Technology of Recovering Refractory from Waste of Bauxite Chamotte by Color Separation Technology

-

摘要:

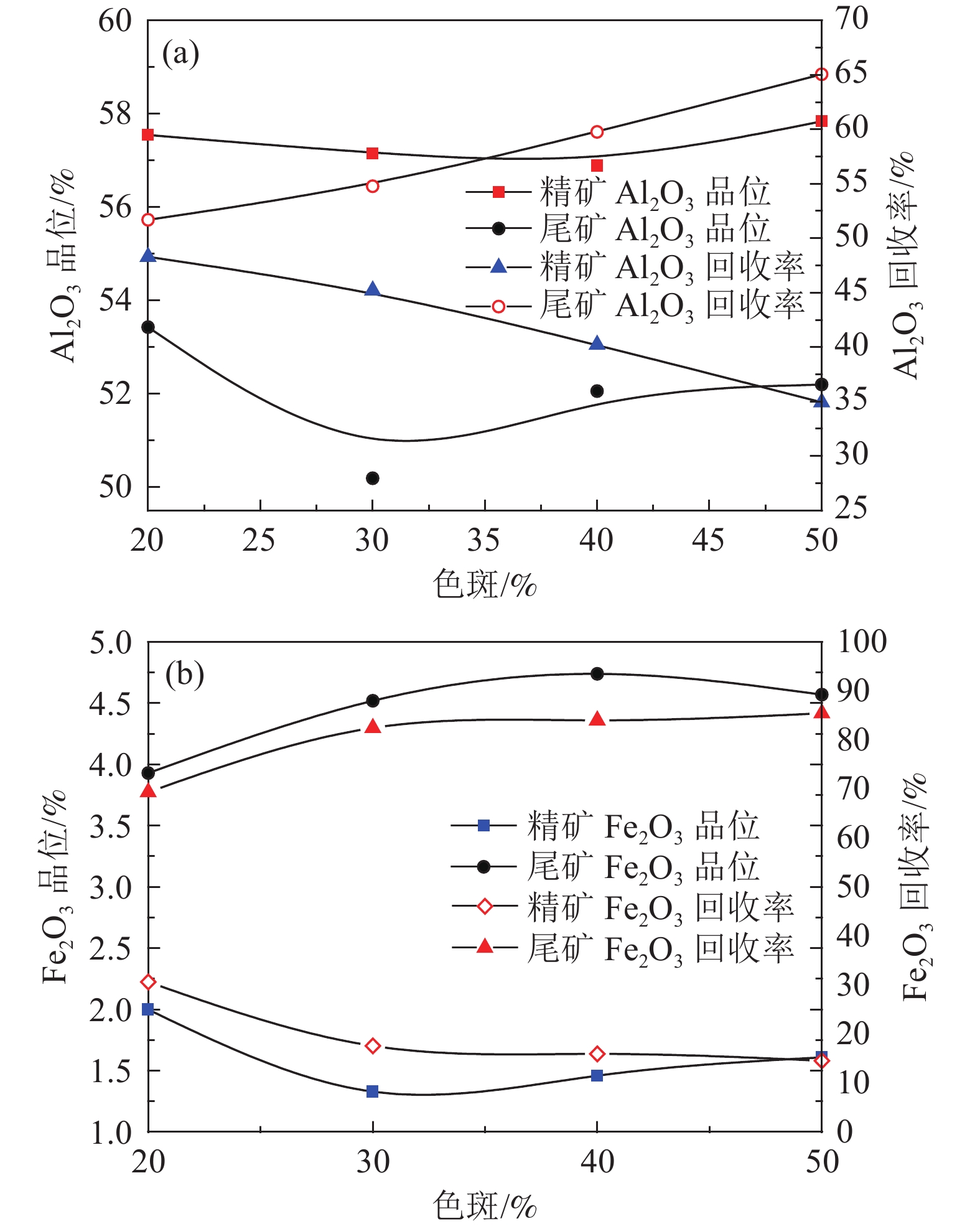

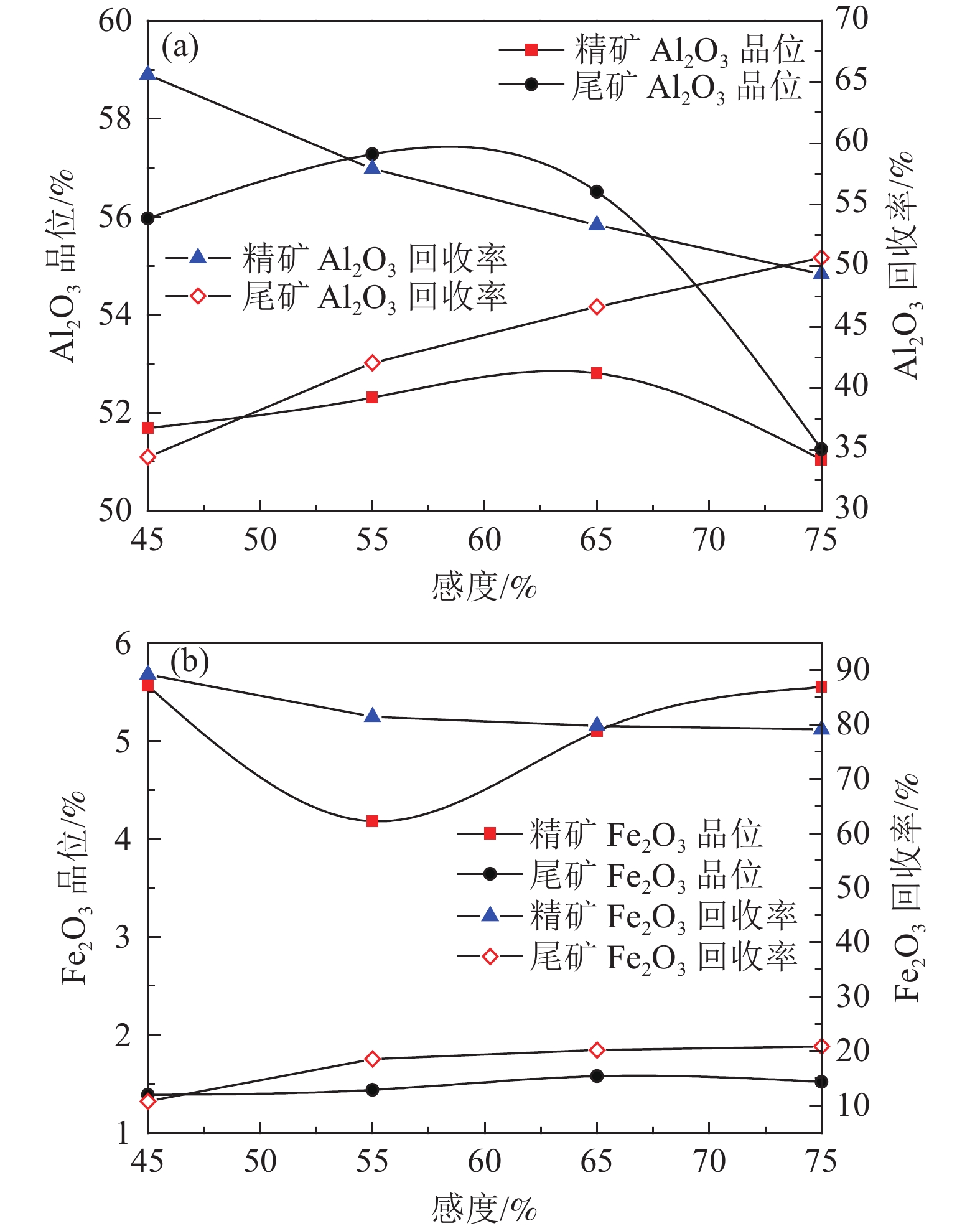

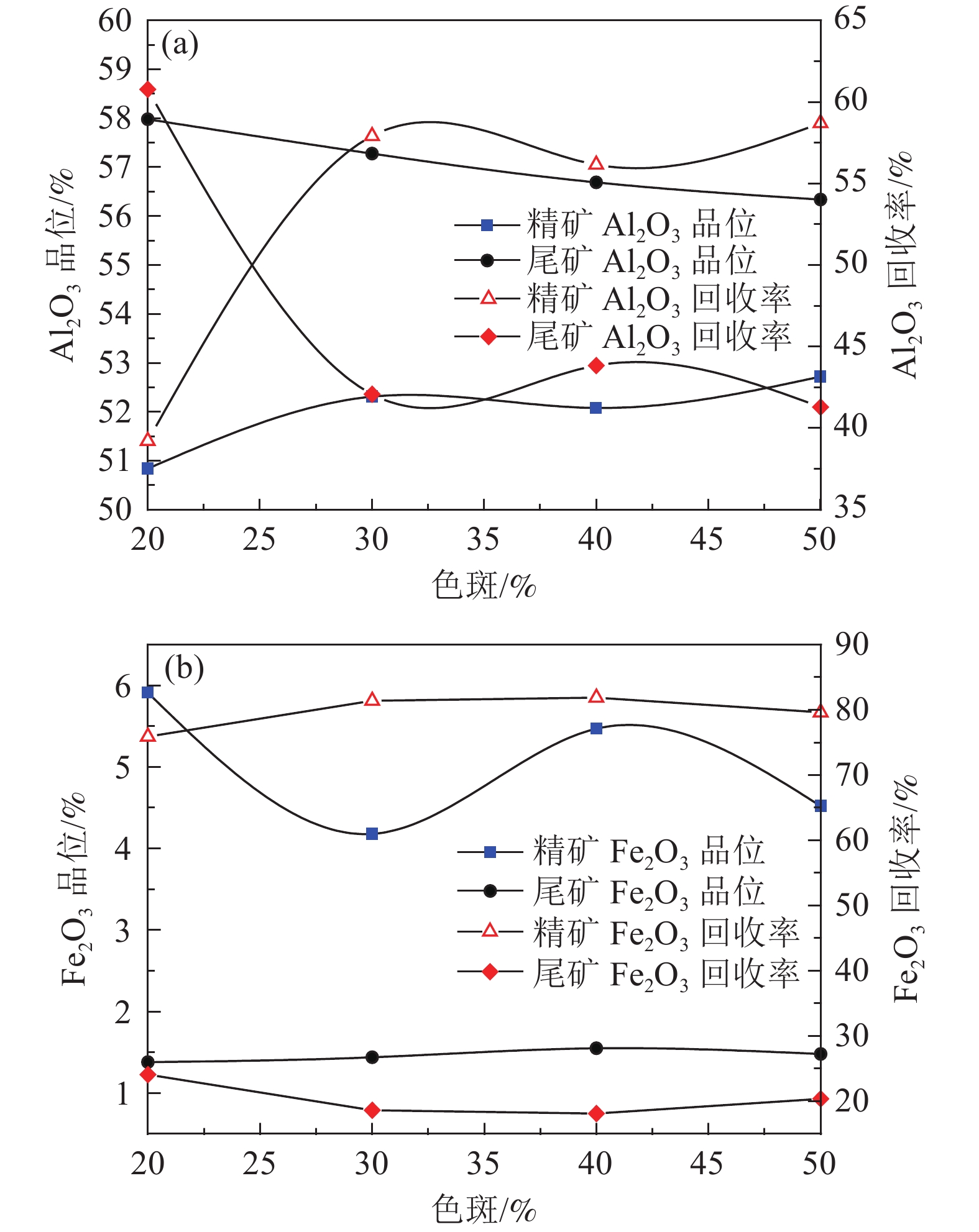

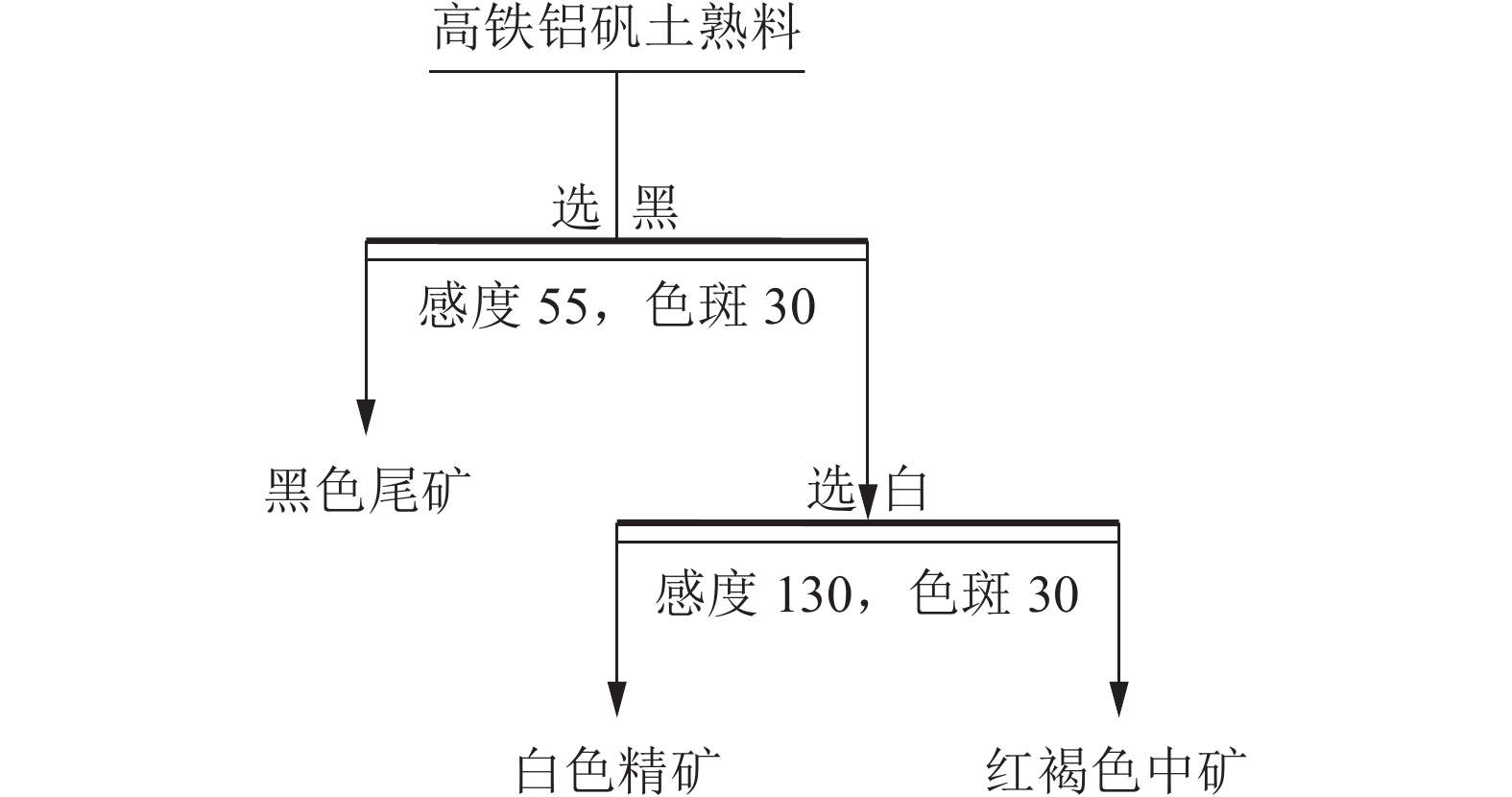

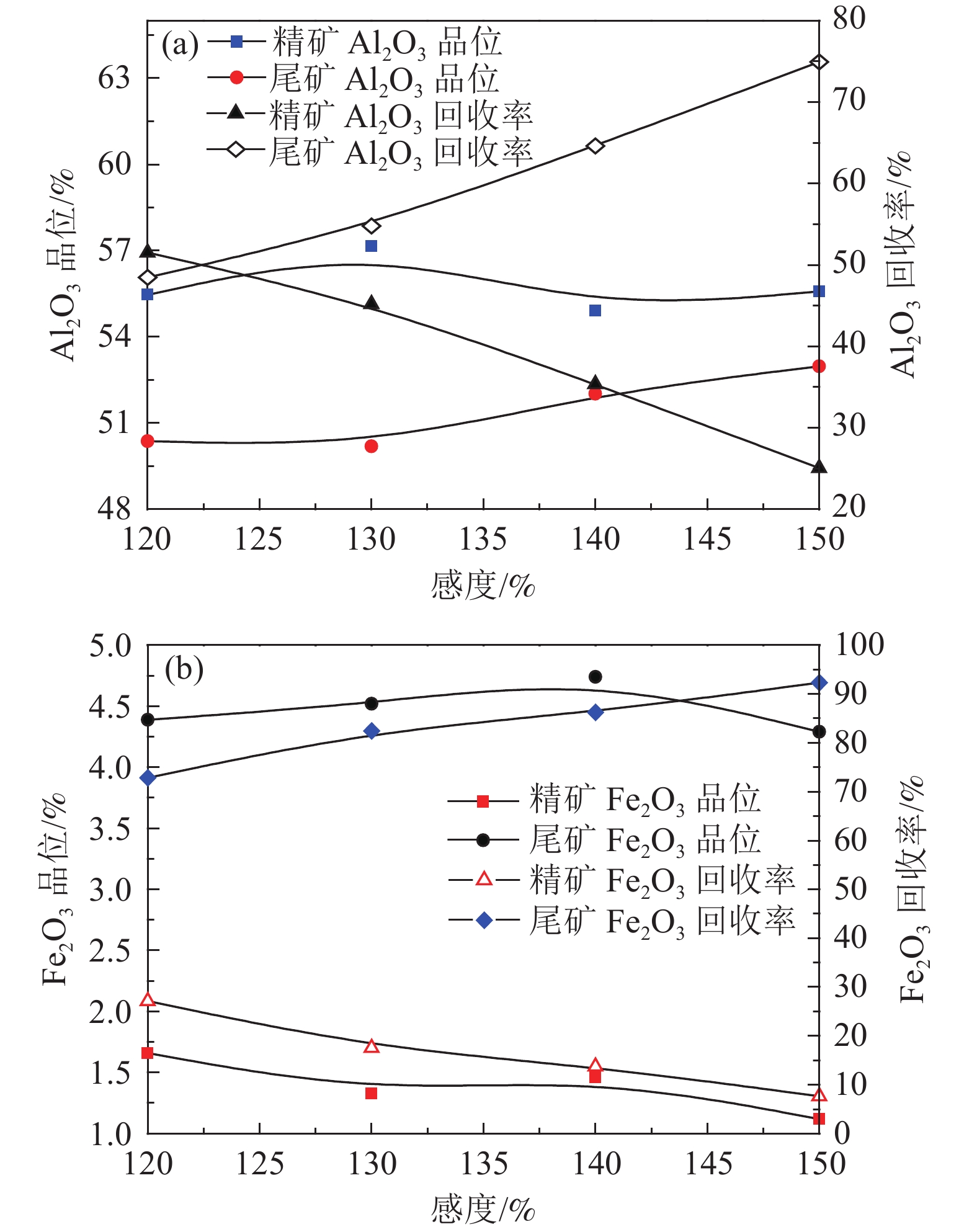

铝矾土在烧成熟料后,含铁高的铝矾土熟料因颜色差异被人工手选挑出;而手选出的高铁铝矾土熟料因无法满足耐火材料的要求而被抛弃。本实验以高铝熟料的废料为原料,先将原料破碎为至5~10 mm,再通过色选机对原料进行分选,最后可得到全铁含量低于2%的合格耐火材料原料。精矿产品全铁品位为1.48%,产率为33.12%。该技术可有效提高耐火行业的铝矾土利用率,具有较为广泛的应用前景。

Abstract:After the bauxite is fired into the clinker, the bauxite chamotte high in iron content is handpicked out because of the color difference, and the bauxite chamotte high in iron content by handpicked was discarded because it does not meet the requirements of the refractory. This test takes waste of bauxite chamotte as raw materials. Firstly, the raw materials are crushed to 5~10 mm, and then the raw materials are sorted by photoelectric color separator. Finally, qualified refractory raw materials with total iron content less than 2% can be obtained. The total iron grade of concentrate product is 1.48% and the yield is 33.12%. This technology can effectively improve the utilization rate of bauxite in refractory industry, and has a wide application prospect.

-

Key words:

- Bauxite chamotte /

- Waste with high iron /

- Photoelectric color selection /

- Refractory

-

-

表 1 原料的化学成分分析结果/%

Table 1. Chemical composition analysis results of raw materials

Al2O3 SiO2 Fe2O3 TiO2 K2O Na2O CaO MgO 50.10 36.90 3.42 2.35 0.39 0.047 0.60 0.15 表 2 高铁铝矾土熟料色选实验结果

Table 2. Test results of color sorting of high iron bauxite clinker

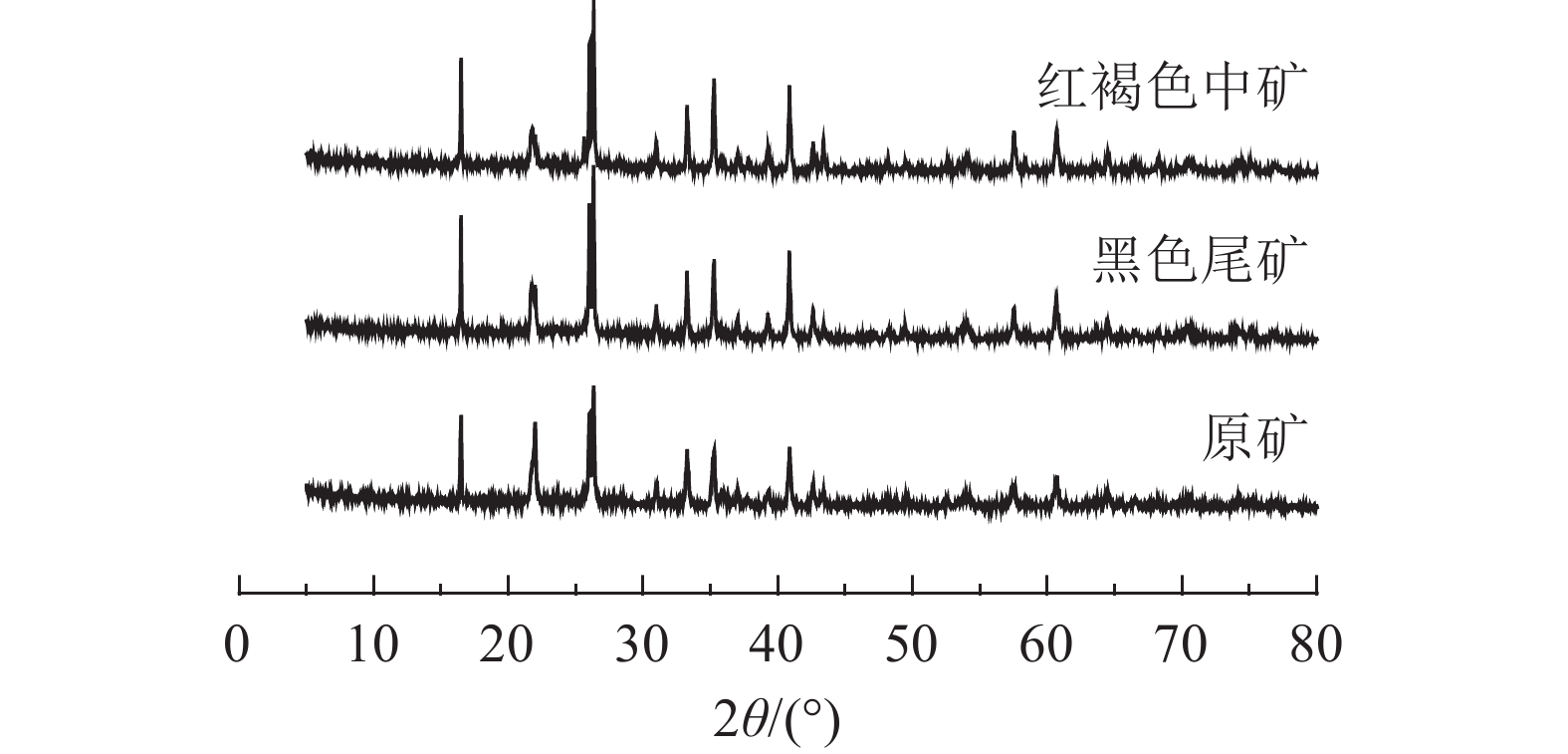

产品名称 产率/% 品位/% 回收率/% Al2O3 Fe2O3 Al2O3 Fe2O3 白色精矿 33.21 60.39 1.46 35.49 12.97 红褐色中矿 48.99 55.83 3.69 48.4 48.35 黑色尾矿 17.80 51.15 8.12 16.12 38.68 合计 100.00 56.51 3.74 100.00 100.00 表 3 原料及分选后产品主要物质组成结果/%

Table 3. Results of main material composition of raw materials and sorted products

产品名称 莫来石 刚玉 方石英 赤铁矿 斜长石 原矿 71.0 11.5 12.0 3.5 1.0 精矿 71.0 13.0 10.0 0.2 5.0 中矿 79.5 7.0 10.0 1.0 1.0 尾矿 70.0 10.0 8.0 5.0 5.5 -

[1] 李欢欢. 低质铝矾土的性能及应用研究[D]. 西安: 陕西科技大学, 2018.LI H H. Research on the characteristic and utilization of low grade bauxite[D]. Xi’an: Shaanxi University of Science and Technology, 2018.

LI H H. Research on the characteristic and utilization of low grade bauxite[D]. Xi’an: Shaanxi University of Science and Technology, 2018.

[2] USGS, Mineral Commodity Summaries 2021[R]. Virginia: U. S. U. S. Government Publishing Office, 2021: 20-22.

[3] 韩跃新, 柳晓, 何发钰, 等. 我国铝土矿资源及其选矿技术进展[J]. 矿产保护与利用, 2019, 39(4):151-158.HAN Y X, LIU X, HE F Y, et al. Current situation of bauxite resource and its beneficiation technology in China[J]. Conservation and Utilization of Mineral Resources, 2019, 39(4):151-158.

HAN Y X, LIU X, HE F Y, et al. Current situation of bauxite resource and its beneficiation technology in China[J]. Conservation and Utilization of Mineral Resources, 2019, 39(4):151-158.

[4] 郭玉香, 曲殿利, 姚瑶. 不同品级铝矾土均化烧结性能及微观结构的研究[J]. 人工晶体学报, 2016(45): 273-278(284).GUO Y X, QU D L, YAO Y. Study on homogenized sintering performance and microstructure of different grades of bauxite[J]. Journal of Synthetic Crystals, 2016(45): 273-278(284).

GUO Y X, QU D L, YAO Y. Study on homogenized sintering performance and microstructure of different grades of bauxite[J]. Journal of Synthetic Crystals, 2016(45): 273-278(284).

[5] 夏飞龙, 李军旗, 陈朝轶, 等. 磁化焙烧对高铁铝土矿铁元素的分离回收影响[J]. 有色金属(冶炼部分), 2018(9):27-31.XIA F L, LI J Q, CHEN C Y, et al. Effect of magnetization-roasting on iron recovery from high iron bauxite[J]. Nonferrous Metals(Extractive Metallurgy), 2018(9):27-31.

XIA F L, LI J Q, CHEN C Y, et al. Effect of magnetization-roasting on iron recovery from high iron bauxite[J]. Nonferrous Metals(Extractive Metallurgy), 2018(9):27-31.

[6] 陈蔚萍, 陈迎伟, 代永信. 铝矾土除铁、硅、钛氧化物工艺的研究[J]. 广州化工, 2009(37):73-74.CHEN W P, CHEN Y W, DAI Y X. Study of the technology on removing silica, titanic and ferric oxide impurities from bauxite[J]. Guangzhou Chemical Industry, 2009(37):73-74.

CHEN W P, CHEN Y W, DAI Y X. Study of the technology on removing silica, titanic and ferric oxide impurities from bauxite[J]. Guangzhou Chemical Industry, 2009(37):73-74.

[7] 李正丹, 王秀峰, 万兵, 等. 某低品位含铁铝土矿选矿试验研究[J]. 有色金属, 2019(1): 62-66(83).LI Z D, WANG X F, WAN B, et al. Beneficiation test of a low grade iron-bearing bauxite[J]. Nonferrous Metals(Mineral Processing Section), 2019(1): 62-66(83).

LI Z D, WANG X F, WAN B, et al. Beneficiation test of a low grade iron-bearing bauxite[J]. Nonferrous Metals(Mineral Processing Section), 2019(1): 62-66(83).

[8] 闫明伟, 李勇, 陈俊红, 等. 高铁低铝矾土莫来石的合成及机理[J]. 硅酸盐学报, 2016(44):1792-1797.YAN M W, LI Y, CHEN J H, et al. Synthesis and mechanism of mullite ceramic prepared from laterite[J]. Journal of the Chinese Ceramic Society, 2016(44):1792-1797.

YAN M W, LI Y, CHEN J H, et al. Synthesis and mechanism of mullite ceramic prepared from laterite[J]. Journal of the Chinese Ceramic Society, 2016(44):1792-1797.

[9] 张占梅, 郑怀礼, 陈春艳. 高铁铝矾土制备聚合氯化铝铁及其在污水处理中的应用研究[J]. 环境污染治理与设备, 2006(7)6: 52-55.ZHANG Z M, ZHENG H L, CHEN C Y. Preparation and application of polymerized aluminum ferrum chloride with bauxite[J]. Techniques and Equipment for Environmental Pollution Control, 2006(7)6: 52-55.

ZHANG Z M, ZHENG H L, CHEN C Y. Preparation and application of polymerized aluminum ferrum chloride with bauxite[J]. Techniques and Equipment for Environmental Pollution Control, 2006(7)6: 52-55.

[10] 刘运连. 高铁铝土矿制备高强度石油压裂支撑剂的研究[D]. 昆明: 昆明理工大学, 2015.LIU Y L. Study on preparation of high strength petroleum fracturing proppant from high iron bauxite[D]. Kunming: Kunming University of Science and Technology, 2015.

LIU Y L. Study on preparation of high strength petroleum fracturing proppant from high iron bauxite[D]. Kunming: Kunming University of Science and Technology, 2015.

[11] 伍世衍. 利用低品位铝土矿制备低烧高强硅铝质陶瓷的研究[D]. 广州: 华南理工大学, 2014.WU S Y. Preparation and study of the bauxite tailings using for high-strength silicon-aluminum ceramics[D]. Guangzhou: South China University of Technology, 2014.

WU S Y. Preparation and study of the bauxite tailings using for high-strength silicon-aluminum ceramics[D]. Guangzhou: South China University of Technology, 2014.

[12] 兰阳. 铝土矿尾矿多孔陶瓷的制备及其力学性能研究[D]. 昆明: 昆明理工大学, 2017.LAN Y. Preparation and mechanical properties of porous ceramics from bauxite tailings[D] . Kunming: Kunming University of Science and Technology, 017.

LAN Y. Preparation and mechanical properties of porous ceramics from bauxite tailings[D] . Kunming: Kunming University of Science and Technology, 017.

[13] 王金相, 钟香崇. 我国DK型烧结高铝矾土的结晶相和玻璃相的研究[J]硅酸盐学报, 1982, 10(3): 289-297.WANG J X, ZHONG X C. A study of the crystalline and glassy phases of sintered Chinese bauxites(DK type)[J]. Journal of the Chinese Ceramic Society, 1982, 10(3): 289-297.

WANG J X, ZHONG X C. A study of the crystalline and glassy phases of sintered Chinese bauxites(DK type)[J]. Journal of the Chinese Ceramic Society, 1982, 10(3): 289-297.

[14] 中国钢铁工业协会. 高铝矾土熟料: YB/T 5179—2005 [S]. 北京: 冶金工业出版, 2005.China Iron and Steel Association. Bauxite clinker : YB/T 5179—2005 [S]. Beijing: Metallurgical Industry Press, 2005.

China Iron and Steel Association. Bauxite clinker : YB/T 5179—2005 [S]. Beijing: Metallurgical Industry Press, 2005.

-

下载:

下载: