥石 粘土 黑云母 其他 合计 0.47 1.28 2.19 2.21 微 100.00 表 5 矿石中主要矿物工艺粒度分析结果

Table 5. Analysis results of process particle size of the main minerals in the ore

矿物 粒级/mm -0.01 -0.02

+0.01-0.03

+0.02-0.04

+0.03-0.05

+0.04-0.06

+0.05-0.07

+0.06-0.08

+0.07-0.09

+0.08-0.10

+0.09-0.15

+0.10-0.20

+0.15+0.20 合计

分

布

率

/%磁铁矿 11.38 13.72 14.37 10.34 10.14 4.78 3.81 4.02 4.17 3.84 8.43 5.42 5.58 100.00 累 计 11.38 25.10 39.47 49.81 59.95 64.73 68.54 72.56 76.73 80.57 89.00 94.42 100.00 赤铁矿 15.37 16.27 13.78 10.73 8.24 3.72 2.77 3.03 3.47 3.13 8.32 7.18 3.99 100.00 累 计 15.37 31.64 45.42 56.15 64.39 68.11 70.88 73.91 77.38 80.51 88.83 96.01 100.00 石英 0.41 0.67 3.54 2.99 4.55 4.44 4.65 4.81 4.62 3.93 13.84 11.27 40.28 100.00 累 计 0.41 1.08 4.62 7.61 12.16 16.60 21.25 26.06 30.68 34.61 48.45 59.72 100.00 碳酸盐 0.21 0.36 4.00 4.77 4.69 3.90 5.51 0.25 0.97 2.83 11.87 12.08 48.56 100.00 累 计 0.21 0.57 4.57 9.34 14.03 17.93 23.44 23.69 24.66 27.49 39.36 51.44 100.00 绿泥石 0.38 3.63 9.15 15.04 9.06 6.10 2.13 5.27 9.23 4.96 6.70 2.32 26.03 100.00 累 计 0.38 4.01 13.16 28.20 37.26 43.36 45.49 50.76 59.99 64.95 71.65 73.97 100.00 表 6 一段磨矿细度实验结果

Table 6. Test results of grinding fineness in single stage

磨矿粒度

P80/μm产品名称 产率/% 铁品位/% 回收率/% 300 弱磁精矿 53.56 84.33 51.05 44.10 70.03 95.26 强磁精矿 30.77 32.02 25.23 尾矿 15.67 11.81 4.74 给矿 100.00 39.04 100.00 180 弱磁精矿 52.01 82.24 52.41 45.08 69.43 94.44 强磁精矿 30.23 32.49 25.01 尾矿 17.76 12.25 5.55 给矿 100.00 39.26 99.99 95 弱磁精矿 43.70 76.88 57.26 47.22 63.63 92.32 强磁精矿 33.18 34.00 28.69 尾矿 23.12 13.08 7.68 给矿 100.00 39.32 100.00 75 弱磁精矿 41.70 74.72 58.55 47.95 62.18 91.24 强磁精矿 33.02 34.55 29.06 尾矿 25.28 13.60 8.76 给矿 100.00 39.27 100.00 63 弱磁精矿 40.88 73.17 59.73 48.97 61.74 90.59 强磁精矿 32.29 35.33 28.85 尾矿 26.83 13.86 9.41 给矿 100.00 39.55 100.00 53 弱磁精矿 39.65 74.29 60.43 48.87 60.61 91.85 强磁精矿 34.64 35.66 31.24 尾矿 25.71 12.54 8.15 给矿 100.00 39.53 100.00 表 7 一段磨矿—弱磁选验证实验结果

Table 7. Test results of single stage of grinding- low-intensity magnetic separation validation

磨矿粒度 产品名称 作业产率/% 铁品位/% 铁回收率/% P80 63 μm 精矿 41.08 59.23 61.83 尾矿 58.92 25.49 38.17 给矿 100.00 39.35 100.00 表 8 一段高梯度强磁选磁场强度实验结果

Table 8. Test results of magnetic field strength of single stage of high-gradient high-intensity magnetic separation

磁场强度/(kA/m) 产品名称 作业产率/% 铁品位/% 回收率/% 795.77 精 矿 57.19 35.08 79.19 尾 矿 42.81 12.32 20.81 给 矿 100.00 25.33 100.00 636.62 精 矿 56.77 35.44 78.90 尾 矿 43.23 12.45 21.10 给 矿 100.00 25.50 100.00 477.46 精 矿 54.62 35.64 75.85 尾 矿 45.38 13.66 24.15 给 矿 100.00 25.67 100.00 318.30 精 矿 49.87 36.94 71.70 尾 矿 50.13 14.50 28.30 给 矿 100.00 25.69 100.00 159.15 精 矿 38.90 37.88 57.53 尾 矿 61.10 17.80 42.47 给 矿 100.00 25.62 100.00 表 9 二段磨矿细度、磁选实验结果

Table 9. Test results of second stage grinding fineness and magnetic separation

磨矿粒度

P80/μm产品名称 产率/% 品位/% 回收率/% 53 弱磁精矿 54.31 87.49 60.80 52.22 68.19 94.36 强磁精矿 33.18 38.20 26.17 尾矿 12.51 21.79 5.64 给矿 100.00 48.42 100.00 45 弱磁精矿 54.19 85.61 61.20 52.87 68.31 93.24 强磁精矿 31.42 38.51 24.93 尾矿 14.39 22.81 6.76 给矿 100.00 48.54 100.00 38 弱磁精矿 52.41 81.91 63.11 54.97 67.65 92.07 强磁精矿 29.50 40.47 24.42 尾矿 18.09 21.47 7.93 给矿 100.00 48.90 100.00 28 弱磁精矿 48.99 80.34 64.44 56.13 64.61 92.30 强磁精矿 31.35 43.17 27.69 尾矿 19.66 19.10 7.70 给矿 100.00 48.86 100.00 表 10 二段高梯度强磁选磁场强度实验结果

Table 10. Test results of magnetic field strength for second stage high-gradient strong magnetic separation

强磁磁场强度/

(kA/m)产品名称 产率/% 品位/% 回收率/% 795.77 弱磁精矿 53.54 86.66 61.70 52.75 67.88 93.94 强磁精矿 33.12 38.30 26.06 尾矿 13.34 22.08 6.06 给矿 100.00 48.66 100.00 636.62 弱磁精矿 53.54 86.06 61.70 53.03 67.64 93.46 强磁精矿 32.52 38.78 25.82 尾矿 13.94 22.85 6.54 给矿 100.00 48.83 100.00 477.46 弱磁精矿 53.54 85.64 61.70 49.58 44.98 87.24 强磁精矿 32.10 38.40 42.26 尾矿 14.36 23.08 12.76 给矿 100.00 48.67 100.00 318.30 弱磁精矿 53.54 84.64 61.70 53.91 67.08 92.67 强磁精矿 31.10 40.50 25.59 尾矿 15.36 23.50 7.33 给矿 100.00 49.24 100.00 表 11 一段弱磁精矿和强磁精矿的混合精矿不同捕收剂种类浮选实验结果

Table 11. Results of flotation test of different types of collector for mixed concentrate of one section of weak and strong magnetic concentrate

捕收剂

名称产品

名称产率/% 铁品位/% 回收率/% 实验条件 MD-28 精 矿 64.06 58.98 77.53 NaOH:1 000 g/t

淀粉:600 g/t

CaO:400 g/t

捕收剂:1 000 g/t尾 矿 35.94 30.46 22.47 给 矿 100.00 48.73 100.00 MF 精 矿 61.89 62.25 78.75 NaOH:1 000 g/t

淀粉:600 g/t

CaO:400 g/t

捕收剂:500 g/t尾 矿 38.11 27.28 21.25 给 矿 100.00 48.92 100.00 十二胺 精 矿 64.35 61.50 81.05 NaOH:200 g/t

淀粉:600 g/t

捕收剂:400 g/t尾 矿 35.65 25.96 18.95 给 矿 100.00 48.83 100.00 MAS 精 矿 63.55 60.70 79.95 NaOH:600 g/t

淀粉:600 g/t

捕收剂:200 g/t尾 矿 36.45 26.54 20.05 给 矿 100.00 48.25 100.00 表 12 二段磁选精矿浮选实验结果

Table 12. Results of flotation tests of second stage magnetic separation concentrate

磨矿粒度P80/μm 产品名称 产率/% 品位/% 回收率/% 53 反浮选精矿 55.00 63.87 67.23 尾 矿 45.00 38.05 32.77 给 矿 100.00 52.25 100.00 45 反浮选精矿 45.67 66.45 57.32 尾 矿 54.33 41.60 42.68 给 矿 100.00 52.95 100.00 38 反浮选精矿 44.50 66.78 54.22 尾 矿 55.50 45.20 45.78 给 矿 100.00 54.81 100.00 28 反浮选精矿 42.15 66.95 50.14 尾 矿 57.85 48.50 49.86 给 矿 100.00 56.28 100.00 表 13 反浮选闭路实验结果

Table 13. Results of reverse flotation closed-circuit test

产率/% 铁品位/% 回收率/% 精矿 60.00 66.75 75.51 尾矿 40.00 32.47 24.49 原矿 100.00 53.04 100.00 -

[1] 陈雯, 张立刚. 复杂难选铁矿选矿技术现状及发展趋势[J]. 有色金属(选矿部分), 2013(S1):19-23.CHEN W, ZHANG L G. Present situation and development trend of beneficiation technology for complex refractory iron ore[J]. Nonferrous Metals(Mineral Processing Section), 2013(S1):19-23.

CHEN W, ZHANG L G. Present situation and development trend of beneficiation technology for complex refractory iron ore[J]. Nonferrous Metals(Mineral Processing Section), 2013(S1):19-23.

[2] 孙炳泉. 我国复杂难选铁矿石选矿技术进展[J]. 金属矿山, 2005(8):31-34.SUN B Q. Advances in beneficiation technology of complex refractory iron ore in China[J]. Metal Mine, 2005(8):31-34.

SUN B Q. Advances in beneficiation technology of complex refractory iron ore in China[J]. Metal Mine, 2005(8):31-34.

[3] 刘杰, 周明顺, 翟立委, 等. 中国复杂难选铁矿的研究现状[J]. 中国矿业, 2011, 20(5):63-66.LIU J, ZHOU M S, ZHAI L W, et al. Research status of complex refractory iron ore in China[J]. China Mining Magazine, 2011, 20(5):63-66.

LIU J, ZHOU M S, ZHAI L W, et al. Research status of complex refractory iron ore in China[J]. China Mining Magazine, 2011, 20(5):63-66.

[4] 印万忠, 徐东, 杨耀辉, 等. 承德某钒钛磁铁矿尾矿资源化利用技术研究[J]. 矿产综合利用, 2020, 41(6):37-42.YIN W Z, XU D, YANG Y H, et al. Research on the recycling technology of vanadium-titanium magnetite tailings in Chengde[J]. Multipurpose Utilization of Mineral Resources, 2020, 41(6):37-42. doi: 10.3969/j.issn.1000-6532.2020.06.007

YIN W Z, XU D, YANG Y H, et al. Research on the recycling technology of vanadium-titanium magnetite tailings in Chengde[J]. Multipurpose Utilization of Mineral Resources, 2020, 41(6):37-42. doi: 10.3969/j.issn.1000-6532.2020.06.007

[5] 刘树永, 杨光, 袁立宾, 等. 东鞍山铁矿石工艺矿物学特征及选矿实验[J]. 矿产综合利用, 2024, 45(4):175-181.LIU S Y, YANG G, YUAN L B, et al. Technological mineralogical characteristics and mineral processing test of Donganshan iron ore[J]. Multipurpose Utilization of Mineral Resources, 2024, 45(4):175-181.

LIU S Y, YANG G, YUAN L B, et al. Technological mineralogical characteristics and mineral processing test of Donganshan iron ore[J]. Multipurpose Utilization of Mineral Resources, 2024, 45(4):175-181.

[6] 李金龙, 李明彦, 赵礼兵, 等. 黑山铁矿选铁工艺中的矿物基因特性分析[J]. 矿产综合利用, 2023, 44(6):197-201.LI J L, LI M Y, ZHAO L B, et al. Analysis of mineral gene characteristics in iron separation process of Heishan iron mine[J]. Multipurpose Utilization of Mineral Resources, 2023, 44(6):197-201.

LI J L, LI M Y, ZHAO L B, et al. Analysis of mineral gene characteristics in iron separation process of Heishan iron mine[J]. Multipurpose Utilization of Mineral Resources, 2023, 44(6):197-201.

[7] 洪秋阳, 李美荣, 李波, 等. 国外某难选冶钒钛铁矿石工艺矿物学特征[J]. 矿产综合利用, 2020(6):48-55.HONG Q Y, LI M R, LI B, et al. Process mineralogical characteristics of a foreign refractory vanadium-titanium iron ore[J]. Multipurpose Utilization of Mineral Resources, 2020(6):48-55.

HONG Q Y, LI M R, LI B, et al. Process mineralogical characteristics of a foreign refractory vanadium-titanium iron ore[J]. Multipurpose Utilization of Mineral Resources, 2020(6):48-55.

[8] 朱一民. 2019年浮选药剂的进展[J]. 矿产综合利用, 2020, 41(5):1-17.ZHU Y M. Present situation of zinc metallurgical slags and dusts treatment technology[J]. Multipurpose Utilization of Mineral Resources, 2020, 41(5):1-17.

ZHU Y M. Present situation of zinc metallurgical slags and dusts treatment technology[J]. Multipurpose Utilization of Mineral Resources, 2020, 41(5):1-17.

[9] 孙传尧, 周俊武, 贾木欣, 等. 基因矿物加工工程研究[J]. 有色金属 (选矿部分), 2018(1):1-7.SUN C Y, ZHOU J W, JIA M X, et al. Research on genetic mineral processing engineering[J]. Non-ferrous Metals(Mineral Processing Section), 2018(1):1-7.

SUN C Y, ZHOU J W, JIA M X, et al. Research on genetic mineral processing engineering[J]. Non-ferrous Metals(Mineral Processing Section), 2018(1):1-7.

[10] 朱一民, 郭文达, 杨艳平, 等. 新型阳离子捕收剂对东鞍山铁矿的浮选实验研究[J]. 中国矿业, 2016, 25(3):97-101.ZHU Y M, GUO W D, YANG Y P, et al. Flotation experiment of a new cationic collectior for Donganshan's iron ore[J]. China Mining Magazine, 2016, 25(3):97-101. doi: 10.3969/j.issn.1004-4051.2016.03.022

ZHU Y M, GUO W D, YANG Y P, et al. Flotation experiment of a new cationic collectior for Donganshan's iron ore[J]. China Mining Magazine, 2016, 25(3):97-101. doi: 10.3969/j.issn.1004-4051.2016.03.022

-

下载:

下载: