Test on Discarding Tailings of Waste Rocks of a Vanadium-titanium Magnetite in Panxi Area

-

摘要:

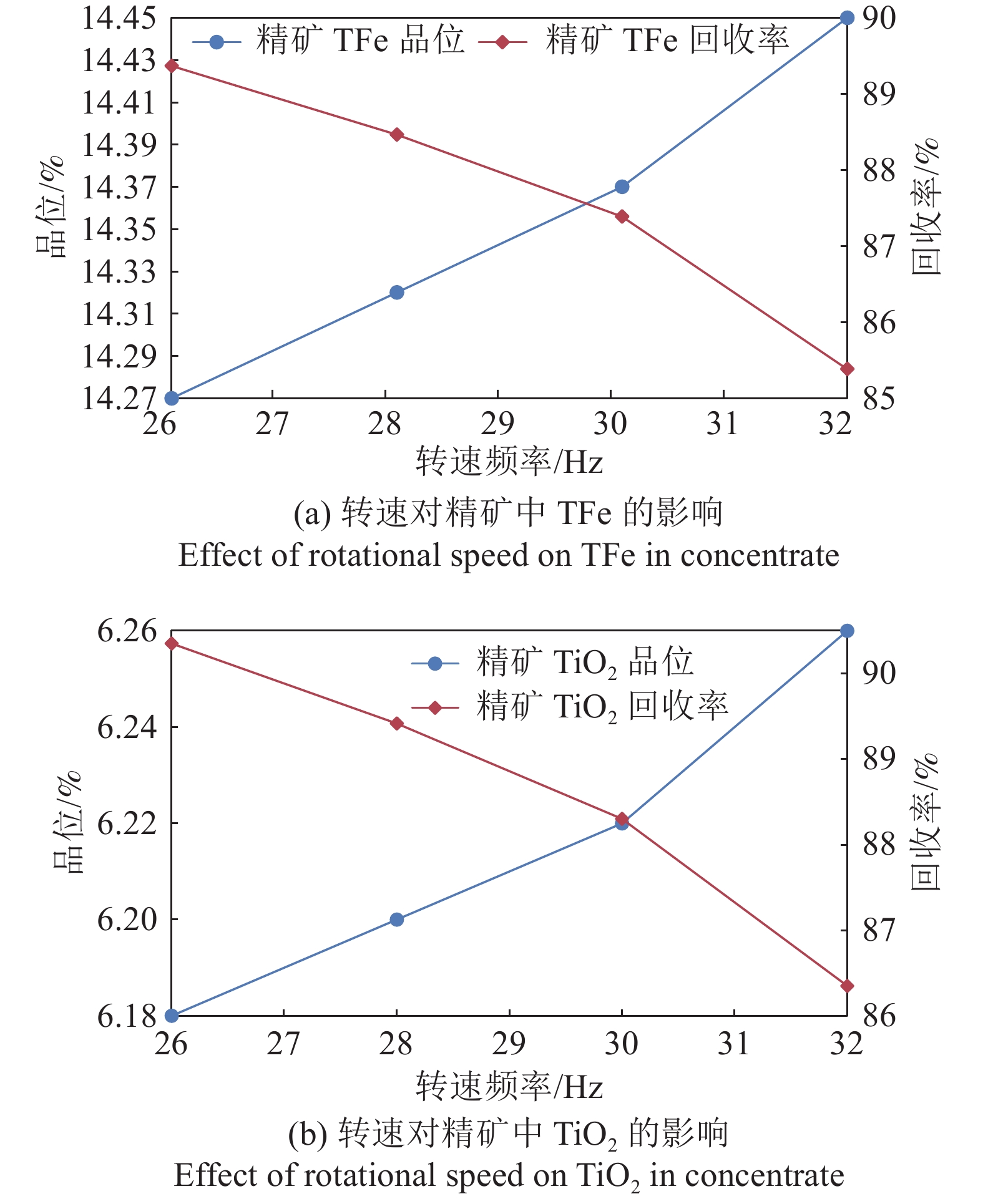

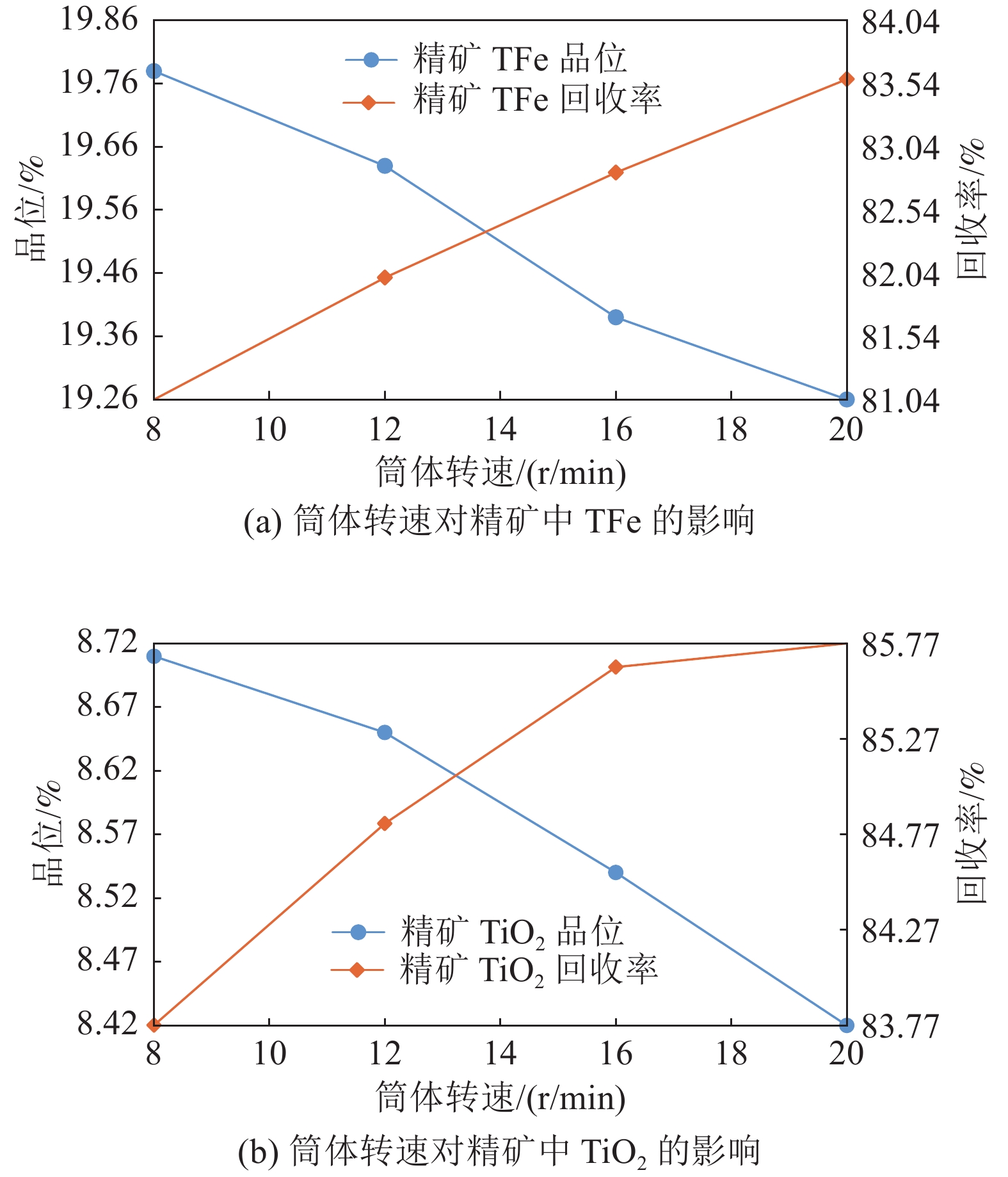

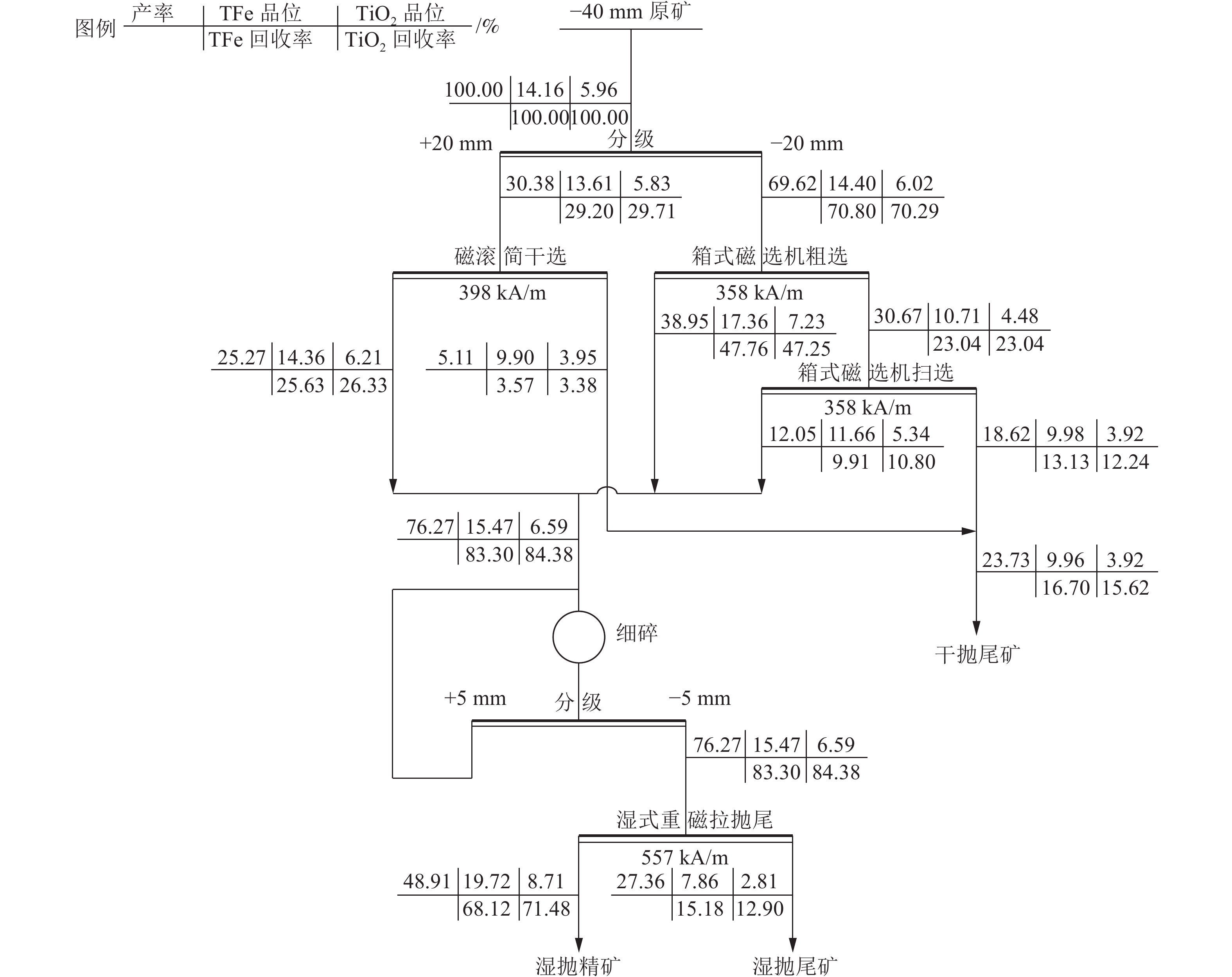

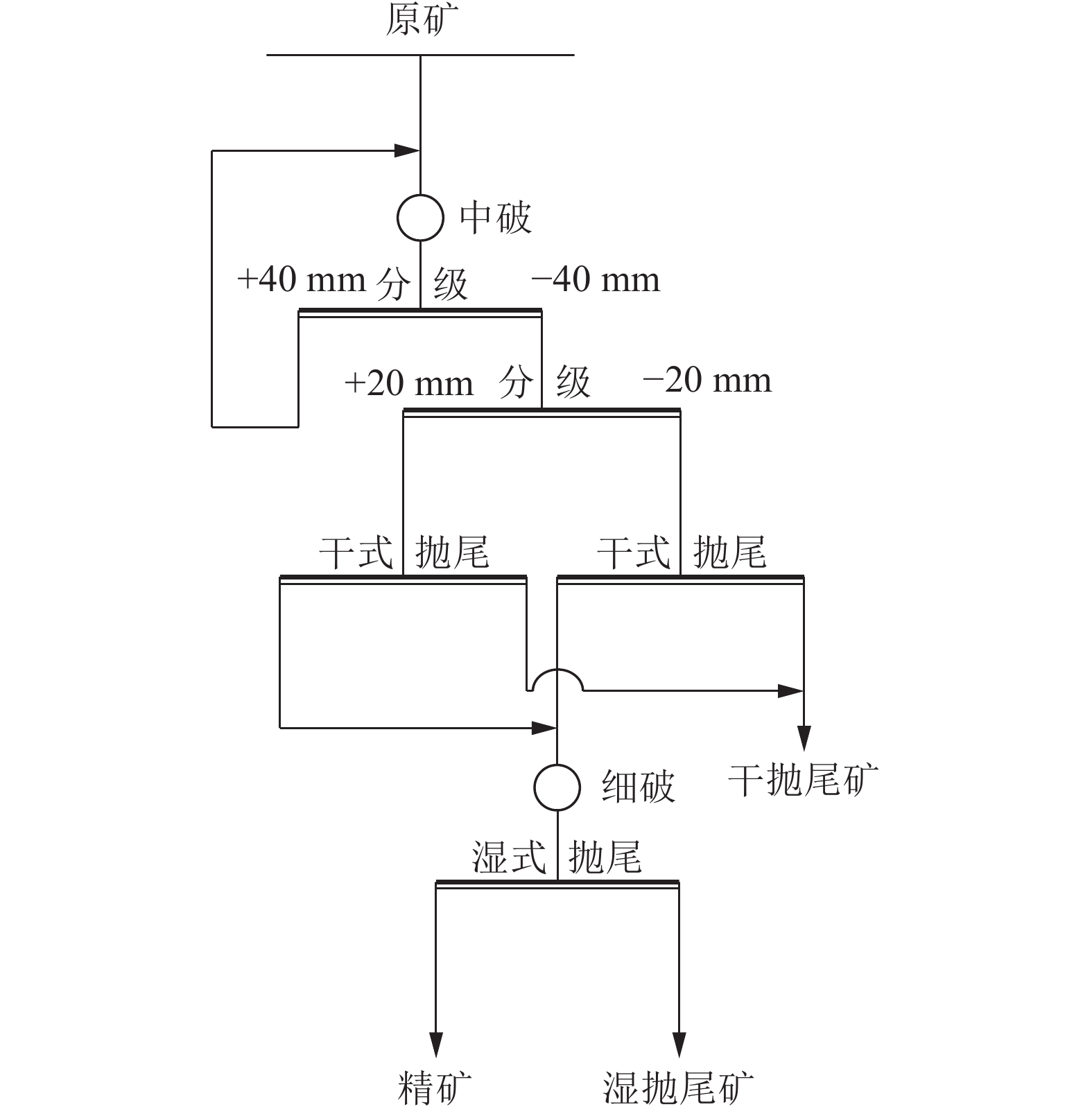

针对攀西某钒钛磁铁矿废石,采用“干式+湿式”组合抛尾。结果表明:废石破碎至-40 mm后,采用干式抛尾,可抛出流程产率23.73%、TFe品位9.96%、TiO2品位3.92%的尾矿;干抛精矿细碎至-5 mm后,采用湿式重磁拉抛尾,可抛出流程产率27.36%、TFe品位7.86%、TiO2品位2.81%的尾矿;“干式+湿式”组合抛尾,最终抛尾率可达51.09%,精矿TFe品位提升5.56个百分点,TiO2品位提升2.75个百分点,可大幅降低后续磨矿量,提高后续入选品位,降低此类资源的选矿成本。

Abstract:The combined methods of dry-discarding and wet-discarding were used to separate the vanadium-titanium-magnetite waste rock in Panxi. The results indicated that the grades of TFe and TiO2 which existed in the tailings reached 9.96% and 3.92%, respectively, and the recovery reached 23.73% using the dry-discarding method after the waste rocks were crushed to -40 mm. In addition, after the concentrates of dry-discarding were crushed to -5 mm, using the wet-discarding method, the grades of TFe and TiO2 which existed in the tailings reached 7.86% and 2.81%, respectively, and the recovery reached 27.36%. Finally, the discarding rate reached 51.09% using the combination methods of dry-discarding and wet-discarding, and the TFe grade of concentrate increased 5.56 percentage, TiO2 grade increased 2.75 percentage. The method could greatly reduce the subsequent grinding amount, improve the initial grade, and reduce the mineral processing cost.

-

Key words:

- Mineral processing engineering /

- Wasterocks /

- Dry-discarding /

- Wet-discarding

-

-

表 1 原矿化学多元素分析结果/%

Table 1. Multi-element analysis results of the raw ore

TFe Fe2O3 FeO V2O5 TiO2 S CaO MgO Al2O3 SiO2 P 14.25 8.69 11.60 0.10 5.83 0.26 11.78 7.52 11.80 36.38 0.33 表 2 原矿铁物相分析

Table 2. Iron phase analysis of the raw ore

名称 钛磁铁矿中铁 钛铁矿中铁 硫化物中铁 硅酸盐中铁 合计 含量/% 6.61 2.95 0.68 4.04 14.28 分布率/% 46.28 20.67 4.74 28.31 100.00 表 3 原矿钛物相分析

Table 3. Titanium phase analysis of the raw ore

名称 钛磁铁矿中钛 钛铁矿中钛 脉石中钛 合计 含量/% 1.32 3.36 1.35 6.03 分布率/% 21.92 55.66 22.42 100.00 表 4 原矿分级实验

Table 4. Classification tests of the raw ores

产品 产率/% 品位/% 回收率/% TFe TiO2 TFe TiO2 粗粒级 30.38 13.61 5.83 29.20 29.71 细粒级 69.62 14.40 6.02 70.80 70.29 原矿 100.00 14.16 5.96 100.00 100.00 表 5 粗粒级干式抛尾生产实验

Table 5. Dry-discarding production test of coarse grain V-Ti magnetite

产品 产率/% 品位/% 回收率/% TFe TiO2 TFe TiO2 精矿 83.18 14.36 6.21 87.77 88.61 尾矿 16.82 9.90 3.95 12.23 11.39 给矿 100.00 13.61 5.83 100.00 100.00 表 6 细粒级干式抛尾生产实验

Table 6. Dry-discarding production test of fine-grain V-Ti magnetite

产品 产率/% 品位/% 回收率/% TFe TiO2 TFe TiO2 粗选精矿 55.95 17.36 7.23 67.45 67.23 扫选精矿 17.31 11.66 5.34 14.01 15.36 扫选尾矿 26.74 9.98 3.92 18.54 17.41 给矿 100.00 14.40 6.02 100.00 100.00 表 7 尾矿选铁实验

Table 7. Iron separation tests of tailings

样品 产品 产率/% 品位/% 回收率/% TFe TiO2 TFe TiO2 粗粒尾矿 精矿 1.12 54.87 7.45 6.21 2.11 尾矿 98.88 9.39 3.91 93.79 97.89 给矿 100.00 9.90 3.95 100.00 100.00 细粒尾矿 精矿 1.23 54.62 7.52 6.73 2.36 尾矿 98.77 9.42 3.88 93.27 97.64 给矿 100.00 9.98 3.92 100.00 100.00 表 8 抛尾设备对比实验

Table 8. Effect of separation equipment on dressing indexes

抛尾设备 产品 产率/% 品位/% 回收率/% TFe TiO2 TFe TiO2 中磁滚筒

磁选机精矿 40.34 23.81 9.22 62.09 56.44 尾矿 59.66 9.83 4.81 37.91 43.56 给矿 100.00 15.47 6.59 100.00 100.00 重磁拉强

磁选机精矿 62.22 20.03 8.90 80.56 84.03 尾矿 37.78 7.96 2.79 19.44 15.97 给矿 100.00 15.47 6.59 100.00 100.00 表 9 湿式抛尾生产实验

Table 9. Wet tailing production test

产品 产率/% 品位/% 回收率/% TFe TiO2 TFe TiO2 精矿 64.13 19.72 8.71 81.77 84.71 尾矿 35.87 7.86 2.81 18.23 15.29 给矿 100.00 15.47 6.59 100.00 100.00 表 10 尾矿选铁实验

Table 10. Iron separation tests of tailings

产品 产率/% 品位/% 回收率/% TFe TiO2 TFe TiO2 精矿 0.46 55.41 6.15 3.24 1.01 尾矿 99.54 7.64 2.79 96.76 98.99 给矿 100.00 7.86 2.81 100.00 100.00 -

[1] 卢斌. 磁滑轮抛尾技术在密地选矿厂的应用实践[J]. 矿冶工程, 2014, 34(2):61-63+67.LU B. Practical application of tailings discarding technology by magnetic pulley in midi concentrator[J]. Mining and Metallurgical Engineering, 2014, 34(2):61-63+67. doi: 10.3969/j.issn.0253-6099.2014.02.016

LU B. Practical application of tailings discarding technology by magnetic pulley in midi concentrator[J]. Mining and Metallurgical Engineering, 2014, 34(2):61-63+67. doi: 10.3969/j.issn.0253-6099.2014.02.016

[2] 王建平. ZCLA选矿机在攀枝花钒钛磁铁矿预选抛尾中的应用[J]. 矿冶工程, 2016, 36(3):47-50.WANG J P. Application of ZCLA concentrator for preconcentration and tailings discarding of vanadium titanium magnetite in Panzhihua[J]. Mining and Metallurgical Engineering, 2016, 36(3):47-50. doi: 10.3969/j.issn.0253-6099.2016.03.012

WANG J P. Application of ZCLA concentrator for preconcentration and tailings discarding of vanadium titanium magnetite in Panzhihua[J]. Mining and Metallurgical Engineering, 2016, 36(3):47-50. doi: 10.3969/j.issn.0253-6099.2016.03.012

[3] 贾雪梅, 宫亮. 重磁拉磁选机在某钒钛磁铁矿粗粒抛尾中的工业应用[J]. 现代矿业, 2019, 35(6):23-26+33.JIA X M, GONG L. Industrial application of heavy magnetic drawing magnetic separator in coarse-grained tailings of a vanadium-titanium magnetite[J]. Modern Mining, 2019, 35(6):23-26+33. doi: 10.3969/j.issn.1674-6082.2019.06.007

JIA X M, GONG L. Industrial application of heavy magnetic drawing magnetic separator in coarse-grained tailings of a vanadium-titanium magnetite[J]. Modern Mining, 2019, 35(6):23-26+33. doi: 10.3969/j.issn.1674-6082.2019.06.007

[4] 陈福林, 杨晓军, 蔡先炎, 等. 攀西地区白马辉长岩型超低品位钒钛磁铁矿选铁实验研究[J]. 矿产综合利用, 2020(6):26-30.CHEN F L, YANG X J, CAI X Y, et al. Experimental study on iron separation of Baima gabbro-type ultra-low-grade vanadium-titanomagnetite in Panxi area[J]. Multipurpose Utilization of Mineral Resources, 2020(6):26-30.

CHEN F L, YANG X J, CAI X Y, et al. Experimental study on iron separation of Baima gabbro-type ultra-low-grade vanadium-titanomagnetite in Panxi area[J]. Multipurpose Utilization of Mineral Resources, 2020(6):26-30.

[5] 曾小波, 张渊, 熊文良, 等. 某低品位钒钛磁铁矿选矿实验研究[J]. 矿产综合利用, 2017(3): 67-70.ZENG X B , ZHANG Y, XIONG W L, et al. Experimental research on the mineral processing technology of a low-grade vanadium-titanium magnetite[J]. Multipurpose Utilization of Mineral Resources, 2017(03): 67-70.

ZENG X B , ZHANG Y, XIONG W L, et al. Experimental research on the mineral processing technology of a low-grade vanadium-titanium magnetite[J]. Multipurpose Utilization of Mineral Resources, 2017(03): 67-70.

[6] 成磊, 尚红亮, 朱道瑶. 外磁式磁选机应用于铁矿预选抛尾工艺的实验研究[J]. 有色金属(选矿部分), 2019(3):78-80.CHENG L, SHANG H L, ZHU D Y. Experimental research of external magnet drum type magnetic separator used on pre-concentration process of iron ore[J]. Nonferrous Metals Mineral Processing Section, 2019(3):78-80.

CHENG L, SHANG H L, ZHU D Y. Experimental research of external magnet drum type magnetic separator used on pre-concentration process of iron ore[J]. Nonferrous Metals Mineral Processing Section, 2019(3):78-80.

[7] 崔少文, 郭小飞, 郗悦, 等. 高压辊磨超细碎在贫磁铁矿石预选中的应用[J]. 金属矿山, 2018(12):115-118.CUI S W, GUO X F, XI Y, et al. Application of ultra-finely crushing by high pressure grinding rolls in pre-concentration of lean magnetite ore[J]. Metal Mine, 2018(12):115-118.

CUI S W, GUO X F, XI Y, et al. Application of ultra-finely crushing by high pressure grinding rolls in pre-concentration of lean magnetite ore[J]. Metal Mine, 2018(12):115-118.

[8] 李国平, 尚红亮, 王芝伟, 等. 新型磨前干式预选工艺在攀西某钒钛磁铁矿的应用[J]. 有色金属(选矿部分), 2018(2):53-56.LI G P, SHANG H L, WANG Z W, et al. Application of new type dry pre-concentration of V-Ti magnetite in Panxi[J]. Nonferrous Metals Mineral Processing Section, 2018(2):53-56.

LI G P, SHANG H L, WANG Z W, et al. Application of new type dry pre-concentration of V-Ti magnetite in Panxi[J]. Nonferrous Metals Mineral Processing Section, 2018(2):53-56.

-

下载:

下载: