Research Status of Resource Utilization and Sulfidation Roasting Technology of a Low-grade Nickel Sulfide Ore

-

摘要:

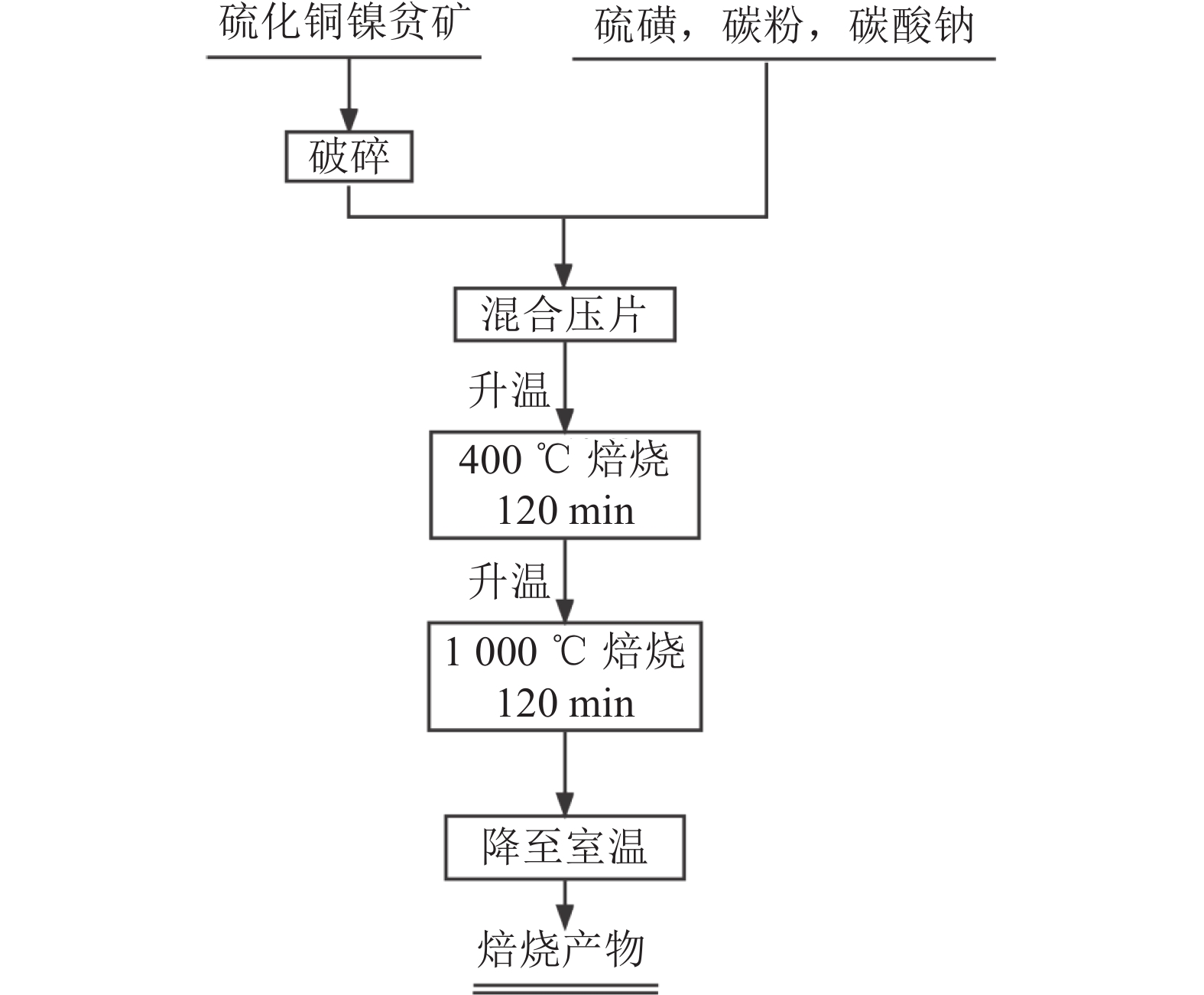

我国镍矿资源储量较为丰富,以硫化镍矿为主。随着优质易选的高品位硫化镍矿不断开采,其储量和产量逐年减少。因此,硫化镍占有率低、嵌布粒度微细、共生关系复杂的低品位硫化镍矿将成为我国主流镍资源。本文对低品位硫化镍矿的综合处理工艺进行了详细的阐述,介绍了低品位硫化镍矿现有的处理工艺,并对金川公司铜镍硫化贫矿,提出“梯级硫化焙烧”处理工艺,指出了发展研究低品位硫化镍矿综合处理技术的重要意义。

Abstract:The reserves of nickel ore resources are rich in China, mainly nickel sulfide.With the continuous exploitation of the high-grade nickel sulfide ore with high quality and easy to choose, its reserves and production are decreasing year by year. Therefore, the low-grade nickel sulfide ore with low nickel sulfide share, fine chimeric particle size and complex symbiosis will become the mainstream nickel resource in China. In this paper, the comprehensive treatment technology of the low-grade nickel sulfide ore is described in detail, and the existing treatment technology of the low grade nickel sulfide ore is introduced. Meanwhile, for the copper nickel sulfide lean ore of Jinchuan Company, the "step sulfidation roasting" process was put forward to, and the important significance of developing and studying the comprehensive treatment technology of the low-grade nickel sulfide ore is pointed out.

-

-

[1] 徐敏, 许茜, 刘日强, 等. 红土镍矿资源开发及工艺进展[J]. 矿产综合利用, 2009(3):28-30.XU M, XU Q, LIU R Q, et al. Exploitation of laterite-nickel mineral resources and technology advances[J]. Multipurpose Utilization of Mineral Resources, 2009(3):28-30. doi: 10.3969/j.issn.1000-6532.2009.03.008

XU M, XU Q, LIU R Q, et al. Exploitation of laterite-nickel mineral resources and technology advances[J]. Multipurpose Utilization of Mineral Resources, 2009(3):28-30. doi: 10.3969/j.issn.1000-6532.2009.03.008

[2] 毛素荣, 杨晓军, 何剑, 等. 云南某红土镍矿酸浸实验研究[J]. 矿产综合利用, 2015(1):39-40+44.MAO S R, YANG X J, HE J, et al. Experimental research on acid leaching for a laterite nickel ore from Yunnan[J]. Multipurpose Utilization of Mineral Resources, 2015(1):39-40+44. doi: 10.3969/j.issn.1000-6532.2015.01.009

MAO S R, YANG X J, HE J, et al. Experimental research on acid leaching for a laterite nickel ore from Yunnan[J]. Multipurpose Utilization of Mineral Resources, 2015(1):39-40+44. doi: 10.3969/j.issn.1000-6532.2015.01.009

[3] 李长玖, 陈玉明, 黄旭日, 等. 镍矿的处理工艺现状及进展[J]. 矿产综合利用, 2012(6):8-11.LI C J, CHEN Y M, HUANG X R, et al. The present situation and development of nickel ore processing technology[J]. Multipurpose Utilization of Mineral Resources, 2012(6):8-11.

LI C J, CHEN Y M, HUANG X R, et al. The present situation and development of nickel ore processing technology[J]. Multipurpose Utilization of Mineral Resources, 2012(6):8-11.

[4] 中华人民共和国国土资源部. 中国矿产资源报告2022[R]. 北京 : 地质出版社, 2022.Ministry of Land and Resources of the People's Republic of China. China Mineral Resources 2022[R]. Beijing: Geology Press, 2022.

Ministry of Land and Resources of the People's Republic of China. China Mineral Resources 2022[R]. Beijing: Geology Press, 2022.

[5] 刘明宝, 印万忠. 中国硫化镍矿和红土镍矿资源现状及利用技术研究[J]. 有色金属工程, 2011, 1(5): 25-28.LIU M B, YIN W Z. Research on the current status and utilization technology of nickel sulfide ore and laterite nickel ore resources in China[J]. Nonferrous Metals Engineering, 2011, 1(5): 25-28.

LIU M B, YIN W Z. Research on the current status and utilization technology of nickel sulfide ore and laterite nickel ore resources in China[J]. Nonferrous Metals Engineering, 2011, 1(5): 25-28.

[6] 路长远, 鲁雄刚, 邹星礼, 等. 中国镍矿资源现状及技术进展[J]. 自然杂志, 2015, 37(4):269-277.LU C Y, LU X G, ZOU X L, et al. Current situation and utilization technology of nickel ore in China[J]. Chinese Journal of Nature, 2015, 37(4):269-277.

LU C Y, LU X G, ZOU X L, et al. Current situation and utilization technology of nickel ore in China[J]. Chinese Journal of Nature, 2015, 37(4):269-277.

[7] 武兵强, 齐渊洪, 周和敏, 等. 红土镍矿火法冶炼工艺现状及进展[J]. 矿产综合利用, 2020(3):78-83+93.WU B Q, QI Y H, ZHOU H M, et al. Status and progress in pyrometallurgy processes of a laterite nickel ore[J]. Multipurpose Utilization of Mineral Resources, 2020(3):78-83+93. doi: 10.3969/j.issn.1000-6532.2020.03.012

WU B Q, QI Y H, ZHOU H M, et al. Status and progress in pyrometallurgy processes of a laterite nickel ore[J]. Multipurpose Utilization of Mineral Resources, 2020(3):78-83+93. doi: 10.3969/j.issn.1000-6532.2020.03.012

[8] 杨志强, 王永前, 高谦, 等. 金川镍矿废弃物在充填采矿中利用现状与展望[J]. 矿产综合利用, 2017(3):22-28.YANG Z Q, WANG Y Q, GAO Q, et al. Present research situation and prospect of nickel utilization of wastes in filling mining technology in Jinchuan mine[J]. Multipurpose Utilization of Mineral Resources, 2017(3):22-28. doi: 10.3969/j.issn.1000-6532.2017.03.003

YANG Z Q, WANG Y Q, GAO Q, et al. Present research situation and prospect of nickel utilization of wastes in filling mining technology in Jinchuan mine[J]. Multipurpose Utilization of Mineral Resources, 2017(3):22-28. doi: 10.3969/j.issn.1000-6532.2017.03.003

[9] 徐莺, 杨磊, 刘飞燕, 等. 金川铜镍矿贫矿石选矿产品的工艺矿物学研究[J]. 矿产综合利用, 2013(3):52-55.XU Y, YANG L, LIU F Y, et al. Study on process mineralogy of mineral processing products in the low-grade ore at Jinchuan[J]. Multipurpose Utilization of Mineral Resources, 2013(3):52-55. doi: 10.3969/j.issn.1000-6532.2013.03.012

XU Y, YANG L, LIU F Y, et al. Study on process mineralogy of mineral processing products in the low-grade ore at Jinchuan[J]. Multipurpose Utilization of Mineral Resources, 2013(3):52-55. doi: 10.3969/j.issn.1000-6532.2013.03.012

[10] 邹愉. 我国镍矿资源勘查开发现状分析及建议[J]. 世界有色金属, 2020(15):225-226.ZOU Y. Analysis and suggestions on the current situation of nickel exploration and development in China[J]. World Nonferrous Metals, 2020(15):225-226. doi: 10.3969/j.issn.1002-5065.2020.15.108

ZOU Y. Analysis and suggestions on the current situation of nickel exploration and development in China[J]. World Nonferrous Metals, 2020(15):225-226. doi: 10.3969/j.issn.1002-5065.2020.15.108

[11] 徐爱东, 陈瑞瑞, 李烁, 等. 镍钴行业发展形势分析及建议[J]. 中国有色冶金, 2021, 50(6):9-15.XU A D, CHEN R R, LI S, et al. Analysis and suggestions on the development of nickel-cobalt industry[J]. China Nonferrous Metallurgy, 2021, 50(6):9-15.

XU A D, CHEN R R, LI S, et al. Analysis and suggestions on the development of nickel-cobalt industry[J]. China Nonferrous Metallurgy, 2021, 50(6):9-15.

[12] 柏帆, 童雄, 谢贤, 等. 我国硫化铜镍矿选矿工艺研究进展[J]. 矿产综合利用, 2018(3):11-17.BAI F, TONG X, XIE X, et al. Research on beneficiation process for development of copper sulfide nickel ore in China[J]. Multipurpose Utilization of Mineral Resources, 2018(3):11-17. doi: 10.3969/j.issn.1000-6532.2018.03.002

BAI F, TONG X, XIE X, et al. Research on beneficiation process for development of copper sulfide nickel ore in China[J]. Multipurpose Utilization of Mineral Resources, 2018(3):11-17. doi: 10.3969/j.issn.1000-6532.2018.03.002

[13] 杨松荣, 邱冠周. 浮选工艺与应用[M]. 北京 : 冶金工业出版社, 2015.YANG S R, QIU G Z. Flotation process and application[M]. Beijing: Metallurgical Industry Press, 2015.

YANG S R, QIU G Z. Flotation process and application[M]. Beijing: Metallurgical Industry Press, 2015.

[14] 叶雪均, 余瑞三. 铜镍硫化矿石直接浮选小型实验研究[J]. 矿产综合利用, 2004(2):6-11.YE X J, YU R S. Experimental study on direct flotation of a copper-nickel sulfide ore[J]. Multipurpose Utilization of Mineral Resources, 2004(2):6-11. doi: 10.3969/j.issn.1000-6532.2004.02.002

YE X J, YU R S. Experimental study on direct flotation of a copper-nickel sulfide ore[J]. Multipurpose Utilization of Mineral Resources, 2004(2):6-11. doi: 10.3969/j.issn.1000-6532.2004.02.002

[15] 孙志健, 吴熙群, 李成必, 等. 高含泥矿石浮选综述[J]. 有色金属 : 选矿部分, 2020(1): 59-63.SUN Z J, WU X Q, LI C B, et al. A summary of high content slime ore flotation[J]. Nonferrous Metals: Mineral Processing Section, 2020(1): 59-63.

SUN Z J, WU X Q, LI C B, et al. A summary of high content slime ore flotation[J]. Nonferrous Metals: Mineral Processing Section, 2020(1): 59-63.

[16] 马鹏飞. 硫化铜镍矿表面氧化机制及浮选行为研究[D]. 赣州: 江西理工大学, 2015.MA P F. The mechanism and flotation behavior of the surface oxidecopper-nickel sulfide ore[D]. Ganzhou: Jiangxi University of Technology, 2015

MA P F. The mechanism and flotation behavior of the surface oxidecopper-nickel sulfide ore[D]. Ganzhou: Jiangxi University of Technology, 2015

[17] 邓伟, 王昌良, 韩跃新, 等. 新型抑制剂用于铜镍矿选矿的工业实践[J]. 矿产综合利用, 2017(4):33-37.DENG W, WANG C L, HAN Y X, et al. Industrial practice of copper-nickel ore flotation by new depressant[J]. Multipurpose Utilization of Mineral Resources, 2017(4):33-37. doi: 10.3969/j.issn.1000-6532.2017.04.007

DENG W, WANG C L, HAN Y X, et al. Industrial practice of copper-nickel ore flotation by new depressant[J]. Multipurpose Utilization of Mineral Resources, 2017(4):33-37. doi: 10.3969/j.issn.1000-6532.2017.04.007

[18] IKOTUNBD, ADAMSFV, IKOTUNAG, et al. Application of three xanthates collectors on the recovery of nickel and pentlandite in a low-grade nickel sulfide ore using optimum flotation parameters[J]. Particulate Science and Technology, 2017, 35(4):462-471. doi: 10.1080/02726351.2016.1165324

[19] 张旭, 冯雅丽, 李浩然, 等. 几种捕收剂对低品位硫化镍矿浮选的作用[J]. 东北大学学报 : 自然科学版, 2016, 37(2): 263-267.ZHANG X, FENG Y L, LI H R, et al. Effect of several collectors on flotation of low-grade nickel sulphide ore[J]. Journal of Northeastern University: Natural Science, 2016, 37(2): 263-267.

ZHANG X, FENG Y L, LI H R, et al. Effect of several collectors on flotation of low-grade nickel sulphide ore[J]. Journal of Northeastern University: Natural Science, 2016, 37(2): 263-267.

[20] 赵开乐, 王昌良, 邓伟, 等. 某富镁贫铜镍矿石选矿新工艺研究[J]. 金属矿山, 2013(12):73-77.ZHAO K L, WANG C L, DENG W, et al. Study on new beneficiation process of mg-rich copper-nickel lean ore[J]. Metal Mine, 2013(12):73-77.

ZHAO K L, WANG C L, DENG W, et al. Study on new beneficiation process of mg-rich copper-nickel lean ore[J]. Metal Mine, 2013(12):73-77.

[21] 王丽, 谢杰, 胡春梅, 等. 某高镁低品位硫化镍矿石的选矿工艺研究[J]. 现代矿业, 2020, 36(9):120-123.WANG L, XIE J, HU C M, et al. Experimental study on a low grade nickel ore with high magnesium[J]. Modern Mining, 2020, 36(9):120-123. doi: 10.3969/j.issn.1674-6082.2020.09.029

WANG L, XIE J, HU C M, et al. Experimental study on a low grade nickel ore with high magnesium[J]. Modern Mining, 2020, 36(9):120-123. doi: 10.3969/j.issn.1674-6082.2020.09.029

[22] 阙绍娟, 黄荣强, 卢琳. 广西某低品位铜镍矿石选矿工艺研究[J]. 金属矿山, 2014(4):91-94.QUE S J, HUANG R Q, LU L. Beneficiation experiment on a low-grade copper-nickel ore from Guangxi[J]. Metal Mine, 2014(4):91-94.

QUE S J, HUANG R Q, LU L. Beneficiation experiment on a low-grade copper-nickel ore from Guangxi[J]. Metal Mine, 2014(4):91-94.

[23] 冯博, 汪惠惠, 罗仙平, 等. 蛇纹石型硫化铜镍矿浮选研究进展[J]. 矿产综合利用, 2015(3):6-10+23.FENG B, WANG H H, LUO X P, et al. The development of flotation for serpentine type nickel sulfide ore[J]. Multipurpose Utilization of Mineral Resources, 2015(3):6-10+23. doi: 10.3969/j.issn.1000-6532.2015.03.002

FENG B, WANG H H, LUO X P, et al. The development of flotation for serpentine type nickel sulfide ore[J]. Multipurpose Utilization of Mineral Resources, 2015(3):6-10+23. doi: 10.3969/j.issn.1000-6532.2015.03.002

[24] 吕沛超, 卢毅屏, 冯博, 等. 超声波对金川硫化镍矿浮选的作用研究[J]. 有色金属 : 选矿部分, 2015(4): 34-38.LYU P C, LU Y P, FENG B, et al. The flotation study of Jinchuan nickel sulfide ores under ultrasonication[J]. Nonferrous Metals: Mineral Processing Section, 2015(4): 34-38.

LYU P C, LU Y P, FENG B, et al. The flotation study of Jinchuan nickel sulfide ores under ultrasonication[J]. Nonferrous Metals: Mineral Processing Section, 2015(4): 34-38.

[25] MOJTABA M, ASGHA A, ZAHRA B, et al. Mechanochemical sulfidization of a mixed oxide-sulphide copper ore by co-grinding with sulfur and its effect on the flotation efficiency[J]. 中国化学工程学报: 英文版, 2020, 28(3):743-748.

[26] 赵红芬. 用硫酸盐化焙烧法从含镍冰铜渣中回收镍[J]. 新疆有色金属, 1998(3):27-29.ZHAO H F. Nickel was recovered from matte slag containing nickel by sulphuric acid roasting[J]. Xinjiang Nonferrous Metals, 1998(3):27-29.

ZHAO H F. Nickel was recovered from matte slag containing nickel by sulphuric acid roasting[J]. Xinjiang Nonferrous Metals, 1998(3):27-29.

[27] 李洁, 徐玉君, 沈洪涛, 等. 红土镍矿焙烧熟料溶出过程中镍的行为[J]. 矿产综合利用, 2019(5):37-41.LI J, XU Y J, SHEN H T, et al. Reaction behaviour of Ni during leaching from roasting materials of laterite nickel ore and ammonium sulfate[J]. Multipurpose Utilization of Mineral Resources, 2019(5):37-41.

LI J, XU Y J, SHEN H T, et al. Reaction behaviour of Ni during leaching from roasting materials of laterite nickel ore and ammonium sulfate[J]. Multipurpose Utilization of Mineral Resources, 2019(5):37-41.

[28] 牟文宁, 崔富晖, 黄志鹏, 等. 红土镍矿硫酸焙烧-浸出溶液中铁、镍回收的研究[J]. 矿产综合利用, 2018(1):22-25.MU W N, CUI F H, HUANG Z P, et al. Research on the recovery of iron and nickel from leaching Liquid of laterite nickel ore treated by sulfuric acid roasting-water leaching[J]. Multipurpose Utilization of Mineral Resources, 2018(1):22-25. doi: 10.3969/j.issn.1000-6532.2018.01.005

MU W N, CUI F H, HUANG Z P, et al. Research on the recovery of iron and nickel from leaching Liquid of laterite nickel ore treated by sulfuric acid roasting-water leaching[J]. Multipurpose Utilization of Mineral Resources, 2018(1):22-25. doi: 10.3969/j.issn.1000-6532.2018.01.005

[29] 李光石. 硫化镍矿硫酸盐化焙烧反应机理及其调控机制的研究[D]. 上海: 上海大学, 2018.LI G S. Study on the reaction and regulatory mechanism of nickel sulfide concentrate during sulfation roasting process[D]. Shanghai: Shanghai University, 2018

LI G S. Study on the reaction and regulatory mechanism of nickel sulfide concentrate during sulfation roasting process[D]. Shanghai: Shanghai University, 2018

[30] MU W N, CUI F H, HUANG Z P, et al. Synchronous extraction of nickel and copper from a mixed oxide-sulfide nickel ore in a low-temperature roasting system[J]. Journal of Cleaner Production, 2018, 177:371-377. doi: 10.1016/j.jclepro.2017.12.260

[31] 刘欣伟, 胡文韬, 李浩然, 等. 高镁型低品位硫化镍矿浸出工艺及机理[J]. 中国有色金属学报, 2014, 24(6):1599-1606.LIU X W, HU W T, LI H R, et al. Leaching process and mechanism of high magnesium low-grade nickel sulfide ore[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6):1599-1606.

LIU X W, HU W T, LI H R, et al. Leaching process and mechanism of high magnesium low-grade nickel sulfide ore[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6):1599-1606.

[32] XING Z X, CHENG G J, YANG H, et al. Mechanism and application of the ore with chlorination treatment: A review[J]. Minerals Engineering, 2020, 154.

[33] LI G S, ZOU X L, CHENG H W, et al. A novel ammonium chloride roasting approach for the high-efficiency Co-sulfation of nickel, cobalt, and copper in polymetallic sulfide minerals[J]. Metallurgical And Materials Transactions A-Physical Metallurgy And Materials Science, 2020, 51(6):2769-2784.

[34] 胡杨甲, 赵志强, 刘慧南, 等. 氯化焙烧综合回收硫精矿中有价金属研究[J]. 贵金属, 2020, 41(4):51-55.HU Y J, ZHAO Z Q, LIU H N, et al. Study on comprehensive recovery of valuable metals in sulfur concentrates by chlorination roasting[J]. Precious Metals, 2020, 41(4):51-55. doi: 10.3969/j.issn.1004-0676.2020.04.009

HU Y J, ZHAO Z Q, LIU H N, et al. Study on comprehensive recovery of valuable metals in sulfur concentrates by chlorination roasting[J]. Precious Metals, 2020, 41(4):51-55. doi: 10.3969/j.issn.1004-0676.2020.04.009

[35] CUI F H, MU W N, ZHAI, et al. The selective chlorination of nickel and copper from low-grade nickel-copper sulfide-oxide ore: Mechanism and kinetics[J]. Separation and Purification Technology, 2020, 239.

[36] MU W N, CUI F H, ZHAI H X, et al. A novel process for simultaneously extracting Ni and Cu from mixed oxide-sulfide copper-nickel ore with highly alkaline gangue via FeCl3·6H2O chlorination and water leaching[J]. Hydrometallurgy, 2020, 191.

[37] 张保平, 唐谟堂. 氨浸法在湿法炼锌中的优点及展望[J]. 有色金属科学与工程, 2001, 15(4):27-28.ZHANG B P, TANG M T. The advantages and prospect on ammonia leaching in the process of zinc hydrometallurgy[J]. Nonferrous Metals Science and Engineering, 2001, 15(4):27-28.

ZHANG B P, TANG M T. The advantages and prospect on ammonia leaching in the process of zinc hydrometallurgy[J]. Nonferrous Metals Science and Engineering, 2001, 15(4):27-28.

[38] 李启厚, 姜波, 刘智勇, 等. 高碱性脉石低品位混合镍矿氧压浸出行为与机制研究[J]. 湿法冶金, 2013, 32(3):154-157.LI Q H, JIANG B, LIU Z Y, et al. Study on leaching behaviors and mechanism of nickel from low grade ore with high alkaline gangue by high-pressure ammonia leaching[J]. Hydrometallurgy of China, 2013, 32(3):154-157.

LI Q H, JIANG B, LIU Z Y, et al. Study on leaching behaviors and mechanism of nickel from low grade ore with high alkaline gangue by high-pressure ammonia leaching[J]. Hydrometallurgy of China, 2013, 32(3):154-157.

[39] 饶富, 马恩, 郑晓洪, 等. 硫化镍矿中镍提取技术研究进展[J]. 化工学报, 2021, 72(1):495-507.RAO F, MA E, ZHENG X H, et al. Research advances on nickel extraction technology from nickel sulfide ore[J]. CIESC Journal, 2021, 72(1):495-507.

RAO F, MA E, ZHENG X H, et al. Research advances on nickel extraction technology from nickel sulfide ore[J]. CIESC Journal, 2021, 72(1):495-507.

[40] 徐建林, 史光大, 钟庆文, 等. 低品位硫化镍矿选矿中矿加压浸出实验研究[J]. 矿冶, 2009, 18(1):40-43.XU J L, SHI G D, ZHONG Q W, et al. Study on pressure leaching of middling from floatation process of low-grade nickel sulfide ore[J]. Mining and Metallurgy, 2009, 18(1):40-43. doi: 10.3969/j.issn.1005-7854.2009.01.010

XU J L, SHI G D, ZHONG Q W, et al. Study on pressure leaching of middling from floatation process of low-grade nickel sulfide ore[J]. Mining and Metallurgy, 2009, 18(1):40-43. doi: 10.3969/j.issn.1005-7854.2009.01.010

[41] HUANG K, LI Q W, CHEN J, et al. Recovery of copper, nickel and cobalt from acidic pressure leaching solutions of low-grade sulfide flotation concentrates[J]. Minerals Engineering, 2007, 20(7):722-728. doi: 10.1016/j.mineng.2007.01.011

[42] XIE Y T, XU Y B, YAN L, et al. Recovery of nickel, copper and cobalt from low-grade Ni-Cu sulfide tailings[J]. Hydrometallurgy, 2005, 80(1-2):54-58. doi: 10.1016/j.hydromet.2005.07.005

[43] 冯雅丽, 康金星, 李浩然, 等. 大洋多金属结核与低品位硫化镍矿耦合浸出特性[J]. 中南大学学报 : 自然科学版, 2018, 49(7): 1582-1589.FENG Y L, KANG J X, LI H R, et al. Characteristics of polymetallic nodules and low-grade nickel sulfide ore coupled leaching[J]. Journal of Central South University: Science and Technology, 2018, 49(7): 1582-1589.

FENG Y L, KANG J X, LI H R, et al. Characteristics of polymetallic nodules and low-grade nickel sulfide ore coupled leaching[J]. Journal of Central South University: Science and Technology, 2018, 49(7): 1582-1589.

[44] 张琛, 郑红艾, 周笑绿, 等. 生物浸出技术的发展及其电化学研究现状[J]. 金属矿山, 2014(12):122-128.ZHANG C, ZHENG H A, ZHOU X L, et al. Bioleaching development and electrochemical research status[J]. Metal Mine, 2014(12):122-128.

ZHANG C, ZHENG H A, ZHOU X L, et al. Bioleaching development and electrochemical research status[J]. Metal Mine, 2014(12):122-128.

[45] 张析, 王军, 王进龙, 等. 生物浸出技术及其应用研究进展[J]. 世界有色金属, 2016(14): 110-112.ZHANG X, WANG J, WANG J L, et al. Research progress of bioleaching technology and its application[J]. World Nonferrous Metals, 2016(14): 110-112.

ZHANG X, WANG J, WANG J L, et al. Research progress of bioleaching technology and its application[J]. World Nonferrous Metals, 2016(14): 110-112.

[46] 张水龙, 刘金艳, 杨林恒, 等. 吉林铜钴镍多金属硫化矿的生物浸出实验研究[J]. 矿产综合利用, 2020(1):50-53+58.ZHANG S L, LIU J Y, YANG L H, et al. Bioleaching of copper-cobalt-nickel polymetallic sulfide ores in Jilin[J]. Multipurpose Utilization of Mineral Resources, 2020(1):50-53+58. doi: 10.3969/j.issn.1000-6532.2020.01.010

ZHANG S L, LIU J Y, YANG L H, et al. Bioleaching of copper-cobalt-nickel polymetallic sulfide ores in Jilin[J]. Multipurpose Utilization of Mineral Resources, 2020(1):50-53+58. doi: 10.3969/j.issn.1000-6532.2020.01.010

[47] 王建伟, 汪模辉, 袁源, 等. 混合细菌浸矿研究进展[J]. 矿产综合利用, 2007(5): 24-27.WANG J W, WANG M H, YUAN Y, et al, The research situation on leaching of ores using mixed bacteria[J]. Multipurpose Utilization of Mineral Resources, 2007(5): 24-27.

WANG J W, WANG M H, YUAN Y, et al, The research situation on leaching of ores using mixed bacteria[J]. Multipurpose Utilization of Mineral Resources, 2007(5): 24-27.

[48] 鲁敏, 关晓辉, 赵浩然, 等. 嗜酸氧化亚铁硫杆菌对低品位硫化镍矿的生物浸出[J]. 材料导报, 2014, 28(12):51-54.LU M, GUAN X H, ZHAO H R, et al. Bioleaching of low-grade nickel sulfide ores by Thiobacillus acidophilus ferrooxidans[J]. Materials Herald, 2014, 28(12):51-54.

LU M, GUAN X H, ZHAO H R, et al. Bioleaching of low-grade nickel sulfide ores by Thiobacillus acidophilus ferrooxidans[J]. Materials Herald, 2014, 28(12):51-54.

[49] ZHEN S J, QIN W Q, YAN Z Q. Bioleaching of low grade nickel sulfide mineral in column reactor[J]. 中国有色金属学报 : 英文版, 2008, 18(6): 1480-1484.

[50] LI S Z, ZHONG H, HU Y H. Bioleaching of a low-grade nickel-copper sulfide by mixture of four thermophiles[J]. Bioresource Technology, 2014, 153:300-306. doi: 10.1016/j.biortech.2013.12.018

[51] YANG C R, QIN W Q, LAI S S. Bioleaching of a low grade nickel-copper-cobalt sulfide ore[J]. Hydrometallurgy, 2011, 106(1-2):32-37. doi: 10.1016/j.hydromet.2010.11.013

[52] 杨磊. 金川龙首西二采区贫矿石工艺矿物学研究[R]. 成都 : 中国地质科学院矿产综合利用研究所, 2012.YANG L. Study on process mineralogy of lean ore in Longshou West No. 2 Mining area of Jinchuan[R]. Chengdu : Institute of MUltipurpose Utilization of Mineral Resources, Chinese Academy of Geological Sciences, 2012.

YANG L. Study on process mineralogy of lean ore in Longshou West No. 2 Mining area of Jinchuan[R]. Chengdu : Institute of MUltipurpose Utilization of Mineral Resources, Chinese Academy of Geological Sciences, 2012.

[53] 赵毕文. 金川铜镍矿选矿工艺矿物学研究之二—矿石工艺矿物学研究[R]. 金昌 : 金川集团股份有限公司, 2013.ZHAO B W. Study on mineralogy of beneficiation process of Jinchuan copper-nickel ore—Study on mineralogy of ore process[R]. Jinchang : Jinchuan Group Co. Ltd. , 2013.

ZHAO B W. Study on mineralogy of beneficiation process of Jinchuan copper-nickel ore—Study on mineralogy of ore process[R]. Jinchang : Jinchuan Group Co. Ltd. , 2013.

[54] 贺壮志, 何晓娟, 陈志强, 等. 硫化技术在重金属固废综合利用方面的研究进展[J]. 有色金属工程, 2020, 10(3):77-85.HE Z Z, HE X J, CHEN Z Q, et al. Research progress on sulfidation technology in comprehensive utilization of heavy metal solid waste[J]. Nonferrous Metals Engineering, 2020, 10(3):77-85. doi: 10.3969/j.issn.2095-1744.2020.03.013

HE Z Z, HE X J, CHEN Z Q, et al. Research progress on sulfidation technology in comprehensive utilization of heavy metal solid waste[J]. Nonferrous Metals Engineering, 2020, 10(3):77-85. doi: 10.3969/j.issn.2095-1744.2020.03.013

[55] 闵小波, 姜光华, 王云燕. 锌浸渣和黄铁矿硫化焙烧回收锌铁(英文)[J]. Journal of Central South University, 2020, 27(4):1186-1196.MIN X B, JIANG G H, WANG Y Y. Sulfidation roasting of zinc leaching residue with pyrite for recovery of zinc and iron[J]. Journal of Central South University, 2020, 27(4):1186-1196. doi: 10.1007/s11771-020-4359-1

MIN X B, JIANG G H, WANG Y Y. Sulfidation roasting of zinc leaching residue with pyrite for recovery of zinc and iron[J]. Journal of Central South University, 2020, 27(4):1186-1196. doi: 10.1007/s11771-020-4359-1

[56] 庞杰, 郑永兴, 戈保梁, 等. 难选氧化铜矿选冶联合技术研究现状与进展[J]. 矿产综合利用, 2019(5):1-5.PANG J, ZHENG Y X, GE B L, et al. Research status and development of the dressing-metallurgy combination processing of refractory copper oxides[J]. Multipurpose Utilization of Mineral Resources, 2019(5):1-5. doi: 10.3969/j.issn.1000-6532.2019.05.001

PANG J, ZHENG Y X, GE B L, et al. Research status and development of the dressing-metallurgy combination processing of refractory copper oxides[J]. Multipurpose Utilization of Mineral Resources, 2019(5):1-5. doi: 10.3969/j.issn.1000-6532.2019.05.001

[57] 石云良, 刘苗华, 肖金雄. 难选氧化铅锌矿硫化焙烧机理与浮选实验研究[J]. 有色金属(选矿部分), 2013(S1):108-111.SHI Y L, LIU M H, XIAO J X. Study on sulfide roasting mechanism and flotation test of lead zinc oxide[J]. Nonferrous Metals(Mineral Processing Section), 2013(S1):108-111.

SHI Y L, LIU M H, XIAO J X. Study on sulfide roasting mechanism and flotation test of lead zinc oxide[J]. Nonferrous Metals(Mineral Processing Section), 2013(S1):108-111.

[58] 贺壮志, 朱阳戈, 刘牡丹, 等. 硫化焙烧技术回收重金属研究现状及展望[J]. 中国有色金属学报, 2021.HE Z Z, ZHU Y G, LIU M D, et al. Research status of sulfidation roasting for heavy metals recovery[J]. The Chinese Journal of Nonferrous Metals, 2021.

HE Z Z, ZHU Y G, LIU M D, et al. Research status of sulfidation roasting for heavy metals recovery[J]. The Chinese Journal of Nonferrous Metals, 2021.

[59] 李勇. 低品位氧化铅锌矿硫化-浮选工艺及理论研究[D]. 昆明: 昆明理工大学, 2009.LI Y. Research on sulfidation flotation process and theory of low grade oxidized lead-zinc ore[D]. Kunming: Kunming University of Science and Technology, 2009.

LI Y. Research on sulfidation flotation process and theory of low grade oxidized lead-zinc ore[D]. Kunming: Kunming University of Science and Technology, 2009.

[60] ZHENG Y X, LIU W, QIN W Q, et al. Sulfidation roasting of lead and zinc carbonate with sulphur by temperature gradient method[J]. Journal of Central South University, 2015, 22(5):1635-1642. doi: 10.1007/s11771-015-2681-9

-

下载:

下载: