Test on Mineral Processing Technology for the Copper-iron Ore

-

摘要:

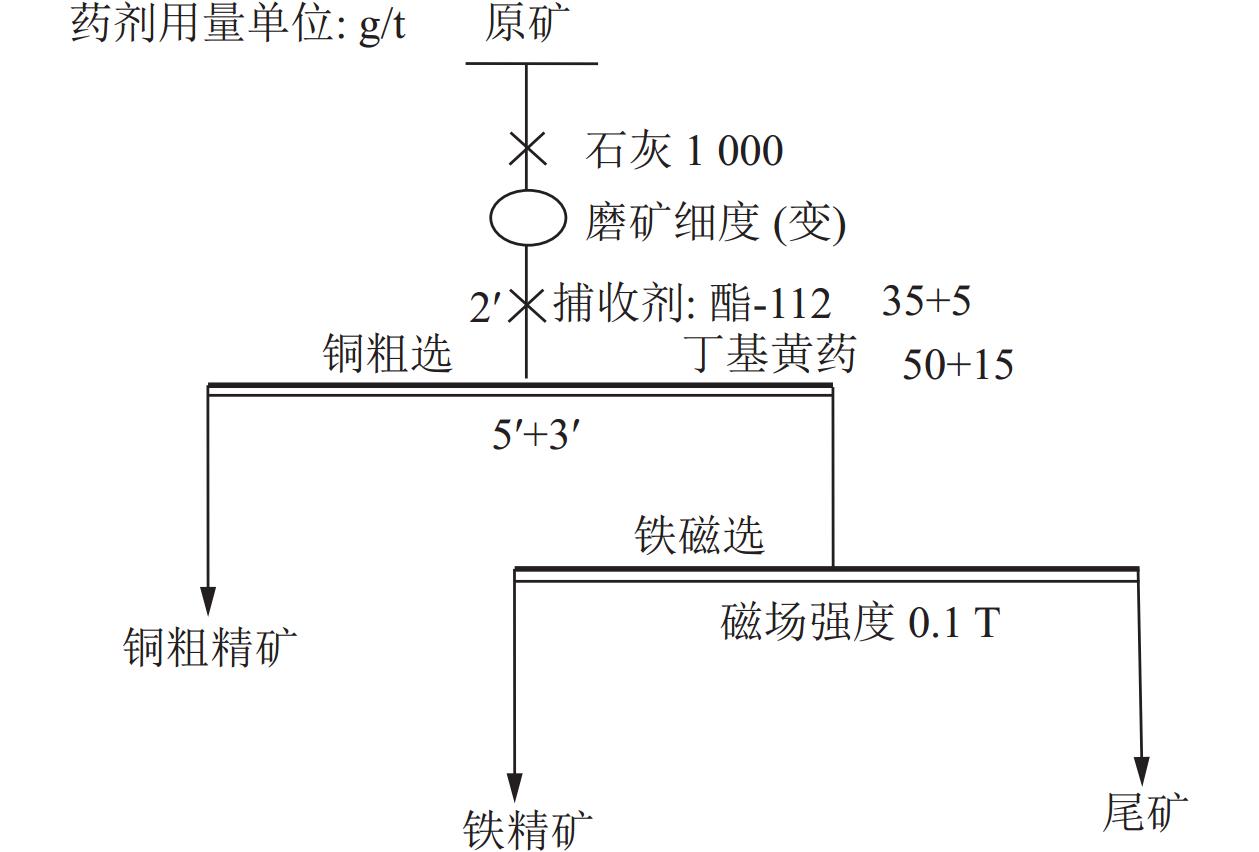

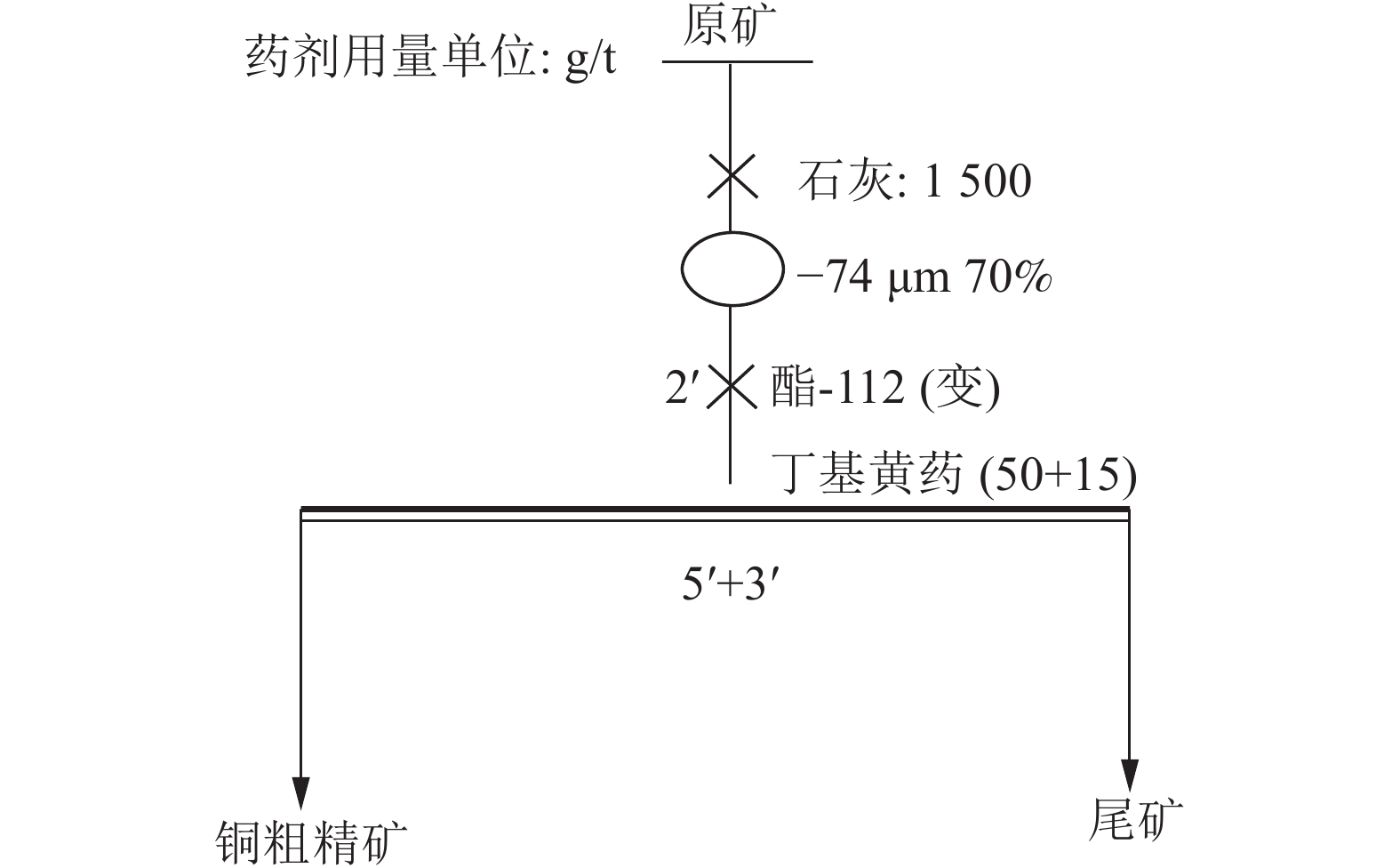

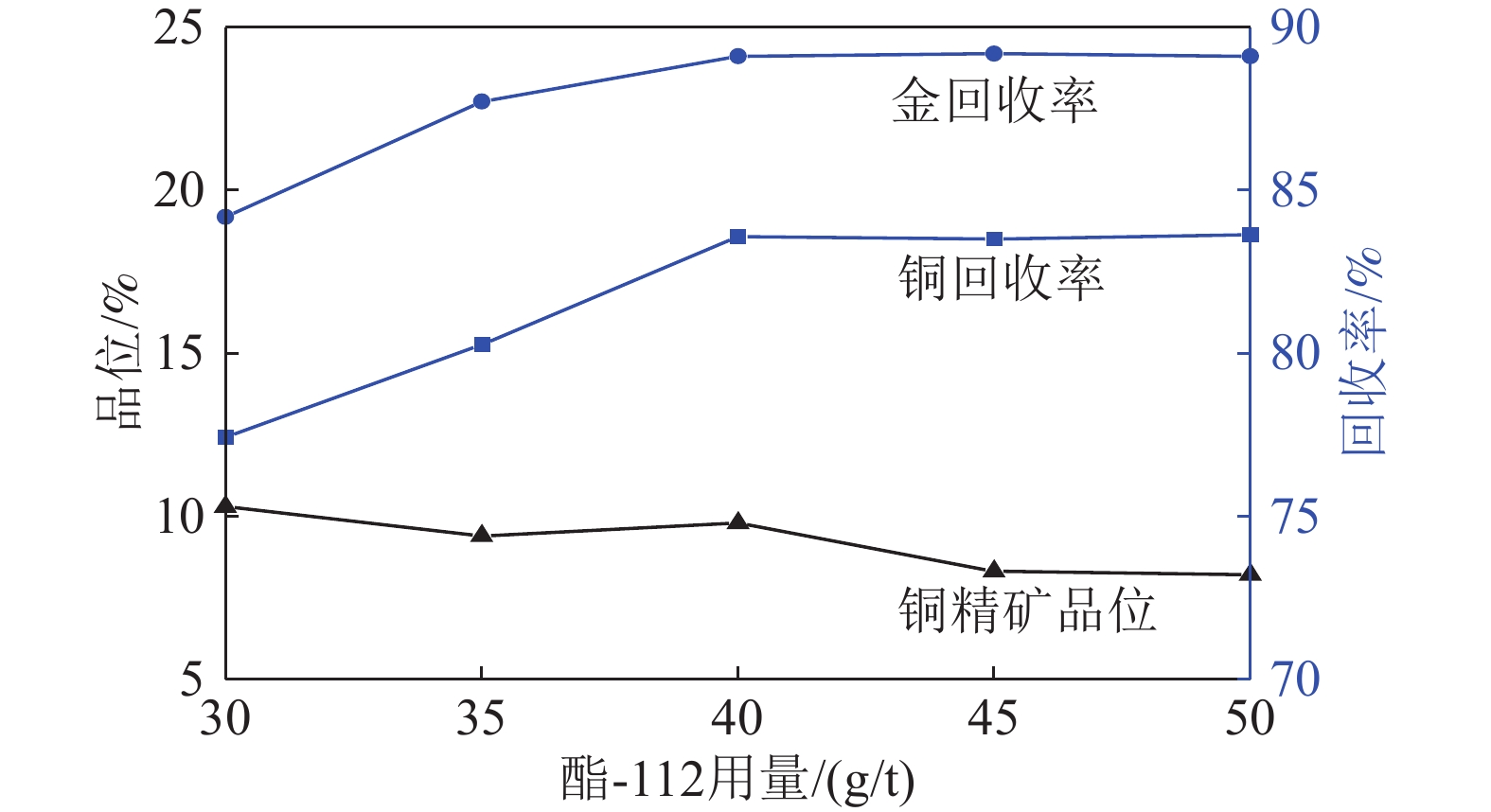

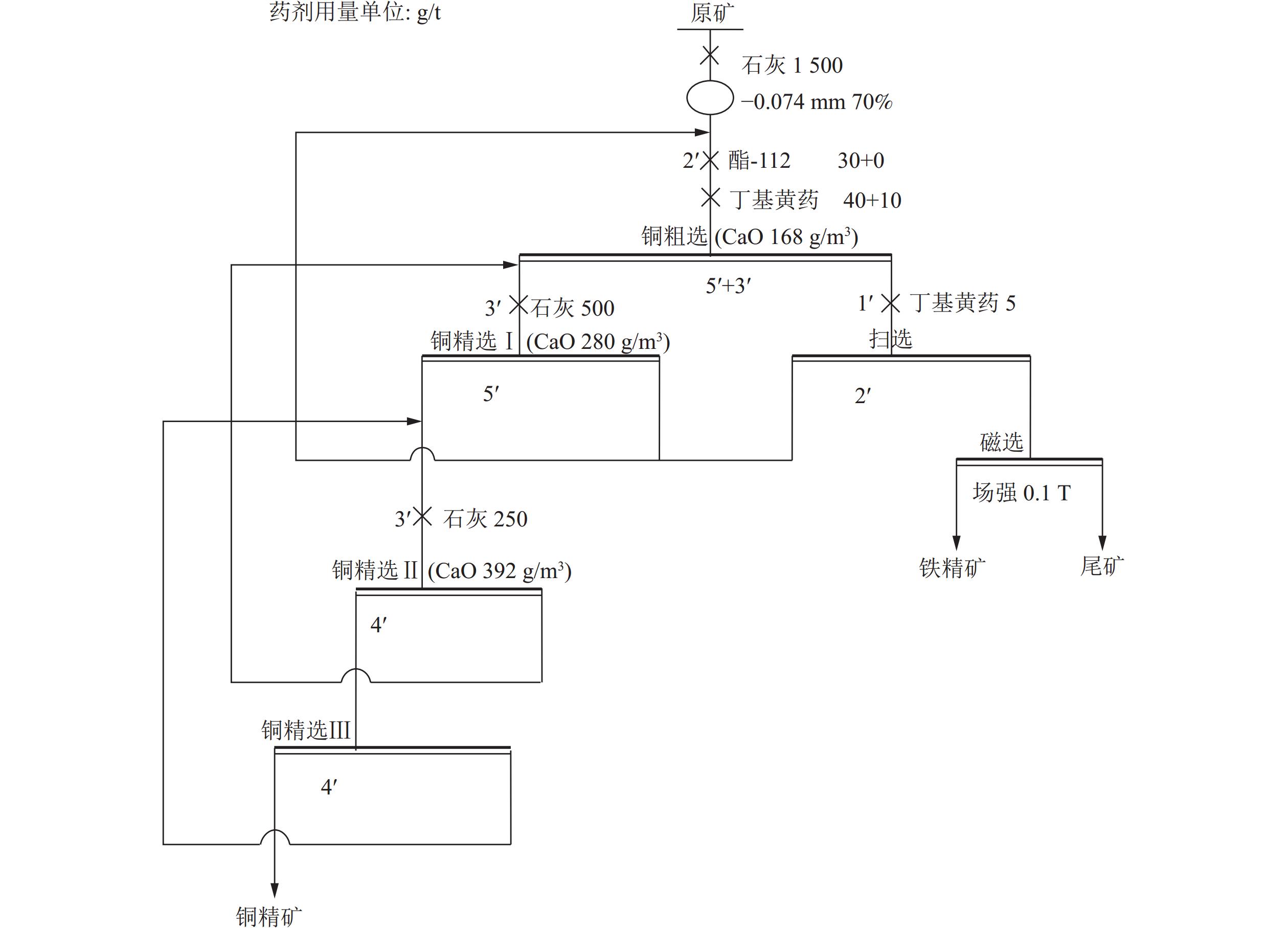

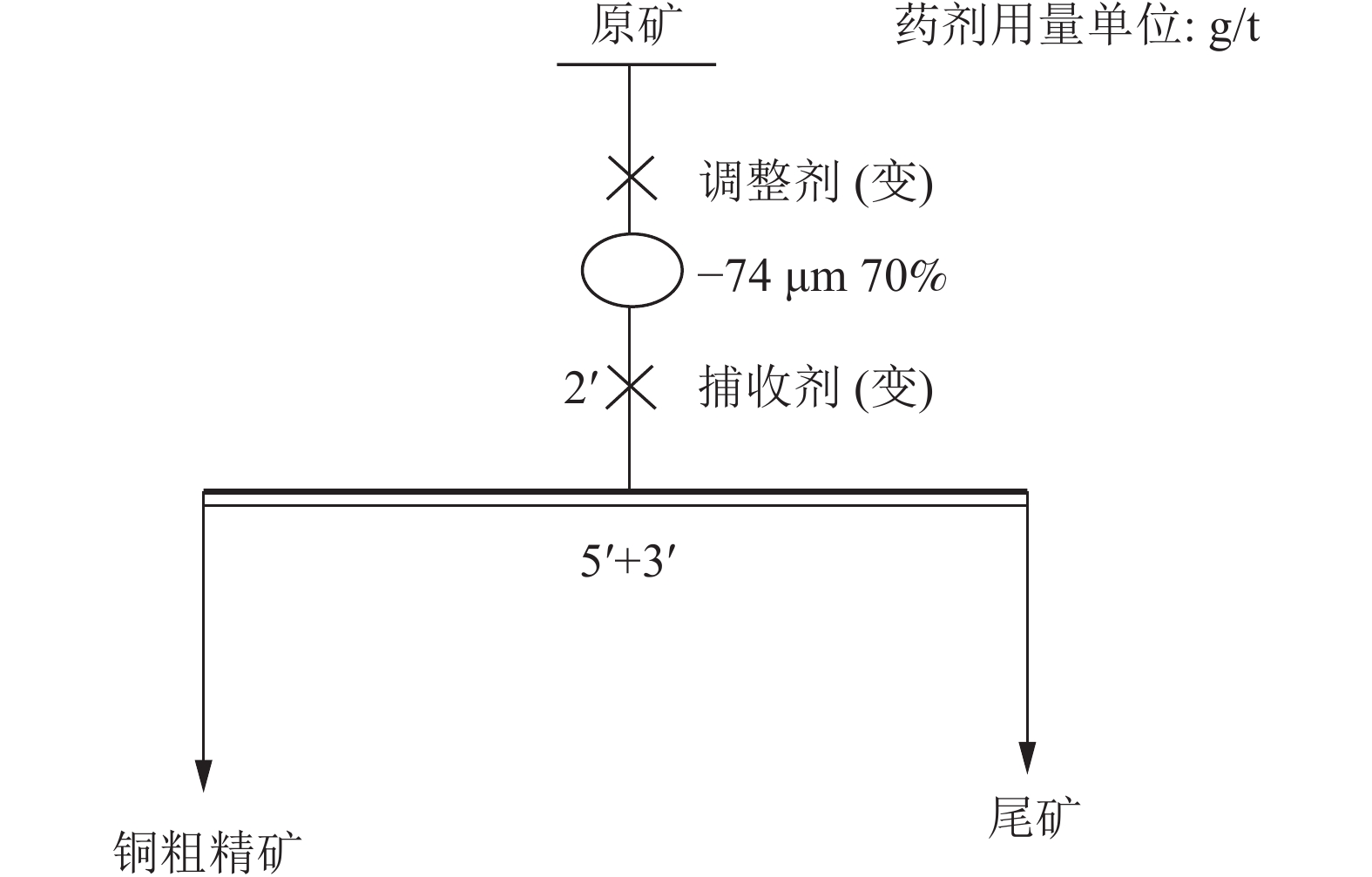

针对某铜铁矿矿石性质特点,采用先浮-后磁工艺流程,配合使用选择性好的捕收剂酯-112,实现了矿石的综合回收。采用“先浮-后磁”工艺,即将原矿磨至-74 μm 70% ,铜回路采用一次粗选、三次精选产出铜精矿;铜扫选尾矿经过一次磁选产出铁精矿。闭路实验获得铜精矿中铜的品位为20.72%,铜回收率为80.76%;铜精矿中金品位43.91 g/t,回收率86.29%,铁精矿品位为66.38%,铁回收率为94.20%,铁精矿中有害元素硫含量仅为0.16%。

Abstract:Aiming at the characteristics of a copper-iron ore, we adopt the process of first flotation and then magnetic process, together with the use of ester-112, which is a good selective collector, to realize the comprehensive recovery of the ore. Using the “first flotation - then magnetic” process, the original ore is ground to -74 μm 70%, copper circuit using one roughing, three cleaning for the output of copper concentrate.copper sweeping tailings after a magnetic separation output of iron ore concentrate. Closed-circuit tests obtained copper grade of 20.72% and recovery rate of 80.76% in the copper concentrate, gold grade of 43.91 g/t and recovery rate of 86.29% in the copper concentrate, iron grade of 66.38% recovery rate of 94.20% in the iron concentrate, among which the content of the harmful elements of the sulfur is only 0.16%.

-

-

表 1 矿石化学多元素分析结果/%

Table 1. Chemical analysis results of the ore

Cu Pb Zn S Fe SiO2 Au* Al2O3 CaO MgO As Co* P* 0.30 微量 微量 0.72 59.30 8.89 0.60 1.85 0.86 5.54 0.06 85.00 58.00 *单位是为g/t。 表 2 矿石铜物相分析结果

Table 2. Phase analysis results of copper

名 称 原生硫化铜 次生硫化铜 自由氧化铜 结合氧化铜 总 铜 含 量/% 0.186 0.080 0.009 0.025 0.300 占有率/% 62.00 26.67 3.00 8.33 100.00 表 3 矿石铁物相分析结果

Table 3. Phase analysis results of iron

名 称 磁铁矿 赤铁矿及褐铁矿 菱铁矿 黄铁矿 其他 总铁 含 量/% 56.06 0.62 0.35 0.46 1.81 59.30 占有率/% 94.53 1.05 0.59 0.78 3.05 100.00 表 4 药剂种类筛选实验结果

Table 4. Screening test results of flotation reagent types

药剂及用量/(g/t) 产品

名称产率

/%品 位/% 回收率/% Cu S Fe Au* Cu S Fe Au 石灰:1000

丁基黄药:60

松醇油:30铜粗精矿 2.44 9.25 22.13 27.65 18.80 74.31 75.46 1.13 78.34 尾矿 97.56 0.08 0.18 60.53 0.13 25.69 24.54 98.87 21.66 原矿 100.00 0.30 0.72 59.73 0.59 100.00 100.00 100.00 100.00 丁铵黑药:40

丁基黄药:50铜粗精矿 2.69 8.95 19.94 28.50 18.90 77.95 74.37 1.29 82.61 尾矿 97.31 0.07 0.19 60.47 0.11 22.05 25.63 98.71 17.39 原矿 100.00 0.31 0.72 59.61 0.62 100.00 100.00 100.00 100.00 碳酸钠:1000

酯-112:40

丁基黄药:50铜粗精矿 2.52 9.87 20.17 27.58 20.20 80.96 72.28 1.16 85.30 尾矿 97.48 0.06 0.20 60.65 0.09 19.04 27.72 98.84 14.70 原矿 100.00 0.31 0.70 59.82 0.60 100.00 100.00 100.00 100.00 石灰:1000

酯-112:40

丁基黄药:50铜粗精矿 2.53 9.75 22.56 27.82 21.30 83.50 78.54 1.18 88.76 尾矿 97.47 0.05 0.16 60.60 0.07 16.50 21.46 98.82 11.24 原矿 100.00 0.30 0.73 59.77 0.61 100.00 100.00 100.00 100.00 石灰:1000

A-2:40

丁基黄药:50铜粗精矿 2.52 9.56 21.42 27.00 20.80 80.46 75.47 1.14 87.05 尾矿 97.48 0.06 0.18 60.45 0.08 19.54 24.53 98.86 12.95 原矿 100.00 0.30 0.72 59.61 0.60 100.00 100.00 100.00 100.00 *单位为g/t。 表 5 磨矿细度对浮选指标影响

Table 5. Effect of grinding fineness on barite flotation

磨矿细度-0.074 mm/% 产品

名称产率

/%品 位/% 回收率/% Cu S Fe Au* Cu S Fe Au 60 铜粗精矿 2.55 9.51 22.18 27.05 19.60 80.11 75.61 1.16 83.91 铁精矿 84.68 0.05 0.14 65.90 0.08 13.99 15.85 93.87 11.37 尾矿 12.77 0.14 0.50 23.12 0.22 5.90 8.54 4.97 4.72 原矿 100.00 0.30 0.75 59.45 0.60 100.00 100.00 100.00 100.00 65 铜粗精矿 2.55 9.55 21.59 26.90 20.60 82.25 75.76 1.15 86.18 铁精矿 85.11 0.04 0.12 66.21 0.07 11.50 14.05 94.18 9.77 尾矿 12.34 0.15 0.60 22.65 0.20 6.25 10.19 4.67 4.05 原矿 100.00 0.30 0.73 59.83 0.61 100.00 100.00 100.00 100.00 70 铜粗精矿 2.58 9.71 21.36 27.15 21.20 82.93 76.75 1.17 88.14 铁精矿 84.81 0.04 0.13 66.45 0.06 11.23 15.35 94.10 8.20 尾矿 12.61 0.14 0.45 22.48 0.18 5.84 7.90 4.73 3.66 原矿 100.00 0.30 0.72 59.89 0.62 100.00 100.00 100.00 100.00 75 铜粗精矿 2.51 9.85 22.05 26.38 21.50 82.59 75.79 1.10 86.24 铁精矿 85.57 0.04 0.13 66.48 0.07 11.44 15.23 94.30 9.57 尾矿 11.92 0.15 0.55 23.28 0.22 5.97 8.98 4.60 4.19 原矿 100.00 0.30 0.73 60.32 0.63 100.00 100.00 100.00 100.00 80 铜粗精矿 2.49 10.01 22.37 26.74 21.60 82.42 77.04 1.11 86.35 铁精矿 84.62 0.04 0.12 66.57 0.07 11.19 14.04 93.99 9.51 尾矿 12.89 0.15 0.50 22.78 0.20 6.39 8.92 4.90 4.14 原矿 100.00 0.30 0.72 59.93 0.62 100.00 100.00 100.00 100.00 *单位为g/t。 表 6 石灰用量对浮选指标影响

Table 6. Effect of lime dosage on barite flotation

石灰用量/(g/t) 产品

名称产率

/%品 位/% 回收率/% Cu S Au* Cu S Au 0

(pH=6.5)铜粗精矿 2.61 8.80 19.99 20.90 77.11 69.06 87.50 尾矿 97.39 0.07 0.24 0.08 22.89 30.94 12.50 原矿 100.00 0.30 0.76 0.62 100.00 100.00 100.00 500

(pH=7)铜粗精矿 2.66 9.11 19.77 20.70 80.58 72.01 87.61 尾矿 97.34 0.06 0.21 0.08 19.42 27.99 12.39 原矿 100.00 0.30 0.73 0.63 100.00 100.00 100.00 1 000

(CaO:67.20 g/m3)铜粗精矿 2.58 9.71 21.36 21.20 83.72 76.89 87.53 尾矿 97.42 0.05 0.17 0.08 16.28 23.11 12.47 原矿 100.00 0.30 0.72 0.62 100.00 100.00 100.00 1 500

(CaO:112.00 g/m3)铜粗精矿 2.53 9.80 21.54 22.10 83.57 77.75 90.53 尾矿 97.47 0.05 0.16 0.06 16.43 22.25 9.47 原矿 100.00 0.30 0.70 0.62 100.00 100.00 100.00 2 000

(CaO:173.60 g/m3)铜粗精矿 2.45 9.85 22.43 22.30 83.19 77.88 88.89 尾矿 97.55 0.05 0.16 0.07 16.81 22.12 11.11 原矿 100.00 0.29 0.71 0.61 100.00 100.00 100.00 *单位为g/t。 表 7 磁场强度实验结果

Table 7. Results of magnetic field intensity

磁场强度

/T产品名称 作业产率

/%品 位/% 作业回收率/% Fe S Fe S 0.06 铁精矿 84.49 66.81 0.10 92.76 54.22 尾 矿 15.51 28.41 0.46 7.24 45.78 给 矿 100.00 60.85 0.16 100.00 100.00 0.08 铁精矿 87.07 66.19 0.10 94.71 53.73 尾 矿 12.93 24.90 0.58 5.29 46.27 给 矿 100.00 60.85 0.16 100.00 100.00 0.10 铁精矿 87.57 66.13 0.10 95.24 55.28 尾 矿 12.43 23.28 0.57 4.76 44.72 给 矿 100.00 60.80 0.16 100.00 100.00 0.12 铁精矿 88.07 65.69 0.12 95.61 64.86 尾 矿 11.93 22.28 0.48 4.39 35.14 给 矿 100.00 60.51 0.16 100.00 100.00 表 8 开路实验结果

Table 8. Results of the open-circuit tests

产品

名称产 率

/%品 位/% 回 收 率/% Cu S Fe Cu S Fe 铜精矿 0.92 22.80 21.41 26.26 66.86 31.37 0.41 中矿1 0.21 13.05 22.48 27.56 8.73 7.52 0.10 中矿2 0.42 3.59 18.34 28.71 4.81 12.27 0.20 中矿3 1.00 0.85 11.23 28.87 2.71 17.88 0.48 中矿4 0.25 0.82 10.25 27.36 0.65 4.08 0.11 铁精矿 83.81 0.04 0.12 66.93 10.69 16.01 93.98 尾 矿 13.39 0.13 0.51 21.05 5.55 10.87 4.72 原 矿 100.00 0.31 0.63 59.69 100.00 100.00 100.00 表 9 闭路实验结果

Table 9. Results of the closed-circuit tests

产品

名称产率

/%品 位/% 回收率/% Cu S Fe Au* Cu S Fe Au 铜精矿 1.18 20.72 34.81 26.19 43.91 80.76 59.80 0.52 86.29 铁精矿 84.39 0.04 0.16 66.38 0.06 11.14 19.64 94.20 8.43 尾矿 14.43 0.17 0.98 21.77 0.22 8.10 20.56 5.28 5.28 原矿 100.00 0.30 0.70 59.47 0.60 100.00 100.00 100.00 100.00 *单位为g/t。 -

[1] 杨凯志, 李汉文, 胡真, 等. 云南某低品位硫氧混合铜矿浮选实验研究[J]. 有色金属(选矿部分), 2022(1):47-52.YANG K Z, LI H W, HU Z, et al. Experimental study on flotation of a low-grade sulfur-oxygen mixed copper ore in Yunnan[J]. Nonferrous Metals(Mineral Processing Section), 2022(1):47-52.

YANG K Z, LI H W, HU Z, et al. Experimental study on flotation of a low-grade sulfur-oxygen mixed copper ore in Yunnan[J]. Nonferrous Metals(Mineral Processing Section), 2022(1):47-52.

[2] 赵天平. 难选铜铁矿选矿实验研究[J]. 矿产综合利用, 2016(1):45-48.ZHAO T P. Experimental Research on mineral processing technology for refractory delafossite ore[J]. Multipurpose Utilization of Mineral Resources, 2016(1):45-48. doi: 10.3969/j.issn.1000-6532.2016.01.011

ZHAO T P. Experimental Research on mineral processing technology for refractory delafossite ore[J]. Multipurpose Utilization of Mineral Resources, 2016(1):45-48. doi: 10.3969/j.issn.1000-6532.2016.01.011

[3] 吴玉元, 何东升, 胡洋, 等. 某铜铁矿尾矿工艺矿物学研究[J]. 矿产综合利用, 2019(2):75-78.WU Y Y, HE D S, HU Y, et al. Mineralogical study on a copper - iron ore tailings process[J]. Multipurpose Utilization of Mineral Resources, 2019(2):75-78. doi: 10.3969/j.issn.1000-6532.2019.02.015

WU Y Y, HE D S, HU Y, et al. Mineralogical study on a copper - iron ore tailings process[J]. Multipurpose Utilization of Mineral Resources, 2019(2):75-78. doi: 10.3969/j.issn.1000-6532.2019.02.015

[4] 王磊, 刘洋, 陈明. 高硫型铜铁矿浮选-磁选联合工艺优化研究[J]. 有色金属工程, 2021, 71(5):45-52.WANG L, LIU Y, CHEN M. Optimization of combined flotation-magnetic separation process for high-sulfur copper-iron ore[J]. Nonferrous Metal Engineering, 2021, 71(5):45-52. doi: 10.3969/j.issn.2095-1744.2021.05.008

WANG L, LIU Y, CHEN M. Optimization of combined flotation-magnetic separation process for high-sulfur copper-iron ore[J]. Nonferrous Metal Engineering, 2021, 71(5):45-52. doi: 10.3969/j.issn.2095-1744.2021.05.008

[5] 张强, 周涛, 吴峰. 磁选预处理对铜铁矿浮选指标的影响[J]. 金属矿山, 2020, 49(8):102-107.ZHANG Q, ZHOU T, WU F. Influence of magnetic separation pretreatment on the flotation index of copper and iron ore[J]. Metal Mine, 2020, 49(8):102-107.

ZHANG Q, ZHOU T, WU F. Influence of magnetic separation pretreatment on the flotation index of copper and iron ore[J]. Metal Mine, 2020, 49(8):102-107.

[6] 李华, 赵伟, 马宁. 新型组合药剂在铜铁矿浮选中的应用研究[J]. 矿产保护与利用, 2019, 39(3):67-72.LI H, ZHAO W, MA N. Research on the application of new combined chemicals in copper and iron ore flotation[J]. Mineral Protection and Utilization, 2019, 39(3):67-72.

LI H, ZHAO W, MA N. Research on the application of new combined chemicals in copper and iron ore flotation[J]. Mineral Protection and Utilization, 2019, 39(3):67-72.

[7] 万丽, 周少珍, 曾克文, 等. 安徽某铜硫矿选矿工艺优化实验[J]. 矿产综合利用, 2019(6):41-44.WAN L, ZHOU S Z, ZENG K W, et al. Experimental research on beneficiation technology of a copper-sulfur ore from Anhui[J]. Multipurpose Utilization of Mineral Resources, 2019(6):41-44. doi: 10.3969/j.issn.1000-6532.2019.06.009

WAN L, ZHOU S Z, ZENG K W, et al. Experimental research on beneficiation technology of a copper-sulfur ore from Anhui[J]. Multipurpose Utilization of Mineral Resources, 2019(6):41-44. doi: 10.3969/j.issn.1000-6532.2019.06.009

[8] 陈艳平, 毛益林, 陈晓青, 等. 四川某铜矿选矿实验研究[J]. 矿产综合利用, 2020(2):87-90.CHEN Y P, MAO Y L, CHEN X Q, et al. Experimental study on mineral processing of a copper ore in Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2020(2):87-90. doi: 10.3969/j.issn.1000-6532.2020.02.015

CHEN Y P, MAO Y L, CHEN X Q, et al. Experimental study on mineral processing of a copper ore in Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2020(2):87-90. doi: 10.3969/j.issn.1000-6532.2020.02.015

[9] 逄军武, 张玲, 达娃卓玛, 等. 某选矿厂处理角岩型铜硫矿选铜浮选实验[J]. 矿产综合利用, 2021(4):139-143.PANG J W, ZHANG L, DAWA Z M, et al. Treatment of breccia in a concentrator copper sulphur ore flotation test of copper separation[J]. Multipurpose Utilization of Mineral Resources, 2021(4):139-143. doi: 10.3969/j.issn.1000-6532.2021.04.021

PANG J W, ZHANG L, DAWA Z M, et al. Treatment of breccia in a concentrator copper sulphur ore flotation test of copper separation[J]. Multipurpose Utilization of Mineral Resources, 2021(4):139-143. doi: 10.3969/j.issn.1000-6532.2021.04.021

-

下载:

下载: